LANDING GEAR DESIGN FORUM - Freea.moirier.free.fr/Train d'atterrissage/Train principal/Landing...

Transcript of LANDING GEAR DESIGN FORUM - Freea.moirier.free.fr/Train d'atterrissage/Train principal/Landing...

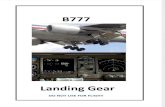

LANDING GEAR DESIGN

FORUMBy Ladislao Pazmany

Condensed By Lu Sunderland

Second in a series of Oshkosh '77 Technical Forums con-densed by Lu Sunderland from tapes made by DaveYeoman. Ladislao Pazmany has approved this summaryof his forum and has generously provided drawings fromhis excellent design manuals. Paz will have a book outsoon on landing gear design.

HISTORICAL SURVEY of early aircraft designsreveals that some features commonly believed to befairly recent developments actually were employed onthe very first airplanes. Landing gear design is a primeexample. For instance, the first oleo shock absorber wasdesigned in England by Duncan in 1915. His basic de-sign is still used today in hydraulic shock absorbers.Duncan, an engineer, worked on guns and experimentedwith ways to absorb recoil. He applied this knowledgeto aircraft as well.

The first retractable gear was patented by Martinin 1911 on the K3 Scout which was a small squarishbiplane. The gear half-retracted into the wing straightaft. Another type of retractable gear was used on theDayton-Wright Gordon Bennett single place racer of1920. The gear, which retracted into the fuselage, wassimilar to many used today. In 1922 another designer,Fred Verville, had a retractable gear on his racer whichretracted, with a screw jack, between the wing and thefuselage. A major innovation was the location of a wheelon the nose and it was used on the June Bug in 1908.

There are three general types of landing gear; namely,tailwheel, tricycle and tandem gear. Let us first con-sider how the designer would go about designing a tail-wheel type gear.

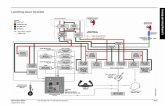

TAILWHEEL CONFIGURATIONTo set up the geometry of the tailwheel type land-

ing gear, first it is necessary to locate the most forwardcenter of gravity on a side view drawing. Then calcu-late the angle of attack for maximum lift coefficient dur-ing landing. This is normally 12° to 15°. When the mainand tail gear are deflected 1 g, the wing angle of attackshould fall in this range. The main gear should contactthe ground at least 15° ahead of the most forward cen-ter of gravity with the aircraft in level attitude as shownin Figure 1. Next you must determine the length of thegear.

u 45«[is»j y V30°-

5°^5r / SPINDLE AXIS V-i

h 25°-15I-r

C.G. (DESIGN --GROSS WEIGHT)

.-1/10 TAIL WHEELDIA.

FIGURE 1

The C.G. should be located as shown in the front view (Figure 2).

NOT LESS THAN 25°FIGURE 2

MAX AFT C.G.

POINT "A" ' CL MAXFIGURES

FAR Part 23 states that with the airplane in levelattitude and the gear deflected for 1 g loading at grossweight, the propeller should have 9 inches clearance.Also, with one flat tire and the gear deflected, theremust be some positive clearance between the propellerand ground.

Another way to locate the gear on a tail sitter is touse equations given in FAR Part 23 concerning reactionson the gear.Vertical load Vr = (n - L)Wn = load factor which gear should take — normally about 3L = lift coefficient of wing which should be taken as .66Vertical load = (3 - .66)W = 2.33WDrag reaction D is found as follows:D = knWk = friction coefficient — normally .25n = load factorW = weightD = .25 x 3 x W = .75WThe resultant of these two forces, Vr and D, is usuallyat 15° to 18°.

Tan 0 = 75W— ——2.33W

= .322

O = 18°Thus the gear should be located about 18° from the eg.If the resultant goes behind the eg, the aircraft couldpitch over.

The tailwheel should be located as far aft as possiblefor best ground handling and to minimize loads in it.

On a front view, the angle between vertical and aline from eg to point of wheel contact with ground shouldbe not less than 25°. See Figure 2. Too narrow a gearwill make the aircraft tip over. For example in theJapanese motor glider, Nippy, the gear is narrow. Itdoesn't have outriggers so these angles are very smalland requires a skilled pilot.

44 JUNE 1978

5" CLEARANCE-4.10" FLAT TIRE RADIUS

UNLOADED TIRE> GROUND LINE AT STATIC LOAD

UNLOADED TIREFIGURE 4

LANDING GEAR CLEARANCES — PL-1 LAMINAR

PLAN VIEW 1C.6. TRACK

AUXILIARY VIEW

-WHEEL BASE —FIGURE 5

TURNOVER ANGLE

NOSE WHEEL CONFIGURATIONFirst locate the wheels on a side view in a landing

attitude at maximum angle of attack, flaps up as shownin Figure 3. To locate main gear, draw a line perpendicularto the ground through the max aft eg. This line is theforward limit for the axle. Preferably, it should be movedone or two inches aft of this line. Make the gear legslong enough to clear the tail skid by one or two inchesand make sure the flaps in full down position have afew inches clearance.

To locate the nose wheel, draw the aircraft sittingon the ground as in Figure 4. It is desirable to have thedistance between nose wheel and main wheel as largeas possible. If this distance is too small, the aircraftwill porpoise. With the nose gear fully compressed, thenose wheel tire flat and main gear fully extended barelytouching the ground, there must be some positive clear-ance between the prop and the ground.

The track and wheel base should be determined next.The relationship between the track and wheel base isdictated by the Turnover Angle which is determined asfollows: (See Figure 5.)

1. Draw a top view showing the desired nose wheeland tail wheel positions. Also show the C.G. loca-tion.

2. Draw a side view showing the C.G. position andthe landing gear with shock absorbers and tiresstatically deflected.

3. Establish line A-B. Extend the line to a point "C".4. Through point "C" draw a perpendicular to line

A-C.

TURNING POINT

FIGURE 6TURNING POINT

5. Through the C.G. (in the plan view) draw a lineparallel to A-B and obtain point "D".

6. From point "D" measure the height of the C.G.(h) obtained from the side view and obtain point"E".

7. Draw line E-C and measure angle "B". This is theturnover angle and should be less than 60°.

If the turnover angle is more than 60°, increase thetrack or the wheel base and try again. For a tail wheeltype airplane, the turnover angle should be checkedusing the same procedure. The angle /3 should not ex-ceed 60°.

The steerable nose wheel should have an angularmovement O such that the turning point falls insidethe wing tip as shown in Figure 6. To check the posi-tion of the turning point, simply project the main wheelaxis and the nose wheel axis at the maximum steer an-gle until they intersect.

TANDEM GEARIn order to minimize drag and weight of landing

gear, especially in sailplanes and motor gliders, it iscommon to use a single main wheel and a tailwheel.The two wheels are located on the center line of the air-craft, so this configuration is called a tandem gear.

Since sailplanes are not landed in the same fashionas airplanes — that is, you don't make full stall land-ings — the angle of attack at touchdown is quite small,between 5 and 8 degrees. To maintain a wings level at-titude for taxiing and to eliminate the need for a groundcrew, it is common to use some type of outrigger. Un-less these are retracted, their drag will approach thatof another wheel and thus lose some of the advantageover a conventional tail sitter design. That is one rea-son the RG-100 Cloudster powered sailplane has con-ventional gear.

SPORT AVIATION 45

COMPARISON OF GEAR TYPESIn comparison to the tricycle gear the tailwheel

type is lighter, cheaper, and has considerably less drag.It also favors use on rough fields. Since the propelleris much further from the ground during taxiing and thebeginning of take-off ground roll, propeller damage dueto debris is far less.

The biggest disadvantage of the tailwheel type gearof course is that with the eg behind the fixed wheels,it is basically unstable. A side force on the main wheelscauses the airplane to tend to turn around with the tailfirst. It takes conscious pilot action to prevent a groundloop. Not so with the nose wheel type.

The nose wheel or tricycle type gear is unques-tionably safest for ground handling and makes landingsa less challenging adventure. With the eg ahead of thefixed wheels, the aircraft is basically stable and will notnormally ground loop as long as the nose wheel is freeto swivel. It is of course heavier and, unless retracted,has considerably higher drag. On a clean airplane, anose wheel will reduce the cruise speed by as much as15%. Since the nose wheel is in the high velocity pro-peller slipstream, it is particularly important to put afairing on both the wheel and strut. The airplane is lesslikely to nose over and cause propeller damage duringbraking, but braking at high speed is ineffective if thenose wheel is carrying much of the load.

On the tandem gear, ground looping is very severesince the eg is aft of the fixed wheel and there is littleor no force on the tailwheel. The critical stage on themotor glider is at intermediate speeds during take-offor landing, between 15 and 25 mph.

SHOCK ABSORBER DESIGNShock absorber design for either oleo or spring steel

gear is very complicated and beyond the scope of thispaper but a few observations will be related here. (For

more information, see Light Airplane Design by Ladis-lao Pazmany or his new book Landing Gear Design ForLight Airplanes soon to be published.)

A spring steel gear must be designed to absorb acertain amount of energy without yielding and stillprovide adequate clearance when deflected. The pro-cess usually requires some trial and error and changesafter testing, however. For instance, three engineersstress analyzed the PL-4 spring steel gear legs and de-termined that Vz inch steel plate would be adequate.But when we tested the first gear, we found we couldpush down on a wing tip until it touched the groundwithout raising the opposite wheel off the ground. Thisgear was obviously too soft so we increased the steelleg to % inch, a 25% thickness increase giving a 100%strength and stiffness increase. This proved to be justright.

The design of oleo shock absorbers also usually re-quires some experimenting to calibrate the orifice size.Part 23 of FAA Regulations gives the requirements forshock absorber drop testing.

Wheels should have zero camber with oleo shockabsorbers. Sufficient camber should be put into a springsteel gear to give the wheel zero camber when loaded.Wheels should have zero toe in or toe out.

ABOUT THE AUTHORLadislao Pazmany, aircraft designer, was born

in Hungary. He migrated to Argentina where helived for 30 years. He was educated there in aero-nautical engineering. He has been in the U.S. since1956 where he has worked for Convair, Ryan, Rohr,San Diego Aircraft, and presently Ryson AircraftCompany. His own company is the Pazmany Air-craft Corporation. He is responsible for the de-sign of the PL 1, PL 2, PL 4, and the Ryson ST 100Cloudster.

N7074

A VP-1 flown for the first time on November 20, 1977 by builder James G. Anton, Jr. (EAA 55891), 6 Marley Place,Waterbury, CT 06705. It Is powered by a 1600cc VW. Building time was 7 years.

46 JUNE 1978

![Landing Gear Accessories - goldlinequalityparts.com€¦ · 12 Landing Gear Accessories Landing Gear Accessories 13 [254.0mm] 10.00" [254.0mm] 10.00" [111.3mm] 4.38" [304.8mm] 12.00"](https://static.fdocuments.net/doc/165x107/5f42201687106b11477aac9b/landing-gear-accessories-12-landing-gear-accessories-landing-gear-accessories.jpg)