KENNAMETAL CASE STUDY PPT

-

Upload

pinkey-gupta -

Category

Documents

-

view

114 -

download

3

Transcript of KENNAMETAL CASE STUDY PPT

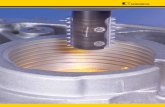

KENNAMETAL

COMPANY OVERVIEW

FOUNDED IN 1938.

MORE THAN 14,000 EMPOLYEE WORLDWIDE.

ANNUAL SELES ARE APPROXIMATELY $3 BILLION.

HEADQUARTERED IN LATROBE, PENNSYLVANIA, USA.

SERVING CUSTOMER’S IN MORE THAN 60 COUNTRIES.

FIRST OR SECOND IN EVERY MARKET THEY SERVE.

GLOBAL MARKET LEADER IN TOOLING FOR THE MINING & HIGHWAY CONSTRUCTION INDUSTRIES

BELIVE IN SUCCESS THROUGH

PEOPLE(Belive in essential to have right people , with

the right skill at the right time & place to continually drive shareowner value & execute

the company’s strategy.)

CHALLENGE’S FOR THE “CHANGE”

COST OF TECHNOLOGY UPGRADITION.

TOTAL UPGRADATION OR PARTIAL ONE.

LICENSE REVENUE COST.

EMPLOYEE’S ADAPTABILITY FOR THE CHANGE.

CONSULTATION.

VENDOR’S RESPONSE TO CHANGE.

MANAGEMENT ACTION TO CHALLENGE’S

$10 million on ERP maintenance gives no advantages to he company past 13 yrs.

Further re-implementation of ERP cost hike from $15 million to $ 54 million estimated by mgmt.

Management choose the SAP system (doesn’t support the complicated, multi-tiered compensation model ) in consultation with IBM.

SAP software is 90% unmodified, which accustomed employee for the changes before rollout.

During 2009, decline in software market benefits the management as new IT vendors offers software at hefty ongoing fees.

Top management take it’s vendor in consideration. So, 21,000 request made by mgmt to the vendor during 2009 which results in 98% of them didn’t involve human intervention.

By eliminating maintenance saves money and the LIBALITIES & TIME comes down by modifying the base applications judiciously.

THANK YOUBY PINKEY GUPTA

CIMS B_SCHOOL