Journal American Lab Automation 2011 v16 p335

-

Upload

peter-tidswell -

Category

Science

-

view

67 -

download

1

description

Transcript of Journal American Lab Automation 2011 v16 p335

Keywords:

fraction

concentration,

solvent exchange,

solid-phase

extraction,

preparative

chromatography

Original Report

On-Column Solvent Exchangefor Purified Preparative Fractions

*Coand811Fax

221

CopScr

doi

Gilles H. Goetz,1* Emily Beck,2 and Peter W. Tidswell11Pfizer Global Research and Development, Analytical Chemistry and Sample Logistics,

St Louis Laboratories, Chesterfield, MO2School of Medicine, Washington University, St Louis, MO

On-column solvent exchange, using many of the

principles of solid-phase extraction, has been im-

plemented to significantly reduce evaporation cycle time

following reverse-phase preparative HPLC. Additional

benefits, such as a reduced potential for salt formation,

thermal decomposition, and residual solvent, are also

described.

Fractions obtained from preparative separations,

typically in a large volume of acetonitrile:water, are

injected into the preparative HPLC and then eluted in

acetonitrile, creating a new fraction in a volatile organic

solvent. Minimal modification to the instrument was

required, and unattended operation is possible.

Acetonitrile evaporation is achieved within 3 h, compared

with 17 h for aqueous-based fractions; lower

temperatures can be used during the evaporation step;

mobile-phase additives, likely to form salts with the target

compound if concentrated in the fraction, are removed

before evaporation; sample recovery and purity are

unaffected. ( JALA 2011;16:335–46)

INTRODUCTION

Preparative reversed-phase chromatography hasbecome the purification method of choice in the

rrespondence: Gilles H. Goetz, Ph.D., Pfizer Global ResearchDevelopment, Groton laboratories, Eastern Point Road, MS

8W-305, Groton, CT 06340, USA; Phone: þ1.860.715.6311;: þ1.860.715.3345; E-mail: [email protected]

1-0682/$36.00

yright �c 2011 by the Society for Laboratory Automation andeening

:10.1016/j.jala.2010.02.004

pharmaceutical industry for small-molecule early-discovery research. Centralized purification groupsrelying heavily on automation are often responsiblefor bridging the gap between medicinal chemistsand biologists. Along with customized separationconditions, the use of mass-directed fractionationenables the isolation of the target compound fromthe crude mixture effectively and efficiently. Focus-ing on cost- and time-reduction, these centralizedautomated platforms provide a high-quality andhigh-throughput purification platform (Fig. 1).

Within this environment, post-purificationworkup of the collected fractions (including evapo-ration, weighing, reconstitution, and reformattingprocedures) can be time-consuming activities butmust be performed accurately to ensure that the finalproduct is of high quality. In our laboratories, the fi-nal product is formulated as a stock solution ata standard, known concentration with supportingpurity and identity data. It is then sent for immedi-ate testing by project teams, and any remaining ma-terial is held for longer-term storage.

Of the various postpurification procedures, evap-oration to dryness of aqueous/organic matrices isthe most time consuming and represents the bottle-neck of the whole purification operation (withinour laboratories). During this procedure, the col-lected target material must be recovered intact froma solution containing low-volatility solvents (partic-ularly water). Precautions against sample decompo-sition, salt formation, and residual solvent must betaken, because any errors in this step will affect thepurity and/or concentration of the final product.1

Previous reports, mirroring our experiences, haveshown that the chromatography-enhancing additives

JALA October 2011 335

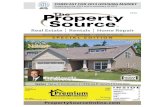

GenevacPrevious Process

17 h

25 min

C 18 Column

8 min 17 hDMSO Water/MeCN

DryPowder

8 min 5 min

Genevac

3 h

C 18 Column C 18 Column

DMSO Water/MeCN MeCN

At Column Solvent Exchange Process Dry Powder

3 h

13 min

Figure 1. At column solvent exchange process improvements.

Original Report

routinely used during preparative liquid chromatography(LC) separations (formic acid, trifluoroacetic acid (TFA),ammonium hydroxide, and others) get concentrated in thefractions during the evaporation process, potentially leadingto salt forms of the target base2 (or, less commonly, acid), tohydrolysis of some functional groups (e.g., esters) or deriva-tization of others (e.g., formylation of amines).

The evaporation procedure used in our laboratories is anincompressible overnight run using reduced-pressure andelevated-temperature programs in Genevac HT24 evapora-tors (Genevac, Gardiner, NY). These programs have beenshown to isolate the target material consistently as a dry solidfrom the solvent matrix (water, organic solvent, and volatileadditive). These programs cannot, however, prevent the for-mation of salts and, in rare cases, the degradation of the finalproduct.

To reduce the time taken for solvent evaporation, avoidsalt formation, and reduce exposure to heat (while still ensur-ing that no residual solvent remains), an investigation intothe removal of water (and HPLC additives) from the frac-tions before the evaporation step was initiated. Various crite-ria were defined, not least that the quality of the final productmust be maintained or improved, little or no capital invest-ment would be required, the existing capabilities of instru-ments would be maintained, and the overall integrity of thepurification platform would not be compromised.

Other authors have recently described solid-phase extrac-tion (SPE) approaches for handling reverse-phase prepara-tive HPLC fractions.3e5 In this study, the Waters (Milford,MA) on-column SPE concept5 is adapted and customized,and the term on-column solvent exchange is used to describethe procedure of loading fractions back onto the preparativeHPLC column under aqueous conditions before elutingthem with acetonitrile to yield a water- and additive-freefraction.

EXPERIMENTAL

Instrumentation

Instrument for Initial Analysis of Crude Compounds. Twoidentical systems consisting of four Waters 1525 micro binarygradient pumps, Waters 2777 sample manager, Waters 2488dual-wavelength absorbance detector, Waters MUX inter-face and system controller, Waters ZQ mass spectrometer,and four Polymer Labs (Shropshire, UK) PL-ELS2100 evap-orative light scattering detectors were used.

Preparative Purification Instrument. Waters 2525 binary gra-dient pump, three Waters 515 HPLC pumps (for at-column-dilution, modifier and MS make-up solvent delivery), Waterspump control module, Waters 2767 sample manager (injec-tionecollection), Waters 2757 sample manager (collection),two Waters 2487 dual-wavelength absorbance detectors,ZQ mass spectrometer, Waters column selector, Watersselector valve (for switching injection mode), two Waters sol-vent selection valves (for additive selection and at-column-

336 JALA October 2011

dilution push solvent selection), and Waters flow splitter(1000:1) made up the preparative instrument. The instrumentwas controlled using MassLynx, version 4.1 SCN627 (Wa-ters, Milford, MA).

Software and Controls. Control of the preparative HPLCcomponents was accomplished through MassLynx, version4.1 SCN627, operating with the FractionLynx applicationmanager (Waters, Milford, MA). MassLynx controls thepumps, detectors, and the injection arm of the sample man-ager, and FractionLynx controls the fraction collection partof the sample manager. The MassLynx sample list providedall the relevant information for the system to perform an in-jection, such as method, sample location, and injection vol-ume. Additional columns were added to the sample list toindicate the specific target mass or masses for the fractioncollection software to monitor. Once the sample was injectedand the appropriate masses entered into the sample list, thecollection software monitored for the target mass. Whenthe target mass was identified, the collection software di-verted the solvent flow through the fraction collector divertervalve to the waiting fraction tube. The collection softwarethat operates the system does not differentiate betweena standard collection routine and this trap and elute routine.

The instruments in the system were controlled through thestandard MassLynx software through General Purpose In-terface Bus (GPIB), Institute of Electrical and ElectronicsEngineers, New York (IEEE), Ethernet, and serial port com-munication. The ultraviolet (UV) detectors operated underIEEE, the primary pump and mass spectrometer were underEthernet control, and the sample managers were controlledthrough serial ports. The three 515 pumps, the selector valve,the solvent modifier selection valve, and the column selectorwere all controlled by contact closures from the primarypump, and the watereacetonitrile solvent selection valvewas operated off-line manually.

Evaporation Systems. Two identical HT24 evaporators wereused for the routine removal of solvents from HPLCfractions.

tneidarG niaMpmuP

H2 NCeM dna O

daoL

reifidoMnmuloC

pU ekaM

rettilpS

etsaW

SM

VU

VU

yramirP xnyL noitcarF

noitcelloC

rotcejnI

pooL elpmaS

evlaV

evlaV

NCeM

H2O

nim/lm 5.62

nim/lm5.2

yradnoceS xnyL noitcarF

noitcelloC

nim/lm1

nim/lm1

Figure 2. Schematic of the modified Waters FractionLynx Instru-ment configured to perform both preparative separations andon-column solvent exchange using direct-injection and at-column-dilution (with acetonitrile or water) injection protocols.

Original Report

Reagents and Materials

Mallinckrodt Baker (Philipsburg, NJ) acetonitrile 20 and4 L, HPLC grade; and EMD Chemicals (Gibbstown, NJ) wa-ter 20 and 4 L, HPLC grade, were used. SigmaeAldrich (St.Louis, MO) ammonium hydroxide American Chemical Soci-ety (ACS) grade reagent and trifluoroacetic acid (TFA) andMallinckrodt Baker formic acid 88% ACS reagent were used.

Waters X-Bridge C18 2.1� 50-mm, 5-mm column; WatersSunFire C18 2.1� 50-mm, 5-mm column; Waters X-BridgePrep C18 optimum bed density (OBD) 19� 50-mm, 5-mmcolumn; Waters X-Bridge Prep C18 OBD 19� 10-mm, 5-mm precolumn; Waters SunFire Prep C18 OBD 19� 50-mm, 5-mm column; Waters SunFire Prep C18 OBD19� 10-mm, 5-mm precolumn; Waters X-Bridge Prep C18OBD 30� 100-mm, 5-mm column; Phenomenex (Torrance,CA) AXIA Gemini C18 110A 21.2� 50-mm, 5-mm column;Phenomenex AXIA Gemini C18 110A 21.2� 10-mm, 5-mmprecolumn; and Waters experimental hydrophilic-lipophilic-balanced (HLB) 19� 50-mm, 30-mm column, were used.

Hardware Configuration

Preinjector Fluidic Pathway. Two modifications to the in-strument were performed; the first was the introduction ofa solvent selection valve for the at-column-dilution pumpto allow the sample to be loaded onto the column with eitheracetonitrile (in preparative mode) or water (in the solvent-exchange mode). In both modes, this pump delivers 20%of the total flow through the instrument when the at-column-dilution injection protocol is used.

The secondmodification inserted a six-port switching valveahead of the in-line T used for at-column-dilution injections.This valve is connected to the column, the sample loop, the2525 pump, and the at-column-dilution pump; it is controlledby MassLynx through contact closures configured in the inleteditor and allows for automated switching between the prepar-ative and solvent-exchange modes (Fig. 2).

Autosampler Valve and Syringe Mechanism. A second sam-ple loop (20 mL), to inject the fractions during the solvent-exchange procedure, was installed alongside the original loop(2 mL) for preparative separations. Both loops can be filledwith the required accuracy and speed using a 10-mL syringe.To maintain autosampler accuracy, the syringe speed is set toaspirate and dispense at 10% maximum motor power(speed).

Autosampler Transfer Tubing. The transfer line volume be-tween the syringe and the needle on the autosampler (alsoknown as the holding loop) was increased from 1.5 to15 mL to accommodate the larger volumes of sample beingaspirated in the on-column solvent-exchange mode.

Collection Delay Timing

To minimize the volume of water collected during thesolvent-exchange procedure, a suitable delay time (from

detection of the compound in the MS to fraction head acti-vation) was found to be 15 s.

Methods

Initial Analysis of Crude Research Compounds. Aliquots(10 mL; 0.1% of the submitted volume) of the crudecompounds were diluted with DMSO (140 mL) to createanalytical samples with a concentration typically between 1and 2 mg/mL.

For acidic LC conditions, formic acid (0.1% v/v) wasadded to both the aqueous and acetonitrile mobile-phase res-ervoirs, and the SunFire C18 2.1� 50-mm, 5-mm column wasinstalled on the instrument.

For basic conditions, ammonium hydroxide (100 mM)was added to both the aqueous and acetonitrile mobile-phase reservoirs, and the X-Bridge C18 2.1� 50-mm, 5-mmcolumn was installed on the instrument.

Under both conditions, an isocratic hold at aqueous:or-ganic (95:5) for 1 min was followed by a linear gradient toaqueous:organic (5:95) during 6.75 min and an isocratic holdat the final set point for 1 min. The instrument was then re-turned to the initial conditions and equilibrated for 1 min.The chromatographic run time was 10 min, and the overallduty cycle was 10.5 min because of the ‘‘inject ahead’’ featureof the autosampler. The method’s flow rate was 1 mL/min;the injection volume was 10 mL; UV detection performed at214 nm, and the Evaporative Light Scattering Detector(ELSD) nebulizer temperature at 40 �C.

Preparative Separation of Flavone. A known accurate weightof flavone (approximately 1 g) was dissolved in DMSO andthen diluted to create a stock solution, typically at eitherthe 30- or the 50-mg/mL level. Aliquots (1.2 mL) were trans-ferred to the matrix tubes with prepierced septa, and 1 mLwas injected into the instrument.

JALA October 2011 337

Original Report

For acidic LC conditions, the modifier pump delivered3% aqueous formic acid at 1 mL/min ahead of a SunFirePrep C18 OBD 19� 50-mm, 5-mm column, equipped witha guard column (30� 10 mm, 5 mm). For basic conditions,the modifier pump delivered 3% aqueous ammonium hy-droxide at 1 mL/min ahead of an X-Bridge Prep C18 OBD30� 100-mm, 5-mm column, equipped with a guard column(30� 10 mm, 5 mm).

Under both conditions, the at-column-dilution solvent se-lector valve was used to select the acetonitrile reservoir(Fig. 3A). The at-column-dilution pump continuously deliv-ered acetonitrile (2.5 mL/min) through the injection valve;the modifier pump continuously delivered an aqueous solu-tion of the additive (1 mL/min), and the 1525 main pumpdelivered a binary gradient (26.5 mL/min) for a total flowof 30 mL/min. An isocratic hold at aqueous:organic (85:15)for 1 min was followed by a linear gradient to

MainGradient

Pump

ColumnA

B

SampleLoop

At-ColumnDilutionPumpON

Acetonitrile Water

MainGradient

Pump

Column

SampleLoop

At-ColumnDilutionPumpON

Acetonitrile Water

Figure 3. (A) Pumping configuration in preparative mode usingat-column-dilution injection protocol. (B) Configuration in on-column solvent-exchange mode using at-column-dilution injectionprotocol.

338 JALA October 2011

aqueous:organic (35:65) during 5.75 min, a column wash inacetonitrile for 1 min, and then a return to the initial condi-tions. Column equilibration occurred during the subsequentaspirate/dispense cycle(s). The run time was 8 min, and theoverall duty cycle was 10 min.

Fractions were collected in tared 18� 100-mm glass tubes,evaporated in an evaporator (see later for conditions), thegross weight was measured, and the net weight was calcu-lated. All fraction tube weights were recorded on the samecustomized Tecan EVO workstation (Tecan Group, Manne-dorf, Switzerland).

Preparative Separation of Caffeine. A known accurate weightof caffeine (1 g) was dissolved in acetonitrile:water (1:1) andthen diluted to create a stock solution, typically at either the30- or the 50-mg/mL level. Aliquots (1.2 mL) were trans-ferred to matrix tubes with prepierced septa, and 1 mL wasinjected into the instrument.

Conditions and practices identical to those used for theseparation of flavone were used, except for the gradient pro-file. An isocratic hold at aqueous:organic (100:0) for 1 minwas followed by a linear gradient to aqueous:organic(80:20) during 5.75 min, a column wash in acetonitrile for1 min, and then a return to the initial conditions. Columnequilibration occurred during the subsequent aspirate/dis-pense cycle(s). The run time was 8 min, and the overall dutycycle was 10 min.

On-Column Solvent Exchange Using Direct Injection. Aknown accurate weight of either flavone or caffeine (approx-imately 1 g) was dissolved in acetonitrile:water (1:1) to createa stock solution, typically at either the 50- or the 70-mg/mLlevel. Aliquots (variable volume) were transferred to18� 100-mm fraction tubes and then diluted to the desiredconcentration with acetonitrile:water (1:1; unless otherwisestated) for a final volume of 10e15 mL.

These samples were injected into the instrument. Researchsamples, as fractions (from preparative experiments; up to18 mL of total volume), were separately injected into the in-strument. For each injection cycle, samples were aspirated inaliquots (10 mL) and dispensed into the injection port; mul-tiple aspirate/dispense cycles before injection valve switchingwere required for volumes greater than 10 mL.

The 1525 main pump continuously delivered water(30 mL/min) through the injection valve ahead of either anX-Bridge Prep C18 OBD 30� 100-mm, 5-mm column, equip-ped with a guard column (30� 10 mm, 5 mm) a Gemini C18110A 21.2� 50-mm, 5-mm column, equipped with a guardcolumn (21.2� 10 mm, 5 mm) or a Waters experimentalHLB (19� 50 mm, 30 mm) column. The at-column-dilutionand modifier pumps were turned off.

An isocratic hold in water for 2 min was followed by anisocratic hold in acetonitrile for 3 min and then a return tothe initial conditions. Column equilibration occurred duringthe subsequent aspirate/dispense cycle(s). For a typical frac-tion volume of 15 mL, the overall run time was 5 min, and

MainGradient

Pump

Column

SampleLoop

Acetonitrile Water

PumpDilution

At-Column

OFF

Figure 4. Configuration in on-column solvent-exchange modeusing direct-injection protocol.

Original Report

the overall duty cycle was 9.5 min. Post-purification practicesidentical to those described earlier measured the final frac-tion weight gravimetrically.

On-Column Solvent Exchange Using At-Column Dilution.Flavone, caffeine, and research samples were prepared anddispensed into the sample loop as described earlier. The samecolumns were also installed on the instrument.

The at-column-dilution solvent selector valve was manu-ally switched over to the water reservoir (Fig. 3B). Initially,the at-column-dilution pump delivered water (6 mL/min)through the injection valve, the 1525 main pump deliveredwater (24 mL/min) directly to the head of the column, andthe modifier pump was turned off. These conditions aremaintained during the injection cycle (6 min). The at-column-dilution pump was then turned off, and the 1525main pump delivered water for two more minutes followedby acetonitrile (30 mL/min) for 3 min to elute the fraction.For a typical fraction volume of 15 mL, the overall run timewas 11 min, and the overall duty cycle was 13 min. Postpur-ification practices identical to those described earlier mea-sured the final fraction weight gravimetrically.

Evaporation

A new short Genevac HT24 program to support thesolvent-exchange process consists of two parts. In the firstpart, rapid ramping from ambient conditions to 250 mbarat 40 �C, then slower ramping to 50 mbar over 15 min, beforerapid ramping to 11 mbar for 45 min, occurs; the second partis a full vacuum stage lasting 2 h at 40 �C. The total cyclelasts for approximately 3 h.

RESULTS AND DISCUSSION

Effects of Changing the Fluidic Pathway

This study was undertaken while attempting to keep anexisting preparative HPLC instrument as close to its opti-mized configuration as possible. All modifications performedneeded to have a low impact on the existing purification plat-form. For example, modifications could only minimallyreduce sample recovery (O90%) and cycle time (!2.5 days).No reduction in final product purity (O80% by UV detec-tion, O85% by ELSD detection, and a 1H NMR spectrumconsistent with these purity results) or increase in manual in-tervention could be tolerated. Additionally, the instrumenthad to remain compatible with the existing infrastructureand work streams.

At the beginning of this study, the instrument was config-ured to deliver an aqueous/organic gradient from the masterpump (2525 pump), with additives being introduced aftermixing by a 515 pump and the sample being injected froma 2767 sample manager using a 515 pump and an at-column-dilution protocol (with acetonitrile as the push sol-vent). Postcolumn UV detection preceded a 1000:1 flow split,with most of the flow being returned to the 2767 sample man-ager for collection, and the remainder of the flow being

diluted with acetonitrile:water:formic acid (60:40:0.1) and en-tering the ZQ mass spectrometer. The MS triggered the 2767fraction collector. When this primary fraction collector wasnot active, material entered the waste stream, where the sec-ond UV detector (2487 dual-wavelength absorbance detec-tor) triggered the second fraction collector (2757 samplemanager) when a UV response was detected. This secondarycollection method ensures that any failure of the MS trigger-ing components does not result in sample loss. It has been inuse successfully in our laboratories for more than 2 years andis similar to the approach described by FitzGibbons et al.6

The six-port switching valve was installed to enable the in-strument to be automatically switched from the direct-injection mode (using the 2525 pump to flush the injectionloop) to the at-column-dilution injection mode.

The first position of six-port switching valve installed dur-ing this study supports the at-column-dilution injection pro-tocol.7 In this mode, the 515 pump delivers a push solventthrough the injection loop, and the 2525 pump delivers theinitial conditions to the head of the column. In this way,the sample is flushed from the injection loop with solventand diluted with the flow from the 2525 pump immediatelybefore entering the column. For preparative separations,the organic modifier (e.g., acetonitrile) is typically used asthe push solvent (Fig. 3A). This valve setting can also be usedin the solvent-exchange mode for polar compounds, becausea fivefold dilution with water is needed to ensure retention onthe column (Fig. 3B; this is described in more detail later).

The second position of six-port switching valve supports di-rect injection of the sample. In this mode, the 2525 pump de-livers the initial conditions through the injection loop to theheadof the columnwhen loading the sample (Fig. 4). Thismodeis not normally used for injection of crude samples for prepara-tive separation in our laboratories, butwas implemented for usewith the on-column solvent-exchange procedure.

The installation of the valve allows the instrument to beswitched between the preparative mode and solvent-

JALA October 2011 339

Figure 5. Measured recoveries of flavone from an instrumentmodified to perform on-column solvent exchange (triangles) andan unmodified instrument (squares).

Original Report

exchange mode without operator intervention, using a con-tact closure within MassLynx methods. The instrumentcan, therefore, run both preparative separations and the sub-sequent solvent-exchange procedures unattended.

The addition of the solvent selection valve enables the at-column-dilution pump to readily switch between acetonitrile,for at-column-dilution injection of the crude compound forpreparative separation, and water, for at-column-dilutionof the purified compound in the on-column solvent-exchangemode. This valve was installed on the low-pressure side of thepump head and had no appreciable effect on the performanceof the injection protocols, chromatographic separation, oroverall instrument performance.

Insertion of the 15-mL transfer line on the autosamplerwas required to support the larger volumes of sample beingaspirated and dispensed in the on-column solvent-exchangemode. The effects on both carryover between modes of oper-ation and injections as well as sample recovery were not mea-sured specifically; however, they were measured as part of theoverall instrument performance and are described in the fol-lowing sections.

Sample Recovery Measurements

One of themost important criteria defined during this studywas to ensure that high sample recoveries of the final productweremaintained. Two separate potential losses ofmaterial canoccur when the on-column solvent-exchange procedure is in-cluded in the overall purification workflowdduring the pre-parative separation and the solvent-exchange procedure.Sample recovery from both modes of operation was assessedto derive an overall recovery measurement.

Sample Recovery During Preparative Liquid Chromatography.Instrument recovery is routinely verified for all preparativeinstruments in our laboratories using a gravimetric assayof flavone. Figure 5 shows the measured sample recoveriesfrom two instruments; one instrument (triangles) was modi-fied to perform on-column solvent exchange during June2008, and the second instrument was not modified. Thisstudy was completed in October 2008, and both instrumentswere subsequently used to support the purification platform.The sample recovery measured from both instruments isconsistently greater than 85% and typically at or above90%. Although it could be argued that the unmodified in-strument recovers more material, the differences are smalland have little effect on the success of the purificationplatform.

Autosampler Syringe Volume Selection. The 2767 autosam-pler supports two fluidic pathways with a single syringeand drive mechanism. The purification platform in our labo-ratories has been optimized for the injection of mixtures sub-mitted in 1 mL of solvent (normally DMSO); hence, it iscritical that the entire sample is injected on to the columnto maximize sample recovery. Therefore, the 2-mL injection

340 JALA October 2011

loop currently installed on the autosampler was retained inone of the flow paths. Based on the maximum volume col-lected in a single fraction tube (18 mL), a 20-mL injectionloop was selected for the second flow path to support on-column solvent exchange.

With such a large volume difference between the two flowpaths, the control of two different syringes to fill the loops ispreferred. Unfortunately, this configuration is not supportedwithin the instrument-control software; hence, a singlesyringe capable of accurately filling both loops had to beselected.

Measuring the gravimetric recovery of flavone (30 mg inDMSO; 1 mL) during the preparative separation, 25- and10-mL syringes were compared with the original 1-mLsyringe. Figure 6 shows that nearly-identical sample recov-eries were observed with the 10- and 1-mL syringes, whereassample recovery was much lower when the 25-mL syringewas used, because the speed of the syringe aspirate and dis-pense steps could not be adequately controlleddsee the fol-lowing. Because one criterion for the acceptable performanceof on-column solvent exchange was to maintain purificationrecovery levels, we sacrificed loading speed (faster using the25-mL syringe) for sample recovery (higher when using the10-mL syringe). This compromise requires any fraction con-taining a volume greater than 10 mL to be loaded using twoaspirate and dispense cycles before the valve switching.

Effects of Altering the Autosampler Syringe Drive Mechanism.The 2767 sample handlers enable customization of the sy-ringe plunger speed as a percentage of full motor power.When aspirating fractions at full speed, during the solvent-exchange procedure, a partial vacuum was created insidethe syringe, because the liquid could not travel through theholding loop fast enough. This resulted in a large portionof the sample remaining in the fraction tube. Similarly, whendispensing into the loop at full speed, the sample leaked fromthe injection port. Combined, these sample losses signifi-cantly reduced sample recovery.

Figure 6. Recovery of flavone (30 mg in DMSO; 1 mL) froma preparative separation using different syringe volumes to performthe injection. Each bar represents an average of three replicateinjections.

Original Report

Visual inspection of the sample still present in the fractiontube after completion of the injection cycle demonstratedthat a syringe motor speed greater than 30% could not beused. To further refine this parameter, recovery of flavone(50 mg in acetonitrile:water [1:1] 15 mL) was measured atmotor speeds of 10% and 30% after the sample been elutedfrom the column in the solvent-exchange mode (Fig. 7).

Sample recovery was closely correlated to both the aspira-tion and dispensing speeds, with slower motor speeds leadingto higher sample recoveries. However, this slower motorspeed increased the length of the overall injection cycle from6 to 7 min. For our application, this increase in cycle timewas an acceptable compromise to ensure that high samplerecoveries were obtained, and the motor speed selected wasthe 10% level.

Overall, installing a 10-mL syringe and using aspirate anddispense speeds at 10% of the maximum motor power

Figure 7. Recovery of flavone (50 mg in acetonitrile:water [1:1]15 mL) in the on-column solvent-exchange mode, using a 10-mLsyringe with different aspirate and dispense speeds. Each bar rep-resents an average of four replicate injections.

ensured that more than 90% of the sample was recovered af-ter both the preparative and on-column solvent-exchangeprocedures were completed.

Effects of Using Multiple Aspirate and Dispense Cycles. Theutility of multiple aspirate and dispense cycles, required be-cause the autosampler syringe volume (10 mL) selected wasapproximately half the size of the injection loop (20 mL),was investigated. This injection protocol did not have anyimpact on sample recovery when loading the contents ofa single fraction tube (Fig. 7); hence, sample recovery wasmeasured after loading from separate fraction tubes. Threeseparate flavone samples (15 mg in acetonitrile:water [1:1]15 mL) were loaded into the loop, then injected onto the col-umn as a single injection using the direct-injection protocol,and eluted into a single tube using acetonitrile. 43.2 mg of fla-vone was recovered, representing a 97% sample recovery.This high level of sample recovery permits the on-column sol-vent-exchange mode to be used to pool different fractions ifdesired.

Retention Behavior of Compounds on Column. Previousreports3e5 have used a fivefold aqueous dilution of fractionsbefore or during the injection protocol to ensure that com-pounds are retained by the C18 column and do not breakthrough with the solvent front.

The results from this laboratory showed that, for the over-whelming majority of compounds purified, no aqueous dilu-tion of the sample was required, and the sample could beretained on column using a direct-injection protocol. Onlythree compounds from a set of 130 samples, representing11 different research projects and 30 chemotypes, were notretained and ‘‘broke through’’ to the solvent front partiallyor completely when using the direct-injection protocol toload, and these three samples could be successfully loaded(with no breakthrough) using the at-column-dilutionprotocol.

These three compounds were the most polar compoundsin the test collection and to mimic this breakthrough behav-ior we selected caffeine, a highly polar and water-solublecompound, to act as a model compound. By developinga method that would retain caffeine, the retention of polarresearch compounds from our laboratories would bepossible.

Samples of caffeine were prepared in various acetonitrile:water ratios and then loaded onto the column using eitherthe direct-injection protocol or the at-column-dilution proto-col (with water acting as the push solvent). Figure 8 showsthat the C18 column did not retain caffeine using either injec-tion protocol when the acetonitrile content was greater than40% and that caffeine was fully retained by both injectionprotocols when the acetonitrile content was 10% or less.When the acetonitrile content was between 10% and 40%,caffeine was completely retained only using the at-column-dilution injection protocol; hence, this injection protocolshould be used for the loading of polar compounds.

JALA October 2011 341

Figure 8. Retention behavior of caffeine (10 mg in various aceto-nitrile:water matrices; 10 mL) using direct-injection and at-column-dilution protocols. Each bar represents an average of two replicateinjections.

Figure 9. Chromatograms of a polar research sample loadedusing the direct-injection protocol (top; approximately 75% break-through) and at-column-dilution injection protocol (bottom; nobreakthrough).

Original Report

During this study, the duty cycle of each injection proto-col was monitored, and the at-column dilution protocol wasfound to be approximately three times longer than the direct-injection protocol. The reason for this is that, to achievea fivefold dilution of the sample with water, the flow throughthe loop is approximately 20% the total-system flow ratewhen the at-column-dilution injection protocol is used (com-pared with 100% of the flow when the direct-injection proto-col is used). In our laboratories, this equates to a 6-mL/minflow through the loop and a 30-mL/min total system flowrate. Under these conditions, the time taken to flush the20-mL injection loop is approximately 3.5 min, and afterallowing for transport time to the column (including anybroadening of the injection band), equilibration and wash-ing, a total injection cycle time of 6 min was determined asoptimal. When loading using the direct-injection protocol,the entire 30-mL/min flow washes the contents of the injec-tion loop onto the column, allowing complete loading ofthe sample in less than 2 min. For polar samples, this in-crease in duty cycle (and hence, the length of the overallmethod) is acceptable, because the corresponding highersample recovery is critical; however, for less-polar samples,where high sample recoveries can be obtained with eitherprotocol, the direct loading protocol is preferred.

To appropriately select the injection protocol needed foreach sample, the retention time observed during initial anal-ysis of the crude sample was used. In our laboratories, thepreparative LC method typically uses a focused gradient de-signed to elute the target compound with a retention timebetween 5 and 6 min (using an 8-min gradient). Selectionof this method is based on the observed retention behaviorof the intended target material and impurities during an ini-tial analysis of the crude material. This initial analysis is per-formed using a generic gradient of acetonitrile in water from5% to 100%, on two identical instruments, one containingthe additive 0.1% formic acid, the other 0.1% ammonium

342 JALA October 2011

hydroxide. From these analyses, the presence of the targetanalyte and its retention time are determined, enabling selec-tion of the appropriate gradient for the preparative run. Be-cause this retention time is related to the molecule’shydrophobicity,8 the retention time can also be used to pre-dict the molecules that are too polar to retain on column ifa direct-injection protocol is used in the on-column solvent-exchange mode.

Correlating the retention time of the set of 130 representa-tive samples with their respective retention time from the ini-tial analysis identified the polar samples that would requirethe use of at-column-dilution injection protocol. Thirteensamples (10% of the set) eluted within 3 min (of the 8-mingradient; approximately 40% acetonitrile) during initial anal-ysis; of these, 10 could be successfully injected onto thecolumn using direct injection, and three required the at-column-dilution injection protocol. A conservative retentiontime threshold of 3 min was, thus, established, to ensure thatno samples would break through during the injection proce-dure. Figure 9 shows a representative chromatogram fromone of the three polar compounds requiring the at-column-dilution injection protocol during the on-column solvent-ex-change procedure.

Conversely, a research sample too lipophilic to elute offthe column during on-column solvent exchange is yet to beencountered. Because the compound must be eluted fromthe column during the preparative separation before on-column solvent exchange, this problem is not anticipated tooccur with any frequency.

Collection Delay Timing. Collection parameters were opti-mized to minimize the volume of water that was collectedwith the target compound without compromising sample-recovery levels. This principally involved setting a delay timebetween target detection by the mass spectrometer and col-lection valve triggering. During initial instrument

Figure 11. Sample recovery of flavone (in acetonitrile:water[1:1] 10 or 15 mL) in the on-column solvent-exchange mode.Samples were loaded using a flow rate of either 75 mL/min (graydiamonds) or 30 mL/min (black diamonds) onto either a 19� 50-mm column (!100 mg) or a 30� 100-mm column (O100 mg).

Original Report

qualification in our laboratories, this delay time is establishedwith a colored performance test mixture, but for ongoingperformance verification (and this study), sample recoverywas determined gravimetrically using flavone.

The volume of water collected in the fraction tube wasmeasured visually against a graduated fraction tube afterthe first stage of the new evaporation program was complete.The recovery of flavone was measured gravimetrically aftercompletion of the entire HT24 program. The results areshown in Figure 10.

More than 90% of the injected flavone was recoveredwhen the delay time was between 7 and 15 s. No water wasvisible for delay times more than 14 s. Therefore, a delay timeof 15 s was selected, to maximize sample recovery and mini-mize residual water content.

Correlation of Sample Recovery With Mass. To mimic sam-ples typically received in our laboratories, accurately weighedknown amounts of flavone ranging from 5 to 300 mg weredissolved in acetonitrile:water (1:1) in volumes ranging from10 to 15 mL and prosecuted through the on-column solvent-exchange procedure using the direct-injection protocol. Thelower-weight samples, from 5 to 100 mg, were loaded ontoa 19� 50-mm, 5-mm column using a 30-mL/min flow rate;the higher-weight samples, from 50 to 300 mg, were loadedonto a 30� 100-mm, 5-mm column using either a 30-mL/min flow rate (dark diamonds in Fig. 11) or a 75-mL/minflow rate (light squares). After collection, all the sampleswere dried, weighed, and the sample recovery was calculated.

For samples weighing more than 100 mg, sample recov-eries at or above 90% were observed; for compounds weigh-ing less than 100 mg, sample recoveries greater than 85%were observed for most samples. The variability in samplerecovery increased as sample mass decreased for reasons thatare not clear. A common rationale for decreased samplerecovery is that a consistent amount of material is lost

Figure 10. Residual water and sample recovery of flavone(25 mg in DMSO; 0.5 mL) using various delay times to triggerthe fraction collector. Each bar represents an average of three rep-licate injections.

(e.g., at the start and the end of the peak) in every injection,and this loss represents a higher percentage of material as thetotal-sample weight decreases. This could explain the lowerrecoveries observed when using smaller samples; however,many recovery values greater than 95% were observed fromessentially identical samples. The robustness of instrumentperformance can also affect sample recovery; this data setwas acquired over a period of 2 months and (as shown inFig. 5), recovery varies over time independent of the sampletype. These variations are frequently attributed to columnand precolumn conditions, timing adjustments, minorrepairs, and other preventative maintenance procedures,although no specific investigation was conducted as a partof this study. Ultimately, recovery values greater than 85%were regarded as acceptable within our application. Interro-gation of this data set of 189 recovery experiments did notshow any significant differences in sample recovery betweensamples prepared in 10 and 15 mL of solvent (data notshown).

Total Sample Recovery. Combining the sample recovery re-sults from the preparative separation with those from theon-column solvent-exchange procedure showed that between80% and 90% of the available sample could be reliably re-covered from the overall workflow. These results were vali-dated by directly measuring compound recovery throughthe entire workflow (Fig. 12).

Injection Carryover

Carryover was assessed by bracketing a solvent blank(acetonitrile:water [1:1] 10 mL) between flavone fractions(acetonitrile:water [1:1] 10 mL). The mass of flavone was

JALA October 2011 343

Figure 13. Chromatograms of flavone (20 mg in acetonitrile:water [1:1] 10 mL; top and bottom) bracketing a blank sample(middle).

Original Report

increased from 20 to 50 mg in 10-mg increments. No flavonewas detected by UV or MS in any of the blank injections, asshown in the example in Figure 13.

Evaporation

The standard reduced pressure with elevated-temperatureevaporation program used in our laboratories for aqueousHPLC fractions consists of three stages. The first one, ramp-ing rapidly from ambient conditions to 300 mbar and 50 �C,then more gradually to 40 mbar over 90 min, and remainingat the set point for 90 min, distills off volatile organic compo-nents (such as acetonitrile) without bumping; the secondstage, at 8 mbar and 50 �C for 12 h, evaporates less-volatilecomponents (e.g., water and volatile additives, such as formicacid and any residual acetonitrile); the last stage, at 2 mbarand 45 �C for 2 h, evaporates any residual solvents and addi-tives. The whole evaporation procedure lasts more than 17 h,is on the critical path and so is the bottleneck of ourpurification operation.

The revised evaporation program, described earlier, runsfor 3 h at a lower temperature. This removes the restrictionthat evaporation cycles have to run overnight, allowingdownstream operations to begin on the same day as the pre-parative separation; increases the effective capacity of theevaporators, because multiple evaporation cycles can berun every day if required; reduces the likelihood of thermaldegradation, because the sample is exposed to lower temper-atures for a shorter time; and chromatography additives arenot concentrated in the early stages of the evaporation cycle.

Removal of Chromatographic Modifiers

Chromatographic modifiers, such as TFA, formic acid,and ammonium hydroxide, are widely used in many labora-tories (including ours) to improve peak shape and enhanceresolution during chromatographic separations. Although

Figure 12. Recovery of flavone (30e50 mg in DMSO; 1 mL)after preparative separation, evaporation, weighing, reconstitutionin acetonitrile:water (1:1; 15 mL) on-column solvent exchange,evaporation, and weighing. Each bar represents an average ofthree replicate injections.

344 JALA October 2011

typically used in low concentrations, these additives are col-lected with the target compound during fractionation andconcentrated during the initial stages of evaporation. Thepresence of these additives can, occasionally, lead to the de-composition of the final product; however, more commonly,they react with the product to form salts. These salt formsimpact downstream processes and affect final product qual-ity. In our laboratories, the immediate effect is an error dur-ing the reconstitution procedure because the final product isformulated as a solution at a standard concentration(30 mM), and the incorrect assignment of a salt form can re-duce the actual concentration of the target material by up to20%, affecting the interpretation of biochemical assayresults. Later processes, such as biological screening, can alsobe impacted by the presence of salts. A dramatic example isthe negative impact of TFA on cultures of osteoblasts andchondrocytes even at concentrations less than 100 nM.9

Using 19F NMR monitoring, Boughtflower et al.3 showedthe effectiveness of SPE for TFA removal from fractionseluting from HPLC columns. The advantage of TFAremoval from fractions before evaporation has become a rou-tine application of on-column solvent exchange in our labo-ratories. In one example, a project team prepared a series ofcompounds using a motif similar to that reported by Buckleyet al.10 (Fig. 14). These compounds could not be purified informic acid (because of a risk of formylating an exposed pri-mary amine), ammonium hydroxide (the azetidine ring wasbase labile), or TFA (incompatible with the biological assay).A purification method using TFA was selected, immediatelyfollowed by on-column solvent exchange using direct injec-tion and evaporation under the revised evaporation condi-tions. The free-base form of the final product wassuccessfully isolated in high recovery (typically 95%; weightsranging from 1 to 20 mg) and tested without any interferencefrom TFA.

In a second example, a project team separated diastereo-mers using supercritical fluid chromatography (SFC) withan ammonium acetate additive. Because the biological assay

Figure 14. Generic structure of a compound requiring TFA pu-rification and on-column solvent exchange.

Original Report

could not tolerate any residual additive or acetate salts, thecompounds were desalted using on-column solvent exchange(with the direct-injection protocol). The alcohol matrix fromthe SFC separation was evaporated using a rotovap (becausecompound stability was not an issue) and then the materialwas reconstituted in acetonitrile:water (1:1) (9 mL) for theon-column solvent-exchange procedure. Subsequent evapo-ration of the acetonitrile using the revised Genevac condi-tions yielded the free base of the final product(approximately 40 mg of each isomer; structure not shown).

Comparison of Solid-Phase Material

Comparison of the X-Bridge or Sunfire columns with theGemini columns demonstrated no significant differences insample recovery or method run times (data not shown).Because the Waters columns are routinely used within ourexisting purification platform, these were selected for detailedinvestigation.

Evaluation of an experimental Waters hydrophobicelipo-philic balanced copolymer (HLB 30 mm) column demon-strated performance similar to the X-Bridge column whenmeasuring loadability and retention capacity for flavoneand cortisone. However, significant breakthrough wasobserved for many other test compounds11 (e.g., metronida-zole, amitriptyline hydrochloride, and labetalol; 25 mg eachin acetonitrile:water [1:1] 11 mL). Additionally, a significantvolume of water was collected with the target compound dur-ing elution, extending the evaporation time required. Conse-quently, further studies using the HLB column were notperformed.

Use of Reversed Flow for Elution

To reduce elution time, solvent volume, and the risk ofresidual water in the final fraction, the feasibility of elutingthe fraction using a reverse acetonitrile flow through the col-umn was investigated. Flavone (25 mg in acetonitrile:water[1:1] 12 mL) was injected onto the column using an unmod-ified direct-injection protocol, the column was then reversed,and the sample was eluted with acetonitrile. High recoveries(O90%) were achieved; however, residual water volumes inthe fraction were also observed. Because there was also nostraightforward solution to automate switching flow direc-tion, further development of this approach was not pursued.

Future Work

Preliminary data show that on-column solvent exchangecould be used to remove DMSO from samples. In our labo-ratories, excess final product is stored as a dry material, re-quiring the evaporation of DMSO from the stock solution.Historically, this has been achieved using high-temperatureand reduced-pressure Genevac programs combined with ly-ophilization procedures, which are time consuming and,sometimes, do not completely remove the DMSO.

Using the on-column solvent-exchange procedure, thestock solution can be loaded onto a C18 column and elutedin acetonitrile before solvent evaporation. Initial results dem-onstrate that samples in DMSO must be loaded using anat-column-dilution protocol to avoid sample breakthrough.Significant back pressure is observed during the sample dis-pense step, and this needs to be mitigated before this ap-proach is robust enough to be used within our purificationplatform.

The worldwide shortage of acetonitrile has encouragedmany laboratories to adopt methanol as their organic modi-fier. In our laboratories, methanol has already replacedacetonitrile for many preparative separations but not foron-column solvent exchange. The weaker elutropic strength(and the corresponding compound solubility) and higher vis-cosity (leading to back-pressure concerns) of methanol needto be investigated before making this transition.

CONCLUSION

At the outset of this study, a procedure to reduce the poten-tial for salt formation, residual solvent, and sample exposureto elevated temperatures for extended times during evapora-tion was envisaged. It was critical that this on-column sol-vent-exchange procedure did not decrease the quality of thefinal product or the amount recovered from our automatedpurification platform. It was also important that the cycletime from sample submission to availability for biologicaltesting did not increase. A final requirement was that minimalcapital expenditure would be required to achieve this goal.

The results clearly demonstrate that all of these objectiveswere achieved. Sample recovery is typically at or greater than85% of the submitted mass. Sample purity, as measured byUV, ELSD, and 1H NMR, is not affected. Overall samplequality is frequently increased, because the formation of saltforms can be avoided, enabling more accurate formulation ofthe compounds and eliminating potential interferences inbiochemical assays. Samples can be evaporated to completedryness within 3 h of the completion of the preparative sep-aration (compared with overnight using previous practices),allowing subsequent procedures to start earlier.

ACKNOWLEDGMENTS

The authors acknowledge Paul Lefebvre (Averica Discovery Services) for

describing the initial concept, Ronan Cleary (Waters) for discussions and

editing comments, and Jason Ramsay (Pfizer) for his contributions to the

hardware modifications.

JALA October 2011 345

Original Report

Competing Interests Statement: The authors certify that they have no relevant

financial interests in this manuscript.

REFERENCES

1. Yan, B.; Fan, L.; Irving, M.; Zhang, S.; Boldi, A. M.; Woolard, F.;

Johnson, C. R.; Kshirsagar, T.; Figliozzi, G. M.; Krueger, C. A.; Col-

lins, N. Quality control in combinatorial chemistry: determination of

the quantity, purity, and quantitative purity of compounds in combina-

torial libraries. J. Comb. Chem. 2003, 5, 547e559.

2. Hochlowski, J.; Cheng, X.; Sauer, D.; Djuric, S. Studies of the relative

stability of TFA adducts vs non-TFA analogues for combinatorial

chemistry library members in DMSO in a repository compound collec-

tion. J. Comb. Chem. 2003, 5, 345e350.

3. Boughtflower,B.;Lane,S.;Mutton, I.; Stasica,P.Generic compound isolation

using solid-phase trappingaspart of the chromatographicpurificationprocess.

Part 1. Proof of generic trapping concept. J. Comb. Chem. 2006, 8, 441e454.

4. Stevens, J.; Crawford, M.; Robinson, G.; Roenneburg, L. Automated

post-collection concentration for purified preparative fractions via solid

phase extraction. J. Chromatogr. A. 2007, 1142, 81e83.

5. Lefebvre, P.; Cleary,R.; Potts,W. III; Plumb,R.A.NovelApproach forRe-

ducing Fraction Drydown Time. Waters Corporation (Milford, MA); 2007;

720002097EN.

346 JALA October 2011

6. FitzGibbons, J.; Op, S.; Hobson, A.; Schaffter, L. Novel approach to

optimization of a high-throughput semipreparative LC/MS system.

J. Comb. Chem. 2009, 11, 592e597.

7. Neue, U. D.; Mazza, C. B.; Cavanaugh, J. Y.; Lu, Z.; Wheat, T. E. At-

column dilution for improved loading in preparative chromatography.

Chromatographia 2003, 57(Suppl.), S121eS126.

8. Valko, K.; Bevan, C.; Reynolds, D. Chromatographic Hydrophobicity

Index by fast-gradient RP-HPLC: a high-throughput alternative to log

P/log D. Anal. Chem. 1997, 69, 2022e2029.

9. Cornish, J.; Callon, K. E.; C. Lin, Q.-X.; Xiao, C. L.; Mulvey, T. B.;

Cooper, G. J. S.; Reid, I. R. Trifluoroacetate, a contaminant in purified

proteins, inhibits proliferation of osteoblasts and chondrocytes. Am. J.

Physiol. Endocrinol. Metab. 1999, 40, E779eE783.

10. Buckley,G.M.; Fosbeary,R.; Fraser, J. L.;Gowers, L.;Higueruelo,A. P.;

James, L. A.; Jenkins, K.;Mack, S. R.;Morgan, T.; Parry, D.M.; Pitt,W.

R.; Rausch, O.; Richard, M. D.; Sabin, V. IRAK-4 inhibitors. Part III:

a series of imidazo[1,2- a]pyridines. Bioorg. Med. Chem. Lett. 2008, 18,

3656e3660.

11. Li, S.; Julien, L.; Tidswell, P.; Goetzinger, W. Enhanced performance

test mix for high-throughput LC/MS analysis of pharmaceutical com-

pounds. J. Comb. Chem. 2006, 8, 820e828.