Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by...

-

Upload

sodamoussez -

Category

Documents

-

view

217 -

download

0

Transcript of Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by...

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

1/8

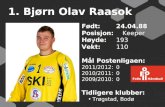

Predicting Blast OverpressuresCaused by Vapor Cloud Explosionsin the Vicinity of Control RoomsKees van Wingerden, Olav Roald Hansen and Pierre FoisselonChristian M ichelsen R esearch, P.O. Box 3, Fantoft, Bergen, Norway

Wh en considering the consequences of gas explosions inpetro-chemical installutions simple methods are used such usW - e q u i v a l e n c ~ ~ethods and the Multi-Energy method. fi es emethods< owew r, do not take into account directional effects,focusing effects, factors related to the source of the explosion(initial strength, shape) an d reflections.FLACS, a 3 - 0 CFD tool,allows o r all actors m entioned including focusing on effectsand wJections neur buildings.

A comparison of the CFD-method including the two tradi-tionalprediction methodsfo r a practical case demonstrates theupplication ureas o the FLACS method as well s the limita-tions o the traditional methods.INTRODUCTIONTwo types o f models are used to predict the potentialconsequences of vapor cloud ex plosion s: TNT-equivalencymethods [51 and the Multi-Energy method (CCPS and Vanden Berg [S,81). Both metho ds predict the strength of blastwaves generated by the vapor cloud explosion as a functionof distance to the center of the explosion. TNT-equivalencymethods use the blast generated by an equivalent amount ofTNT to describe the strength of the vapor cloud explosionand the decay of the blast as a function of distance. TheMulti-Energy method uti l izes the blast decay a nd initialstrength from an idealized gas explosion generated by com-putation.Both models assum e that the blast genera ted is similar in alldirections with no directional effects. Only an und isturbe d,incoming hlast is described and the description of the explo-sion itself is ina deq uat e. Comparative stud ies sho w that theMulti-Energ)r me thod is capa ble of describing far field blasteffects of strong explosions (Van W ingerden et al., @I). In addi-tion, the far field blast predicted by a TNT-equivalency methodcompares reasonably well with estimated pressures made fromdamage due to vapor cloud e xplosions provided the TNT-equivalency or yield factor is chose n correctly. Gugan [6]demonstrates that there is little correlation between the quanti-

ty of fuel involved in the explosion and the equivalent-chargeweight of TNT required to model its blast effects. It should alsobe m entioned that the decay of a TNT-blast is faster than ablast generated by idealized gas [51.

The applicabilityof these methods is limited because of thefollowing: the choice of location of a control room and the nec-essary structural strength of this facility plus the applicabilityofthese m ethods. This paper investigates the limitationsof suchmodels by using a CFD-model (FLACS) to predict some aspectsof the behavior of vapor cloud ex plosions. Simultaneously wepresent this CFD-model as an alternativeto predict the potentialconsequences of vapor cloud explosions.

The p ape r will briefly describe the FLACS cod e an d som erecent extensions which are directly related to blast predic tion inboth the near- and far field consisting of three parts:a multi-block concept, dividing the comp utational region in

various contiguous blocksa special solver for describing the blast propagation awayfrom the explosiona boundary condition to reduce reflections of blast wavesfrom calculation boundariesIn addition, the Multi-Energy method and one of the TNT-

equivalency methods is introduced.SHORT DESCRIPTIONOF FIACS

FLACS is a fluid dynamic code developed for description ofgas dispersion and explosion processes in complex geom etriessuch as offshore modules [91.FLACS calculates explosion pres-sure and other flow parameters as a function of time and spacefor different geometries and explosion scenarios. It takesaccount of the interaction between flame, vent areas and obsta-cles such as equipment and pipe work. The FLACS code solvesthe full gas dynamic partial d fferentia l equations for a set of con-trol volum es. The effects of turbulence and chemical reactionsare included in the differential equations. The equations are dis-cretized using a finite-volume technique a nd a w eightedupw ind/ central differing schem e for the convection terms.

Process Safety Progress (Vol. 18,No. ) Spring 1099 17

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

2/8

Velocities are calcukated on staggered grids. The effect of turbu-lence is included through the eddy viscosity concept by solvingequations for turbulent kinetic energy (K ) and its rate of decay(E). The tool has bee n validated extensively against expe rime ntsthe majority of those being experiments carried out in partiallyconfined geometries such as geometries representing confine-ment conditions prevailing in offshore modu les [lo].The mainapplication area is the prediction of overpressures inside gasclouds and gas and oil production facilities.The latest version of FLACS, FLACS-96, has a possibility- tomake direct predictions of the streng th of blast waves gene ratedby gas explosions. The extension of FLACS allows for describingboth the explosion process inside a congested area and thepropagation of blast waves genera ted by the e xplosion and theirinteraction with structures. The extension involves:

a m ulti-block concept, dividing the co mputational region ina special solver for describing the blast propagation a~ v aya boundary condition to reduce reflections of blast waves

various contiguous blocksfrom the explosionfrom calculation bound aries

i2lulti-block ConceptThe multi-block concept allows for dividing the com putation-

al region into several co nt ipo us blocks. In this mann er one canuse different resolutions in different blocks. The advantage ofusing such an appro ach is that on e can use a special purposesolver for the simulation of propag ating blast waves in theregion outside the area where the explosion takes place. Thiscan save both CPU-time and memory in comparison t o usingFLACS n a single block m odu s.

The main cha nges which are necessary to allow for using dif-ferent blocks in FLACS are:do rm atio n exchange between blockshandling o f flow a cr o s internal boundariesAn exam ple of ho w a multi-block grid can look like is show n

in Figure 1.In order to ensu re continuity across the block boundaries it is

necessary for individual blocks to obtain info rimtion from theirneighboring blocks. In the new multi-block extension the vari-able and flux variables on the bou ndary of the blocks are foundfrom interpolation from adjacent block values.

For flows crossing the block b oundaries the variables to beobtained in the next block are found by interpolation.

The multi-block feature allows for using different solvers indifferent blocks. For the p resent ap plication a special solver wasimplemented to describe blast wave propagation. H ence themulti-block concept allows for using FLACS in a centrally k d t e dblock for calculating the g as explosion parameters and the spe-cial S ~ I W for describing blast propag ation in neighboringblocks.Special Soher f o r Blast Propagation

The solver used for describing the propagation of blast wavesis only utilized to solve the Euler equations w here w e assumethat viscosity effects can be neglected in the uncongested regicjn.The implem ented solver uses the Flux Corrected Transport

S

s

a

3I

E

FIGURE 1 h xample of a multi-block grid used in FLACS forblast calculationsscheme [4J.The method adds to a first-order monotone solutiona limited amount of the difference between second-order andfirst-order fluxes. The diff erenc e is called a n anti-diffusive fluxcontribution. This contribution allows for remo ving first-ordernumerical diffusion without creating unw anted overshoots o roscillations. As such the s chem e allows for a g a x l description ofshock waves without smearing them out over many computa-tional cells.

The blast solver as such has bee n validated. An example isshown in Figures 2 an d 3. Figure 2 shows an experimental set-up described by Absil et al. [ I ] , consisting of two obstacles(bo xes) placed in a shock tube. The obstacles were providedwith pressu re transducers at the positions 1-6as ind icated. Theobstacles are 5 cni high an d 5 cm wide and are placed 7. 5 cmfrom each other. The obstacles are as long as the width of theshock tub e. Pressure-time hstories w ere calculated at each mon-itoring position. Figure 3 shows m easured and calculated pres-sure-time histories at the positions 3 and 4. The results sh ow thatthe blast solver reproduces the m easured blast pressure-time his-tories reasonably well. The main features o f the pressure-timehistories are reproduced. Each "step" and " p e ak is either due tothe initial shock wave o r due to reflections in hemeen the two

Incomingbla9FIGURE 2 la\,orator).~scaleset-up used for studying blast-object

interaction.

18 Spring 1999

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

3/8

D I J

FIGURE3. Calculated and measured pressure-time histories at positions 3 and 4 n the laboratory scaie set-up shown in Figure 2

9 4 ---.8 49I 1 7 847.18 - - .6.53 - -5.88 '- -5.23 '-. .4.57 --.-3.92-.27 - - - -2.61 -...1.96 . ..1.310653 - -

8.67.937.276.615.955.284.623.963.292.631.971.31 - -0.644 - -

8.77 ----p. , A .....

3.12 ----2.49 - - . . .

FIGURE4 Se\ era1 moments of 2-D shock wave propagation at aii in&

boxes. If a finer grid would h ave been used in the simula tionsthe resolution of ach pressure spike in the simulations wouldhave bee n better resulting in an ev en better resemblance ofmeasured and simulated pressure-time histories.Boundaryconditions

In order to avoid reflections and rarefaction waves occurringat the outer boundaries of the blast blocks a special boundarycondition was developed. The boundary condition is based onlinear acoustics.

The ne w bound ary condition was validated extensively aswell.An example of such a validation exercise is shown in Fig-ure 4. Several moments of the propagation of a 2-D shock waveat a 45" angle in a 70 m x 30 m computational domain are illus-trated in the figure. The strength of the shock wave is 10 kPa.The shock waves are represented by isobars.The figure showsthat no reflections occur at the boundaries and w e concludetherefore that the boundary conditions work satisfactorily.TNT-EQUIVALENCY METHODS AND MULTI-ENERGY METHOD

The TNT-equivalency method is originally used for predic-tion of far field effects of vapor cloud explosions. The principleis to convert the available combustion energy in a vapor cloudinto an equivalent charge weight of TNT using the followingrelationship:

w n.-, = a r W , H , /ITw

Process Safely Progress (Vol. 18, No . 1) Spring 1999 19

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

4/8

10'

bs2tn

F ooi

10-1

10-2100 10' 102

rnkg-'"ctual distance."scaleddistam" =

with W, = the weight of the fuel involvedWHfHma,

= equivalent weight of TNT or yield (kgl= heat of combustion of the fuel in question= "NTblast energy Q/k@= TXT equivalency based on energy-(-)

Wkgl

If the equivalent weight of TNT is know n the blast character-istics as a function of distance can b e derived from a chart con-taining a scaled representation of experimental data. The dis-tance in the chart is scaled using the weight of TNT as a scalingparameter. The TNT equivalency in the equation presentedvaries strongly when reproducing blast effects from damage dueto vapor cloud explosions [b].n spite of these variations the LKHealth and Safety Executive recommends that a TNT-equivalen-cy of 3 % of the total combustion energy available in the cloudshould be mi ce the theoretical flash of the amount of materialreleased to account for spray-and aerosol formation. If thisamount exceeds the total amount of fuel available the recom-mended amount should of course be us ed. The blast dataaccording to Marshall [71are used to estimate the blast effects(See Figure 5 )The M ulti-Energy method uses blast from a n idealized gasexplosion generated by computation to predict the conse-quences of vapor cloud explosions. In contradiction to conven-tional TNT-equiKilency me thods the Multi-Energy me thod rec-

FIGURE 5 Peak side-on overpressure due to a surface TN Texplosion accordng to Marshall PI.

ognizes that blast is only generated in congested areas: areaswhere an interaction of combustion and conibustion generated

t8

10

1

0.1

0.01

0.00

10

5

1

0.5

0.1-R O combustionenergy-scaleddistance (R)

. Po =atmosphericpressureco = atmosphericsoond speedE = amount of combustion energyR = charge radius

.------- .FIGURE 6 Blast characteristics accordmg to the Multi-Energymethod 181.

20 Spring 1c)C)c)

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

5/8

FIGURE7. Representation of a 25m wide, 50m ong and 5m highfacility used in the present investigation to investigatesome aspects of modelling of near-field blast effectsclue to vapor cloud explosions.

turbulence can a rise. In fact the Multi-Energy method regards avapor cloud explosion as a number of explosions correspondmgto the various parts of the clouds where congested areas havebeen engulfed. Therefore only these parts of the combustionenergy are used to scale blast decay away from each of theseexplosions.The model uses a chart representing the blast char-acteristics of a hemispherical fuel-air cloud. The blast characteris-tics are given as a function of distance from the center of thecloud. The main parameter used for scaling of the distance tothe blast center is the combustion energy in each of the congest-ed parts of the cloud (Figure 6). In contradiction to the TNT-equivalency m ethod the M ulti-Energy metho d uses a set ofcurves depending on the initial strength of the explosion.BLAST EFFECTS ON A CONTROL ROOM DUETO NEARBY VAPOR CLOUD EXPLOSIONS

The strength of blast waves generated by vapor cloud explc-sions occurring in a realistic plant were investigated using thethree methods introduced above. The blast wave strength wasinvestigated at a contro l room located in the vicinity of the plant.

The geometry that has been chosen as a basis for the presentstudy is shown in Figure 7. It is 50 m long, 25 m wide and 5 mhigh and consists of several vessels of varying sizes located atthe ground and interconnected by piping. A pipe-rack coversthe vessels on the east side of the facility whereas a grated floorwith some equipm ent located on it, covers s d a r equipment onthe west side of the facility.

Table 1 . Estimate of Loading on a Control RoomLocated40m From a Facility in Which a VaporCloud Explosion Occurs*.- -Bkast prediction Side-on Reflectedmethod overpressure overpressure

(bar) (bar)~-0.3 0.67methodMulti-Fnergy method 0 43-1 2 10-34 ~-

'The e\t inidte has k e n made usmg n TNT-equivalency me thod.ind the Multi-Energy me tho d The reflected overpressure at thecontrol r(x)ni was estimated using data presented by Raker eta1 , [31

A control room is located at a distance of 40 m from thecenter of the facility.

A gas cloud of a stoichiometric mixture of propylene andair was assum ed engulfing th e entire facil ity reachin g aheight of 8 m.

The effects as predicted by the TN Tequivalency method pre-sented above and the Multi-Energy methcd are calculated.Predictions of PressureLoadsat the ControlRoom Usingthe 71vT-EquivalencyMethod and Multi-Energy Method

Table 1shows the results of predictions of the pressure load-ing at the control room du e to a vapor cloud explosion in theinstallation described above using the TN Tequ ivalency methodand the Multi-Energy method.For calculating the TNTequivalency the size of the full cloudwas used: 25 m x 50 m x 8 m = 10 000 m3 involving 774 kg ofpropylene. This corresponds to a TNT-equivalencyof 258 kg.Using Figure 5 one can find that the side-on overpressure is 300mbar. As the control room walls will reflect the incoming shockwave the pressure loading on the control room will be larger.This can be estimated using data presented in Baker et al. [31.Thus the loading on a control room wall at an angle of incidenceof 0" with respect to the dlrection of propagation of the incom-ing blast wave can be estimated tobe 6% mbar.

When estimating the strength of the incoming blast wave bythe Multi-Energy method the initial strength of the gas explosionmust be estimated. Regarding the dfiiculty in estimating the ini-tial strength a range of initial blast streng ths varying from 6 (m.overpressure in the cloud is 0.5 bar) to 9 (initial strength 5 bar).The size of the facility and the reactivity of the released materialhave been the main reasons for choosing thts range of values. Amore accurate estimate is only possible by either performingscaled experiments for this particular plant or performing CFD-simulations using a recognized model such as FLACS [lo].Thecombustion energy used for estimating the strength of the blastTable 2. Results of Predictions for the Pressure loadingat a Control Room Located40 m from the Center of aFacility in Which a Vapor Cloud Explosion Occurs*

-_____ -Igrxhon source locahon

central north east south west~~~~~Control roomlocabon -~--North 0.66 0.12 0.29 2.7 0.77East 0.31 0.3 0.21 0.32 0.76south 1.7 3.3 0.59 0.22 1.2West 0.37 0.23 0.53 0.27 0.37Maximumpressureinside plant 1.0 2.2 0.36 1.7 0.54T h e overpressure predictions were inad e for varic)us ignitionsource locat ions and locat ions of the con t ro l room. Theoverpressures are given in bar.

_.__~ ~ ~- ~-~~~~ ~~ ~ ~~ ~~ ~~ ~ ~

Spring I999 21

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

6/8

FIGURE 8 Moment of vapor cloud explosion in a 25m wide,join long and i m high installation. The figure showsthe pressure distribution at moment 1.065s afterignition. To limit the num ber of simulatio ns, controlrooms have been erected south, west. north and eastof the facility.

FIGURE 9 Similar to Figure 8 but at 1.09s after ign ition.

FIGURE 10 Similar to Figure 8 hu t a t 1.1% after ignition. TheFigure shows the reflection of the incoming shockwave n-it11 he control room.

wave at the location of the control room is calculated from thesize of the plant. The volume of the cloud occu pied by the planthaving the dimensions 25 m x 50 111 x 5 m. epresenting avolume of 10 000mi, will only co ntribute to hlast genera-

tion. This coincides with a hlast energy of 3.51010J . Usingthe blast curves of Figure 6 it can be estimated that the side-on overpressure is equal to 0.43 -1.2 bar. [:sing the da ta pre-sented in Raker et al. [31 again it can be estimated that thereflected pressure of the blast a w e at a wall of the controlroom a t 40 ni from the center of the plant is 1.0 - 3.4 baroverpressure.

Both the TNT-equivalency method and the Multi-Energymetho d canno t describe direct ional effects, the effect ofigni tion sou rce locat ion and the effect of locat ion of th econtrol room other than the distance to the center of th efaci l i ty-. How important these lat ter factors are wil l bedem onstrate d by using the FLACS cod e.Predictions at the control room using FLACS

Table 2 show s predict ions using the FLACS co de . TheFLACS code can take the effect of gas explosion scenariointo accou nt an d calculates the reflected blast loading o nthe bu ilding direct ly. In the calculat ions the mult i -blockfacility and associated blast code was not applied as the dis-tance betw een blast source an d target s not large. The cal-culations were performed assuming the location of the con-trol room to he varying as far as orientation is conce rned .Keeping the distance to the center of the plant constant, thecontrol room was assumed to be w est, north, east and southof the plant respectively. The loading on th e control roomwas then investigated for several ignition source locations.

An example of a result is shown in Figures 8 through 10 .The result concerns a simulation of a cloud ignited at thesou t h e nd of the fac i li ty . The f igures sho w the pressuredevelopment at several moments in time. The flame propa-gates and accelerates tow ards the sou th generating gradual-ly higher pressures during this propag ation. The highestoverpressure that is generated in the plant occurs at thesouthernmost end of the plant and reaches a value of 1. 9bar. In the other direction the pressure is considerably lowerand high pressures are generated only if the control room islocated towards th e south of the plant: ;Icontrol room at thesouth end 40 in from the center of the plant will experiencepressures up t o 2.7 bar, a control room at the same distancebut at the opposite direction (i.e. south of the plant) willexperience a pressure o f only 0.22 bar. If the control roomis on the west or east side of the plant reflected pressures of0.27 bar an d 0.32 bar respec t ive ly i s exp er ienc ed. Thisstrong directional effect is also see n in Figures 8 through 10.Similar effects are se en w he n igni t ion is effected on thenorth end o f the plant: a maximum pressure of 2 .2 bar in

Table 3. Blast Decay Away from a Propylene-air Explosion in a 50 rn x 25 rn x 5 rn Facility Where ignition of theCloud was Effected in the North End of the Facility.~ ~~~~ ~~ ~~~~~ ~~~~~

D i s t m c e f r om FLACS TN T equk Multi-Energ)plant cent re (m) method m e t h o d23.4 1 1 0 14 0 14 1 2 0 9 0 - 4 837 5 0 9 2 0 10 0 11 0 58 0 37 0 45-1 0

0 06 0 07 0 32 o 17 0 4-0 558 7 0 24

sw NW NE SE

22 Spring 1999 Irocexs Safety frogress (Vo1.18.No. )

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

7/8

the plant (south end) and a pressure of 3.3 bar at a controlroom towards the south of the p lant and only 0 .12 bartowards the n orth. The difference in maximum pressureboth inside the plant and at the control room for the twoignition sources reflects the differences in geometry detailsin the plant. Ignition in the center results in a maximumpressure of 1 bar in the plant whereas reflected pressures of0.66 bar, 0.31 bar, 2 .7 bar and 0.34 bar are fou nd at controlrooms located at 40 m from the center of the plant in thenorth, east, south a nd west respectively. The lower maxi-mum overpressure inside the plant in comparison to the twoend ignition cases reflects the shorter distance of flame trav-el. A summary of the results using the FLACS cod e is pre-sented in Table 2 .

Another interesting feature to investigate is the blastdecay away from the facility according to the two raditionalmethod s and FLACS. The compa rison has been m ade for 1single case, viz. ignition in the north en d of the plant (Table3). Blast pressures have been measured in four directions

W, NW , NE and SE . The traditional methodscannot predict the effect of direction and they therefore pre-dict only 1 overpressure for each distance to the centre ofthe plant irrespective the direction.

The results show that blast decay away from the facilityis stronger than predic ted by the Multi-Energy method . Thisreflects the assumption of an exploding hemi-sphericalcloud in the Multi-Energy method whereas in reality thecloud is strongly asymme trical. Such asymmetrical blastdecay behavior has also been noticed experimentally [ill.Further, it should be noted that the Multi-Energy methodpredicts very conservatively near the location where ignitionoccurs whereas an underestimate in the near field and anoverest imate beyo nd the locat ion of t he con t ro l roomoccurs at the opp osi te direction. Also the TNT-equivalencymethod predictions overestimate in the direction whereignition occurs and underestimates pressure loads in theother d i rection . On the h igh pressure s ide b last decayappears to be stronger initially but further down FLACS andthe TNT-equivalency method co me closer.

I t is . of cours e , possib le to invest igate several o theraspects, such a s, the influence of installations loca ted inbetween the installation in which the explosion occurs, andthe control room, aspects related to the cloud (includingrealistic clouds gen erated from a leak). aspects related to theinstallation (including the effects of distance between twoseparate installations: what should the distance be to assurethat an explosion in on e installation does not cause a muchstronger explosion in the second) , pressure distribution onthe control room w alls, etc.It should be pointed out, however, that the use of a codesuch as FLACS for predicting the potential consequences ofvapor cloud explosions necessitates the investigation of sev-eral explosion scenarios. In this way one can find the sce-nario which gives the strongest loading on the control roomor on e can find the most o ptimum location for the controlroom. This approac h is now com mon in the offshore indus-try a n d is very often performed as part of a risk analysis

approach where several scenarios are investigated to buildup a relationship between the consequence of an explosion.This is usually described by the peak overpressure generat-ed , and the frequency at which these overpressures are pre-dicted to be exceeded (a so-called exceedance curve. [21).CONCLUSIONS

The FLACS code as a tool for prediction of blast due to vaporcloud explosions has been introduced and compared to tradi-tional methods be ing a TNT-equivalency method an d the Multi-Energy method.

Due to simplifications in the two traditional methodologiesthe effects of vapor cloud explosions in the near field can beboth overestimated and underestimated. The main reasons forthis anomaly are:limited possibilities tovary accident scenarios

no representation of asymmetry in the geom etry in which theexplosion occursno representation of asymmetry in the explosion eventlimited possibilities to represent the strength of the gasexplosionAdditional advantages of the use of FLACS are:investigation of the influence of installations loc ated inbetween the installation in which the explosion occurs and acontrol roominvestigation of explosion effects due to realistic releasesinvestigation of aspects related to the installation in which theexplc )sion occurspossibility to describe the pressure distribution on the control

room wallsAn obvious disadvantage is that an analysis using FLACS ismore comprehensive and therefore more resources are needed.

LITERATURE CITED1. Absil, LHJ.,VandenBerg,A.C. andW e h e i j m , J. (19931,

Blast interactionwithmultiple obstacles.Paper presented atthe 13th Int. Symp. On Military Appl. Of Blast Simulation,The Hague, The Netherlands ( 19 3) .

2. Bailey, E. andGregory, C.A.J. (1976) The application of ameta-model to the analysis of explosion risk. InternationalSymposium o n Hazards, Prevention and Mitigation of Indus-trial Fxplosions,pp. 552-5.73, une 1796, Bergen.

3. Baker, W.E., Co x, P.A., West ine , P.S., Kulesz,J.J. a n dStrehlow, R.A. Explosion Hazards an d Eualuation,Funda-mental Studies in Engineering, 5. Elsevier Scientific Publish-ing Com pany, Amsterdam, (1783).4. Boris, .P. andBook,D.L Solution of continuity equationsby the method of Flu-Corrected Trampofl,Meth. Computat.Phys., ~01.16.Academic Press, New York (1976)5. Center for Chemical Process Safety. C u ~ l i n e s ~ ~ ~ E v a l ~ t i nthe Charac tdticso f VaporCloudExposiom,Flash Fires, andBLEW3 AIChE: New York (1794)6. Gugan, K. Unconjked vapor cloud q l o s io is IChemE. Lon-don (1978)7. Marshall,V.C. he siting and construction o f control huilding.5- a strategic approach, IChemE Symp. Series. no . 47 (1976)

8. VandenBag, .C. B eMulti-Enmgymethod - A rameworkProcess Safety frogress (Vol. IS, No. 1)

-

8/3/2019 Kees van Wingerden, Olav Roald Hansen and Pierre Foisselon- Predicting Blast Overpressures Caused by Vapor Clo

8/8

fo r vapor cloud explosion blastprediction,J.Haz. Mat., vol. 12,9. Van W inge rde n, C.J.M., Opschmr,G. andPasman,HJ.Analysis of vapor cloud incidents,Les accidents industriels:

quelles leco ns e n tirer?, Sociktk Alpine d e Pu blications,Grenoble (190).

10.VanWhgerden,K., Storvik, I., Arntzen,B., Teigland,R,W e , .R, Sand, 1.0.andSBrheim, H .R ,FUCS-93 - Anewq l o s i o n simulator, Proceedings of the 2nd Internation-al Conference on O ffshore Structural Design against Extreme

pp . 1-10(1985).Loads, London (1993).

11.Zeeuwen,J.P., Van Wi ng erd en , C.J.M.andDauw e, R.M.Ehperimental investigation into th e blast effect produced byunc onf ine d vapor cloud explosions, Proceedings of th eFourth International Symposium on Loss Prevention andSafety Promotion in the Process Industries, pp. D20-D29(1983).

ni sp ap er (4b) waspresented at the AIChE Spring NationalMeeting in N ew Orleans, Louisiana on March 10, 1998.

24 Spring 1999