Kostegids 2014

Transcript of Kostegids 2014

KOSTEGIDS | COST GUIDE

2014/15

VINPRO KOSTEGIDS / COST GUIDE • 1

Samestelling / CompositionPieter van Niekerk & Andries van Zyl

VinPro Landbou-ekonomiese Dienste / VinPro Agro-economic ServicesSel: 083 561 9465 / 073 280 8703

[email protected], [email protected]

’n Spesiale woord van dank aan ons borge wat die druk van hierdie Kostegids, asook die gratis verspreiding daarvan aan alle VinPro-lede en

rolspelers in die wynbedryf moontlik maak.

A special word of thanks to our sponsors without whom this Cost Guide could not have been published or distributed for free to all VinPro

members and role-players in the wine industry.

Orchard Suppliers • Netafim • Boshoff Visser Hauptfleisch Grondverskuiwing • Terason / Villa Crop

VINPRO KOSTEGIDS / COST GUIDE • 3

Inhoud / Contents

Voorwoord / Foreword ................................................................................................................ 5

Doel / Purpose ............................................................................................................................. 5

Koste van wyndruifproduksie (2013-oes) / Cost of wine grape production (2013 harvest) .... 6Inleiding en agtergrond / Introduction and background .......................................................... 6Koste van wyndruifproduksie / Cost of wine grape production .............................................. 7Kontantuitgawes / Cash Expenditure ...................................................................................... 8Voorsiening vir vervanging / Provision for renewal .................................................................. 10Produksie se invloed op gelykbreek / Influence of production on break-even ........................ 12

Kostestruktuur van top presteerders / Cost structure of top performers................................. 16Wat doen top presteerders anders? / What sets top performers apart? ................................. 18

Teikeninkomste (2013-oes) / Target income (2013 harvest) ...................................................... 20

Arbeidsriglyne / Labour guidelines ............................................................................................. 22Arbeidsnorme / Labour norms ................................................................................................. 22Minimum loon / Minimum wage............................................................................................... 23

Vestigingskoste / Establishment cost ........................................................................................ 23Grondvoorbereiding / Soil preparation .................................................................................... 23Koste van prieelstelsels / Cost of trellis systems ..................................................................... 26Besproeiing / Irrigation ............................................................................................................. 34Ander nuttige inligting / Other useful information .................................................................... 35

Koste van meganisasie / Cost of mechanisation ....................................................................... 35Metodiek / Methodology .......................................................................................................... 36Trekkers / Tractors ................................................................................................................... 37Parsmasjiene / Harvesters ....................................................................................................... 39Spuitpompe / Spraypumps ...................................................................................................... 39Sleepwaens / Trailers ............................................................................................................... 40Ander implemente / Other implements .................................................................................... 40Bakkies / Pick-ups ................................................................................................................... 41Vragmotors / Trucks ................................................................................................................. 42

VinPro kontakbesonderhede / VinPro contact details .................................................... Agterblad

Vrywaring / Indemnity

Die samestellers van die VinPro Kostegids het deurgaans te goeder trou opgetree. Enige besluit voortspruitend, of aksie gebaseer op die inligting soos vervat in die gids, word op eie risiko gedoen. Nie die samestellers of VinPro kan verantwoordelik gehou word vir enige finansiële verlies weens so ’n besluit of aksie nie, terwyl enige finansiële wins slegs tot die voordeel van die gebruiker daarvan is.

The VinPro Cost Guide was compiled in good faith. Any decision taken as a result of, or actions based on information contained in the guide is solely at the user’s own risk. Neither the compil-ers nor VinPro are accountable for any financial loss due to such decisions or actions, while any financial gain derived from it is solely to the benefit of the users thereof.

B

ellville 021 914 9604 Bredasdorp 028 424 2840 C

aledon 028 212 1159 G

eorge 044 802 5700 Grabouw

021 859 2834 Heidelberg 028 722 1192 M

almesbury 022 482 3838

Mosselbaai 044 601 8600 P

aarl 021 871 1837 Riversdal 028 713 1072 Stilbaai 028 754 2009 Sw

ellendam 028 514 1102 U

pington 054 332 3047 W

orcester 023 342 2374

Bellville 021 914 9604 B

redasdorp 028 424 2840 Caledon 028 212 1159 G

eorge 044 802 5700 Grabouw

021 859 2834 Heidelberg 028 722 1192 M

almesbury 022 482 3838

Mosselbaai 044 601 8600 P

aarl 021 871 1837 Riversdal 028 713 1072 Stilbaai 028 754 2009 Sw

ellendam 028 514 1102 U

pington 054 332 3047 Worcester 023 342 2374

VINPRO KOSTEGIDS / COST GUIDE • 5

Voorwoord / ForewordIn die strewe na ’n volhoubare en deelnemende wynprodusentegemeenskap bly die VinPro Land-bou-ekonomiese Diens verbind tot effek tiewe en waardetoegevoegde ekonomiese diens lewering aan VinPro se lede en ander rolspelers in die bedryf.

Die Suid-Afrikaanse wyndruifprodusent is die afgelope paar jaar blootgestel aan stygende insetkostes en dalende winsmarges, wat daar-toe lei dat die produsent se winsgewendheid onder geweldige druk verkeer. Met hierdie in ag geneem, openbaar die VinPro Landbou-ekonomiese Diens jaarliks kritiese finansiële aanwysers wat regdeur die wynbedryf erken en gebruik word as ’n betroubare maatstaf. ’n Uit-vloeisel daarvan is die samestelling van hierdie meer gedetailleerde Kostegids – wat jaarliks in Mei opgedateer en beskikbaar gestel word – ter verdere ondersteuning van die produsent.

VinPro Landbou-ekonomiese Dienste• Lewensvatbaarheidstudies, koste- en wins -

gewendheidsanalises, asook skade bepalings.

• Koördinering van finansiële studiegroepe/Produksieplan – finansiële geheelplaas- en bedryfstak-analises op plaasvlak.

• Ekonomiese en bedryfsverwante artikels en aanbiedings.

• Versameling en verspreiding van verteen-woordigende landbou-ekonomiese bedryfs-inligting.

In the quest towards a sustainable and partici-pating wine producer community, VinPro’s Agro-economic Service is committed to providing effective and value-added economic services to all members of VinPro, as well as other role players in the industry.

The South African wine producer’s profitability has been under enormous pressure over the past few years due to rising input costs, as well as low and decreasing profit margins. With this in mind, VinPro’s Agro-economic Service annually reveals financial indicators that are ac-cepted and used throughout the wine industry as a trusted benchmark. As an extension of its support to producers, VinPro compiled this more detailed Cost Guide, which is updated annually and available in May.

VinPro Agro-economic Services• Feasibility studies, cost- and profitability

analyses, as well as damage assessments.

• Coordinating financial study groups/Produc-tion Plan – financial analyses of total farm or operational enterprise.

• Economic and industry-related articles and presentations.

• Collecting and distributing relevant financial industry information.

Doel / PurposeDie hoofdoel van hierdie Kostegids is om sekere noodsaaklike ekonomiese aspekte in ’n een-voudige formaat te verpak wat as hulpmiddel kan dien vir die opstel van begrotings deur wyn-druifprodusente. Weens dramatiese prysskom-melinge is dit baie moeilik om sinvol en akkuraat te begroot en kan hierdie gids as riglyn daarvoor aangewend word.

The main purpose of this guide is to provide wine grape producers with specific financial indicators to assist them in compiling a budget. Due to the fact that prices vary dramatically, it is difficult to compile a budget that is both mean-ingful and accurate. This guide is a useful aid in compiling a more accurate budget.

6 • VINPRO KOSTEGIDS / COST GUIDE

VinPro’s agro-economic division conducted financial analyses in all nine wine districts in 2013 to investigate both the production cost of wine grape cultivation and financial situation of wine grape producers. The project is undertaken with the support of Winetech, the National Ag-ricultural Marketing Council (NAMC), Standard Bank, Absa, Land Bank, FNB, Nedbank and Capital Harvest.

A total of 237 farming units from nine wine districts participated in the 2013 Production Plan Survey, and 529 producers and industry role-players attended 45 study group sessions during the course of the survey, during which economic indicators and other relevant informa-tion was conveyed to participants. The sample consisted of 21 734 ha (22% of the total South African harvest) in 2013, which produced 358 838 tons (24% of the total South African harvest in 2013). Of these, 66% represented white and 34% red wine grapes, and 58% of the tonnage was mechanically harvested. The participants were predominantly producers with good to above-average managerial ability.

The Malmesbury district is evaluated separately and does not form part of the industry average figures, as this study group’s wine grape culti-vation includes a large component of dryland vineyard, which necessitates an alternative production, cost and capital structure. Evalu-ations are not cultivar or block specific – wine grapes (bearing and non-bearing) are evaluated as an entity. Most of the farming units that are evaluated differ in respect of the farm size, cul-tivar composition and diversification with regard to other industry enterprises in the respective regions. The report represents industry average figures, which are calculated by determining the weighted average of all the participants.

VinPro se landbou-ekonomiese afdeling het in 2013 finansiële ontledings in al nege wyndis-trikte uitgevoer om beide die produksiekoste van wyndruifverbouing en finansiële welstand van wyndruifprodusente te ondersoek. Die projek word uitgevoer met die ondersteuning van Wine-tech, die Nasionale Landboubemarkingsraad (NLBR), Standard Bank, Absa, Land Bank, ENB, Nedbank en Capital Harvest.

Altesaam 237 boerdery-eenhede uit nege wyndistrikte het aan die 2013 Produksieplan Opname deelgeneem, en 529 produsente en rolspelers in die bedryf het gedurende die op-name 45 studiegroep-byeenkomste bygewoon, waartydens ekonomiese aanwysers en ander relevante inligting aan deelnemers oorgedra is. Die steekproef het in 2013 uit 21 734 ha (22% van die totale Suid-Afrikaanse wingerdstand in 2012) bestaan, wat 358 838 ton lewer (24% van die totale Suid-Afrikaanse oes in 2013). Hiervan was 66% wit en 34% rooi wyndruiwe, en 58% van die tonne is meganies gepars. Die steek-proef bestaan oorwegend uit produsente met goeie tot bogemiddelde bestuursvermoë.

Die Malmesbury-distrik word deurgaans apart geëvalueer en vorm nie deel van die bedryfs-gemiddelde syfers nie, aangesien die studie-groep ’n groot komponent droëlandwingerd verbou, wat ’n alternatiewe produksie-, koste- en kapitaalstruktuur benodig. Evaluerings is nie kultivar- en/of blokspesifiek nie – wyn-druiwe (draend en nie-draend) word as ’n ge-heel geëvalueer. Die meeste van die boerdery-ondernemings wat geëvalueer word, verskil ten opsigte van die plaasgrootte, kultivarsamestel-ling en diversifisering ten opsigte van ander bedryfstakke in die onderskeie streke. Die ver-slag verteenwoordig bedryfsgemiddelde syfers, wat bereken word deur die geweegde gemid-delde van al die deelnemers te bepaal.

Koste van wyndruifproduksie (2013-oes) / Cost of wine grape production (2013 harvest)

Inleiding en agtergrond / Introduction and background

VINPRO KOSTEGIDS / COST GUIDE • 7

Totale produksiekoste per distrik / Total production cost per district 2013

R45 000

R40 000

R35 000

R30 000

R25 000

R20 000

R15 000

R10 000

R5 000

R0

R/h

a

Paa

rl

Wor

cest

er

Rob

erts

on

Kle

in K

aroo

Ste

llenb

osch

Olif

ants

Riv

(i)er

Ora

nge

Riv

(i)er

Bed

ryf/

Ind

ustr

y

Mal

mes

bur

y

Bre

edek

loof

Kontantuitgawes / Cash expenditure Voorsiening vir vervanging / Provision for renewal

Totale produksiekoste / Total production cost

R33 098 R34 546 R34 976 R31 963 R31 240

R42 386

R37 580 R36 531 R35 739

R25 297

R9 160 R9 079 R9 118R8 771 R8 030

R9 135

R10 798 R8 729 R9 080

R6 960

R23 938 R25 467 R25 858 R23 192 R23 210 R33 251 R26 783 R27 801 R26 659 R18 377

KLAAR

KLAAR

Kontantuitgawes / Cash expenditure Voorsiening vir vervanging / Provision for renewal

R40 000

R35 000

R30 000

R25 000

R20 000

R15 000

R10 000

R5 000

R0

2005 2006 2007 2008 2009 2010 2011 2012 20132004

R19 000R20 643

R21 332 R22 125R23 578

R26 580R28 580

R30 582R32 439

R35 739

R14

221

R15

010

R15

599

R16

017

R16

702

R19

039

R20

643

R22

443

R23

834

R26

659

R4 779R5 633 R5 733 R6 108

R6 876

R7 541R7 937

R8 139R8 606

R9 080

R/h

a

Totale produksiekoste / Total production cost

Totale produksiekoste / Total production cost

Jaarlikse totale produksiekoste – belasting, rente en ondernemersloon uitgesluit – bestaan uit twee komponente, naamlik kontantuitgawes en voorsiening vir vervanging. Die bedryfsgemid-delde totale produksiekoste het sedert 2012 met 10% toegeneem na R35 739/ha in 2013.

Total annual production cost – excluding tax, interest and remuneration – consists of two components, namely cash expenditure and provision for renewal. The industry average total production cost increased by 10% from 2012 to R35 739/ha in 2013.

Koste van wyndruifproduksie / Cost of wine grape production

8 • VINPRO KOSTEGIDS / COST GUIDE

2004 2005 2006 2007 2008 2009 2010 2011 2012 2013

Kontantuitgawes / Cash expenditureBedryf / Industry

R30 000

R25 000

R20 000

R15 000

R10 000

R5 000

R0

R/h

a R14 221R15 010 R15 599 R16 017

R16 702

R19 039R20 648

R22 443R23 834

R26 659

Cash expenditureCash expenditure is categorised as direct cost, labour, mechanisation, fixed improvements and general expenditure. Total cash expenditure increased by 12% from 2012 to R26 659/ha in the 2013 production year.

The increase is mainly due to the record harvest in 2013, as well as exceptionally high increases in the cost of electricity, wages and fuel. Most of the other cost components increased more or less in line with inflation.

KontantuitgawesKontantuitgawes word gekategoriseer as di-rekte koste, arbeid, meganisasie, vaste verbe-teringe en algemene uitgawes. Totale kontant-uitgawes toon ’n 12% styging sedert 2012 tot R26 659/ha in die 2013-oesjaar.

Die toename is grotendeels aangevuur deur die rekordoes in 2013, asook buitengewone hoë stygings in die koste van elektrisiteit, lone en brandstof. Die meeste ander kostekomponente het min of meer in lyn met inflasie toegeneem.

Die volgende vier grafieke illustreer die bewe-ging van ongeveer 80% van die jaarlikse kon-tantuitgawes oor die afgelope 10 jaar:

The movement of close to 80% of the annual cash expenditure in the past 10 years is illus-trated in figures 4 to 7.

R2 000

R1 800

R1 600

R1 400

R1 200

R1 000

R800

R600

R400

R200

2004 2005 2006 2007 2008 2009 2010 2011

R0

Bemesting / Fertiliser Plaag- & siektebeheer / Pesticide control Onkruidbeheer / Herbicide control

R/h

a

Direkte koste / Direct costBedryf / Industry

20132012

R1 655 R1 639

R1 257 R1 251 R1 176 R1 144

R1 257

R1 506

R1 758R1 839

R1 831

R1 570

R1 382R1 327

R1 172

R1 012

R875R756R686R679

R346R420

R344 R370R424

R549 R544 R592 R548R589

KLAAR

VINPRO KOSTEGIDS / COST GUIDE • 9

2004 2005 2006 2007 2008 2009 2010 2011 2012 2013

Kontantuitgawes / Cash expenditureBedryf / Industry

R30 000

R25 000

R20 000

R15 000

R10 000

R5 000

R0

R/h

a R14 221R15 010 R15 599 R16 017

R16 702

R19 039R20 648

R22 443R23 834

R26 659

Arbeid / LabourBedryf / Industry

R7 000

R6 000

R5 000

R4 000

R3 000

R2 000

R1 000

0

2004 2005 2006 2007 2008 2009 2010 2011

Permanente arbeid / Permanent labour Seisoensarbeid & kontrakteurs / Seasonal labour & contractors

R/h

a

20132012

R6 076

R2 755R2 325R2 246R2 132R2 137

R1 719R1 589R1 547R1 556R1 388

R5 616R5 272

R4 920R4 459

R4 097R4 219R4 185R4 006R3 962

KLAAR

Meganisasie / MechanisationBedryf / Industry

R2 500

R2 000

R1 500

R1 000

R500

R0

2004

R859

R1 449 R1 505 R1 468 R1 517 R1 586

R1 842R1 983

R2 243R2 136

R2 352

R921R1 106

R1 252R1 464

R1 639R1 533

R1 726

R2 040

R2 358

2005 2006 2007 2008 2009 2010 2011

Brandstof / Fuel Herstel, onderdele & reparasies (los bates) / Repair, parts & maintenance (moveable assets)

R/h

a

20132012

KLAARR2 000

R1 500

R1 000

R500

R0

R/h

a

2004

R605 R627 R647 R655 R652 R681R720

R846R931 R971

R1 421R1 254

R1 176R1 339R1 072

R1 119R1 043R1 019

R861R688

R2 287

R2 063

R1 768

R1 339

R1 040

R831R845R803

R789R717

2005 2006 2007 2008 2009 2010 2011 20132012

R2 500

Elektrisiteit / Electricity Waterkoste / Water cost Administrasie / Administration

Algemene uitgawes / General expenditureBedryf / Industry

KLAAR

10 • VINPRO KOSTEGIDS / COST GUIDE

Die samestelling van kontantuitgawes het sedert 2004 grootliks onveranderd gebly, met arbeid wat steeds die grootste komponent verteen-woordig, naamlik 40% in die 2013-oesjaar. Die tendens beeld wel uit dat die komponent gespandeer aan arbeid ten opsigte van totale produksiekoste wel afneem, nieteenstaande loonaanpassings gedurende die tydperk. Dit kan toegeskryf word aan produktiwiteitsverbetering, asook toenemende meganisering. Meganisasie, direkte koste, algemene uitgawes en vaste ver-beteringe verteenwoordig onderskeidelik 21%, 18%, 19% en 2% van kontantuitgawes.

The composition of cash expenditure remained largely unchanged since 2004, with labour still representing the biggest component – 40% in the 2013 production year. Despite adjustments in the minimum wage in this period, there was a decrease in the component spent on labour with regard to production cost. This can be attributed to improvement in productivity, as well as an increase in mechanisation. Mechanisation, direct cost, general expenditure and fixed improve-ments respectively represent 21%, 18%, 19% and 2% of cash expenditure.

Voorsiening vir vervanging / Provision for renewal

Gedurende die produksieproses word nie net dit wat jaarliks aangekoop word vir die produk-sieproses gebruik nie, maar gereedskap en implemente is ook nodig. So word trekkers, gereedskap en ander produksiemiddele oor tyd “opgebruik”. Selfs wingerde en geboue gaan agteruit en moet vervang word. Die “agteruit-gang” en “opgebruik” van hierdie items maak deel uit van kostes in die produksieproses.

The production process not only uses that which is purchased annually for the production process – tools and implements are also needed. Over a period of time tractors, tools and other produc-tion means are “consumed”. Even vineyards and buildings deteriorate and need to be replaced. The “deterioration” and “consumption” of these items are part and parcel of the costs involved in the production process.

Samestelling van jaarlikse kontantuitgawes / Composition of annual cash expenditureBedryf / Industry

Direkte koste / Direct cost Arbeid / Labour

Meganisasie / Mechanisation Vaste verbeteringe / Fixed improvements

Algemene uitgawes / General expenditure

100%

90%

80%

30%

40%

50%

60%

70%

0%

10%

20%

2004

17%

15%

19%

44%

4%

2005

16%

16%

19%

44%

5%

2006

15%

17%

19%

44%

5%

2007

15%

17%

20%

43%

4%

2008

17%

16%

21%

42%

4%

2009

18%

15%

21%

42%

4%

2010

19%

16%

20%

41%

4%

2011

18%

18%

21%

41%

3%

2012

19%

20%

40%

17%

4%

2013

19%

21%

40%

18%

2%

KLAAR

VINPRO KOSTEGIDS / COST GUIDE • 11

Taking into account the fact that the purchase value of an item needs to be recovered in the course of its lifetime, as well as the fluctuation of inflation, sufficient provision has to be made for renewal. By using the principle ‘provision for renewal’ a larger amount is recovered than in the case of ‘depreciation’. To a certain extent this addresses the problem of rectilinear de-preciation in value and ensures that the running concern is maintained.

When calculating provision for renewal, items are written off against renewal value over va-rious periods:

Buildings 60 yearsVineyards 20 yearsMoveable assets / means of production 7 - 15 years

Inaggenome die feit dat die aankoopwaarde van ’n item oor sy leeftyd verhaal moet word, asook die wisselvalligheid van inflasie, moet voldoende voorsiening hiervoor gemaak word. Deur die beginsel ‘voorsiening vir vervanging’ te gebruik, word ’n groter bedrag verhaal as in die geval van ‘depresiasie’. Dit spreek die probleem van reglynige waardevermindering tot ’n mate aan en verseker dat die lopende saak gehandhaaf word.

Met die berekening van voorsiening vir vervan-ging word items oor verskillende termyne af-geskryf teen vervangingswaarde:

Geboue 60 jaarWingerde 20 jaarLos bates / produksiemiddele 7 - 15 jaar

Totale voorsiening vir vervanging het in die 2013-oesjaar R9 080/ha beloop – ’n 5% styging sedert 2012.

Total provision for renewal amounted to R9 080/ha in the 2013 production year – a 5% increase since 2012.

Vervangingswaarde van kapitaalstruktuur / Replacement value of capital structure Bedryf / Industry

2004 - 2013

R19

4 85

4

R10

1 93

5

R33

905

R20

321

R52

789

R26

880

R10

8 16

0

R54

734

R/h

a

KLAAR

R200 000

R150 000

R100 000

R50 000

R0

Wingerde / Vineyards Vaste verbeterings (geboue) /

Fixed improvements (buildings)

Losgoed (produksiemiddele) /

Moveable assets (production means)

Totaal (grond uitgesluit) / Total (land excluded)

12 • VINPRO KOSTEGIDS / COST GUIDE

Produksie se invloed op gelykbreek / Influence of production on break-even

Die gemiddelde plaasgrootte vir die studie-groepe beloop tans 87 ha onder wyndruiwe (ander vertakkings word nie hier in bereken-ing gebring nie). Die gemiddelde produksie – draende en nie-draende hektare ingesluit – het in die 2013-oesjaar 17.50 ton/ha beloop.

Die invloed van verhoogde produksie op die gelykbreekprys van totale produksiekoste in rand per ton is wesenlik. Totale produksiekoste per hektaar wat met 10% sedert 2012 gestyg het, het daartoe gelei dat die gelykbreek in terme van rand per ton van R1 910/ton na R2 042/ton toegeneem het in 2013. Anders gestel; die eerste R2 042 wat die produ sent gedurende die 2013-oes vir ’n ton druiwe ontvang het, behoort vir totale produksiekoste aangewend te word – geen ondernemersloon, rente of belasting is nog in berekening gebring nie. Hierdie toename kan hoofsaaklik toegeskryf word aan die bo-inflasie styging van produk-siekoste in die totale bedryf. Let daarop dat sommige distrikte ’n kleiner styging in produk-siekoste gerealiseer het. Dit, tesame met ’n rekordoes in 2013, het ’n positiewe impak op sekere produsente se gelykbreekprys gehad.

The average farm size for the study groups comprised 87 ha under wine grapes (other enterprises are not taken into account here). The average production – including bearing and non-bearing hectares – amounted to 17.50 tons/ha in the 2013 production year.

The impact of increased yield on the break-even price of total production cost in rand per hectare is considerable. An increase of 10% in total pro-duction cost per hectare since 2012 resulted in an increase in the break-even in terms of rand per ton from R1 910/ha to R2 042/ha in 2013. In other words, the first R2 042 that the producer received for a ton of grapes during the 2013 harvest, should be used for total production cost (no entrepreneurial remuneration, interest or tax has been taken into account). This increase can be ascribed mainly to the above-inflation increase in production cost for the total indus-try. Note that certain districts realised a smaller increase in production cost. This, in conjunction with a record harvest in 2013, had a positive im-pact on the break-even price of some producers.

Voorsiening vir vervanging / Provision for renewalBedryf / Industry

2004

R4 779

2005

R5 633

2006

R5 733

2007

R6 108

2008

R6 876

2009

R7 541

2010

R7 937

2011

R8 139

R9 080

2013

R8 606

2012

R/h

aR10 000

R9 000

R8 000

R7 000

R6 000

R5 000

R4 000

R3 000

R2 000

R1 000

R0

KLAAR

VINPRO KOSTEGIDS / COST GUIDE • 13

Die gemiddelde ouderdomsamestelling van deelnemers se wingerde het heelwat verswak sedert 2004 – ’n sterk aanduiding dat pro-dusente hul kapitale instandhouding agterweë gelaat het weens lae winsmarges. Meer as 14% van die wingerdoppervlak is ouer as 20 jaar en 12% van die wingerde in die steekproef is drie jaar en jonger. Sommige distrikte toon wel ’n gesonde ouderdomsamestelling en wingerde word noukeurig vervang, wat lei tot ’n verhoging in die totale wingerdstand.

The average age composition of participants’ vineyards has definitely deteriorated since 2004 – a strong indication that producers failed to keep up with capital maintenance due to low profit margins. More than 14% of the vineyard area is older than 20 years and 12% of the vineyards in the sample are younger than three years. However, some districts had a healthy age composition, where vineyards are meticulously replaced, which leads to an increase in total vineyard area.

Gemiddelde produksie wissel wesenlik tussen die onderskeie distrikte, terwyl die totale produksie-koste in rand per hektaar nie noe mens waardig verskil nie. Hierdie produksieverskille gee egter aanleiding daartoe dat daar groot verskille is tussen die gelykbreekprys ten opsigte van totale produksiekoste per ton in die onderskeie distrikte.

Average production varies considerably among the respective districts, while the total produc-tion cost in rand per hectare does not differ significantly. The above-mentioned differences in production cause the break-even price in respect of total production cost per ton to differ immensely among the various districts.

Invloed van produksie op gelykbreek / Influence of production on break-evenBedryf / Industry

18.00 R2 500

R2 000

R1 500

R1 000

R500

R0

17.00

16.00

15.00

14.00

13.00

12.00

Ton/

ha

R/t

on

2004 2005 2006 2007 2008 2009 2010 2011 2012 2013

13.1

1

13.7

9

15.3

4

15.5

8

16.3

1

15.5

5

14.7

3

15.0

8

17.5

0

16.9

8

R1 449 R1 497 R1 391 R1 420

R1 709R1 941

R2 028 R1 910 R2 042

R1 446

Gelykbreek / Break-even (R/ton)Produksie / Production (ton/ha)

KLAAR

8.10

17.5

0

31.1

3

28.6

1

7.76

11.9

5

20.4

5

18.1

8

20.4

19.5

4

R5 462

R3 123

R2 042

R1 173

R1 563R1 924R1 693R1 694

R2 614

Gelykbreek / Break-even (R/ton)Produksie / Production (ton/ha)

Paa

rl

Ste

llenb

osch

Kle

in K

aroo

Rob

erts

on

Wor

cest

er

Bre

edek

loof

Olif

ants

Riv

(i)er

Ora

nge

Riv

(i)er

Bed

ryf /

Ind

ustr

y

Mal

mes

bur

y

R 6 000

R 4 000

R 3 000

R 2 000

R 1 000

R 0

R/t

on

35.00

30.00

25.00

20.00

15.00

10.00

5.00

0.00

R 5 000

Ton/

ha

Invloed van produksie op gelykbreek per distrik (2013-oes) / Influence of production on break-even per district (2013 harvest)

KLAAR

R1 314

VINPRO KOSTEGIDS / COST GUIDE • 15

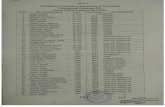

PRODUKSIEKOSTE VIR WYNDRUIWE – KOSTE AS RAND PER HEKTAAR (2013-OES) PRODUCTION COST FOR WINE GRAPES – COST AS RAND PER HECTARE (2013 HARVEST)

DISTRIK / DISTRICT Stellenbosch Paarl Robertson Breedekloof Olifants Riv(i)er Worcester Oranje Riv(i)er Klein Karoo BedryfIndustry Malmesbury

KOSTESTRUKTUUR / COST STRUCTURE R/ha

DIREKTE KOSTE / DIRECT COST 4 438 3 742 5 298 5 528 5 139 5 197 2 944 3 823 4 670 3 141

SAAD / SEED 205 95 57 131 16 82 8 425 110 94

KUNSMIS / FERTILISER 768 932 2 005 1 321 2 122 1 908 1 327 1 130 1 405 863

ORGANIESE BEMESTING / ORGANIC MATERIAL 48 192 205 904 560 164 224 250 316 47

PLAAG- & SIEKTEBEHEER / PESTICIDE CONTROL 2 206 1 615 2 057 2 028 1 769 1 758 747 1 347 1 839 1 477

ONKRUIDBEHEER / HERBICIDE CONTROL 625 559 651 714 404 677 458 248 589 466

HERSTEL- & BINDMATERIAAL / REPAIR & BINDING MATERIAL 586 348 325 430 267 608 179 423 411 195

ARBEID/ LABOUR # 16 766 10 083 8 886 9 174 7 563 8 135 13 275 7 707 10 639 7 802

TOESIG & BESTUURSHULP / SUPERVISION 3 676 1 110 1 616 1 903 1 135 1 073 1 125 1 273 1 808 760

PERMANENTE ARBEID / PERMANENT LABOUR 7 979 6 090 5 023 5 983 4 911 6 056 5 924 5 125 6 076 3 495

SEISOENSARBEID & KONTRAKTEURS / SEASONAL & CONTRACT WORKERS 5 110 2 883 2 246 1 287 1 517 1 006 6 225 1 309 2 755 3 548

MEGANISASIE / MECHANISATION 5 700 4 717 5 508 5 232 6 488 4 804 6 609 6 837 5 501 4 498

BRANDSTOF / FUEL 2 383 2 158 1 934 2 416 2 659 2 268 3 377 2 766 2 358 1 749

HERSTEL, ONDERDELE & REPARASIES / REPAIR, PARTS & MAINTENANCE 2 705 1 652 2 902 2 123 2 592 1 919 2 115 3 456 2 352 1 509

LISENSIES & VERSEKERING / LICENCES & INSURANCE 471 374 483 472 735 484 709 365 497 354

VERVOER GEHUUR / TRANSPORT HIRED 141 534 189 221 502 134 408 251 294 886

VASTE VERBETERINGE / FIXED IMPROVEMENTS 981 696 716 1 184 1 238 933 884 339 913 644

HERSTEL & ONDERHOUD / REPAIR & MAINTENANCE 781 537 549 911 527 679 400 150 635 500

VERSEKERING / INSURANCE 200 159 167 273 711 254 484 189 278 145

ALGEMENE UITGAWES / GENERAL EXPENDITURE 5 367 3 971 5 450 4 349 6 355 4 869 4 090 4 486 4 936 2 251

ELEKTRISITEIT / ELECTRICITY 1 855 1 896 3 024 2 689 2 818 2 137 1 384 1 490 2 287 665

WATERKOSTE / WATER COST 791 574 984 211 2 050 1 450 1 288 1 838 971 674

GROND- EIENDOMS- & MUN BELASTINGS / LAND- PROPERTY- & MUN TAXES 452 191 179 225 287 177 288 125 257 108

ADMINISTRASIE / ADMINISTRATION * 2 269 1 310 1 263 1 224 1 200 1 105 1 131 1 032 1 421 804

TOTALE KONTANTUITGAWES / TOTAL CASH EXPENDITURE 33 251 23 210 25 858 25 467 26 783 23 938 27 801 23 192 26 659 18 337

VOORSIENING VIR VERVANGING / PROVISION FOR RENEWAL 9 135 8 030 9 118 9 079 10 798 9 160 8 729 8 771 9 080 6 960

WINGERDE / VINEYARDS 5 347 5 442 5 487 5 491 5 077 5 635 5 313 5 432 5 408 4 590

VASTE VERBETERINGS / FIXED IMPROVEMENTS 1 149 634 905 884 1 040 838 564 646 880 586

LOSGOED OF PRODUKSIEMIDDELE / MOVEABLE ASSETS OR PRODUCTION MEANS 2 639 1 954 2 726 2 703 4 681 2 688 2 852 2 692 2 792 1 785

TOTALE UITGAWES / TOTAL EXPENDITURE 42 386 31 240 34 976 34 546 37 580 33 098 36 531 31 963 35 739 25 297

GEMIDDELDE OPP GEPLANT / AREA PLANTED (HA) 99 92 103 109 58 85 16 43 87 163

AREA ONDER BESPROEIING / AREA UNDER IRRIGATION (%) 91% 90% 100% 100% 100% 99% 100% 100% 96% 38%

OUDERDOMSAMESTELLING / AGE COMPOSITION (%)

3 JAAR & JONGER / 3 YEARS & YOUNGER 8.97 10.14 18.42 14.52 9.88 15.20 7.36 14.46 12.42 5.86

TUSSEN 4 & 7 JAAR / BETWEEN 4 & 7 YEARS 13.85 13.03 19.40 14.02 16.80 19.36 29.71 16.42 16.52 15.51

TUSSEN 8 & 15 JAAR / BETWEEN 8 & 15 YEARS 43.52 51.12 33.24 39.33 37.91 33.65 42.65 47.98 41.03 60.43

TUSSEN 16 & 20 JAAR / BETWEEN 16 & 20 YEARS 16.05 15.22 15.18 17.84 19.26 15.21 10.82 14.15 15.95 13.55

OUER AS 20 JAAR / OLDER THAN 20 YEARS 17.61 10.50 13.76 14.28 16.14 16.58 9.47 6.99 14.08 4.65

GEMIDDELDE OPBRENGS / AVERAGE YIELD (TON/HA) 7.76 11.95 18.18 20.40 28.61 19.54 31.13 20.45 17.50 8.10

KONTANTUITGAWES / CASH EXPENDITURE (R/TON) 4 285 1 942 1 422 1 248 936 1 225 893 1 134 1 523 2 264

TOTALE UITGAWES / TOTAL EXPENDITURE (R/TON) 5 462 2 614 1 924 1 693 1 314 1 694 1 173 1 563 2 042 3 123

# Ingesluit: Voorsorgfonds, WVF, medies, beskermde klere, klerasie, bonusse, rantsoene, ongevalle / vergoeding kommisaris, ens. # Included: Provident fund, UIF, medical, protected clothes, clothing, bonus, ransom, workman’s compensation comission, etc.

* Ingesluit: Bankkoste, ouditeursgelde, lidmaatskappe, sekuriteit, rekenaaronderhoud, professionele dienste, kursusse/opleiding, posgeld, telefoon, skryfbehoeftes, besproeiingsmonitering en diverse uitgawes.

* Included: Banking costs, bookkeeping fees, membership fees, security, computer maintenance, professional fees, training/courses, postage, telephone, stationery, irrigation monitoring and sundries.

16 • VINPRO KOSTEGIDS / COST GUIDE

Kostestruktuur van top presteerders / Cost structure of top achievers

Die top presteerders word volgens beste netto boerdery inkomste (NBI) geselekteer. Top pres-teerders se jaarlikse kontantuitgawes (R24 806/ha) was gedurende die 2013-oesjaar minstens 7% laer as dié van die bedryf (R26 659/ha), terwyl die voorsiening vir vervanging van die top presteerders (R9 509/ha) 2% hoër was as die bedryfsgemiddeld (R9 080/ha). Totale produksie-koste van die top presteerders het R34 314/ha teenoor die bedryfsgemiddelde R35 739/ha beloop – 5% laer.

The top achievers are selected according to highest net farming income (NFI). Top achiev-ers’ annual cash expenditure (R24 806/ha) was at least 7% lower than that of the industry (R26 659/ha) during the 2013 production year, while the provision for renewal of the top achievers (R9 509/ha) was 2% higher than the industry average (R9 080/ha). Total produc-tion cost of the top achievers amounted to R34 314/ha compared to the industry average of R35 739/ha, which was 5% lower.

PRODUKSIEKOSTE VIR WYNDRUIWE (R/HA) / PRODUCTION COST FOR WINE GRAPES (R/HA)

KOSTESTRUKTUUR / COST STRUCTURETop 50 2011R/ha

Bedryf Industry

2011R/ha

Top 50 2012R/ha

Bedryf Industry

2012R/ha

Top 50 2013R/ha

Bedryf Industry

2013R/ha

DIREKTE KOSTE / DIRECT COST 4 140 3 992 4 530 4 150 5 063 4 670

SAAD / SEED 65 97 84 107 109 110

KUNSMIS / FERTILISER 1 155 1 061 1 393 1 221 1 327 1 405

ORGANIESE BEMESTING / ORGANIC MATERIAL 346 225 417 242 569 316

PLAAG- & SIEKTEBEHEER / PESTICIDE CONTROL 1 661 1 655 1 661 1 639 1 963 1 839

ONKRUIDBEHEER / HERBICIDE CONTROL 541 592 552 548 594 589

HERSTEL- & BINDMATERIAAL / REPAIR & BINDING MATERIAL 373 362 422 393 501 411

ARBEID / LABOUR # 7 412 9 111 7 937 9 630 8 751 10 639

TOESIG & BESTUURSHULP / SUPERVISION 1 140 1 593 1 568 1 689 1 648 1 808

PERMANENTE ARBEID / PERMANENT LABOUR 4 728 5 272 5 092 5 616 5 668 6 076

SEISOENSARBEID & KONTRAKTEURS / SEASONAL & CONTRACT WORKERS 1 544 2 246 1 278 2 325 1 435 2 755

MEGANISASIE / MECHANISATION 4 341 4 633 4 543 4 868 5 369 5 501

BRANDSTOF / FUEL 1 599 1 726 1 820 2 040 2 350 2 358

HERSTEL, ONDERDELE & REPARASIES / REPAIR, PARTS & MAINTENANCE 1 976 2 243 2 059 2 136 2 208 2 352

LISENSIES & VERSEKERING / LICENCES & INSURANCE 507 422 464 460 522 497

VERVOER GEHUUR / TRANSPORT HIRED 260 242 199 232 289 294

VASTE VERBETERINGE / FIXED IMPROVEMENTS 517 707 715 720 953 913

HERSTEL & ONDERHOUD / REPAIR & MAINTENANCE 296 486 488 490 721 635

VERSEKERING / INSURANCE 221 221 227 230 231 278

ALGEMENE UITGAWES / GENERAL EXPENDITURE 4 125 3 999 4 328 4 466 4 670 4 936

ELEKTRISITEIT / ELECTRICITY 1 777 1 768 2 269 2 063 2 245 2 287

WATERKOSTE / WATER COST 1 060 846 861 931 963 971

GROND-, EIENDOMS- & MUN BELASTINGS / LAND-, PROPERTY- & MUN TAXES 223 209 172 218 222 257

ADMINISTRASIE / ADMINISTRATION * 1 066 1 176 1 026 1 254 1 241 1 421

TOTALE KONTANTUITGAWES / TOTAL CASH EXPENDITURE 20 537 22 443 22 054 23 834 24 806 26 659

VOORSIENING VIR VERVANGING / PROVISION FOR RENEWAL 8 324 8 140 8 815 8 606 9 509 9 080

WINGERDE / VINEYARDS 4 714 4 725 5 143 5 082 5 509 5 408

VASTE VERBETERINGS / FIXED IMPROVEMENTS 774 791 910 832 936 880

LOSGOED OF PRODUKSIEMIDDELE / MOVEABLE ASSETS OR PRODUCTION MEANS 2 835 2 623 2 761 2 691 3 063 2 792

TOTALE UITGAWES / TOTAL EXPENDITURE 28 860 30 582 30 869 32 439 34 315 35 739

VINPRO KOSTEGIDS / COST GUIDE • 17

Die persentasie samestelling van top presteerders se kontantuitgawes verskil nie noemenswaardig van die bedryfsgemiddeld nie. Direkte kostes by top presteerders was gedurende die vier oorsigjare hoër as dié van die bedryf, hoofsaaklik vanweë groter spandering aan bemesting en plaag- en siektebeheer. Die mega nisasie-komponent is by top presteerders groter en totale spandering aan arbeid by die groep laer as die bedryfsgemiddeld. Gesien in die lig hiervan wil dit voorkom of die top presteerders tot ’n mate meer gemeganiseerd is ten koste van arbeid, of arbeid word meer produk-tief aangewend. Die ander kostekomponente toon egter nie veel verskille nie.

The percentage composition of top achievers’ cash expenditure does not differ significantly from the industry average. Top achievers’ di-rect costs were higher than that of the industry during the four years under review, mainly due to greater spending on fertiliser and pest and disease management. Top achievers’ mechani-sation component is bigger, while total spending on labour is lower with this group than the in-dustry average. In view of the above it seems as though the top achievers are more mechanised at the expense of labour, or labour is applied more productively. The other cost components do not differ much.

Hoewel die kostestruktuur van top presteerders van die bedryfsgemiddeld verskil wat betref samestelling en werklike randwaarde, was dit inkomste per hektaar – hoofsaaklik gedryf deur produksie en gemiddelde uitbetaling – wat vir die vierde agtereenvolgende jaar die aansienlike verbetering in NBI bewerkstellig het.

Die ouderdomsamestelling van wingerd oor die oorsigperiode toon nie wesenlike verskille nie. Beide groeperings beskik na regte oor ’n aan-vaarbare ouderdomsamestelling.

Although the cost structure of top achievers differs from the industry average with regard to composition and actual rand value, it was income per hectare – mainly fuelled by produc-tion and average payment – that resulted in the considerable improvement in NFI for the fourth consecutive year.

The age composition of grapevines over the three year period under review does not differ much. For both groups the age composition is quite acceptable.

Samestelling van jaarlikse kontantuitgawes (top presteerders teenoor bedryfsgemiddeld) / Composition of annual cash expenditure (top achievers compared to industry average)

Direkte koste / Direct cost Arbeid / Labour

Meganisasie / Mechanisation Vaste verbeteringe / Fixed improvements

Algemeen / General

Top 502010

100%

90%

80%

30%

40%

50%

60%

70%

0%

10%

20%

Bedryf/Industry 2010

Top 50 2011

Bedryf/Industry 2011

Top 50 2012

Top 50 2013

Bedryf/Industry 2012

Bedryf/Industry 2013

21%

17%

22%

38%

3%

19%

16%

20%

41%

4%

20%

20%

21%

36%

3%

18%

18%

21%

41%

3%

21%

20%

21%

36%

3%

17%

19%

20%

40%

3%

KLAAR

19% 19%

4% 3%

22% 21%

35% 40%

20% 18%

18 • VINPRO KOSTEGIDS / COST GUIDE

Wat doen top presteerders anders? / What sets top performers apart?

Die volgende korttermyn tegniese praktyke het oor die afgelope drie tot vyf jaar die winsgewend-heid van individuele wynprodusente ’n hupstoot gegee.

Snoeimetodes

In ’n poging om produksie te verhoog, poog produsente om oogladings tydens snoei te verhoog deur die toepassing van verskillende snoeipraktyke. Die aantal oë word toegeken met inagneming van die groeikrag – geiler stokke kry dus meer of langer draers en ’n hoër ooglading. Verskillende snoeimetodes/-stelsels word ook vir verskillende wyndoelwitte toegepas.

Lowerbestuurspraktyke

Lower word bestuur om vegetatiewe groei te akkommodeer sonder verlies aan vrugbaarheid en met behoud van kwaliteit. Groot fokus word geplaas op lig in die lower en suier-, top- en blaar breek-aksies word uitgevoer om te verhoed dat stokke te dig en onvrugbaar raak. Pro dusente poog ook om op arbeid te bespaar deur sekere praktyke uit te skakel of af te skaal. Só word wingerde onder andere meer toegelaat om oop te lê (sprawl) om voldoende deurlugting en belig-ting te verseker. Voorheen is voorkeur gegee aan vertikale lootposisionering (VSP) waar al die lote tussen die loofdrade ingedruk word en ver digting maklik kan plaasvind indien daar nie gesuier word nie.

Bemesting en besproeiing

Groeikrag het ’n groot impak op produksie en produsente pas hul bemestings- en besproei-ingspraktyke volgens spesifieke wyndoelwitte toe. Premium-blokke het matige groei en drag wat in balans is, terwyl bulkwynblokke sterker groeikrag het wat ’n groter lower en drag kan akkommodeer. Besproeiing en bemesting word hierby aangepas.

Blokke met hoër produksies word dikwels geas-sosieer met:

• Goed gedreineerde grond• Diep grondvoorbereiding• Meer stikstof (N)• Luukse watervoorsiening (nie te veel nie –

risiko van versuiping).

Tekortbesproeiing (“RDI”) word slegs toegepas indien die wynprys dit regverdig.

The following short-term technical practices improved the profitability of individual wine pro-ducers over the past three to five years.

Pruning methods

In an attempt to increase production, producers attempt to increase bud load during pruning by means of various pruning practices. The number of buds allocated depends on vigour – grape-vines that are more vigorous have more spurs or longer bearers – in other words, a higher bud load. Moreover, different pruning methods/systems are used for different wine objectives.

Canopy management practices

Canopies are managed to accommodate veg-etative growth without loss of fertility, while retaining quality. There is considerable focus on sunlight penetration within the canopy, and suckering techniques, topping and leaf removal are performed to prevent grapevine cano-pies from becoming too dense and infertile. Producers also attempt to save on labour by eliminating or downscaling certain practices. By allowing certain grapevines to sprawl in order to ensure sufficient aeration and light penetration, shoots do not need to be tucked into wires as required with vertical shoot positioning sys-tems. The latter practice could be responsible for too dense canopies unless proper suckering takes place.

Fertilisation and irrigation

Vigour has a great impact on yield; therefore producers apply their fertilisation and irrigation practices according to specific wine objectives. The growth and yield in premium blocks are moderate and in balance, whereas bulk wine blocks are more vigorous in order to accom-modate larger canopies and yields. Irrigation and fertilisation are adjusted accordingly.

Blocks with high yield are often associated with:

• Well-drained soil• Deep soil preparation• More nitrogen (N)• Abundant water provision (not too much –

risk of drowning).

Deficit irrigation (“RDI”) is applied only if it is justified by the price of the wine.

VINPRO KOSTEGIDS / COST GUIDE • 19

Belyn praktyke met die wyndoelwitWingerdbestuur het tot ’n groot mate verskuif vanaf slegs gehalte teen alle koste na win-sgewendheid teen die regte gehalte. Produsente belyn dus hul praktyke met die uiteindelike wyn-doelwit en druiweprys. ’n Langtermynpraktyk wat vorentoe ’n groot rol gaan speel, is die ge-bruik van nouer plantwydtes, en spesifiek nouer rywydte, wat meer rye per hektaar gee.

Alternatiewe prieelstelselsDie keuse van prieelstelsel het ’n baie groot impak op winsgewendheid, en hoewel nog in die beginfase, gebruik ál meer produsente alter-natiewe prieelstelsels of bestuur hul bestaande stelsel(s) anders.

Alternatiewe prieelstelsels kan:

• Produksie (ton/ha) verhoog deurdat ver-hoogde effektiewe blaaroppervlak ’n groter oes kan rypmaak

• Arbeidskostes verlaag, byvoorbeeld ooplê-stelsels teenoor VSP

• Sonligpenetrasie verbeter• Tot meer gebalanseerde groeikrag lei• Tot beter gehalte teen ’n hoër produksie aan-

leiding gee, vanweë groter effektiewe lowers.

Uitkap van nie-winsgewende blokkeLaer-produserende blokke of dié waarvan die drui we nie meer in aanvraag is nie, word uitgekap.

Doeltreffende arbeidsbestuurAs deel van beter algemene kostebestuur, word arbeid meer doeltreffend bestuur deur onder andere te meganiseer waar moontlik en gebruik te maak van meer opgeleide arbeiders waar hande-arbeid wel benodig word.

Plant nuwe wingerde aanSlegs winsgewende produsente plant tans nuwe wingerde aan, maar doen fyn beplanning vir beter produksies met betrekking tot die grond, kultivar, onderstok, klone, prieel, besproeiing, bemesting, snoei en lowerbestuur.

Tydsberekening van aksiesDie korrekte tydsberekening van verskillende wingerdaksies is baie belangrik – dit kan kostes bespaar en effektiwiteit verbeter. Feitlik alle ak-sies vereis ’n bepaalde tyd; verbeur dit en betaal die gevolge.

Align practices with the wine objectiveViticultural management has shifted to a large extent from quality alone at all costs, to profit-ability combined with the right quality. Producers are therefore aligning their practices with the eventual wine objective and grape price. A long-term practice that is set to play a significant role in the future, is the use of narrower plant widths, and specifically narrower row width, which gives more rows per hectare.

Alternative trellising systemsThe choice of trellis system has an enormous impact on profitability, and although it is early days yet, more and more producers are using alternative trellis systems, or manage their exist-ing system(s) differently.

Alternative trellis systems can:

• Increase yield (ton/ha), as a larger effective leaf surface area is able to ripen a larger crop

• Reduce labour costs, for example sprawling systems versus vertical positioning

• Improve sunlight penetration• Result in more balanced vigour• Result in improved quality and higher yield,

due to bigger effective canopies.

Uprooting of non-profitable blocksBlocks with low yields, or blocks with grapes that are no longer in demand, are uprooted.

Efficient labour managementAs part of improved general cost management, labour is managed more efficiently by means of mechanisation, inter alia, where possible, and where manual labour is required, by making use of more skilled labourers.

Plant new vineyardsOnly producers who make a profit are currently planting new vineyards, following meticulous planning for improved yields with regard to the soil, cultivar, rootstock, clones, trellis, irrigation, fertilisation, pruning and canopy management.

Timing of actionsCorrect timing of various vineyard activities can go a long way to reducing costs and increasing the effectiveness of operations, where late action often comes with extra costs. Just about every activity has it’s time; miss it and it will cost you.

20 • VINPRO KOSTEGIDS / COST GUIDE

Dit is van uiterste belang dat produsente en ander rolspelers in die wynbedryf weet wat die teikeninkomste per hektaar moet wees om te verseker dat redelike en aanvaarbare ekono-miese opbrengste gerealiseer word. Om die tei-keninkomste te bepaal word die totale produk-siekoste, ’n aanvaarbare ondernemersloon, asook ’n realistiese opbrengs op kapitaalbeleg-ging in berekening gebring. Sodoende word die teikeninkomste per hektaar bepaal, wat na gelang van verskillende produksies aange-pas moet word om teikenpryse vir spesifieke produkte te bepaal. Hierdie syfers is slegs ’n gemiddelde teikeninkomste per distrik ten opsigte van Produksieplan-deelnemers en die ideaal is dat elke produsent sy eie individuele teikeninkomste bepaal na gelang van sy plaas-grootte, kostestruktuur, ens.

Teikeninkomste (2013-oes) / Target income (2013 harvest) It is important that producers and other role players are informed of what their target income per hectare should be to ensure that reasonable and acceptable economic yields are obtained. Total production cost, entrepreneurial remunera-tion and a realistic return on capital investment are all taken into account to determine the total target income. After the target income per hec-tare has been calculated, it should be divided according to varying levels of production in order to determine target prices for specific prod-ucts. The target income guidelines shown here represent the average for all the participants of the Production Plan per district and producers should ideally calculate their individual target income according to their own cost structure, farm size, etc.

VINPRO KOSTEGIDS / COST GUIDE • 21

TE

IKE

NIN

KO

MS

TE

RIG

LYN

E P

ER

HE

KTA

AR

(201

3) /

TA

RG

ET

INC

OM

E G

UID

ELI

NE

S P

ER

HE

CTA

RE

(201

3)

DIS

TR

IK /

DIS

TR

ICT

Ste

llenb

osc

hP

aarl

Ro

ber

tso

nB

reed

eklo

of

Olif

ants

R

iv(i)

erW

orc

este

rO

rang

e R

iv(i)

erK

lein

Kar

oo

Bed

ryf

/ In

dus

try

Mal

mes

bur

y

Pla

asg

roo

tte

/ F

arm

siz

e (h

a)40

4040

4040

4040

4040

70

R/h

a

Tota

le k

ont

antu

itgaw

esTo

tal c

ash

exp

end

iture

s 3

3 25

1 2

3 21

0 2

5 85

8 2

5 46

7 2

6 78

3 2

3 93

8 2

7 80

1 2

3 19

2 2

6 65

9 1

8 33

7

Voor

sien

ing

vir

verv

angi

ngP

rovi

sion

for

rene

wal

9 1

35

8 0

30

9 1

18

9 0

79

10

798

9 1

60

8 7

29

8 7

71

9 0

80

6 9

60

Teik

enin

kom

ste

na p

rod

uksi

eko

ste

Targ

et in

com

e af

ter

pro

duc

tion

cost

42

386

31

240

34

976

34

546

37

580

33

098

36

531

31

963

35

739

25

297

Ren

te o

p b

eleg

ging

(ves

tigin

gsko

ste

– R

130

000/

ha)

Inte

rest

on

inve

stm

ent

(est

ablis

hmen

t co

st –

R13

0 00

0/ha

) 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 1

0 40

0 8

000

Teik

enin

kom

ste

voo

r o

nder

nem

ing

slo

on

Targ

et in

com

e b

efo

re e

ntre

pre

neur

ial r

emun

erat

ion

52

786

41

640

45

376

44

946

47

980

43

498

46

931

42

363

46

139

33

297

Ond

erne

min

gslo

on (R

32 0

00/m

aand

)E

ntre

pre

neur

ial r

emun

erat

ion

(R32

000

/mon

th)

9 6

00

9 6

00

9 6

00

9 6

00

9 6

00

9 6

00

9 6

00

9 6

00

9 6

00

5 4

86

Teik

enin

kom

ste

per

ha

Targ

et in

com

e p

er h

a 6

2 38

6 5

1 24

0 5

4 97

6 5

4 54

6 5

7 58

0 5

3 09

8 5

6 53

1 5

1 96

3 5

5 73

9 3

8 78

3

TE

IKE

NIN

KO

MS

TE

RIG

LYN

E P

ER

TO

N (2

013)

/ T

AR

GE

T IN

CO

ME

GU

IDE

LIN

ES

PE

R T

ON

(201

3)

Pro

duk

sie

per

hek

taar

/ Y

ield

per

hec

tare

R/t

on

5 1

2 47

7 1

0 24

8 1

0 99

5 1

0 90

9 1

1 51

6 1

0 62

0 1

1 30

6 1

0 39

3 1

1 14

8 7

757

8 7

798

6

405

6

872

6

818

7

198

6

637

7

066

6

495

6

967

4

848

10 6

239

5

124

5

498

5

455

5

758

5

310

5

653

5

196

5

574

3

878

12 5

199

4

270

4

581

4

546

4

798

4

425

4

711

4

330

4

645

3

232

15 4

159

3

416

3

665

3

636

3

839

3

540

3

769

3

464

3

716

2

586

20 3

119

2

562

2

749

2

727

2

879

2

655

2

827

2

598

2

787

1

939

25 2

495

2

050

2

199

2

182

2

303

2

124

2

261

2

079

2

230

1

551

30 2

080

1

708

1

833

1

818

1

919

1

770

1

884

1

732

1

858

1

293

22 • VINPRO KOSTEGIDS / COST GUIDE

Arbeid is verreweg die grootste komponent van die wyndruifprodusent se jaarlikse kostes. Daar-om is die effektiewe bestuur van die arbeidsmag op die plaas baie belangrik. In die volgende tabel is arbeidsnorme vir sekere aksies saamgevat wat die wyndruifprodusent sal help met die beplan-ning, bestuur van, en begroting vir arbeid – beide permanent en seisoenaal – deur die jaar.

Arbeidsriglyne / Labour guidelines

Labour is by far the largest component of wine grape producers’ annual expenditure. Therefore efficient management of the labour corps on the farm is of utmost importance. The following table includes labour norms for specific actions that will assist the wine grape producer to plan, manage and budget for labour – both permanent and seasonal – throughout the year.

Arbeidsnorme / Labour norms

ARBEIDSNORME / LABOUR NORMS

Tipe aksie / Type of action Man-ure per hektaar / Man hours per hectare

Vir eie gebruik /For own use

Wingerd uittrek / Vineyard uproot

Bosstok / Bush vines 40 - 55

Opleiwingerd / Trellised vineyards 1100 - 1400

Skoonmaak van grond / Field clearing 23 - 30

Skoonmaak van grond (trekker) / Field clearing (tractor) 25 - 35

Verwyder ou stokke / Uproot old vines 23 - 30

Wegry van stokke / Remove vines from site 25 - 35

Wingerdvestiging (alle aktiwiteite) / Establishment (all activities)

Jaar 1 / Year 1 900 - 1300

Jaar 2 / Year 2 1000 - 2400

Jaar 3 / Year 3 1000 - 1500

Wingerdvestiging (gespesifiseerde aktiwiteite) / Establishment (specified activities)

Pale plant / Plant posts 320 - 380

Draadspan / Strain wires 70 - 90

Besproeiing installeer / Install irrigation 170 - 200

Opleistelsel oprig (medium tot groot) / Erect trellis systems (medium to large) 1200 - 1700

Saai van dekgewas / Sow cover crop seed 3 - 5

Plant van stokke / Plant vines 160 - 185

Lê van dekplastiek / Lay plastic covering 24 - 30

Groenlootontwikkeling / Green shoot development 230 - 300

Winterloot op raamwerk / Winter cane on framework 110 - 125

Oesbeheer / Crop control 65 - 80

Ander aktiwiteite / Other activities

Voorsnoei vir oplei / Pre-prune for trellising 30 - 37

Skoonsnoei vir bosstok / Clear pruning for bush vines 86 - 160

Skoonsnoei vir oplei / Clear pruning for trellising 105 - 120

Stompsnoei vir bosstok / Blunt pruning for bush vines 45 - 55

Stompsnoei vir oplei / Blunt pruning for trellising 42 - 62

Gesamentlike snoei (skoon en stomp) / Collective pruning (blunt and clear) 90 - 145

Suier intensief / Intensive offset 45 - 80

Suier ekstensief / Extensive offset 24 - 45

Lote deursteek / Plant shoots 20 - 36

Top van lote / Top shoots 15 - 25

Blare uitbreek / Remove leaves 20 - 30

Oesbeheer / Crop control 65 - 80

Oes van bosstok (man-ure per ton) / Harvest of bush vines (man hours per ton) 11 - 15

Oes van oplei (man-ure per ton) / Harvest of trellis (man hours per ton) 9 - 11

VINPRO KOSTEGIDS / COST GUIDE • 23

Minimum loon / Minimum wage

The minimum wage from 1 March 2014 until 28 February 2015 is as follows:

Die minimum loon vanaf 1 Maart 2014 tot 28 Februarie 2015 is soos volg:

Vestigingskoste / Establishment cost

Dit is wenslik om die volgende prosedures te volg ten einde ’n eenmalige, korrekte voorberei-ding vir die meerjarige wingerd daar te stel.

(In samewerking met Braham Oberholzer, VinPro-grondkundige).

GrondontledingsChemiese regstellings, soos die uitstrooi van die regte hoeveelheid kalk vir die regstel van die grond se pH en fosforstatus, gaan gepaard met grond-voorbereiding. In die meeste gevalle lei grond wat bekalk is tot ’n pH van 6 tot ’n betekenisvolle ver-hoging in wortelmassas van onderstokke.

Grondprofiel-inspeksieDie maak van profielgate vir grondklassifika-sie is nodig sodat beoordeel kan word watter bewerkingsmetode nodig sal wees. Grondver-skuiwingsmaatskappye werk vandag baie nou saam met grondkundiges en dring dikwels aan by produsente dat grondkundiges eers gronde moet besigtig of klassifiseer. Netjiese profielgate wat strek tot 1 500 mm en selfs dieper bied goeie aanwysers vir besluitneming.

Die vestiging van wingerd is ’n langtermyn, kapitaal-intensiewe besluit waarmee die pro-dusent vir meer as 20 jaar moet saamleef. Dit is dus krities dat alle aspekte rondom so ’n besluit deeglik besin moet word alvorens dit geneem of uitgevoer word.

The following procedures are recommended to ensure once-off, correct soil preparation for the perennial grapevine.

(In collaboration with Braham Oberholzer, VinPro soil scientist).

Soil analysesChemical adjustments such as the application of the right amount of lime to adjust the soil’s pH and phosphorus status, go hand in hand with soil preparation. In most instances soil that had been limed to a pH of 6 led to a significant increase in the root mass of rootstocks.

Soil profile inspectionIt is necessary to create profile pits for soil clas-sification, in order to determine the required cultivation method. Nowadays there is excellent collaboration between earthmovers and soil scientists, the former often urging producers to have a soil scientist view or classify the soil beforehand. Neat profile pits up to a depth of 1 500 mm and deeper are very good indicators in decision-making.

The establishment of vineyard is a long-term, capital-intensive decision, which will have an effect on the producer for the next 20 years or more. It is therefore critical that all aspects sur-rounding the matter are thoroughly considered before the decision is made or implemented.

Grondvoorbereiding / Soil preparation

Uurlikse loon / Hourly wage R12.41 per uur / per hour

Daaglikse loon / Daily wage R111.72 per dag / per day

Weeklikse loon / Weekly wage R558.60 per week

Maandelikse loon / Monthly wage R2 420.41 per maand / per month

ARBEIDSNORME / LABOUR NORMS

Tipe aksie / Type of action Man-ure per hektaar / Man hours per hectare

Vir eie gebruik /For own use

Besproeiing in seisoen / Irrigation in season 20 - 35

Plaagbeheer (trekker) / Pest control (tractor) 60 - 75

Somerloofaksie / Summer foliage action 230 - 320

Skoffel / Hand clean 25 - 40

24 • VINPRO KOSTEGIDS / COST GUIDE

Implementkeuse / Implement selection

Wieltrekkers is lankal nie meer die oplossing vir diep grondbewerking nie, omdat kontak met die grondoppervlak te min is, genoegsame krag op die grond ontbreek en die wielglip moontlik grondkompaksie bevorder. Kruiptrekkers is die enigste kragbron wat suksesvol gebruik kan word, aangesien dit meer krag na die grond verplaas met minder kompaksie weens groter kontak tussen die rusperbande en die grondop-pervlak.

Tipe vermenging

Tans is die gebruik van slootgrawers, bekend as spitdol, ’n gemaklike opsie om te oorweeg. Daar is egter min gronde wat uitstekend gepas is tot die gebruik van die spitdol; daarom word groot masjiene eerder aanbeveel. Indien lae voorkom, weens onder andere drastiese tekstuurverskille (dupleksgronde), moet versigtig omgegaan word met ’n slootgrawer wat lae vermeng, en sal ’n skuifmengdol wat lae in posisie hou, beter gepas wees.

’n Skeurploeg en skuifmengdol se aanvoorwydte – die wydte tussen die implement se skare – moet ook voor die tyd bepaal word, hoofsaak-lik weens koste-implikasies en die nodigheid daarvan. Indien groot lense onversteurde grond tussen die aanvoorwydtes vermy wil word, sal hierdie keuse oordeelkundig gemaak moet word. Die lense kan gewoonlik met ’n kruisaksie ver-klein word. Indien daar tot dieptes van 900 mm bewerk word, moet die aanvoor twee-derdes opneem – dus 600 mm.

Tydperk van grondvoorbereiding

Die tydperk van grondvoorbereiding is baie belangrik. In té droë grond sal groot kluite, veral op die oppervlakte, breek wat ’n ongewenste situasie skep wanneer ingewerk word met dol-aksies. Die grondklimaat is byvoorbeeld geskik vir bewerking wanneer ’n balletjie grond gerol kan word en met geringe druk uitmekaar kan val. Klimaat en kalkbehoefte sal dan bepaal of die grond gekruisdol moet word of anders net ’n enkele aksie sal benodig. Die vorming van groot kluite kan beperk word deur benatting van die grond vir vier ure met sprinkelbesproeiing in die orde van ± 25 mm water en ’n toelating van 48 – 72 uur daarna vir uitdroging.

Implement selection

Tractors are no longer suitable for deep soil preparation, as their soil surface contact is in-sufficient, there is not sufficient power available on the soil and if used, slipping wheels could add to soil compaction. Bulldozers are the only source of power that can be used successfully, as they displace more power to the soil with less compaction due to the larger contact area of the caterpillar tyres on the soil’s surface.

Type of mix

Currently the use of digger loaders, known as “spit” delve, is a good option to consider. How-ever, there are not many soils that are totally suited to the use of the “spit” delve; therefore large machines are preferred. If layers occur due to, inter alia, drastic differences in texture (du-plex soils), a digger loader should be used with caution, since it mixes layers, and one would prefer a finger mix delve plough, which keeps layers in position.

The furrow width – the width between the plough-shares – of a ripper and finger mix delve plough needs to be determined well in advance, mainly due to cost implications and the neces-sity thereof. If you want to avoid large lenses of undisturbed soil between the furrow widths, this will have to be a carefully considered decision. Lenses can usually be reduced with a cross action. If vines are planted up to a depth of 900 mm, the furrow should be take up two-thirds – in other words 600 mm.

Period of soil preparation

The period of soil preparation is of utmost im-portance. In excessively dry soils, large clods will break, especially on the surface, which creates an undesirable situation when the soil is trenched. The soil climate is, for example, most optimal for cultivation when a ball of soil can be rolled and falls apart with the slightest of pressure. Climate and lime requirements will determine whether the soil should be cross-delved or alternatively require a single action. The formation of large clods can be limited if the soil is wetted for four hours with sprinkler irrigation at ± 25 mm water, followed by a drying period of 48 - 72 hours.

VINPRO KOSTEGIDS / COST GUIDE • 25

OpsommingDie volgende moet in gedagte gehou word:

• Oormatige bewerking kan lei tot struktuurver-nietiging en die grond, wanneer droog, sal tot poeierstof bewerk wees.

• Té wye aanvoorwydtes lei tot swak vermen-ging met groot onaangeraakte grondbanke/-lense.

• Die bewerkingsrigting moet korrek gekies word met die oog op ondergrondse dreinering.

• Die grondklimaat moet korrek wees – ’n té droë klimaat lei tot groot kluite en ’n té nat klimaat smeer die ondergrond.

Gereelde evaluering van grondvoorbereiding is on-ontbeerlik. Profielgate moet gereeld gemaak word (hou slootgrawer byderhand), sodat vorde ring en kwaliteit deur kundiges beoordeel kan word.

Die koste van grondvoorbereidingDie moontlike kostes van verskillende grond-voorbereidingsaksies word in die volgende tabel opgesom. Let wel dat hierdie slegs riglyne is en dat die kostes sal wissel afhangende van grondtipe, implement-tipe en die spesifieke aksies wat deur die produsent verlang word. Die produsent moet verder self vervoerkostes in berekening bring volgens sy/haar eie situasie.

SummaryThe following should be kept in mind at all times:

• Excessive tillage can result in destruction of the structure and the soil, when dry, will have been tilled to a powdery matter.

• Excessively wide furrow widths result in poor mixing with large untouched soil banks/lenses.

• Cultivation row should be selected correctly with a view to drain the subsoil.

• The soil climate should be correct – a too dry climate will lead to large clods and a too wet climate will smear the subsoil.

Regular evaluation of soil preparation is es-sential. That means creating regular profile pits (keep trencher handy), so that progress and quality may be judged by the experts.

Cost of soil preparationThe potential costs of certain soil preparation actions are summarised in the following table. Please note that these are only guidelines and that the actual costs will differ depending on soil type, implement type and the specific ac-tions required by the producer. Furthermore, the producer must calculate the transport cost according to his/her own situation.

TIPE BEWERKINGTYPE OF ACTION

DROë KOSTEDRY COSTS (R/HA)

DIESELVERBRUIKDIESEL USAGE

Caterpillar D8 / Komatsu D155

Caterpillar D9 /Komatsu D275

Caterpillar D8 / Komatsu D155

Caterpillar D9 / Komatsu D275

Rip maklike grond (wye aanvoorwydtes)Rip easy soil (wide furrow width) R6 300/ha R7 350/ha 37% 45%

Rip moeilike grond (nou aanvoorwydtes)Rip difficult terrain and soil (narrow furrow widths) R8 400/ha R9 450/ha 48% 62%

Rip en kruis maklike grond (wye aanvoorwydtes)Rip and cross easy soil (wide furrow width) R10 500/ha R14 700/ha 44% 40%

Rip en kruis moeilike grond (nou aanvoorwydtes)Rip and cross difficult terrain and soil (narrow furrow width) R14 700/ha R19 950/ha 43% 40%

Diep meng- en skuifdolploeg (sonder rip)Deep mix and delve plough (without rip) R14 175/ha R17 325/ha 44% 40%

Rip en kruisdol (nou aanvoorwydte)Rip and cross delve (narrow furrow width) R16 800/ha R23 100/ha 45% 40%

Enkeltoon rip en 3 toon kruis-mengripSingle blade rip and 3 blade cross-mix rip R7 875/ha R9 450/ha 50% 55%

Spitdol vol oppervlakte (25 ton slootgrawer)Spit delve full area (25 ton excavator) R17 850/ha 35%

Spitdol net op rye en opert (25 ton slootgrawer)Spit delve only on rows and ridging (25 ton excavator) R9 450/ha 40%

Ontbossing (D8 Cat) Deforestation (D8 Cat) R4 200/ha 26%

Rye opert met bulldozer (D5-D6 Cat)Ridging of rows with bulldozer (D5-D6 Cat) R4 200 - R6 300/ha 30%

Wingerd uitrip met vlerk (D8 Cat)Remove vines with wing (D8 Cat) R3 150/ha 40%

Slootgrawer (CAT 22 ton) – werkstempo afhangend van grondtipe Diggerloader (Cat 22 ton) – work tempo dependent on soil type R525/h 45 l/h

26 • VINPRO KOSTEGIDS / COST GUIDE

Die koste van prieelstelsels word bereken deur die nuutste pryse (BTW uitgesluit) vanaf verskeie verskaffers van pale, draad en ander materiaal te verkry. Die gemiddelde pryse word in ’n teo retiese model ingevoeg om die koste van verskillende prieelstelsels met verskillende paallengtes, paal-spasiërings, ens te bepaal. Dit bly dus teo retiese bedrae en kan van werklike kostes verskil. Vir ’n meer akkurate kosteberekening van prieel-stelselkoste, kontak die samestellers.

Vir vertikale prieelstelsels is die pale in 6 m-vakke geplant en vir die alternatiewe stelsels is die vakke 7.5 m. Kontak die samestellers gerus om u unieke prieelstelselkoste te bepaal met verskillende vaklengtes, paallengtes en -diktes.

The cost of a trellis system is calculated by ob-taining the latest prices (VAT excluded) for the poles, wire and other materials from a number of suppliers. These prices are entered into a theoretical model to calculate the cost of various trellis systems with different pole lengths, pole spacings, etc. These are therefore theoretical costs and may differ from actual costs. For a more accurate cost calculation of different trellis systems, please contact the compilers.

For the vertical trellis systems a pole spacing of 6 m is used and 7.5 m for alternative trellis systems. Feel free to contact the compilers to calculate your unique trellis system cost with different pole types and spacing.

Koste van prieelstelsels / Cost of trellis systems

Daar mag soms verwarring voorkom tussen die benamings en konstruksies van verskillende vertikale prieelstelsels. Ten einde enige verwar-ring uit te skakel word ’n skematiese voorstelling van die stelsels voorsien met die voorgestelde benamings en afkortings tussen hakies.

There may be some confusion regarding the names and constructions of different vertical trellis systems. To eliminate any confusion, a schematic representation of the systems is provided, with their names and abbreviations in brackets.

ALTERNATIEWE PRIEELSTELSELS / ALTERNATIVE TRELLIS SYSTEMS

Tipe stelselType of system

PaalPole

Ryspasiëring / Row spacing (m)

2.1 2.5 2.75 3 3.3

Skuinskap – 1.5 m kappaalSlanting trellis – 1.5 m slanting pole 2.4 m (50 - 75) – – 49 731 44 387 40 363

Skuinskap – 1.8 m kappaalSlanting trellis – 1.8 m slanting pole 2.4 m (50 - 75) – – 52 812 48 421 44 030

Gewelstelsel – 2.1 m paalGable system – 2.1 m pole 2.1 m (75 - 100) – – 70 620 64 938 58 983

Fabrieksdak – 2.1 m paalFactory roof – 2.1 m pole 2.1 m (75 - 100) – – 58 614 52 664 48 937

U-stelselU-system 2.1 m (75 - 100) – – – 75 414 66 689

DraadgewelWire gable 2.1 m (50 - 75) – – 54 468 – –

LierstelselLyre system 2.4 m (100 - 125) – – – 86 138 –

Scott Henry 2.7 m (75 - 100) 59 910 51 026 45 929 42 112 38 294

Grobbelaar 2.1 m (75 - 100) – 66 020 61 095 56 170 53 773

T-kapT-system 2.4 m (75 - 100) 62 800 58 115 53 430 51 151

VINPRO KOSTEGIDS / COST GUIDE • 27

VE

RT

IKA

LE P

RIE

ELS

TE

LSE

LS /

VE

RT

ICA

L T

RE

LLIS

SY

ST

EM

S

Prie

elst

else

l / T

relli

s sy

stem

Paa

lP

ole

Rys

pas

iërin

g /

Row

sp

acin

g

1.8

1.9

22.

12.

22.

32.

42.

52.

62.

752.

82.

93

3.1

3.2

3.3

Een

dra

ad h

eini

ngO

ne s

tran

d h

edge

1.2

m (5

0 -7

5)20

394

19 2

8318

547

17 4

3616

700

15 9

4915

213

14 8

3814

102

13 3

6612

991

12 6

1512

255

11 8

7911

504

11 1

43

Twee

dra

ad h

eini

ngTw

o st

rand

hed

ge1.

2 m

(50

-75)

22 1

1620

911

20 1

1318

907

18 1

0917

295

16 4

9716

090

15 2

9214

493

14 0

8613

680

13 2

8812

881

12 4

7512

083

Drie

dra

ad h

eini

ngTh

ree

stra

nd h

edge

2.1

m (7

5 -

100)

60 8

1357

497

55 3

0451

988

49 7

9547

550

45 3

5744

235

42 0

4139

848

38 7

2637

604

36 5

3235

410

34 2

8833

217

Vie

rdra

ad h

eini

ngFo

ur s

tran

d h

edge

2.1

m (7

5 -

100)

62 5

3559

125

56 8

6953

460

51 2

0448

897

46 6

4145

487

43 2

3140

975

39 8

2238

668

37 5

6636

412

35 2

5934

156

Vyf

dra

ad h

eini

ngFi

ve s

tran

d h

edge

2.4

m (5

0 -

75)

61 6

0258

247

56 0

2552

670

50 4

4948

182

45 9

6044

827

42 6

0541

471

39 2

5038

116

37 0

2835

895

34 7

6133

673

Per

old

1.8

m (1

00 -

125

)65

365

61 8

0159

443

55 8

7953

522

51 1

0848

751

47 5

4445

187

42 8

3041

623

40 4

1639

266

38 0

5936

852

35 7

02

Dub

bel

Per

old

Dou

ble

Per

old

1.8

m (1

00 -

125

)67

923

64 2

1961

769

58 0

6555

615

53 1

0850

658

49 4

0546

955

44 5

0443

251

41 9

9740

801

39 5

4738

294

37 0

97

Sku

ifbar

e P

erol

dM

ovab

le P

erol

d2.

1 m

(100

- 1

25)

76 1

6272