KEY BENEFITS CONDENSATE STABILIZER SYSTEMSenerflex.com/Reports/Condensate...

Transcript of KEY BENEFITS CONDENSATE STABILIZER SYSTEMSenerflex.com/Reports/Condensate...

WWW.ENERFLEX.COM

PRODUCT FEATURES

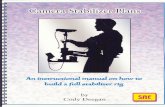

Enerflex designs and manufactures high quality condensate stabilizer systems that effectively separate, capture, and prepare condensate (C5+) liquids for transportation via rail, truck, or storage. Whether at the inlet of the process or after the de-ethanizer or de-methanizer, Enerflex works closely with customers to design a stabilizer system that meets application specific demands. Custom modular designs that minimize the interconnecting piping result in simplified installation and reduced on-site construction speeding the development of the stabilizer system and overall gas plant. Enerflex provides NGL and condensate stabilizer systems built to fit applications ranging in size from 3,000 bbl/d to 15,000 bbl/d.

KEY BENEFITS

Single SourceEnerflex offers a single point of contact for evaluating and integrating the design of other complimentary systems, such as overhead compression, cryogenic plants, mechanical refrigeration, and fractionation trains.

ExperienceOur proven portfolio of designs in manufacturing condensate stabilizer systems for flow rates of 3,000 bbl/d to 15,000 bbl/d and compliance with NGL Reid Vapor Pressure (RVP) or True Vapor Pressure (TVP) requirements represents a great advantage to customers, helping them realize maximum recovery of valuable hydrocarbons.

FlexibilityEnerflex leverages close relationships with vendors to provide the most appropriate and cost effective equipment options. This includes systems designed with complex instrumentation and controls that meet desired specifications and integrate into a plant’s Distributed Control System or PLC.

SAFELY STABILIZING CONDENSATES OVER A WIDE RANGE OF COMPOSITIONS. ENERFLEX DELIVERS.

CONDENSATE STABILIZER SYSTEMSGAS TREATING

CORE CONFIGURATION

Stabilizer Skid

» Shell and tube feed/bottoms exchanger

» Shell and tube reboiler

Vertical Stabilizer Tower

INDUSTRY STANDARD SPECIFICATIONS

Enerflex meets or exceeds industry standard specifications for:

» ASME code for piping and vessels

» AISC for structural steel

» NEC for electrical

» ISA for instrumentation

STANDARD FEATURES

» Designed for hot oil heat medium

» High/low level shutdown valve

» Downcomer piping

OPTIONAL FEATURES

» Hot oil system

» Feed separator

» Hydrocarbon filter

» Interconnecting piping

» Overhead compression

» Product cooler

Enerflex Ltd. (TSX: EFX) is an international company with thousands of

skilled, customer-focused personnel and carefully assembled operations

in dynamic energy-producing markets worldwide. Enerflex supplies

natural gas compression, gas processing, refrigeration systems, and

electric power equipment – plus in-house engineering and mechanical

service expertise and full after-market support.