Kunak Jaya _Final_ - 14_4_08

-

Upload

preecha-lim -

Category

Documents

-

view

226 -

download

0

Transcript of Kunak Jaya _Final_ - 14_4_08

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 1

CLEAN DEVELOPMENT MECHANISM PROJECT DESIGN DOCUMENT FORM (CDM-PDD)

Version 03.1 - in effect as of: 28 July 2006

CONTENTS A. General description of project activity B. Application of a baseline and monitoring methodology C. Duration of the project activity / crediting period D. Environmental impacts E. Stakeholders’ comments

Annexes Annex 1: Contact information on participants in the project activity Annex 2: Information regarding public funding Annex 3: Baseline information

Annex 4: Monitoring plan Annex 5: Calculation of heating values of biomass fuel and fuel needs for the plant Annex 6: Measurement of heating value for EFB Annex 7: Details of leakage calculation Annex 8: Cost-benefit analysis of using EFB for mulching Annex 9: Illustration of technical barriers in EFB combustion Annex 10: Weighted average cost of capital calculation

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 2

SECTION A. General description of project activity A.1. Title of the project activity:

KUNAK JAYA BIO ENERGY PLANT, MALAYSIA

Version 2.0 25/02/2008

A.2. Description of the project activity:

The project activity involves the installation of a new biomass energy plant at the new palm oil refinery and kernel crushing plant of TSH-Wilmar Sdn Bhd located at Kunak Jaya (the Refinery). The biomass energy plant will utilise, biomass waste, a renewable biomass that is produced from palm oil mills to generate steam and power. The project activity will reduce the energy system’s dependency on fossil fuel resources and the emissions of GHG emissions.

Under the baseline situation, the electricity and steam required by the Refinery would be imported from the power grid and produced in a biomass boiler respectively. The biomass boiler in the baseline would use only mesocarp fibre, and palm kernel shell (PKS) and a small amount of palm kernel cake (PKC) as fuel and no empty fruit bunches (EFB) would be use as EFB is well known to be a difficult fuel to handle.

In the project situation, the biomass energy plant on site will use biomass waste to generate useful power and steam. The biomass waste used in the project activity will be sourced from palm oil mills and is made up of EFB, PKS, mesocarp fibre and PKC. There is a significant contribution in reducing the methane emission from the landfills previously used for deposition of EFB.

The project activity consists of two parts:

1) Production of CO2-neutral electricity that will replace conventional electricity generation based on fossil fuel and thereby reducing GHG emission in the electricity production.

2) Start of utilisation of EFB as a fuel and that will lead to avoided methane emissions from landfill sites where EFB was deposited.

Other expected benefits from the project activity include:

• Sustainable development

The project activity will contribute to the use of sustainable renewable energy sources in the power generation system and support the country’s fifth fuel policy that promotes the use of renewable energy.

• Environmental sustainability

The project activity will have a positive impact on the environment as it will reduce power production based on fossil fuels and lead to an increased sustainability in the power generation sector. Furthermore, the power plant will be equipped with high-efficient technologies that

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 3

reduce the fuel consumption per unit output and increase the combustion efficiency. Pollution control equipment will be installed in order to ensure minimum emissions of particulates and other pollutants from the plant.

The project activity will lead to reduced disposal of waste products from the palm oil mill and increase the utilisation of the energy content in waste products.

• Social sustainability

The project activity will generate new jobs for people from the surrounding area since the biomass energy plant is more labour intensive than buying power from grid. The workers will need to be trained in using the state of the art machinery.

Economic spill over of the Kunak Jaya Bio Energy Project will also increase business opportunities for local suppliers in transportation, maintenance and repair, parts supply, food and other services.

• Economic sustainability

The project activity will lead to economic sustainability as the fuel sources are sustainable, indigenous resources, which reduces fuel imports and negative impact on foreign exchange. The project activity will also have a positive impact on the economic performance of the Refinery, as energy production will be more reliable and efficient, leading to a more reliable production at the Refinery.

Additional to a business-as-usual scenario

The project activity is additional to a business-as-usual scenario as it will be among the first cogeneration plants in Malaysia fired mainly with EFB from palm oil mills, to supply electricity and steam to a palm oil refinery. The business-as-usual scenario for power generation is to purchase power from the grid and to produce steam with use of the same types of biomass as in the project activity.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 4

A.3. Project participants:

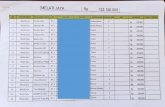

Table A.1: Project participants

Name of Party involved (*) ((host) indicates a host Party)

Private and/or public entity(ies) project participants (*) (as applicable)

Kindly indicate if the Party involved wishes to be considered as project

participant (Yes/No)

Malaysia (Host) Private entity TSH-Wilmar (BF) Sdn Bhd (TSH-Wilmar)

No

United Kingdom Private Entity: EnergiMidt Handel A/S

No

(*) In accordance with the CDM modalities and procedures, at the time of making the CDM-PDD public at the stage of validation, a Party involved may or may not have provided its approval. At the time of requesting registration, the approval by the Party (ies) involved is required.

A.4. Technical description of the project activity: A.4.1. Location of the project activity: The Kunak Jaya Bio Energy Project is located at KM 1, Kampung Kunak Jaya, 91207 Kunak, Sabah. A.4.1.1. Host Party(ies):

Malaysia A.4.1.2. Region/State/Province etc.:

Sabah

A.4.1.3. City/Town/Community etc: Kunak Jaya

A.4.1.4. Detail of physical location, including information allowing the unique identification of this project activity (maximum one page):

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 5

Figure A.1 : Location Map of Project Activity. A.4.2. Category(ies) of project activity: The project activity falls under Sectoral Scope 01: energy industries (renewable - / non-renewable sources) as per the sectoral scoped related to approved methodologies and Designated Operational Entities (DOEs).

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 6

A.4.3. Technology to be employed by the project activity : The project activity, cogeneration plant involves the installation of two new biomass fired steam boilers and a new condensing steam turbine. To further improve the use of EFB as a source of energy, a fuel preparation system will be established to prepare the EFB as a fuel. The fuel preparation system consists mainly the shredding of the very bulky EFB into fibres and a reduction of moisture content to obtain better combustion properties. The two new boilers are: Boiler 1 Vickers boiler producing 48 bar (g) super heated steam at 450ºC at a capacity of 52 tonnes per hour using biomass waste as fuel. It has an automatic combustion control system that ensures the effectiveness of biomass combustion and control of emission. Emission is mitigated using multi-cyclone system and the emission control complies with the prevailing emission regulation standards in Malaysia. Boiler 2 Another biomass boiler is a 30t/hour steam generation boiler supplied by Mc Kenzie. This boiler is designed to produce 20 bar saturated steam for the needs of the Refinery. The steam generated in the Boiler 1, will be used to run the 10 MWh full condensing and multi stage Siemens steam turbine detailed below:

o Turbine Type : SIEMENS GK 26/40 o Turbine Speed : 10,673 rpm o Generator Speed : 1,500 rpm o Main Steam Pressure : 43 bar (abs) o Main Steam Temp. : 425 Deg C o Pressure at Exhaust : 0.2 bar (abs) Fully Condensing

The plant is constructed to supply at least 65,700 MWh of electricity for consumption of the Refinery every year. The commissioning programme for the new installation will include adequate training and familiarisation of the new technology among the relevant operators and maintenance staff. This is important as it will minimise the maintenance costs and dependency on the foreign technical support for the aforesaid equipment. The Kunak Jaya Bio Energy Project plant requires a steady supply of biomass. The sources of fuel comprise 70% of EFB, 15% mesocarp fibre, 10% PKS and 5% PKC (on weight basis).

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 7

A.4.4. Estimated amount of emission reductions over the chosen crediting period:

Table A.3: The total GHG emission reductions in tCO2-e over the crediting period

Years Annual estimation of emission reductions in tonnes of CO2e

Year 1 42,018 Year 2 45,669 Year 3 49,195 Year 4 52,599 Year 5 55,887 Year 6 59,061 Year 7 62,126

Total estimated reductions (tonnes of CO2e) 366,555 Total number of crediting years 7

Annual average over the crediting period of estimated reductions (tonnes of CO2e) 52,365

A.4.5. Public funding of the project activity: No public funding from parties included in Annex I of convention is involved in the project activity. SECTION B. Application of a baseline methodology B.1. Title and reference of the approved baseline methodology applied to the project activity: ACM0006 (version 06): “Consolidated baseline methodology for grid-connected electricity generation from biomass residues” version 06 (ACM0006 (version 06). The methodology refers to the following tools for specific parts of the calculations:

• “Tool to determine methane emissions avoided from dumping waste at a solid waste disposal site“; (version 02)

• “Tool to calculate project or leakage CO2 emissions from fossil fuel combustion” (version 01); and

• “Tool to calculate project emissions from electricity consumption (version 01)” • ACM0002 (“Consolidated baseline methodology for grid-connected electricity generation from

renewable sources”); The reference to the ACM0002 is according to the EB 351 ACM002 has been replaced with the “Tool to calculate emission factors for electricity system” (version 01)

1 The Board in approving the above tool, requested the secretariat to amend all the approved methodologies and tools that refer to ACM0002, replacing the reference to ACM0002 by a reference to the above approved tool. This will constitute a revision of the methodologies and these revisions shall come into effect 2 November 2007, 17:00 GMT

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 8

Finally the methodology refers to the “Combined tool to identify the baseline scenario and demonstrate additionality”. The latest version of the tool is version 02.1 (Combined Additionality Tool). B.2. Justification of the choice of the methodology and why it is applicable to the project activity This consolidated methodology covers a number of different project types for power generation with biomass residues. This methodology is applicable to biomass residue fired electricity generation projects activities, including cogeneration plants. The consolidated methodology ACM0006 (version 06) has a number of applicability criteria discussed in the table set out in Section B.2 below. Applicability criterion Project compliance with the criterion The methodology is applicable for “biomass residue fired electricity generation project activities, including cogeneration plants

Since the project activity is a cogeneration plant using biomass residues for generating power and heat, thus it meets the criteria.

Biomass residues are defined as biomass that is a by-product, residue or waste stream from agriculture, forestry and related industries. This shall not include municipal waste or other wastes that contain fossilized and/or non-biodegradable material

The biomass residues used as fuel in the project activity include EFB, mesocarp fibres, PKS and PKC from palm oil mills. None of these wastes contains fossilized waste or municipal solid waste.

The installation of a new biomass residue fired power plant at a site where currently no power generation occurs (greenfield power projects);

There was no power production at the site before the project activity – it is a greenfield power project.

No other biomass types than biomass residues, as defined above, are used in the project plant and these biomass residues are the predominant fuel used in the project plant (some fossil fuels may be co-fired)

There will not be other types of biomass used other than biomass from oil palm mills as covered by the definition of biomass residue. Small amounts of fossil fuels may be used as back up fuel. This use will be monitored and calculated as project emissions.

For projects that use biomass residues from a production process (e.g. production of sugar or wood panel board), the implementation of the project shall not result in an increase of the processing capacity of raw input (e.g. sugar, rice, logs, etc) or in other substantial changes (e.g. product range) in this process;

The utilisation of the biomass residues does not affect the production process of the palm oil mills as the production of crude palm oil is guided by the harvesting and demand in the market. The project activity will not result in any change in the processing capacity or product.

The biomass residues used by the project facility should not be stored for more than one year;

The biomass fuel will typically only be stored for one week. There is a good supply over the whole year of biomass residues so seasonal storage is not necessary and not possible either

No significant energy quantities, except from transportation or mechanical treatment of the biomass residues, are required to prepare the

There is only simple mechanical treatment of the biomass residues before they are used as fuel –shredding of the EFB. The energy used for these

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 9

Applicability criterion Project compliance with the criterion biomass residues for fuel combustion, i.e. projects that process the biomass residues prior to combustion (e.g. esterification of waste oils)

activities are included in the project emissions

As discussed in the table the Kunak Jaya Bio Energy Project clearly falls within the application criteria of ACM0006 (version 06). A further application criterion is that the project activity must fall under one of the approved baseline scenarios. This will be discussed and documented below. B.3. Description of how the sources and gases included in the project boundary Table B.1: Sources and gasses included in the project boundary

Source

Gas

Justification / Explanation

CO2 Included By using the calculations prescribed by the ACM0006.

CH4 Excluded For the purpose of simplification – this is conservative.

Grid electricity generation

N2O Excluded For the purpose of simplification – this is conservative.

CO2 Excluded Emissions are not included as biomass is the baseline for the heat production.

CH4 Excluded For the purpose of simplification – this is conservative.

Heat generation

N2O Excluded For the purpose of simplification – this is conservative.

CO2 Excluded Biomass is considered carbon neutral. CH4 Included Methane emissions from previously land-

filled biomass waste products are calculated and considered part of the

Bas

elin

e

Disposal of biomass

N2O Excluded For the purpose of simplification – this is conservative.

CO2 Excluded CO2 emissions from biomass are considered carbon neutral.

CH4 Included Methane emissions from the utilisation of the biomass as fuel are calculated and included in the project emissions.

Pro

ject

Combustion of biomass residues for renewable electricity and/or heat generation

N2O Excluded For the purpose of simplification.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 10

Source

Gas

Justification / Explanation

CO2

Included Emissions from using fossil fuels for

start-ups or when biomass humidity is too high at the project site.

CH4

Excluded For the purpose of simplification. It is

assumed that CH4 emissions to be very small.

On-site fossil fuel and electricity consumption due to the project activity (stationary or mobile)

N2O Excluded For the purpose of simplification. It is assumed that N2O emissions to be very small.

CO2 Included Emissions from transportation of biomass residues to the project plant by vehicles.

CH4 Excluded For the purpose of simplification. It is assumed that CH4 emissions to be very

Transportation of biomass and ash

N2O Excluded For the purpose of simplification. It is assumed that N2O emissions to be very

CO2

Excluded

CH4

Storage of biomass

N2O

The biomass will only be stored for a short period of time – up to one week.

CO2

Excluded

CH4

Waste water from the treatment of biomass residues

N2O

Wastewater from the preparation of EFB will be sent to Kunak Palm Oil Mill biogas plant (Methane Recovery and Utilisation Project at TSH Kunak Oil Palm Mill, Reg. No. 0916) for treatment. The methane is collected and used in gas engines for power production. There is no project emission from the water as emission in relation to the biogas plant will be handled in relation to that project.

CO2 Included Emissions from transportation of waste water from the project plant to Kunak Palm Oil Mill biogas plant by vehicles.

CH4 Excluded For the purpose of simplification. It is assumed that CH4 emissions to be very small.

Transportation of waste water

N2O Excluded For the purpose of simplification. It is assumed that N2O emissions to be very small.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 11

B.4. Description of how the baseline scenario is identified and description of the identified baseline scenario: The identification of the baseline scenario is in accordance to ACM0006 (version 06) with demonstration of additionality using steps prescribed in the latest version of the Combined Additionality Tool. The Combined Additionality Tool prescribes four steps to establish the baseline scenario and demonstrate additionality: STEP 1. Identification of alternative scenarios STEP 2. Barrier analysis STEP 3. Investment analysis (if applicable) STEP 4. Common practice analysis These four steps will be undertaken in the following. STEP 1. Identification of alternative scenarios Step 1a. Define alternative scenarios to the proposed CDM project activity Pursuant to the Combined Additionality Tool, project proponent shall identify all alternatives scenarios that are available to the project proponent and that provide outputs or services with comparable quality, properties and application areas as the proposed CDM project activity. In applying Step 1 of the Combined Additionality Tool, ACM0006 (version 06) requires realistic and credible alternatives should be separately determined regarding:

• How power would be generated in the absence of the CDM project activity; • What would happen to the biomass residues in the absence of the project activity; and • In case of cogeneration projects: how the heat would be generated in the absence of the project

activity. The plausible baseline scenarios for power generation identified in ACM0006 (version 06) are set out in Table B2 with comments and conclusion for each plausible baseline scenario discussed in the corresponding right columns. Table B.2: Realistic and credible alternatives for power generation:

Plausible baseline

scenarios for power

generation

Description Comments Realistic and credible

alternative? (Yes/No)

P1

The proposed project activity not undertaken as a CDM

This is a realistic and credible alternative.

Yes

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 12

Plausible baseline

scenarios for power

generation

Description Comments Realistic and credible

alternative? (Yes/No)

project activity.

P2 The continuation of power generation in an existing biomass residue fired power plant at the project site, in the same configuration, without retrofitting and fired with the same type of biomass residues as (co-)fired in the project activity.

Continuation of power generation is not applicable as the project activity is a greenfield project where no prior energy production took place. This is not a realistic and credible alternative.

No

P3 The generation of power in an existing captive power plant, using only fossil fuels.

Generation of power in an existing captive power plant is not applicable as the project activity is a greenfield project where no prior energy production took place. This is not a realistic and credible alternative.

No

P4 The generation of power in the grid.

In absence of the project activity, the equivalent power generated by the project activity would be purchased by refinery from the grid. Hence this is a realistic and credible alternative.

Yes

P5 The installation of a new biomass residue fired power plant, fired with the same type and with the same annual amount of biomass residues as the project activity, but with a lower efficiency of electricity generation (e.g. an efficiency that is common practice in the relevant industry sector) than the project plant and therefore with a lower power output than in the project case.

The project activity is not claiming to be more efficient than other projects options. There is no common practice of installing lower efficiency electricity generation in palm oil mills. Thus the installation of a lower efficiency power plant at the site would not be a realistic and credible alternative.

No

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 13

Plausible baseline

scenarios for power

generation

Description Comments Realistic and credible

alternative? (Yes/No)

P6 The installation of a new biomass residue fired power plant that is fired with the same type but with a higher annual amount of biomass residues as the project activity and that has a lower efficiency of electricity generation (e.g. an efficiency that is common practice in the relevant industry sector) than the project activity. Therefore, the power output is the same as in the project case.

The project activity is not claiming to be more efficient than other projects options. There is no common practice of installing lower efficiency electricity generation in palm oil mills. Thus the installation of a lower efficiency power plant at the site would not be a realistic and credible alternative.

No

P7 The retrofitting of an existing biomass residue fired power, fired with the same type and with the same annual amount of biomass residues as the project activity, but with a lower efficiency of electricity generation (e.g. an efficiency that is common practice in the relevant industry sector) than the project plant and therefore with a lower power output than in the project case.

Retrofitting of an existing biomass residue fired power is not applicable as the project activity is a greenfield project involving construction of a new plant. This is not a realistic and credible alternative.

No

P8 The retrofitting of an existing biomass residue fired power that is fired with the same type but with a higher annual amount of biomass residues as the project activity and that has a lower efficiency of electricity generation (e.g. an efficiency that is common practice in the relevant industry sector) than the project activity.

Retrofitting an existing biomass residue fired power is not applicable as the project activity is a greenfield project involving construction of a new plant. This is not a realistic and credible alternative.

No

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 14

Plausible baseline

scenarios for power

generation

Description Comments Realistic and credible

alternative? (Yes/No)

P9 The installation of a new fossil fuel fired captive power plant at the project site.

Installation of new fossil fuel fired captive power plant at the project site would be economically unattractive. In addition it would also lead to higher baseline emissions. Thus it is a conservative assumption to eliminate this alternative. Therefore this is not a realistic and credible alternative.

No

Pursuant to Table B2, the realistic and credible alternatives identified for power generation are:-

• P1; and • P4.

The plausible baseline scenarios for generation of heat identified in ACM0006 (version 06) are set out in Table B3 with comments and conclusions for each plausible baseline scenario discussed in the corresponding right columns. Table B.3: Realistic and credible alternatives for heat generation

Plausible baseline

scenarios for heat

generation

Description Comments Realistic and credible

alternative? (Yes/No)

H1 The proposed project activity not undertaken as a CDM project activity

This is a realistic and credible alternative

Yes

H2 The proposed project activity (installation of a cogeneration power plant), fired with the same type of biomass residues but with a different efficiency of heat generation (e.g. an efficiency that is common practice in the relevant industry sector)

The project activity is not increasing the efficiency of heat production compared to the baseline. This is not a realistic and credible alternative.

No

H3 The generation of heat in an existing captive cogeneration plant, using only fossil fuels

Generation of heat in an existing captive cogeneration plant is not applicable because

No

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 15

Plausible baseline

scenarios for heat

generation

Description Comments Realistic and credible

alternative? (Yes/No)

the project activity is a greenfield project where no prior energy production took place. This is not a realistic and credible alternative.

H4 The generation of heat in boilers using the same type of biomass residues

The biomass of the same type could also have been used for the generation of heat in the baseline. This is a realistic and credible alternative.

Yes

H5 The continuation of heat generation in an existing biomass residue fired cogeneration plant at the project site, in the same configuration, without retrofitting and fired with the same type of biomass residues as in the project activity

Generation of heat in an existing captive cogeneration plant is not applicable because the project activity is a greenfield project where no prior energy production took place. This is not a realistic and credible alternative.

No

H6 The generation of heat in boilers using fossil fuels

Installation of new fossil fuel fired captive power plant at the project site would have been one of the realistic and credible alternative.

Yes

H7 The use of heat from external sources, such as district heat

There is no district heating system in the region. This is not a realistic and credible alternative.

No

H8 Other heat generation technologies (e.g. heat pumps or solar energy)

Other renewable energy technologies are not available for generation of steam at the required temperature and pressure. This is not a realistic and credible alternative.

No

Pursuant to Table B3, the realistic and credible alternatives identified for heat generation are:-

• H1; • H4; and • H6.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 16

In accordance to type and specifications of boiler discussed in Section A.4.3, four types of biomass fuel specified for use in the Kunak Jaya Bio Energy Project are:

a) EFB b) PKS c) Mesocarp fibre d) PKC

Pursuant to ACM0006 (version 06), which reads: “Where the project activity uses different types of biomass residues, the baseline scenario should be identified for each type of biomass residue separately. Biomass residues from different sources should be considered as different types of biomass residues k. Similarly, biomass residues with different uses in the absence of the project activity should be considered as different types of biomass residues k”, Each type of biomass residues are explained and documented in separate tables i.e. Table B.4A to Table B.4D.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 17

Table B.4A: Realistic and credible alternatives for use of EFB

Plausible baseline

scenarios for use of EFB

Description Comments Realistic and credible

alternative? (Yes/No)

B1 The biomass residues are dumped or left to decay under mainly aerobic conditions. This applies, for example, to dumping and decay of biomass residues on fields.

Use of EFB for mulching is economically unattractive especially in Sabah where the land is dominated by hilly terrain.2 Besides that, there are innumerable problems associated with EFB application as a mulch3 such as:

• Distance of the field from mill,

• Heavy traffic causing damage to field roads

• Harvesting paths requiring frequent upgrading, which can be costly,

• Field inaccessibility to light vehicles during rainy months,

• Mulching field close to worker’s quarters can encourage breeding of flies and rhinoceros beetle,

• Insufficient vehicles during peak cropping months as vehicles are given priority for FFB evacuation

• Settlers are not given benefit to mulch their field in the case of Government land scheme.

No

2 Calculated value of EFB as fertilizer is MYR10.33 /ton and the costs of distribution are calculated as MYR9.50/ton. See Annex 8 for more details. 3 Dr, Chow Mee Chin, MPOB, 2006: “An Assessment Of Potential And Availability Of Palm Biomass For Bioconversion To Bioethanol” page 35-36. Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 18

Plausible baseline

scenarios for use of EFB

Description Comments Realistic and credible

alternative? (Yes/No)

Mulching is only done by bigger plantation4.There are still companies that dispose the empty fruit bunches using landfill method particularly mill with smaller plantations or estates5. The EFB used in this project activity will be sourced from palm oil mills using landfills and such actual landfills can be verified during validation. Thus this is not a realistic and credible alternative following the barriers discussed above.

B2 The biomass residues are dumped or left to decay under clearly anaerobic conditions. This applies, for example, to deep landfills with more than 5 meters. This does not apply to biomass residues that are stock-piled or left to decay on fields.

Landfill is the common practice in the region due to abundant EFB supply. The EFB used in this project activity will be sourced from palm oil mills using landfills and such actual landfills can be identified during validation. This is a realistic and credible alternative.

Yes

B3 The biomass residues are burnt in an uncontrolled manner without utilizing it for energy purposes.

Open burning of biomass residues is prohibited according to the Malaysian Legislation – Environmental Quality Act 1974 (amended 2000).This is not a realistic and credible alternative.

No

4 Ludin, N., et. Al, “Palm Oil Biomass for Electricity Generation in Malaysia”, (http://www.biogen.org.my/bris/Biogen/Tech/(d)Documents/technology(d)7.pdf) accessed 4 January 2008 5 Ludin, N., et. Al, “Palm Oil Biomass for Electricity Generation in Malaysia”, (http://www.biogen.org.my/bris/Biogen/Tech/(d)Documents/technology(d)7.pdf) accessed 4 January 2008

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 19

Plausible baseline

scenarios for use of EFB

Description Comments Realistic and credible

alternative? (Yes/No)

B4 The biomass residues are used for heat and/or electricity generation at the project site

EFB is a difficult fuel to handle as it has high silica and moisture content. As such, both the costs of EFB fuel preparation and associated risks involved are high. Therefore, EFB will not be used for heat and/or electricity generation at the project site. This is not a realistic and credible alternative.

No

B5 The biomass residues are used for power generation, including cogeneration, in other existing or new grid-connected power plants.

EFB is a difficult fuel to handle. Costs of EFB fuel preparation and associated risks involved are big and rendering such projects not commercially feasible. (See results of calculations set out in Step 3 below).

Furthermore, there has not been any project in Malaysia using EFB as fuel for electricity production – except for CDM projects. Thus this is not a realistic and credible alternative.

No

B6 The biomass residues are used for heat generation in other existing or new boilers at other sites

EFB is a difficult fuel to handle. Costs of EFB fuel preparation and the associated risks involved are big and rendering such projects not commercially feasible. (See results of calculations set out in Step 3 below).

There has not been any project in Malaysia using EFB as fuel for heat production – except for CDM projects. Thus this is not a realistic and credible alternative.

No

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 20

Plausible baseline

scenarios for use of EFB

Description Comments Realistic and credible

alternative? (Yes/No)

B7 The biomass residues are used for other energy purposes, such as the generation of biofuels

The technology to convert EFB into biofuels is still in a laboratory scale6 and can thus it is not a realistic and credible alternative for the project proponent.

No

B8 The biomass residues are used for non-energy purposes, e.g. as fertilizer or as feedstock in processes (e.g. in the pulp and paper industry)

EFB is not used for non-energy purposes like fertilizer due to eco-conditions in this region mainly due to adverse field conditions such as like hilly areas and steep terrain. (See comments in scenario B1 of this Table B.4A)

Use of EFB in the production of pulp and paper is relatively a new technology in this region and hence would not be financially attractive without registration as a CDM project activity. Therefore this is not a realistic and credible alternative.

No

Pursuant to Table B.4A, the realistic and credible alternative identified for use of EFB is:-

• B2 Table B.4B: Realistic and credible alternatives for use of PKS

Plausible baseline

scenarios for use of PKS

Description Comments Realistic and credible

alternative? (Yes/No)

6 Danish Technical University, 2006: “Ethanol potential for Empty Fruit Bunches pre-treated by Wet-Explosion” downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 21

Plausible baseline

scenarios for use of PKS

Description Comments Realistic and credible

alternative? (Yes/No)

B1 The biomass residues are dumped or left to decay under mainly aerobic conditions. This applies, for example, to dumping and decay of biomass residues on fields.

PKS is a useful resource and is not dumped or left to decay. Hence it cannot be taken as a realistic and credible alternative.

No

B2 The biomass residues are dumped or left to decay under clearly anaerobic conditions. This applies, for example, to deep landfills with more than 5 meters. This does not apply to biomass residues that are stock-piled or left to decay on fields.

PKS is a useful resource and is not dumped or left to decay. Hence it cannot be taken as a realistic and credible alternative. It is also a conservative assumption to rule out this alternative.

No

B3 The biomass residues are burnt in an uncontrolled manner without utilizing it for energy purposes.

PKS is a useful resource and is not burnt in an uncontrolled manner. Further, open burning of biomass residues is prohibited according to The Malaysian Legislation – Environmental Quality Act 1974 (amended 2000). This is not a realistic and credible alternative.

No

B4 The biomass residues are used for heat and/or electricity generation at the project site

In the absence of the project activity, PKS would have been used for heat generation at project site. This is a credible and realistic alternative.

Yes

B5

The biomass residues are used for power generation, including cogeneration, in other existing or new grid-connected power plants

There has not been any project in Malaysia for use of PKS as fuel for grid connected electricity production7 – except for CDM projects. This is not a realistic and credible alternative.

No

7 EPU, 2006: 9th Malaysia Plan 2006-2010: p 401: “Under the Small Scale Renewable Energy Power Programme (SREP) two projects with a combined grid connected capacity of 12 MW were implemented” – during the 8th Plan from 2000-2005. These were the Kunak Biomass Power Plant (10 MW) and a landfill gas project (2 MW)

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 22

Plausible baseline

scenarios for use of PKS

Description Comments Realistic and credible

alternative? (Yes/No)

B6 The biomass residues are used for heat generation in other existing or new boilers at other sites

PKS is to a certain extent used as fuel in palm oil mills. It is estimated that around 50% of the available PKS is used for energy in palm oil mills.8 There is thus a large excess of PKS in the palm oil mill that can be used for other purposes. However, there are only a few other industries in East Sabah. Thus there is no demand for the excess PKS. This is thus not a realistic and credible alternative.

No

B7 The biomass residues are used for other energy purposes, such as the generation of biofuels

The technology to convert PKS into biofuels is still in a laboratory scale and the yields from PKS are not attractive compared to other sources of biomass9. Thus, this is not a realistic and credible alternative for the project proponent.

No

B8 The biomass residues are used for non-energy purposes, e.g. as fertilizer or as feedstock in processes (e.g. in the pulp and paper industry)

No technology exists currently to use PKS for non-energy purposes. Thus this is not a realistic and credible alternative.

No

Pursuant to Table B.4B, the realistic and credible alternative for use of PKS is:-

• B4

8 Anders Evald et all. 2005: Renewable Energy resources. Pages 19-20 Downloaded from www.eib.ptm.org.my 9 Danish Technical University, 2006: “Ethanol potential for Empty Fruit Bunches pre-treated by Wet-Explosion”

Table p 11. Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 23

Table B.4C: Realistic and credible alternatives for use of mesocarp fibre

Plausible baseline

scenarios for use of

mesocarp fibre

Description Comments Realistic and credible

alternative? (Yes/No)

B1 The biomass residues are dumped or left to decay under mainly aerobic conditions. This applies, for example, to dumping and decay of biomass residues on fields.

Mesocarp fibre are a useful resource and are not dumped or left to decay. Hence this is not a realistic and credible alternative.

No

B2 The biomass residues are dumped or left to decay under clearly anaerobic conditions. This applies, for example, to deep landfills with more than 5 meters. This does not apply to biomass residues that are stock-piled or left to decay on fields.

Mesocarp fibre are a useful resource and are not dumped or left to decay. Hence this is not a realistic and credible alternative. It is a conservative assumption to rule out this alternative.

No

B3 The biomass residues are burnt in an uncontrolled manner without utilizing it for energy purposes.

Mesocarp fibre is a useful resource and is not burnt in an uncontrolled manner. In addition, open burning of biomass residues is prohibited according to The Malaysian Legislation – Environmental Quality Act 1974 (amended 2000). This is not a realistic and credible alternative.

No

B4 The biomass residues are used for heat and/or electricity generation at the project site

In the absence of the project activity, mesocarp fibre would have been used for heat generation at project site. This is the most realistic and credible alternative.

Yes

B5 The biomass residues are used for power generation, including cogeneration, in other existing

There have not been any projects in Malaysia for using mesocarp fibre as fuel for grid

No

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 24

Plausible baseline

scenarios for use of

mesocarp fibre

Description Comments Realistic and credible

alternative? (Yes/No)

or new grid-connected power plants3

connected electricity production10 – except for CDM projects. This is not a realistic and credible alternative.

B6 The biomass residues are used for heat generation in other existing or new boilers at other sites4

Mesocarp fibre is used as fuel in palm oil mills. However, there are only a few other industries in East Sabah. Thus, there is no demand for the excess mesocarp fibre. This is thus not a realistic and credible alternative.

No

B7 The biomass residues are used for other energy purposes, such as the generation of biofuels

The technology to convert mesocarp fibre into biofuels is still in a laboratory scale and the yields from mesocarp fibre are not attractive compared to other sources of biomass11. This is thus not a realistic and credible alternative for the project proponent.

No

B8 The biomass residues are used for non-energy purposes, e.g. as fertilizer or as feedstock in processes (e.g. in the pulp and paper industry)

No technology exists currently to use mesocarp fibre for non-energy purposes. Thus this is not a realistic and credible alternative.

No

Pursuant to Table B.4C, the realistic and credible alternative for use of mesocarp fibre is:-

• B4

10 EPU, 2006: 9th Malaysia Plan 2006-2010: p 401: “Under the Small Scale Renewable Energy Power Programme (SREP) two projects with a combined grid connected capacity of 12 MW were implemented” – during the 8th Plan from 2000-2005. These were the Kunak Biomass Power Plant (10 MW) and a landfill gas project (2 MW) 11 Danish Technical University, 2006: “Ethanol potential for Empty Fruit Bunches pre-treated by Wet-Explosion”

Table p 11. Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 25

Table B.4D: Realistic and credible alternatives for use of PKC

Plausible baseline

scenarios for use of PKC

Description Comments Realistic and credible

alternative? (Yes/No)

B1 The biomass residues are dumped or left to decay under mainly aerobic conditions. This applies, for example, to dumping and decay of biomass residues on fields.

PKC is a useful resource and is not dumped or left to decay. Hence this is not a realistic and credible alternative.

No

B2 The biomass residues are dumped or left to decay under clearly anaerobic conditions. This applies, for example, to deep landfills with more than 5 meters. This does not apply to biomass residues that are stock-piled or left to decay on fields.

PKC is a useful resource and is not dumped or left to decay. Hence this is not a realistic and credible alternative. It is also a conservative assumption to rule out this alternative.

No

B3 The biomass residues are burnt in an uncontrolled manner without utilizing it for energy purposes.

PKC is a useful resource and is not burnt in an uncontrolled manner. In addition, open burning of biomass residues is prohibited according to The Malaysian Legislation – Environmental Quality Act 1974 (amended 2000). This is not a realistic and credible alternative.

No

B4 The biomass residues are used for heat and/or electricity generation at the project site

PKC is a useful resource with a high commercial value12 by-product produced by the Refinery. PKC has high net calorific value and is a more economical supplement (to other biomass fuel discussed in Table B.4A to Table B.4C)

Yes

12 PKC has a cost of MYR27.80/GJ compared to the other biomass fuels with a price between MYR1.50 and MYR5.70 /GJ

Source: Financial spreadsheet for the Kunak Jaya Bio Energy Project.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 26

Plausible baseline

scenarios for use of PKC

Description Comments Realistic and credible

alternative? (Yes/No)

as compared to conventional fossil fuel e.g. Medium Fuel Oil (MFO). Thus, the use of PKC is a realistic and credible alternative.

B5

The biomass residues are used for power generation, including cogeneration, in other existing or new grid-connected power plants

There has not been any project in Malaysia using PKC as fuel for grid connected electricity production13 – except for CDM projects. This is not a realistic and credible alternative

No

B6 The biomass residues are used for heat generation in other existing or new boilers at other sites

PKC is a useful resource with a high commercial value and therefore would not be normally use by other project proponent a source of energy in other existing or new boiler at other sites. This is not a realistic and credible alternative.

No

B7 The biomass residues are used for other energy purposes, such as the generation of biofuels

The technology to convert PKC into biofuels is still in its laboratory stage and the yields from PKC are not attractive as compared to other sources of biomass14. Thus, this is not a realistic and credible alternative for the project proponent.

No

B8 The biomass residues are used for non-energy purposes, e.g. as fertilizer or as feedstock in processes (e.g. in the pulp and

The use of PKC as animal feed is not an alternative as the PKC will be used in the baseline as a source of energy

No

13 EPU, 2006: 9th Malaysia Plan 2006-2010: p 401: “Under the Small Scale Renewable Energy Power Programme (SREP) two projects with a combined grid connected capacity of 12 MW were implemented” – during the 8th Plan from 2000-2005. These were the Kunak Biomass Power Plant (10 MW) and a landfill gas project (2 MW) 14 Danish Technical University, 2006: “Ethanol potential for Empty Fruit Bunches pre-treated by Wet-Explosion”

Table p 11. Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 27

Plausible baseline

scenarios for use of PKC

Description Comments Realistic and credible

alternative? (Yes/No)

paper industry) and also to compensate for any shortage in other biomass fuel in the absence of the project activity (as discussed in scenario B4in Table B.4D). This is not a realistic and credible alternative.

Pursuant to Table B.4C, the realistic and credible alternative for use of PKC is:-

• B4 Sub-step 1b. Consistency with mandatory applicable laws and regulations Baseline scenarios B3 in Table B.4A to Table B.4D refers to uncontrolled burning of biomass residues. These baseline scenarios are not in compliance with existing Malaysia legislation. Open burning of biomass residues is prohibited according to The Malaysian Legislation – Environment Quality Act 1974 (amended 2000). Thus these baseline scenarios have thus been disregarded as realistic and credible alternatives. Other realistic and credible alternatives discussed in Table B.4A to Table B.4D are all in compliance with Malaysia legislation. Following Step 1 of the Combined Additionality Tool i.e. “Identification of alternative scenarios”, the following realistic and credible alternatives are identified: For power: P1 and P4 For steam: H1, H4 and H6 For biomass residues- (i) EFB: B2 (ii) PKS: B4 (iii) Mesocarp fibre: B4

(iv) PKC: B4 Based on the above discussions, the most credible combinations of baseline scenarios are as follow:-

1. Generation of power in the grid (P4), the generation of heat in boilers using biomass residues (H4) from PKS, mesocarp fibre and PKC (B4) and dumping or leaving EFB to decay under anaerobic conditions in deep landfills (B2), which is consistent with Scenario 3 of “Table 2:Combinations of project types and baseline scenarios applicable to this methodology” prescribed in ACM0006 (version 06) (“Alternative 1”);

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 28

2. Generation of power in the grid (P4), the generation of heat in boilers using fossil fuels i.e.

medium fuel oil (MFO), (H6) and dumping or leaving EFB to decay under anaerobic conditions in deep landfills (B2), which is consistent with Scenario 2 of “Table 2:Combinations of project types and baseline scenarios applicable to this methodology” prescribed in ACM0006 (version 06) (“Alternative 2”); and

3. The proposed project activity not undertaken as a CDM project activity (P1 and H1)

(“Alternative 3”) STEP 2. Barrier analysis This step serves to identify barriers and to assess which alternatives are prevented by barriers discussed in Sub-step 2a below. As prescribed in ACM0006 (version 06), the barrier analysis consists of two sub-steps namely: Sub-step 2a: Identify barriers that would prevent the implementation of alternative scenarios

identified in Step 1 above. Sub-step 2b: Eliminate alternative scenarios which are prevented by the identified barriers Sub-step 2a. Identify barriers that would prevent the implementation of alternative scenarios Sub-step 2a requires the establishment of a complete list of realistic and credible barriers that may prevent alternative scenarios to occur. The complete list of realistic and credible barriers that may prevent implementation of alternative scenarios are analysed as follows:

• Investment barriers • Technology barriers • Lack of prevailing practice

• Market barriers

Sub-step 2b. Eliminate alternative scenarios which are prevented by the identified barriers This step identifies alternative scenarios which are prevented by at least one of the barriers listed in Sub-step 2a above and eliminate those alternative scenarios from further consideration. Alternatives to power generation:

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 29

Out of the nine (9) alternatives to power generation analysed in Sub-step 1a and Sub-step 1 b above, only alternative P1 and P4 can be considered as realistic and credible baseline scenarios and are subjected to barrier analysis prescribed in Step 2. Table B.5: Barrier analysis for alternatives to power generation

Alternatives to power generation Barrier P1: Proposed project activity not

undertaken as a CDM project activity.

P4: Generation of power in the grid.

Investment Power production based on biomass and specifically EFB has meet strong investment barriers in Malaysia. The barriers are mainly the following15: 1. Tariff not meeting market IRR

expectations; 2. Lack of long term fuel supply; 3. Lack of financing; and 4. Certain provisions in Renewable

Energy Power Purchase Agreement (REPPA) unacceptable to SREP developers.

The only biomass power projects that have been implemented has been registered as CDM projects or are in the application process: • Lahad Datu Edible Oil (Reg. No.

395) • Sandakan Edible Oil (Reg. No. 402) • Sahabat Empty Fruit Bunch Biomass

(Reg. No. 288); and • Kunak Bio Energy Project (in

process for registration as a CDM project activity)

No investment barriers

15 Erik Dugstad et al 2007: Options for implementation of the RE target in 9th Malaysia Plan. Page 3 Summary Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 30

Alternatives to power generation Barrier P1: Proposed project activity not

undertaken as a CDM project activity.

P4: Generation of power in the grid.

Technology The formation of clinker and slag in the boiler and this has the following effects16:- • Damage to boiler tubes by direct

abrasion; • Damage to boiler tubes due to

impact of dropping large mass of clinker/slag; and

• Reduction in boiler efficiency due to formation of slag/clinker layer on boiler tubes

Difficulties in the fuel preparation of EFB17

The EFB is very bulky and with high moisture content. Therefore it is necessary to press the EFB and shred the EFB to obtain a particular size that is acceptable for use in the boiler. Furthermore the equipment used in the preparation of the EFB fuel will generally experience significant wear and tear which is due to the high presence of silica content in the EFB resulting in an increase in the maintenance cost.

Risk of technological failure: The project activity faces significant risks in performance of the technology illustrated by the low availability of the Kunak Bio Energy Project (in process for registration as a CDM project activity), which only had an availability of 25% in the first year and 50% in the second year after commissioning.

No technology risk

16 Experience from Kunak Bio Energy Project – see photos in Annex 9 17 Experience from Kunak Bio Energy Project

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 31

Alternatives to power generation Barrier P1: Proposed project activity not

undertaken as a CDM project activity.

P4: Generation of power in the grid.

Lack of prevailing practice

The experience with biomass power is very limited in Malaysia and the negative perceptions of the major players is one of the major barriers – according to Minister for Energy, Lim Keng Yaik18: What can we do to tap the high potential of renewable energy in our country? While there are barriers that need to be ironed out, I strongly believe that the biggest barrier is our mindset and perceptions. In this instance, all of us are victims to the old way of thinking”

Power from the grid is the prevailing practice

Market There are significant market barriers in utilising EFB as fuel for biomass power plant. In a major study for the EFB supply chain19 one of the conclusions is as follows: “The demand of EFB fuel is subjected to various barriers such as accessibility of fuel due to high transportation costs, uncertainty of EFB fuel prices… difficulty in handling as well as fluctuation of supply due to cropping seasons (peak/off peak)”

Power readily available

It may be observed in Table B.5 that there are very significant barriers for the proposed project activity to be undertaken not as a CDM project activity (P1) as compared to generation of power in the grid (P4) as the use of power from the grid is well known and has low technology risk.

18 Speech by The Minister for Energy Water and Communication Y.B. Dato' Sri Dr. Lim Keng Yaik at the National Renewable Energy Forum 21/09/2006. Downloaded from www.ktak.gov.my 19 Eco-Ideal Consulting & Mensilin Holdings, 2005: Barrier Analysis for the Supply Chain of Palm Oil Processing Biomass (Empty Fruit Bunch) as Renewable Fuel. Page 43 Downloaded from www.eib.ptm.org.my

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 32

Alternatives to heat generation: Among the nine (9) alternatives to heat generation analysed in Sub-step 1a and Sub-step 1b above, only alternatives H1, H4 and H6 can be considered as realistic and credible baseline scenarios and are subject to barrier analysis prescribed in Step 2. Table B.6: Barrier analysis for alternatives to heat generation

Alternatives to heat generation Barrier H1: Proposed

project activity not undertaken as a CDM project activity.

H4: Generation of heat in boiler using the same type of biomass residues i.e. mesocarp fibre, PKS and PKC.

H6: Generation of heat in boiler using fossil fuels i.e. MFO

Investment Similar barriers as for P1 (discussed in Table B.5) but less pronounced as steam production requires lower temperature and pressure of the boiler and therefore less investment. Investment in fuel preparation equipment is not commercially practical due to low use for steam boiler.

No investment barrier No investment barrier

Technology Similar barriers as for P1 (discussed in Table B.5) but less pronounced as steam production requires lower temperature and boiler pressure. Thus there is less risk of corrosion

No technology risk No technology risk

Lack of prevailing practice

Similar barriers as for P1 (discussed in Table B.5) but less pronounced as steam production requires lower temperature and boiler pressure.

No barrier No barrier

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 33

Alternatives to heat generation Barrier H1: Proposed

project activity not undertaken as a CDM project activity.

H4: Generation of heat in boiler using the same type of biomass residues i.e. mesocarp fibre, PKS and PKC.

H6: Generation of heat in boiler using fossil fuels i.e. MFO

Market Similar barriers as for P1 (discussed in Table B.5)

No barrier No barrier

As discussed in Table B.6, there are significant barriers for H1 – Proposed project activity not undertaken as a CDM project activity for heat generation using biomass residue from EFB, whilst there are no significant barriers for alternatives H4 and H6- as baselines for the project activity. For the four biomass types (EFB, PKS, mesocarp fibre and PKC) identified in Sub-step 1a and Sub-step 1b, only one alternative was identified for each biomass type as discussed in Sub-step 1b. Thus, no barrier analysis was conducted in relation to these alternatives. Outcome of Step 2b From Sub-step 2a and Sub-step 2b, it is observed that Alternative 3 (P1 and H1) identified in Step 1 experiences significant barriers. Following Sub-step 2b, alternatives scenarios to the project activity that are not prevented by any barriers are as follow:-

• P4: The generation of power in the grid

• H4: The generation of heat in boilers using the same type of biomass residues

• H6: The generation of heat in boilers using fossil fuels

• B4: The biomass residues i.e. mesocarp fibre, PKS, and PKC are used for both heat and electricity generation and

• B2: The biomass residues i.e. EFB are dumped or let to decay under clearly anaerobic

conditions.

Following Sub-step 2a and Sub-step 2b, there are still several alternative scenarios i.e.: 1. P4, H4, B4 and B2 (i.e. Alternative 1); and 2. P4, H6 and B2 (i.e. Alternative 2)

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 34

remaining, but do not include the proposed activity undertaken without being registered as a CDM project activity (i.e. P1 and H1). Thus, explanations using qualitative and quantitative arguments on how the registration of the CDM project activity will alleviate the barriers that prevent the proposed project activity from occurring in the absence of the CDM are set out below. This is in line with the Combined Additionality Tool which reads: “If there are still several alternative scenarios remaining, but which do not include the proposed project activity undertaken without being registered as a CDM project activity, explain using qualitative and quantitative arguments how the registration of the CDM project activity will alleviate the barriers that prevent the proposed project activity from occurring in the absence of the CDM.” Qualitative arguments As set out briefly in Step 2, the project activity experiences financial and technological barriers and risks. Details of the technological barriers and risks are further discussed in Annex 9. The registration of the project activity as a CDM project activity allows the project proponent to accept the inherent risks of the power plant arising from technological risks of utilization EFB as a primary biomass fuel. This contribution from sale of CERs may also assist in overcoming the barriers posed by employment of new technology to ensure the project activity is reasonably viable from commercial perspective. In addition, it can be justified that CDM will help to overcome the major barriers based on the financial contribution to the project activity. The income from sale of CERs can be calculated as 0.044 MYR/kWh as average for the first 7-years crediting period. This can be compared with the cost of purchasing power from the grid of 0.20 RM/kWh. Thus, the sale of CERs gives an increase of 22% in the value of the power produced. This argument will be further developed in the investment analysis process described in Step 3. Additional income from sale of CERs assists to overcome investment barriers of the project activity. Such additional revenue also enables the project proponent to accept risks associated with low availability of the power plant due to the inherent technological risks arising from use of EFB as biomass fuel. Finally, this extra incentive also assists to overcome perceived barriers posed by the new technology employed in the project activity Quantitative arguments From the quantitative viewpoint, the financial indicator set out below has been identified as most suitable for the project type and decision making context:

• Project internal rate of return (“Project IRR”) In demonstrating how registration of the project activity as a CDM project activity will alleviate the barriers that prevent the proposed project activity from occurring in the absence of the CDM, the Project IRR of the project activity is set out in Table B.7 for further discussion:

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 35

Table B.7: Project IRR of the project activity without and with CDM registration Financial indicator Project activity without CDM

registration Project activity with CDM

registration Project IRR 5.6%20 11.9%21

As observed from the above table, registration of the project activity as a CDM project activity is critical to ensure a commercially reasonable return of 11.9%, which is relatively close to the weighted average cost of capital22 of the company of 11.4%23. STEP 3. Investment analysis Step 3 involving investment comparison analysis is also conducted to determine if Alternative 1, Alternative 2 or Alternative 3 shortlisted in Step 1 is the most economically or financial attractive. Similar financial indicator i.e. Project IRR is applied and computed for Alternative 1, Alternative 2 and Alternative 3. In undertaking the investment comparison various variables and input data for project cost, revenues, operating and maintenance cost have been included. Outcome of Step 3 The investment comparison analysis yielded the following results in Table B.8:- Table B.8: Project IRR of Alternative 1, Alternative 2 and Alternative 3 Financial indicators Alternative 1 Alternative 2 Alternative 3 Project IRR 28.1%24 -25 5.6%26

20 Please refer to column C34, worksheet Proj NPV_without CERs, filename Copy of Copy of Kunak Jaya-IRR 080308 (TAS)_DNV (Old basis). 21 Please refer to column C36, worksheet Proj NPV_with CERs, filename Copy of Copy of Kunak Jaya-IRR 080308 (TAS)_DNV (Old basis). 22 Prescribed in Sub-step 2b – Option III, para 4C of “Tools for the demonstration and assessment of additionality, Version 04 (EB36)”. 23 Please refer Annex 10 for detailed calculation 24 Please refer to column C33, worksheet Proj NPV-Baseline1(Grid&B.mass), filename Copy of Copy of Kunak Jaya-IRR 080308 (TAS)_DNV (Old basis). 25 Please refer to column C33, worksheet Proj NPV-Baseline2(Grid&MFO), filename Copy of Copy of Kunak Jaya-IRR 080308 (TAS)_DNV (Old basis). 26 Please refer to column C34, worksheet Proj NPV-without CERs, filename Copy of Copy of Kunak Jaya-IRR 080308 (TAS)_DNV (Old basis).

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 36

As observed from the above results, Alternative 1 is the economically or financially more attractive alternative scenario and can be concluded as the baseline scenario. Sensitivity analysis A sensitivity analysis is also included to assess whether the conclusion regarding the financial attractiveness identified in Table B.8 is robust to reasonable variations in the critical assumptions applied to all three baseline scenarios i.e. Alternative 1, Alternative 2 and Alternative 3. The result of the sensitivity analysis is set out in Table B.9. Table B.9: Result of sensitivity analysis on Alternative 1, Alternative 2 and Alternative 3.

Project IRR (%) Variables Sensitivity test range Alternative 1 Alternative 2 Alternative 3

-5.0% 30.7 - 8.5 -2.5% 29.6 - 7.1

No change 28.1 - 5.6 +2.5% 27.4 - 4.1

Fixed and variable costs

+5.0% 26.3 - 2.3 -5.0% 24.0 - 4.2 -2.5% 26.1 - 4.9

No change 28.1 - 5.6 +2.5% 30.0 - 6.3

Price per MT of steam

+5.0% 32.0 - 7.0 -5.0% 18.5 - 1.6 -2.5% 23.4 - 3.8

No change 28.1 - 5.6 +2.5% 32.6 - 7.4

Running hours

+5.0% 37.1 - 8.9 Sensitivity analysis on the Project IRR taking into account reasonable variations in the assumptions of the critical variables has been carried out. Table B.9 sets out the results on sensitivity analysis performed on Project IRR, taking into account variations in fixed and variable costs, running hours and price of steam per MT. The sensitivity analysis result in Table B.9 further concludes that Alternative 1 is the most financially attractive scenario and is the baseline scenario.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 37

In addition, the sensitivity analysis results on Project IRRs of Alternative 3 are in general well below the 11.4%27, which is the weighted average cost of capital28 of the company. These results also support the conclusion that the project activity is unlikely to be financially attractive without CDM registration. Step 4: Common practice analysis Sub-step 4a: Analyse other activities similar to the proposed project activity Energy consumption in the industry accounts for close to 40% of total energy consumption in Malaysia. A broad variety of fuels is used currently, by far dominated by fossil fuels, and only to a very small extent – less than 0.5%, and not accounted for in official energy statistics. Figure B.1: Distribution of fuels used in the total industrial sector in Malaysia, 2003. Source: National Energy Balance, PTM

Figure B.1 depicts that the energy use in the industry in Malaysia is dominated by the used of fossil fuels. Very few companies have been using biomass residue as fuel. Most of the biomass fuel used is PKS i.e. cement industry whereas the use of EFB has been very limited (and mainly confined to CDM projects). The statistics clearly set out that the use of biomass (what more EFB) in industrial application is very limited in Malaysia – i.e. outside palm oil mills. 27 Please refer Annex 10 for detailed calculation

28 Prescribed in Sub-step 2b – Option III, para 4C of “Tools for the demonstration and assessment of additionality, Version 04 (EB36)”

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 38

There are in total 107 palm oil mills and 3 palm oil refineries in the state of Sabah. Out of this, only 429 projects in the region are of similar to the Kunak Jaya Bio Energy Project and are registered as CDM projects. Thus the Kunak Jaya Bio Energy Project is additional to the business as usual scenario. In addition, it could also be viewed that no other project activities similar to the Kunak Jaya Bio Energy Project will be implemented without registration as CDM project activities which will assist to alleviate and mitigate the inherent and associated risks involved in the implementation of such high efficient biomass boilers for power production in Malaysia. Sub-step 4b: Discuss any similar options that are occurring Save and except for Kunak Jaya Bio Energy Project, there have not been other similar project ongoing in Malaysia and thus no further discussion have been concluded. Summary of choice of baseline scenario The only remaining alternative identified following Step 1, Step 2 and Step 3 above is a combination of baseline scenario as prescribed in Scenario 3, Table 2 of ACM0006 (version06) which reads: “The project activity involves the installation of a new biomass residue fired cogeneration plant at a site where no power was generated prior to the implementation of the project activity. The power generated by the project plant is fed into the grid or would in the absence of the project activity be purchased from the grid. The biomass residues would in the absence of the project activity (a) be used for heat generation in boilers at the project site and (b) be dumped or left to decay or burnt in an uncontrolled manner without utilizing it for energy purposes. This may apply, for example, where the quantity of biomass residues that was not needed for heat generation was dumped, left to decay or burnt in an uncontrolled manner prior to the project implementation. The heat generated by the new cogeneration plant would in the absence of the project activity be generated in boilers using the biomass residues that are fired in the cogeneration plant.” The description fits precisely to the situation and circumstances in the project activity. The cogeneration plant is built to supply electricity and heat to the Refinery, which is newly constructed. Thus, there was no heat or power production at the site prior to the project activity. As discussed in the baseline, the electricity requirement of the Refinery would have been met through purchase from the grid, whilst the requirement for heat would have been fulfilled by a biomass steam boiler. The biomass residue would either have been used in the baseline steam boiler as prescribed in the baseline (in the case of PKS, PKC and mesocarp fibre) or been dumped in deep or shallow landfills (in the case of EFB).

29 See barrier analysis for power above for the list of projects

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 39

B.5. Description of how the anthropogenic emissions of GHG by sources are reduced below those that would have occurred in the absence of the registered CDM project activity (assessment and demonstration of additionality): This section elaborates the additionality of this project activity. The basic demonstration of additionality is handled in the previous section by means of the Combined Additionality Tool. Two elements included in the argument are: 1) The timeline of the related documents of the project activity indicate that CDM was seriously

considered in the decision to proceed with the project activity. 2) The financial impact of sale of CERs on commercial viability of the project activity. Timeline

The Kunak Jaya Bio Energy Project was submitted previously to the CDM Executive Board and was rejected after a series of reviews.

A chronology of the previous submission discussed earlier is set out below:

1. January 2006: A Board meeting was convened by the project proponent, TSH-Wilmar resolved to proceed with the project activity taking into consideration that the project activity i.e. Kunak Jaya Bio Energy Project shall qualify as a CDM project activity.

2. July 2006: Engagement of a CDM project consultant.

3. August 2006: Initiation of work at site.

4. 17th January 2007: Site validation by DOE i.e. Det Norsket Veritas.

5. 21st March 2007: National approval from Designated National Authority of Malaysia was obtained.

6. 17th April 2007: Submission of Kunak Jaya Bio Energy Project to CDM Executive Board for registration.

7. 27th July 2007: The CDM Executive Board accepted information provided during review of the project activity and agrees to register the project with correction i.e. the project participant and DOE to submit a revised PDD containing an investment comparison analysis that the project activity is less financially attractive than at least one alternative, and a corresponding revised validation report (EB 33; Point 70b).

8. 5th September 2007: Initial trial run of the project activity.

9. 19th October 2007: The CDM Executive Board could not register the project activity as the project participant and DOE failed to provide an investment comparison of the two separate alternatives presented in the PDD that could be used

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 40

to determine whether the project activity scenario was more or less financially attractive than the baseline scenario presented (EB 35; Point 76b.

This PDD represent the fourth version (including all PDD previously submitted to CDM Executive Board) for registration. The project activity remains identical despite the different version of PDD. As CDM registration was seriously considered (as shown in the above chronology of events) prior to proceeding with the Kunak Jaya Bio Energy Project, the project activity thus clearly fulfils with the requirements in the additionality tool which reads:

“Provide evidence that the incentive from the CDM was seriously considered in the decision to proceed with the project activity. This evidence shall be based on (preferably official, legal and/or other corporate) documentation that was available at, or prior to, the start of the project activity”.

Thus, it is clear from the above chronology events, that the project proponent has emphasized and taken into account CDM registration as a key factor prior to initiation of the Kunak Jaya Bio Energy Project and the project activity only commenced operation after the project activity was submitted for registration as a CDM project activity.

The financial impact of sale of CERs on commercial viability of the project activity The approval and registration of the Kunak Jaya Bio Energy Project as a CDM project activity will assist the project activity to overcome the associated and related barriers (as discussed in Section B.4 and further detailed in Annex 9) in implementation and completion of the project activity and other company(ies) in Malaysia that decides to embark on to the similar project activity in the future. The benefits arising from successful implementation, completion and registration of the project activity as a CDM project activity by the CDM Executive Board are as follow:

• The project activity will unquestionably reduce anthropogenic greenhouse emissions by generating electricity supply via clean energy source;

• The income derived from the sale of CERs to Annex 1 party will assist to overcome the barriers

as demonstrated in Section B.4 above as it will the additional revenue coming from the sale of CERs will also helps to mitigate the extra costs arising from the related technological barriers, rendering the project activity to be reasonably and commercially viable; and

• The investment cost involved for development of clean technologies project is considerably

high presently. In general, this poses difficulties for companies to embark on similar project as Kunak Jaya Bio Energy Project without the project activity being registered as a CDM project activity. As mentioned in Section B.4, Kunak Jaya Bio Energy Project is one of the few biomass fired power plants in Malaysia (using EFB as fuel), which have not been registered as a CDM project activity. Registration of the project activity as a CDM project activity does not only open a new funding possibility solely for the Kunak Jaya Bio Energy Project, but also encourages new entrant(s) to participate in similar project activity in the country.

PROJECT DESIGN DOCUMENT FORM (CDM PDD) - Version 03 .1 CDM – Executive Board

page 41

B.6. Emission reductions:

B.6.1. Explanation of methodological choices: The first methodological choice is to decide on the appropriate baseline methodology. In this PDD, ACM0006 (version 06) was applied as the appropriate baseline methodology based on justification discussed in Section B.2. The second choice is the baseline scenario described in detail in Section B.4 above. The conclusion is that this project should be evaluated under Scenario 3 of Table 2 of ACM0006, (version 06). This scenario is relevant since Kunak Jaya Bio Energy Project is a greenfield project where the baseline scenario established in Section B.4 is Scenario 3 ,Table 2 of ACM0006, (version 06) i.e.: