Jeep Cherokee XJ 1995-1999 Instrument Panel and Gauges

description

Transcript of Jeep Cherokee XJ 1995-1999 Instrument Panel and Gauges

INSTRUMENT PANEL AND GAUGES

GROUP INDEX

INSTRUMENT PANEL AND GAUGES—XJ . . . . . . 1 INSTRUMENT PANEL AND GAUGES—YJ . . . . . 24

INSTRUMENT PANEL AND GAUGES—XJ

CONTENTS

page page

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 1

SERVICE PROCEDURES . . . . . . . . . . . . . . . . . . 17SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 23

GENERAL INFORMATION

Following are general descriptions of major instru-ment panel components. Refer to Group 8W - WiringDiagrams for complete circuit descriptions and dia-grams.

INSTRUMENT PANELModular instrument panel construction allows all

gauges and controls to be serviced from the front ofthe panel. In addition, most instrument panel wiringor heater and air conditioning components can be ac-cessed without complete instrument panel removal. Ifnecessary, the instrument panel can be rolled-downand removed from the vehicle as an assembly.

Removal of the instrument cluster bezel allows ac-cess to the cluster assembly, most switches, the cli-mate controls, and the radio. Removal of the clusterassembly allows access to the individual gauges, illu-mination and indicator lamp bulbs, printed circuits,and most wiring.

Removal of the lower instrument panel allows ac-cess to heater and air conditioning components, thefuseblock module, the relay center, and other wiringand electrical components. Those models equippedwith a driver’s-side airbag restraint have a kneeblocker and reinforcement behind the driver’s-sidelower instrument panel.

The instrument panel layout is mirror image forleft-hand and right-hand drive vehicles. In mostcases, the diagnosis and service procedures found inthis group are applicable to either vehicle. Although,

most illustrations represent only the typical left-handdrive version. Exceptions are clearly identified asRight-Hand Drive (RHD).

INSTRUMENT CLUSTERSTwo basic instrument cluster options are offered on

XJ (Cherokee) models. One is referred to as a low-line cluster, and the other is referred to as a high-line cluster. Each cluster is divided into two areas:the gauge area, and the tell-tale area. Each area isserved by a separate printed circuit and wiring con-nector. Some variations of each cluster exist due tooptional equipment and regulatory requirements.

The low-line cluster includes the following gauges:• fuel gauge• speedometer/odometer.

The low-line cluster includes provisions for the fol-lowing indicator lamps:• anti-lock brake system lamp• brake warning lamp• coolant temperature warning lamp• four-wheel drive indicator lamps• generator warning lamp• headlamp high beam indicator lamp• low oil pressure warning lamp• low washer fluid warning lamp• malfunction indicator (Check Engine) lamp• seat belt reminder lamp• turn signal indicator lamps• upshift indicator lamp.

J INSTRUMENT PANEL AND GAUGES 8E - 1

The high-line cluster includes the following gauges:• coolant temperature gauge• fuel gauge• oil pressure gauge• speedometer/odometer• tachometer• trip odometer• voltmeter.

The high-line cluster includes provisions for the fol-lowing indicator lamps:• anti-lock brake system lamp• brake warning lamp• four-wheel drive indicator lamps• headlamp high beam indicator lamp• low fuel warning lamp• low washer fluid warning lamp• malfunction indicator (Check Engine) lamp• seat belt reminder lamp• turn signal indicator lamps• upshift indicator lamp.

GAUGESWith the ignition switch in the ON or START posi-

tion, voltage is supplied to all gauges through the in-strument cluster gauge area printed circuit. With theignition switch in the OFF position, voltage is notsupplied to the gauges. A gauge pointer may remainwithin the gauge scale after the ignition switch isOFF. However, the gauges do not accurately indicateany vehicle condition unless the ignition switch isON.

All gauges except the odometer are air core mag-netic units. Two fixed electromagnetic coils are lo-cated within the gauge. These coils are wrapped atright angles to each other around a movable perma-nent magnet. The movable magnet is suspendedwithin the coils on one end of a shaft. The gauge nee-dle is attached to the other end of the shaft.

One of the coils has a fixed current flowing throughit to maintain a constant magnetic field strength.Current flow through the second coil changes, whichcauses changes in its magnetic field strength. Thecurrent flowing through the second coil can bechanged by:• a variable resistor-type sending unit (fuel level,coolant temperature, or oil pressure)• changes in electrical system voltage (voltmeter)• electronic control circuitry (speedometer/odometer,tachometer).

The gauge needle moves as the movable permanentmagnet aligns itself to the changing magnetic fieldscreated around it by the electromagnets.

COOLANT TEMPERATURE GAUGEThe coolant temperature gauge gives an indication

of engine coolant temperature. The coolant tempera-ture sending unit is a thermistor that changes elec-trical resistance with changes in engine coolant

temperature. High sending unit resistance causeslow coolant temperature readings. Low resistancecauses high coolant temperature readings.

The gauge will read at the high end of the scalewhen the ignition switch is turned to the START po-sition. This is caused by the bulb test circuit wiringprovision. The same wiring is used for the high-linecluster with a coolant temperature gauge and thelow-line cluster with a coolant temperature warninglamp. Sending unit resistance values are shown in achart in Specifications.

FUEL GAUGEThe fuel gauge gives an indication of the level of

fuel in the fuel tank. The fuel gauge sending unit hasa float attached to a swing-arm in the fuel tank. Thefloat moves up or down within the fuel tank as fuellevel changes. As the float moves, an electrical con-tact on the swing-arm wipes across a resistor coil,which changes sending unit resistance. High sendingunit resistance causes low fuel level readings. Lowresistance causes high fuel level readings. Sendingunit resistance values are shown in a chart in Spec-ifications.

OIL PRESSURE GAUGEThe oil pressure gauge gives an indication of en-

gine oil pressure. The combination oil pressure send-ing unit contains a flexible diaphragm. Thediaphragm moves in response to changes in engineoil pressure. As the diaphragm moves, sending unitresistance increases or decreases. High resistance onthe gauge side of the sending unit causes high oilpressure readings. Low resistance causes low oilpressure readings. Sending unit resistance values areshown in a chart in Specifications.

SPEEDOMETER/ODOMETERThe speedometer/odometer gives an indication of

vehicle speed and travel distance. The speedometerreceives a vehicle speed pulse signal from the VehicleSpeed Sensor (VSS). An electronic integrated circuitcontained within the speedometer reads and analyzesthe pulse signal. It then adjusts the ground path re-sistance of one electromagnet in the gauge to controlneedle movement. It also sends signals to an electricstepper motor to control movement of the odometernumber rolls. Frequency values for the pulse signalare shown in a chart in Specifications.

The VSS is mounted to an adapter near the trans-mission (two-wheel drive) or transfer case (four-wheeldrive) output shaft. The sensor is driven through theadapter by a speedometer pinion gear. The adapterand pinion vary with transmission, transfer case,axle ratio and tire size. Refer to Group 21 - Trans-mission and Transfer Case for more information.

8E - 2 INSTRUMENT PANEL AND GAUGES—XJ J

TACHOMETERThe tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the enginerunning, the tachometer receives an engine speedpulse signal from the Powertrain Control Module(PCM). An electronic integrated circuit containedwithin the tachometer reads and analyzes the pulsesignal. It then adjusts the ground path resistance ofone electromagnet in the gauge to control needlemovement. Frequency values for the pulse signal areshown in a chart in Specifications.

TRIP ODOMETERThe trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-ever, by depressing the trip odometer reset knob onthe face of the speedometer, the trip odometer can bereset to zero. The trip odometer is serviced only as apart of the speedometer/odometer gauge assembly.

VOLTMETERThe voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-dicates battery or generator output voltage,whichever is greater.

INDICATOR LAMPSIndicator lamps are located in two areas within the

cluster. Each of these areas is served by a separateprinted circuit and cluster connector. Those lamps inthe gauge area of the cluster share the gauge areaprinted circuit and cluster connector A. Those lampsin the tell-tale area of the cluster use the tell-taleprinted circuit and cluster (tell-tale) connector B.

Up to ten indicator lamps can be found in the tell-tale area of the cluster. These lamps are arranged infive stacked rows with two lamps in each row, locatedto the driver’s side of the main cluster.

ANTI-LOCK BRAKE SYSTEM LAMPThe Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The modulelights the lamp when the ignition switch is turned tothe START position as a bulb test. The lamp willstay on for 3 to 5 seconds after vehicle start-up to in-dicate a system self-test is in process. If the lamp re-mains on after start-up, or comes on and stays onwhile driving, it may indicate that the ABS modulehas detected a system malfunction or that the systemhas become inoperative. Refer to Group 5 - Brakesfor more information.

BRAKE WARNING LAMPThe brake warning lamp warns the driver that the

parking brake is applied or that the pressures in thetwo halves of the split brake hydraulic system areunequal. With the ignition switch turned ON, battery

voltage is supplied to one side of the indicator bulb. Aground path for the bulb is provided by 3 switches.The bulb will light when:• the brake warning switch is closed (indicating un-equal brake system hydraulic pressures possibly dueto brake fluid leakage)• the ignition switch is in the START position (bulbtest)• the parking brake switch is closed (parking brakeis applied).

Refer to Group 5 - Brakes for more information.

COOLANT TEMPERATURE WARNING LAMPThe coolant temperature warning lamp lights

whenever engine coolant temperature is too high.Battery voltage is supplied to one side of the indica-tor bulb when the ignition switch is turned ON. Thenormally open coolant temperature switch is con-nected to the other side of the bulb. When coolanttemperature is too high, the switch closes. This pro-vides a ground path for the indicator bulb, whichcauses it to light. The lamp is also grounded andshould light with the ignition switch in the STARTposition as a bulb test.

FOUR-WHEEL DRIVE INDICATOR LAMPS

PART TIMEOn vehicles with Command-Trac 4WD, the Part

Time lamp lights when the transfer case is engagedin the 4H or 4L position. On vehicles with Selec-Trac4WD, the Part Time lamp lights when the transfercase is engaged in the 4 X 4 PART TIME or 4 LO po-sition. Voltage is supplied to one side of the indicatorbulb. A switch in the transfer case is connected to theother side of the indicator bulb. When the switch isclosed, a path to ground is provided and the indicatorbulb lights.

FULL TIMEThe Full Time lamp is only operational on vehicles

equipped with Selec-Trac 4WD. The Full Time lamplights when the transfer case is engaged in the 4 X 4Full Time position. Voltage is supplied to one side ofthe indicator bulb. A switch in the transfer case isconnected to the other side of the indicator bulb.When the switch is closed, a path to ground is pro-vided and the indicator bulb lights.

GENERATOR WARNING LAMPThe generator warning lamp lights with the igni-

tion switch turned to ON, but should go out when-ever the engine is running. If the lamp comes on andstays on while the engine is running, it indicatesthat a charging system malfunction exists. One sideof the bulb is connected to ignition-switched batteryfeed. The other side of the bulb is switched to groundby the Powertrain Control Module (PCM).

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 3

HEADLAMP HIGH BEAM INDICATOR LAMPThe high beam indicator lamp is controlled by the

headlamp dimmer (multi-function) switch. One sideof the indicator bulb is grounded at all times. Theother side of the bulb receives battery feed throughthe contacts of the dimmer switch when the multi-function switch stalk is actuated to turn the head-lamp high beams on. Refer to Group 8L - Lamps formore information.

LOW FUEL WARNING LAMPA Light-Emitting Diode (LED) on the face of the

fuel gauge will light when the fuel level falls belowapproximately 4 gallons. A low fuel warning moduleattached to the rear of the fuel gauge controls whenthe LED will light. When the module senses 66.5ohms or more resistance from the fuel level sendingunit for 10 continuous seconds, the LED will light.When the module senses 63.5 ohms or less resistancefrom the fuel level sending unit for 20 continuousseconds, the LED is turned off.

LOW OIL PRESSURE WARNING LAMPThe low oil pressure warning lamp lights with the

ignition switch in the ON position and the engine notrunning. The lamp should be off when the engine isrunning. Battery voltage is supplied to one side ofthe indicator bulb when the ignition switch is turnedON. The warning lamp side of the combination oilpressure sending unit is connected to the other sideof the bulb. When normal engine oil pressure is ap-plied to the sending unit, resistance on the warninglamp side is high and the lamp goes off. When engineoil pressure is too low, resistance on the warninglamp side of the sending unit is low, which causesthe bulb to light.

LOW WASHER FLUID WARNING LAMPThe low washer fluid warning lamp indicates when

the fluid level in the washer reservoir is too low. Thewasher fluid level sensor uses a float in the reservoirto monitor fluid level. The action of the float opens orcloses the switch within the sensor that provides ig-nition-switched battery voltage to the lamp bulb. Re-fer to Group 8K - Wiper and Washer Systems formore information.

MALFUNCTION INDICATOR LAMPThe CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch isturned ON, and stays on for 3 seconds as a bulb test.If the Powertrain Control Module (PCM) receives anincorrect signal or no signal from certain fuel or

emission system related circuits or components, thelamp is turned on. This will indicate that the PCMhas recorded a Diagnostic Trouble Code (DTC) inelectronic memory for a circuit or component mal-function. Refer to Group 14 - Fuel System for moreinformation.

SEAT BELT REMINDER LAMPThe seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-sition. A timer in the chime/buzzer module controlsignition-switched battery feed to the lamp. Refer toGroup 8U - Chime/Buzzer Warning Systems for moreinformation.

TURN SIGNAL INDICATOR LAMPSThe left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning(multi-function) switches. One side of the bulb foreach lamp is grounded at all times. The other side ofthe bulb receives battery feed through the contacts ofthe multi-function switch when the turn signal lever(multi-function switch stalk) or hazard warning but-ton are actuated. Refer to Group 8J - Turn Signaland Hazard Warning Systems for more information.

UPSHIFT INDICATOR LAMPVehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed forthe lamp is switched by the Powertrain Control Mod-ule (PCM). The lamp lights to indicate when thedriver should shift to the next highest gear for bestfuel economy. The PCM will turn the lamp off after 3to 5 seconds if the upshift is not performed. The lampwill remain off until the vehicle stops acceleratingand is brought back to the range of lamp operation,or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-tion switch is turned ON and is turned off when theengine is started. The lamp will be turned on duringvehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPSAll cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblockmodule through the panel dimmer rheostat of theheadlamp switch. When the park or headlamps areon, the cluster illumination lamps light. Illuminationbrightness can be adjusted by rotating the headlampswitch knob (clockwise to dim, counterclockwise tobrighten).

8E - 4 INSTRUMENT PANEL AND GAUGES—XJ J

DIAGNOSIS

GAUGESIf an individual gauge is inoperative, see the diag-

nostic procedure under the heading for that gauge. Ifmore than one gauge is inoperative, perform the fol-lowing:

(1) Check fuse 17 (fuse 26 - RHD) in the fuseblockmodule. If OK, go to next step. If not OK, replacefuse.

(2) Check for battery voltage at fuse 17 (fuse 26 -RHD) with ignition switch in ON position. If OK, goto next step. If not OK, repair open in circuit fromignition switch and/or refer to Group 8D - IgnitionSystems for testing of ignition switch.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Disconnect gauge cluster connectorA.

(4) Connect battery negative cable. Turn ignitionswitch to ON. Check for battery voltage at cavity A8(cavity A7 - RHD) of cluster connector A. If OK, go tonext step. If not OK, repair open in circuit from fuse17 (fuse 26 - RHD) as required.

(5) Turn ignition switch to OFF. Disconnect batterynegative cable. Probe cavities A3 and B2 of clusterconnector A. Check for continuity to a good ground.There should be continuity. If OK, replace gaugecluster printed circuit. If not OK, repair open in cir-cuit as required.

COOLANT TEMPERATURE GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with cooling systemperformance. Actual engine coolant temperatureshould be checked with a test gauge or thermometerand compared to gauge readings before you proceedwith gauge diagnosis. Refer to Group 7 - Cooling Sys-tem for more information.

(1) Turn ignition switch to ON. Disconnect coolanttemperature sending unit connector. Sending unit(Fig. 1) is located near the left rear corner of the cyl-inder head. The gauge needle should move to low endof gauge scale. If OK, go to next step. If not OK, go tostep 3.

(2) Install a jumper wire from sending unit wiringto ground. The gauge needle should move to high endof gauge scale. If OK, replace sending unit. If notOK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Disconnect gauge cluster connectorA.

(4) Probe cavity A1 of cluster connector A. Checkfor continuity to a good ground. There should be no

continuity. If OK, go to next step. If not OK, repairshort in circuit as required.

(5) Still probing cavity A1 of cluster connector A,check for continuity to sending unit wiring connector.There should be continuity. If OK, replace gauge. Ifnot OK, repair open in circuit as required.

FUEL GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with fuel tank. In-spect fuel tank for signs of damage or distortion thatcould affect sending unit performance before you pro-ceed with gauge diagnosis. Refer to Group 14 - FuelSystem for more information.

(1) Turn ignition switch to ON. Disconnect fuelgauge sending unit connector. Connector is locatednear the left front corner of the fuel tank. The gaugeneedle should move to low end of gauge scale. If OK,go to next step. If not OK, go to step 4.

(2) Connect a jumper wire between terminals Aand B in the body half of the fuel gauge sending unitconnector (Fig. 2). The gauge needle should move tohigh end of gauge scale. If OK, refer to Group 14 -Fuel System for procedure to replace sending unit. Ifnot OK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Check for continuity between termi-nal A in the body half of fuel gauge sending unit con-nector and a good ground. There should becontinuity. If OK, go to next step. If not OK, repaircircuit to ground as required.

(4) Remove instrument cluster bezel and clusterassembly. Disconnect instrument cluster connector A.

Fig. 1 Coolant Temperature Switch/Sending Unit -Typical

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 5

(5) Probe cavity B1 of cluster connector A. Checkfor continuity to a good ground. There should be nocontinuity. If OK, go to next step. If not OK, repairshort circuit as required.

(6) Still probing cavity B1 of cluster connector A,check for continuity to cavity B of sending unit bodyhalf connector. There should be continuity. If OK, re-place gauge. If not OK, repair open circuit as re-quired.

OIL PRESSURE GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with engine oiling sys-tem performance. Actual engine oil pressure shouldbe checked with a test gauge and compared to gaugereadings before you proceed with gauge diagnosis.Refer to Group 9 - Engines for more information.

(1) Turn ignition switch to ON. Disconnect oil pres-sure sending unit connector. The sending unit (Fig. 3)is located on right side of engine block. On 2.5L en-gine, it is just forward of ignition distributor and justto the rear of generator mounting bracket. On 4.0Lengine, it is just to the rear of ignition distributorand above oil filter adapter. The gauge needle shouldmove to high end of gauge scale. If OK, go to nextstep. If not OK, go to step 3.

(2) Install a jumper wire from sending unit wiringto ground. The gauge needle should move to low endof gauge scale. If OK, replace sending unit. If notOK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Disconnect instrument cluster con-nector A.

(4) Probe cavity B7 (cavity B8 - RHD) of clusterconnector A. Check for continuity to a good ground.There should be no continuity. If OK, go to next step.If not OK, repair short circuit as required.

(5) Still probing cavity B7 (cavity B8 - RHD) ofcluster connector A, check for continuity to sendingunit wire connector. There should be continuity. IfOK, replace gauge. If not OK, repair open circuit asrequired.

SPEEDOMETER/ODOMETERThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with incorrect speed-ometer pinion, axle ratio or tire size. Refer to Group21 - Transmission and Transfer Case for more infor-mation.

(1) Perform vehicle speed sensor test as describedin the appropriate Powertrain Diagnostic Proceduresmanual. If OK, go to next step. If not OK, replace ve-hicle speed sensor.

(2) Disconnect battery negative cable. Unplug vehi-cle speed sensor, PCM, and daytime running lampmodule connectors. Remove instrument cluster bezeland cluster assembly. Disconnect instrument clusterconnector A.

(3) Probe cavity A5 (cavity B6 - RHD) of clusterconnector A. Check for continuity to a good ground.There should be no continuity. If OK, go to next step.If not OK, repair short circuit as required.

(4) Still probing cavity A5 (cavity B6 - RHD) ofcluster connector A, check for continuity to cavity 1 ofvehicle speed sensor connector (Fig. 4). There shouldbe continuity. If OK, replace speedometer/odometer. Ifnot OK, repair open circuit as required.

TACHOMETER(1) With engine running, check for tachometer sig-

nal at pin 43 of PCM connector (Fig. 5). See Tachom-eter Calibration chart in Specifications. If OK, go tonext step. If not OK, replace PCM.

Fig. 2 Fuel Gauge Sending Unit Connector Fig. 3 Oil Pressure Switch/Sending Unit - Typical

8E - 6 INSTRUMENT PANEL AND GAUGES—XJ J

(2) Disconnect battery negative cable. Unplug PCMconnector. Remove instrument cluster bezel and clus-ter assembly. Disconnect instrument cluster connec-tor A.

(3) Probe cavity A6 of cluster connector A. Checkfor continuity to a good ground. There should be nocontinuity. If OK, go to next step. If not OK, repairshort circuit as required.

(4) Still probing cavity A6 of cluster connector A,check for continuity to cavity 43 of PCM connector.There should be continuity. If OK, replace tachome-ter. If not OK, repair open circuit as required.

TRIP ODOMETERIf the trip odometer is inoperative, but the speed-

ometer/odometer functions are unaffected, replacespeedometer assembly. If speedometer/odometer func-tions are affected, see Speedometer/Odometer diagno-sis in this section.

VOLTMETER(1) Turn ignition switch to ON. Voltmeter should

read battery voltage. If all gauges except voltmeterare OK, go to next step. If other gauges are inopera-tive, see Gauges in this section for diagnosis.

(2) Using an accurate test voltmeter, measure bat-tery voltage at battery. Compare this reading to in-strument cluster voltmeter reading. Now seeVoltmeter Calibration chart in Specifications. If volt-meter does not perform to specification, replace volt-meter.

Fig. 4 Vehicle Speed Sensor Connector

Fig. 5 Powertrain Control Module Connector

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 7

LOW-LINE GAUGE CLUSTER

8E - 8 INSTRUMENT PANEL AND GAUGES—XJ J

HIGH-LINE GAUGE CLUSTER (LHD)

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 9

TELL-TALE CLUSTER (LHD)

8E - 10 INSTRUMENT PANEL AND GAUGES—XJ J

CLUSTER CONNECTORS (RHD)

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 11

INDICATOR LAMPSIf an individual indicator lamp is inoperative, see

the diagnostic procedure under the heading for thatlamp. If more than one indicator lamp or a combina-tion of lamps and gauges in the gauge area of the in-strument cluster is inoperative, see Gauges in thissection for diagnosis.

If more than one indicator lamp in the tell-talearea of the cluster is inoperative, perform the follow-ing:

(1) Check fuse 17 (fuse 26 - RHD) in the fuseblockmodule. If OK, go to next step. If not OK, replacefuse.

(2) Check for battery voltage at fuse 17 (fuse 26 -RHD) with ignition switch in ON position. If OK, goto next step. If not OK, repair circuit to ignitionswitch and/or refer to Group 8D - Ignition Systemsfor testing of ignition switch.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Unplug cluster (tell-tale) connectorB.

(4) Connect battery negative cable. Turn ignitionswitch to ON. Check for battery voltage at cavities 3,4, and 14 (cavities 3 and 14 - RHD) of cluster connec-tor B. If OK, go to next step. If not OK, repair opencircuit to fuse 17 (fuse 26 - RHD) as required.

(5) Turn ignition switch to OFF. Disconnect batterynegative cable. Probe cavity 16 (cavity 1 - RHD) ofcluster connector B. Check for continuity to a goodground. There should be continuity. If OK, replacecluster tell-tale printed circuit. If not OK, repair opencircuit to ground as required.

ANTI-LOCK BRAKE SYSTEM LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the ABS lamp stays on with the ig-nition switch in the ON position, or comes on andstays on while driving, refer to Group 5 - Brakes fordiagnosis. If no ABS problem is found, the followingprocedure will help locate a short or open in the ABSlamp circuit.

(1) Disconnect battery negative cable. Remove in-strument cluster bezel and cluster assembly. Discon-nect ABS control module connector.

(2) Install a jumper wire between cavity 6 of clus-ter (tell-tale) connector B and a good ground. Connectbattery negative cable and turn ignition switch toON. Lamp should light. If OK, remove jumper wireand go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable and unplug cluster connector B. Checkfor continuity between cavity 6 of cluster connector Band a good ground. There should be no continuity. IfOK, go to next step. If not OK, repair short circuit asrequired.

(4) Check continuity between cavity 6 of clusterconnector B and cavity 52 of ABS control module con-nector (Fig. 6). There should be continuity. If OK, re-fer to Group 5 - Brakes for diagnosis of ABS controlmodule. If not OK, repair open circuit as required.

BRAKE WARNING LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the brake warning lamp stays onwith the ignition switch in the ON position and theparking brake released, refer to Group 5 - Brakes fordiagnosis. If no service brake or parking brake prob-lem is found, the following procedure will help locatea short circuit or faulty switch.

(1) Unplug parking brake switch connector. Turnignition switch to START position. Lamp shouldlight. Release ignition switch to ON position. Lampshould go OFF. If OK, go to step 10. If not OK, go tonext step.

(2) Unplug brake warning switch connector. Installa jumper wire between two cavities of connector.Turn ignition switch to START. Lamp should light.Remove jumper wire and lamp should go off. If OK,replace brake warning switch. If not OK, removejumper wire and go to next step.

(3) Turn ignition switch to ON position. Install ajumper wire between cavity B (cavity A - RHD) ofbrake warning switch connector and a good ground.Lamp should light. If OK, go to step 5. If not OK, goto next step.

(4) Turn ignition switch to OFF. Remove jumperwire and disconnect battery negative cable. Removeinstrument cluster bezel and cluster assembly. Installa jumper wire between cavity 8 (cavity 9 - RHD) ofcluster (tell-tale) connector B and a good ground.

Fig. 6 ABS Control Module Connector

8E - 12 INSTRUMENT PANEL AND GAUGES—XJ J

Connect battery negative cable and turn ignitionswitch to ON. Lamp should light. If OK, repair opencircuit to brake warning switch. If not OK, replacebulb.

(5) Turn ignition switch to OFF and removejumper wire. Disconnect battery negative cable.Check for continuity between cavity A (cavity B -RHD) of brake warning switch connector and a goodground with ignition switch in START position.There should be continuity. If not OK, go to nextstep.

(6) Turn ignition switch to OFF and removejumper wire. Disconnect battery negative cable. Un-plug ignition switch connector. Check for continuitybetween ignition switch connector cavity 3 and agood ground. There should be no continuity. If OK, goto next step. If not OK, repair short circuit betweenignition switch and brake warning switch connectorsas required.

(7) Check for continuity between ignition switchconnector cavity 3 and brake warning switch connec-tor cavity A (cavity B - RHD). There should be conti-nuity. If OK, go to next step. If not OK, repair opencircuit as required.

(8) Check for continuity between metal steeringcolumn jacket and a good ground. There should becontinuity. If OK, go to next step. If not OK, refer toGroup 19 - Steering to check steering column groundclip installation.

(9) Turn ignition switch to START position andhold there. Check for continuity between terminal 3of ignition switch and a good ground. There shouldbe continuity. If not OK, replace ignition switch.

(10) Unplug brake warning switch connector.Check for continuity between parking brake switchconnector and a good ground. There should be nocontinuity. If OK, go to next step. If not OK, repairshort circuit as required.

(11) Check for continuity between parking brakeswitch connector and cavity B (cavity A - RHD) ofbrake warning switch connector. There should becontinuity. If OK, replace parking brake switch. Ifnot OK, repair open circuit to brake warning switchas required.

COOLANT TEMPERATURE WARNING LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-lated to lamp accuracy, be certain to confirm thatproblem is with lamp and not with cooling systemperformance. Actual engine coolant temperatureshould be checked with a test gauge or thermometerbefore proceeding with lamp diagnosis. Refer toGroup 7 - Cooling System for more information.

(1) Turn ignition switch to START position. Lampshould light. If OK, go to next step. If not OK, go tostep 3.

(2) Turn ignition switch to ON. Disconnect coolanttemperature switch connector (Fig. 1). Jump switchconnector to ground. Lamp should light. If OK, re-place switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Unplug coolant temperature switchconnector. Remove instrument cluster bezel and clus-ter assembly. Disconnect cluster connector A andprobe cavity A1. Check for continuity to a goodground. There should be no continuity. If OK, go tonext step. If not OK, repair short circuit to coolanttemperature switch or ignition switch as required.

(4) Connect cluster connector A to cluster. Install ajumper wire from cavity A1 of cluster connector A toa good ground. Connect battery negative cable andturn ignition switch to ON. Lamp should light. If OK,repair open circuit to coolant temperature switch orignition switch as required. If not OK, replace bulb.

FOUR-WHEEL DRIVE INDICATOR LAMPS(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switchoperation, replace if bad. If bulb is OK, repair opento indicator.

GENERATOR WARNING LAMP(1) Disconnect battery negative cable and unplug

PCM connector. Install a jumper wire between cavity36 of PCM connector (Fig. 5) and a good ground. Con-nect battery negative cable and turn ignition switchto ON. Lamp should light. Unplug jumper wire andlamp should go off. If OK, refer to Powertrain Diag-nostic Procedures to check PCM. If not OK, go tonext step.

(2) Turn ignition switch to OFF and disconnectbattery negative cable. Remove instrument clusterbezel and cluster assembly. Install a jumper wire be-tween cavity B8 of cluster connector A and a goodground. Connect battery negative cable and turn ig-nition switch to ON. Lamp should light. If OK, go tonext step. If not OK, replace bulb.

(3) Turn ignition switch to OFF and disconnectbattery negative cable. Unplug cluster connector A.Probe cavity B8 of cluster connector A and check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortcircuit as required.

(4) Check for continuity between cavity B8 of clus-ter connector A and cavity 36 of PCM connector.There should be continuity. If not OK, repair opencircuit as required.

HEADLAMP HIGH BEAM INDICATOR LAMP(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer toGroup 8L - Lamps for diagnosis of headlamp system.

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 13

(2) Disconnect battery negative cable. Remove in-strument cluster bezel and cluster assembly. Unplugcluster connector A. Connect battery negative cable.Turn headlamps on and select high beam. Check forbattery voltage at cavity A4 of cluster connector A. IfOK, replace indicator bulb. If not OK, repair circuitto headlamp dimmer (multi-function) switch as re-quired.

LOW FUEL WARNING LAMP(1) Check that fuel gauge is operating as designed.

See Fuel Gauge Calibration chart in Specifications. IfOK, go to next step. If not OK, see Fuel Gauge inthis section for diagnosis.

(2) With at least 10 gallons of fuel in fuel tank, un-plug fuel tank sending unit connector. Turn ignitionswitch to ON and wait 10 seconds. Lamp (LED)should light. Reconnect fuel tank sending unit andwait 20 seconds. Lamp (LED) should go off. If notOK, replace low fuel warning lamp module.

LOW OIL PRESSURE WARNING LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-lated to lamp accuracy, be certain to confirm thatproblem is with lamp and not with engine oiling sys-tem. Actual engine oil pressure should be checkedwith a test gauge before you proceed with lamp diag-nosis. Refer to Group 9 - Engines for more informa-tion.

(1) Turn ignition switch to ON. Lamp should light.Start engine. Lamp should go off. If not OK, turn en-gine off and go to next step.

(2) Unplug connector at oil pressure switch (Fig.3). The switch is located on right side of engine block.On 2.5L engine, it is just forward of ignition distrib-utor and just to the rear of generator mountingbracket. On 4.0L engine, it is just to the rear of igni-tion distributor and above oil filter adapter. Install ajumper wire from connector to a good ground. Turnignition switch to ON. Lamp should light. Unplugjumper wire. Lamp should go out. If OK, replace oilpressure switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Install a jumper wire from cavityB7 (cavity B8 - RHD) of cluster connector A to a goodground. Connect battery negative cable and turn ig-nition switch to ON. Lamp should light. If OK, go tonext step. If not OK, replace lamp bulb.

(4) Turn ignition switch to OFF. Disconnect batterynegative cable. Unplug instrument cluster connectorA. Check continuity between cavity B7 (cavity B8 -RHD) of cluster connector A and a good ground.There should be no continuity. If OK, go to next step.If not OK, repair short circuit as required.

(5) Check continuity between cavity B7 (cavity B8- RHD) of cluster connector A and oil pressure switch

connector. There should be continuity. If not OK, re-pair open circuit as required.

LOW WASHER FLUID WARNING LAMP(1) Unplug washer fluid level switch connector.

Turn ignition switch to ON. Check for battery voltageat connector cavity A. If OK, turn ignition switch toOFF and go to next step. If not OK, repair open cir-cuit to fuse F6 in PDC.

(2) Install a jumper wire from cavity A to cavity Bof washer fluid level switch connector. Turn ignitionswitch to ON. Lamp should light. Unplug jumper andlamp should go OFF. If OK, replace washer fluidlevel switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Unplug instrument cluster (tell-tale) connector B. Check continuity between cavity 16(cavity 1 - RHD) of cluster connector B and a goodground. There should be continuity. If OK, plug clus-ter connector B back into cluster and go to next step.If not OK, repair open circuit to ground as required.

(4) Connect battery negative cable. Install ajumper wire from a 12-volt battery feed to cavity 1(cavity 16 - RHD) of cluster connector B. Lampshould light. If OK, go to next step. If not OK, re-place bulb.

(5) Disconnect battery negative cable. Unplug clus-ter connector B. Check continuity between cavity 1(cavity 16 - RHD) of cluster connector B and a goodground. There should be no continuity. If OK, go tonext step. If not OK, repair short circuit to switch asrequired.

(6) Check continuity between cavity 1 (cavity 16 -RHD) of cluster connector B and cavity B of washerfluid level switch connector. There should be continu-ity. If not OK, repair open circuit to switch as re-quired.

MALFUNCTION INDICATOR LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays onwith engine running, refer to Group 14 - Fuel Systemfor diagnosis. If no fuel or emission system problemis found, the following procedure will help locate ashort or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCMconnector. Install a jumper wire from cavity 32 ofPCM connector (Fig. 5) to a good ground. Connectbattery negative cable. Turn ignition switch to ON.Lamp should light. Remove jumper wire and lampshould go OFF. If OK, refer to Powertrain DiagnosticProcedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove instrument cluster bezel andcluster assembly. Install a jumper wire from cavity 2(cavity 15 - RHD) of cluster (tell-tale) connector B toa good ground. Connect battery negative cable. Turn

8E - 14 INSTRUMENT PANEL AND GAUGES—XJ J

ignition switch to ON. Lamp should light. If OK, goto next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Unplug cluster connector B. Check forcontinuity between cavity 2 (cavity 15 - RHD) of clus-ter connector B and a good ground. There should beno continuity. If OK, go to next step. If not OK, re-pair short circuit to PCM as required.

(4) Check continuity between cavity 2 (cavity 15 -RHD) of cluster connector B and cavity 32 of PCMconnector. There should be continuity. If not OK, re-pair open circuit to PCM as required.

SEAT BELT REMINDER LAMP(1) Refer to Group 8U - Chime/Buzzer Warning

Systems to check chime/buzzer module operation. IfOK, go to next step. If not OK, replace chime/buzzermodule.

(2) Disconnect battery negative cable. Remove in-strument cluster bezel and cluster assembly. Unplugcluster (tell-tale) connector B. Check for continuitybetween cavity 16 (cavity 1 - RHD) of cluster connec-tor B and a good ground. There should be continuity.If OK, plug cluster connector B back into cluster andgo to next step. If not OK, repair open circuit toground as required.

(3) Connect battery negative cable. Install ajumper wire between a 12-volt battery feed and cav-ity 15 (cavity 2 - RHD) of cluster connector B. Lampshould light. If OK, go to next step. If not OK, re-place bulb.

(4) Disconnect battery negative cable. Unplugchime/buzzer module from fuseblock module (connec-tor near fuseblock module - RHD). Unplug clusterconnector B. Check for continuity between cavity 15(cavity 2 - RHD) of cluster connector B and a goodground. There should be no continuity. If OK, go tonext step. If not OK, repair short circuit to chime/buzzer module as required.

(5) Check continuity between cavity 15 (cavity 2 -RHD) of cluster connector B and cavity for terminalA3 of chime/buzzer module (Fig. 7) in fuseblock mod-ule (connector near fuseblock module - RHD). Thereshould be continuity. If not OK, repair open circuit tochime/buzzer module as required.

TURN SIGNAL INDICATOR LAMPS(1) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Probecavity A3 of cluster connector A. Check for continuityto a good ground. There should be continuity. If OK,go to next step. If not OK, repair open circuit toground.

(2) Connect battery negative cable. Install ajumper wire from cavity A2 (left indicator) or cavityB6 (cavity B7 - RHD)(right indicator) of cluster con-nector A to a 12-volt battery feed. Lamp should light.If OK, continue to next step. If not OK, replace bulb.

(3) Disconnect battery negative cable. Check forcontinuity between cavity A2 (left indicator) or cavityB6 (cavity B7 - RHD)(right indicator) of cluster con-nector A and cavity A1 (cavity 11 - RHD)(left frontturn signal) or cavity F2 (cavity 10 - RHD)(rightfront turn signal) of bulkhead disconnect (dash to in-strument panel connector B - RHD). There should becontinuity. If OK, refer to Group 8J - Turn Signaland Hazard Warning Systems for further diagnosis.If not OK, repair open circuit as required.

UPSHIFT INDICATOR LAMP(1) Disconnect battery negative cable. Unplug PCM

connector. Connect battery negative cable. Turn igni-tion switch to ON. Install a jumper wire from cavity54 of PCM connector (Fig. 5) to a good ground. Lampshould light. Remove jumper from ground. Lampshould go off. If OK, refer to Powertrain DiagnosticProcedures manual to diagnose PCM. If not OK, turnignition switch to OFF and go to next step.

(2) Disconnect battery negative cable. Remove in-strument cluster bezel and cluster assembly. Install ajumper wire from cavity 7 of cluster (tell-tale) con-nector B to a good ground. Connect battery negativecable. Turn ignition switch to ON. Lamp should light.If OK, go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Unplug cluster connector B. Check forcontinuity between cavity 7 of cluster connector Band a good ground. There should be no continuity. IfOK, go to next step. If not OK, repair short circuit asrequired.

(4) Check for continuity between cavity 7 of clusterconnector B and cavity 54 of PCM connector. Thereshould be continuity. If not OK, repair open circuit asrequired.

Fig. 7 Chime/Buzzer Module Receptacle

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 15

CLUSTER ILLUMINATION LAMPS(1) Check fuse 19 (fuse 25 - RHD) in fuseblock

module. If OK, go to next step. If not OK, replacefuse.

(2) Turn park lamps on at headlamp switch. Rotateheadlamp switch knob counterclockwise to just beforeinterior lamps detent. Check for battery voltage atfuse 19 (fuse 25 - RHD) in fuseblock module. Rotateheadlamp switch clockwise while observing test volt-meter. Reading should go from battery voltage to zerovolts. If OK, go to next step. If not OK, repair opencircuit to headlamp switch or refer to Group 8L -Lamps to diagnose headlamp switch.

(3) Disconnect battery negative cable. Remove in-strument cluster bezel and cluster assembly. Unplugcluster connector A. Connect battery negative cable.

Turn park lamps on at headlamp switch. Rotateheadlamp switch knob counterclockwise to just beforeinterior lamps detent. Check for battery voltage atcavity A7 (cavity A6 - RHD) of cluster connector A. IfOK, go to next step. If not OK, repair open circuit tofuse as required.

(4) Turn park lamps off. Disconnect battery nega-tive cable. Remove fuse 19 (fuse 25 - RHD) from fuse-block module. Probe cavity A7 (cavity A6 - RHD) ofcluster connector A. Check for continuity to a goodground. There should be no continuity. If OK, go tonext step. If not OK, repair short circuit as required.

(5) Probe cavity A3 of cluster connector A. Checkfor continuity to ground. There should be continuity.If not OK, repair open circuit as required.

8E - 16 INSTRUMENT PANEL AND GAUGES—XJ J

SERVICE PROCEDURES

CLUSTER ASSEMBLY REMOVE/INSTALL(1) Disconnect battery negative cable.(2) Remove upper and lower steering column

shrouds and steering column to instrument panel be-zel gap hider. If equipped with tilt steering, applytape to tilt mechanism on top of steering column toprotect instrument panel bezel from damage duringremoval.

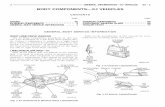

(3) Remove 4 instrument cluster bezel attachingscrews and remove bezel. Bezel is snap fit at loca-tions shown (Fig. 8).

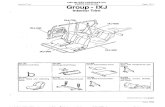

(4) Remove cigar lighter housing attaching screws(Fig. 9).

(5) If equipped, remove switch housing(s) attachingscrews (Fig. 9).

(6) Remove cluster assembly attaching screws (Fig.9).

(7) Pull cluster assembly far enough out to discon-nect 2 cluster harness connectors from the rear. Re-move cluster assembly.

(8) Reverse removal procedures to install.

GAUGES REMOVE/INSTALL(1) Remove cluster assembly as described in Clus-

ter Assembly Remove/Install.

Fig. 8 Cluster Bezel Remove/Install

Fig. 9 Cluster Assembly Remove/Install

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 17

(2) If equipped with trip odometer, gently pullknob off trip odometer push pin. Remove cluster lens

and mask (Fig. 10).

Fig. 10 Instrument Cluster

8E - 18 INSTRUMENT PANEL AND GAUGES—XJ J

(3) Remove gauge attaching screws from rear ofcluster housing (Fig. 11). Remove gauge from front ofhousing.

(4) Reverse removal procedures to install.

PRINTED CIRCUIT REMOVE/INSTALL

GAUGE CLUSTER(1) Remove cluster assembly as described in Clus-

ter Assembly Remove/Install.(2) Remove all gauges as described in Gauges Re-

move/Install.(3) Remove screw holding the cluster connector re-

taining strap to cluster housing. Remove strap andpivot connector down (Figs. 12 and 13).

(4) Remove all lamp holders from printed circuit.(5) Remove printed circuit including connector.(6) Reverse removal procedures to install.

TELL-TALE CLUSTER(1) Remove cluster assembly as described in Clus-

ter Assembly Remove/Install.(2) Remove all lamp holders from printed circuit.(3) Remove printed circuit.(4) Reverse removal procedures to install.

HEADLAMP SWITCH REMOVE/INSTALL(1) Disconnect battery negative cable.

(2) Place headlamp switch control knob in theheadlamp ON position.

Fig. 11 Printed Circuit Remove/Install

Fig. 12 Cluster Connector Retaining Strap

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 19

(3) Reach under the instrument panel and depressthe switch shaft release/retainer button (Fig. 14).Pull the switch control knob and shaft outward.

(4) Remove the headlamp switch retaining nutfrom the front of the instrument panel (Fig. 15).

(5) Disconnect the wire harness connector from theswitch.

(6) Remove the headlamp switch from the instru-ment panel.

(7) Reverse removal procedures to install.

INSTRUMENT PANEL REMOVE/INSTALL(1) Disconnect battery negative cable.(2) Remove the following (Fig. 16):

• parking brake release handle• lower heat/AC duct below steering column• ash receiver• lower instrument panel• cluster bezel• cluster assembly• radio• climate control panel• instrument panel switches• headlamp switch• antenna connector• blower motor resistors• ground lead• unplug glove box lamp• defroster cowl outlet panel

Remove driver’s side heat/AC outlet to gainaccess to driver’s side defroster cowl outletpanel retaining clip to aid in removal (Fig. 17).• instrument panel attaching bolts• steering column attaching bolts• instrument panel assembly.

The instrument panel wiring harness is at-tached to the back of the instrument panel as-sembly and must be installed correctly.

(3) To install instrument panel, position instru-ment panel assembly on side mounting bolts (Fig.18).

(4) Route wiring harnesses and secure instrumentpanel assembly mounting points.

(5) Connect tube to lap cooler.(6) Reverse removal procedures to complete instal-

lation.

Fig. 13 Printed Circuit And Cluster Connector

Fig. 14 Headlamp Switch Knob And Shaft Remove/Install

Fig. 15 Headlamp Switch Remove/Install

8E - 20 INSTRUMENT PANEL AND GAUGES—XJ J

Fig. 16 Instrument Panel Exploded View

Fig. 17 Driver’s Side Defroster Cowl Retaining Clip

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 21

Fig. 18 Instrument Panel Install

8E - 22 INSTRUMENT PANEL AND GAUGES—XJ J

SPECIFICATIONSGAUGE CLUSTER

J INSTRUMENT PANEL AND GAUGES—XJ 8E - 23

INSTRUMENT PANEL AND GAUGES—YJ

CONTENTS

page page

INSTRUMENT PANEL AND GAUGES—YJ . . . . . 22DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23GENERAL INFORMATION . . . . . . . . . . . . . . . . . 20

SERVICE PROCEDURES . . . . . . . . . . . . . . . . . . 31SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 39

GENERAL INFORMATION

Following are general descriptions of major instru-ment panel components. Refer to Group 8W - WiringDiagrams for complete circuit descriptions and dia-grams.

INSTRUMENT PANELModular instrument panel construction allows all

gauges and controls to be serviced from the front ofthe panel. In addition, most instrument panel wiringand heater components can be accessed without com-plete instrument panel removal.

Removal of the left instrument cluster bezel allowsaccess to the main cluster assembly and mostswitches. Removal of the center cluster bezel allowsaccess to the gauge package cluster assembly, theheater controls, and the radio. Removal of the clusterassemblies allows access to the individual gauges, il-lumination and indicator lamp bulbs, printed cir-cuits, and most wiring.

INSTRUMENT CLUSTERSThe instrument cluster used on YJ (Wrangler) mod-

els consists of two separate assemblies. The maincluster assembly is located on the left side of the in-strument panel, centered over the steering columnopening. The gauge package cluster assembly is lo-cated near the center of the instrument panel. Eachcluster assembly is served by a separate printed cir-cuit and wiring connector. Some variations of eachcluster exist due to optional equipment and regula-tory requirements.

The main cluster assembly includes a speedometer/odometer/trip odometer and a tachometer. It also in-cludes provisions for the following indicator lamps:• anti-lock brake system lamp• brake warning lamp• headlamp high beam indicator lamp• malfunction indicator (Check Engine) lamp• seat belt reminder lamp

• turn signal indicator lamps• upshift indicator lamp.

The gauge package cluster assembly includes afour-wheel drive indicator lamp and the followinggauges:• coolant temperature gauge• fuel gauge• oil pressure gauge• voltmeter.

GAUGESWith the ignition switch in the ON or START posi-

tion, voltage is supplied to all gauges through thetwo cluster printed circuits. With the ignition switchin the OFF position, voltage is not supplied to thegauges. A gauge pointer may remain within thegauge scale after the ignition switch is OFF. How-ever, the gauges do not accurately indicate any vehi-cle condition unless the ignition switch is ON.

All gauges except the odometer are air core mag-netic units. Two fixed electromagnetic coils are lo-cated within the gauge. These coils are wrapped atright angles to each other around a movable perma-nent magnet. The movable magnet is suspendedwithin the coils on one end of a shaft. The gauge nee-dle is attached to the other end of the shaft.

One of the coils has a fixed current flowing throughit to maintain a constant magnetic field strength.Current flow through the second coil changes, whichcauses changes in its magnetic field strength. Thecurrent flowing through the second coil can bechanged by:• a variable resistor-type sending unit (fuel level,coolant temperature, or oil pressure)• changes in electrical system voltage (voltmeter)• electronic control circuitry (speedometer/odometer,tachometer).

8E - 24 INSTRUMENT PANEL AND GAUGES—YJ J

The gauge needle moves as the movable permanentmagnet aligns itself to the changing magnetic fieldscreated around it by the electromagnets.

COOLANT TEMPERATURE GAUGEThe coolant temperature gauge gives an indication

of engine coolant temperature. The coolant tempera-ture sending unit is a thermistor that changes elec-trical resistance with changes in engine coolanttemperature. High sending unit resistance causeslow coolant temperature readings. Low resistancecauses high coolant temperature readings. Sendingunit resistance values are shown in a chart in Spec-ifications.

FUEL GAUGEThe fuel gauge gives an indication of the level of

fuel in the fuel tank. The fuel gauge sending unit hasa float attached to a swing-arm in the fuel tank. Thefloat moves up or down within the fuel tank as fuellevel changes. As the float moves, an electrical con-tact on the swing-arm wipes across a resistor coil,which changes sending unit resistance. High sendingunit resistance causes high fuel level readings. Lowresistance causes low fuel level readings. Sendingunit resistance values are shown in a chart in Spec-ifications.

OIL PRESSURE GAUGEThe oil pressure gauge gives an indication of en-

gine oil pressure. The combination oil pressure send-ing unit contains a flexible diaphragm. Thediaphragm moves in response to changes in engineoil pressure. As the diaphragm moves, sending unitresistance increases or decreases. High resistance onthe gauge side of the sending unit causes high oilpressure readings. Low resistance causes low oilpressure readings. Sending unit resistance values areshown in a chart in Specifications.

SPEEDOMETER/ODOMETERThe speedometer/odometer give an indication of ve-

hicle speed and travel distance. The speedometer re-ceives a vehicle speed pulse signal from the VehicleSpeed Sensor (VSS). An electronic integrated circuitcontained within the speedometer reads and analyzesthe pulse signal. It then adjusts the ground path re-sistance of one electromagnet in the gauge to controlneedle movement. It also sends signals to an electricstepper motor to control movement of the odometernumber rolls. Frequency values for the pulse signalare shown in a chart in Specifications.

The VSS is mounted to an adapter near the trans-fer case output shaft. The sensor is driven throughthe adapter by a speedometer pinion gear. Theadapter and pinion vary with transmission, axle ratioand tire size. Refer to Group 21 - Transmission andTransfer Case for more information.

TACHOMETERThe tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the enginerunning, the tachometer receives an engine speedpulse signal from the Powertrain Control Module(PCM). An electronic integrated circuit containedwithin the tachometer reads and analyzes the pulsesignal. It then adjusts the ground path resistance ofone electromagnet in the gauge to control needlemovement. Frequency values for the pulse signal areshown in a chart in Specifications.

TRIP ODOMETERThe trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-ever, by depressing the trip odometer reset knob onthe face of the speedometer, the trip odometer can bereset to zero. The trip odometer is serviced only as apart of the speedometer/odometer gauge assembly.

VOLTMETERThe voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-dicates battery or generator output voltage,whichever is greater.

INDICATOR LAMPSAll indicator lamps, except the four-wheel drive in-

dicator, are located in the main cluster tell-tale areaabove the steering column opening. Each of thelamps is served by the main cluster printed circuitand cluster connector. The four-wheel drive indicatorlamp is located in the gauge package cluster and isserved by the gauge package printed circuit and clus-ter connector.

Up to eleven indicator lamps can be found in thetell-tale area of the main cluster. These lamps are ar-ranged in two rows, with six lamps in the upper rowand five lamps in the lower row.

ANTI-LOCK BRAKE SYSTEM LAMPThe Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The modulelights the lamp when the ignition switch is turned tothe START position as a bulb test. The lamp willstay on for 3 to 5 seconds after vehicle start-up to in-dicate a system self-test is in process. If the lamp re-mains on after start-up, or comes on and stays onwhile driving, it may indicate that the ABS modulehas detected a system malfunction or that the systemhas become inoperative. Refer to Group 5 - Brakesfor more information.

BRAKE WARNING LAMPThe brake warning lamp warns the driver that the

parking brake is applied or that the pressures in thetwo halves of the split brake hydraulic system areunequal. With the ignition switch turned ON, battery

J INSTRUMENT PANEL AND GAUGES—YJ 8E - 25

voltage is supplied to one side of the indicator bulb. Aground path for the bulb is provided by 3 switches.The bulb will light when:• the brake warning switch is closed (indicating un-equal brake system hydraulic pressures possibly dueto brake fluid leakage)• the ignition switch is in the START position (bulbtest)• the parking brake switch is closed (parking brakeis applied).

Refer to Group 5 - Brakes for more information.

FOUR-WHEEL DRIVE INDICATOR LAMPThis lamp lights when the transfer case is engaged

in the 4H or 4L position. Voltage is supplied to oneside of the indicator bulb. A switch on the front axledisconnect housing is connected to the other side ofthe indicator bulb. When the switch is closed, a pathto ground is provided and the indicator bulb lights.

HEADLAMP HIGH BEAM INDICATOR LAMPThe high beam indicator lamp is controlled by the

headlamp dimmer switch. One side of the indicatorbulb is grounded at all times. The other side of thebulb receives battery feed through the contacts of thedimmer switch when the turn signal switch lever isactuated to turn the headlamp high beams on. Referto Group 8L - Lamps for more information.

MALFUNCTION INDICATOR LAMPThe CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch isturned ON, and stays on for 3 seconds as a bulb test.If the Powertrain Control Module (PCM) receives anincorrect signal or no signal from certain fuel oremission system related circuits or components, thelamp is turned on. This will indicate that the PCMhas recorded a Diagnostic Trouble Code (DTC) inelectronic memory for a circuit or component mal-function. Refer to Group 14 - Fuel System for moreinformation.

SEAT BELT REMINDER LAMPThe seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-

sition. A timer in the chime/buzzer module controlsignition-switched battery feed to the lamp. Refer toGroup 8U - Chime/Buzzer Warning Systems for moreinformation.

TURN SIGNAL INDICATOR LAMPSThe left and right turn signal indicator lamps are

controlled by the turn signal and hazard warningswitches. One side of the bulb for each lamp isgrounded at all times. The other side of the bulb re-ceives battery feed through the contacts of the turnsignal switch, when the turn signal lever or hazardwarning button are actuated. Refer to Group 8J -Turn Signal and Hazard Warning Systems for moreinformation.

UPSHIFT INDICATOR LAMPVehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed forthe lamp is switched by the Powertrain Control Mod-ule (PCM). The lamp lights to indicate when thedriver should shift to the next highest gear for bestfuel economy. The PCM will turn the lamp off after 3to 5 seconds if the upshift is not performed. The lampwill remain off until the vehicle stops acceleratingand is brought back to the range of lamp operation,or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-tion switch is turned ON and is turned off when theengine is started. The lamp will be turned on duringvehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPSAll cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblockmodule through the panel dimmer switch. When thepark or headlamps are on, the cluster illuminationlamps light. Illumination brightness can be adjustedby rotating the panel dimmer thumb-wheel, which isnext to the headlamp switch.

8E - 26 INSTRUMENT PANEL AND GAUGES—YJ J

DIAGNOSIS

GAUGESIf an individual gauge is inoperative, see the diag-

nostic procedure under the heading for that gauge. Ifmore than one gauge in the main cluster or gaugepackage cluster is inoperative, perform the following:

(1) Check fuse 9 in the fuseblock module. If OK, goto next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9 with igni-tion switch in ON position. If OK, go to next step. Ifnot OK, repair open in circuit from ignition switchand/or refer to Group 8D - Ignition Systems for test-ing of ignition switch.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove the affected instrument clus-ter bezel and cluster assembly. Disconnect the clusterconnector.

(4) Connect battery negative cable. Turn ignitionswitch to ON. If problem is in main cluster, check forbattery voltage at cavity 3 and cavity 19 of maincluster connector. If problem is in gauge packagecluster, check for battery voltage at cavity 2 and cav-ity 12 of gauge package cluster connector. If OK, goto next step. If not OK, repair open in circuit fromfuse 9 as required.

(5) Turn ignition switch to OFF. Disconnect batterynegative cable. Probe cavities 14 and 20 of main clus-ter connector, or cavities 1 and 13 of gauge packagecluster connector. Check for continuity to a goodground. There should be continuity. If OK, replacethe cluster printed circuit. If not OK, repair open incircuit as required.

COOLANT TEMPERATURE GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with cooling systemperformance. Actual engine coolant temperatureshould be checked with a test gauge or thermometerand compared to gauge readings before you proceedwith gauge diagnosis. Refer to Group 7 - Cooling Sys-tem for more information.

(1) Turn ignition switch to ON. Disconnect coolanttemperature sending unit connector. Sending unit(Fig. 1) is located near left rear corner of the cylinderhead. The gauge needle should move to low end ofgauge scale. If OK, go to next step. If not OK, go tostep 3.

(2) Install a jumper wire from sending unit wiringto ground. The gauge needle should move to high endof gauge scale. If OK, replace sending unit. If notOK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove center instrument cluster be-zel and gauge package cluster assembly. Disconnectcluster connector.

(4) Probe cavity 11 of cluster connector. Check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortin circuit as required.

(5) Still probing cavity 11 of cluster connector,check for continuity to sending unit wiring connector.There should be continuity. If OK, replace gauge. Ifnot OK, repair open in circuit as required.

FUEL GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with fuel tank. In-spect fuel tank for signs of damage or distortion thatcould affect sending unit performance before you pro-ceed with gauge diagnosis. Refer to Group 14 - FuelSystem for more information.

(1) Turn ignition switch to ON. Disconnect fuelgauge sending unit connector. Connector is locatednear the left front upper corner of fuel tank. Thegauge needle should move to high end of gauge scale.If OK, go to next step. If not OK, go to step 4.

(2) Connect a jumper wire between terminals 1and 2 in the body half of the fuel gauge sending unitconnector (Fig. 2). The gauge needle should move tolow end of gauge scale. If OK, refer to Group 14 -Fuel System for procedure to replace sending unit. Ifnot OK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Check for continuity between termi-nal 1 in the body half of fuel gauge sending unit con-nector and a good ground. There should be

Fig. 1 Coolant Temperature Sending Unit - Typical

J INSTRUMENT PANEL AND GAUGES—YJ 8E - 27

continuity. If OK, go to next step. If not OK, repaircircuit to ground as required.

(4) Remove center instrument cluster bezel andgauge package cluster assembly. Disconnect clusterconnector.

(5) Probe cavity 6 of cluster connector. Check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortcircuit as required.

(6) Still probing cavity 6 of cluster connector, checkfor continuity to cavity 2 of sending unit wiring bodyhalf connector. There should be continuity. If OK, re-place gauge. If not OK, repair open circuit as re-quired.

OIL PRESSURE GAUGEThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with engine oiling sys-tem performance. Actual engine oil pressure shouldbe checked with a test gauge and compared to gaugereadings before you proceed with gauge diagnosis.Refer to Group 9 - Engines for more information.

(1) Turn ignition switch to ON. Disconnect oil pres-sure sending unit connector. The sending unit (Fig. 3)is located on right side of engine block. On 2.5L en-gine, it is just forward of ignition distributor and justto the rear of generator mounting bracket. On 4.0Lengine, it is just to the rear of ignition distributorand above oil filter adapter. The gauge needle shouldmove to high end of gauge scale. If OK, go to nextstep. If not OK, go to step 3.

(2) Install a jumper wire from sending unit wiringto ground. The gauge needle should move to low endof gauge scale. If OK, replace sending unit. If notOK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable. Remove center instrument cluster be-zel and gauge package cluster assembly. Disconnectcluster connector.

(4) Probe cavity 9 of cluster connector. Check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortcircuit as required.

(5) Still probing cavity 9 of cluster connector, checkfor continuity to sending unit wire connector. Thereshould be continuity. If OK, replace gauge. If not OK,repair open circuit as required.

SPEEDOMETER/ODOMETERThe diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-lated to gauge accuracy, be certain to confirm thatproblem is with gauge and not with incorrect speed-ometer pinion, axle ratio or tire size. Refer to Group21 - Transmission and Transfer Case for more infor-mation.

(1) Perform vehicle speed sensor test as describedin the appropriate Powertrain Diagnostic Proceduresmanual. If OK, go to next step. If not OK, replace ve-hicle speed sensor.

(2) Disconnect battery negative cable. Unplug vehi-cle speed sensor, PCM, and daytime running lampmodule connectors. Remove left instrument clusterbezel and main cluster assembly. Disconnect clusterconnector.

(3) Probe cavity 13 of cluster connector. Check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortcircuit as required.

(4) Still probing cavity 13 of cluster connector,check for continuity to cavity 1 of vehicle speed sen-sor connector (Fig. 4). There should be continuity. IfOK, replace speedometer/odometer. If not OK, repairopen circuit as required.

Fig. 2 Fuel Gauge Sending Unit Connector Fig. 3 Oil Pressure Sending Unit - Typical

8E - 28 INSTRUMENT PANEL AND GAUGES—YJ J

TACHOMETER(1) With engine running, check for tachometer sig-

nal at pin 43 of PCM connector (Fig. 5). See Tachom-eter Calibration chart in Specifications. If OK, go tonext step. If not OK, replace PCM.

(2) Disconnect battery negative cable. Unplug PCMconnector. Remove left instrument cluster bezel andmain cluster assembly. Disconnect cluster connector.

(3) Probe cavity 12 of cluster connector. Check forcontinuity to a good ground. There should be no con-tinuity. If OK, go to next step. If not OK, repair shortcircuit as required.

(4) Still probing cavity 12 of cluster connector,check for continuity to cavity 43 of PCM connector.There should be continuity. If OK, replace tachome-ter. If not OK, repair open circuit as required.

TRIP ODOMETERIf the trip odometer is inoperative, but the speed-

ometer/odometer functions are unaffected, replacespeedometer assembly. If speedometer/odometer func-tions are affected, see Speedometer/Odometer diagno-sis in this section.

VOLTMETER(1) Turn ignition switch to ON. Voltmeter should

read battery voltage. If all gauges except voltmeterare OK, go to next step. If other gauges are inopera-tive, see Gauges in this section for diagnosis.

(2) Using an accurate test voltmeter, measure bat-tery voltage at battery. Compare this reading to in-strument cluster voltmeter reading. Now seeVoltmeter Calibration chart in Specifications. If volt-meter does not perform to specification, replace volt-meter.

Fig. 4 Vehicle Speed Sensor Connector

Fig. 5 Powertrain Control Module Connector

J INSTRUMENT PANEL AND GAUGES—YJ 8E - 29

MAIN CLUSTER

8E - 30 INSTRUMENT PANEL AND GAUGES—YJ J

GAUGE PACKAGE CLUSTER

J INSTRUMENT PANEL AND GAUGES—YJ 8E - 31

INDICATOR LAMPSIf an individual indicator lamp is inoperative, see

the diagnostic procedure under the heading for thatlamp. If more than one indicator lamp or a combina-tion of lamps and gauges in the main cluster or thegauge package cluster is inoperative, see Gauges inthis section for diagnosis.

ANTI-LOCK BRAKE SYSTEM LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the ABS lamp stays on with the ig-nition switch in the ON position, or comes on andstays on while driving, refer to Group 5 - Brakes fordiagnosis. If no ABS problem is found, the followingprocedure will help locate a short or open in the ABSlamp circuit.

(1) Disconnect battery negative cable. Remove leftinstrument cluster bezel and main cluster assembly.Disconnect ABS control module connector.

(2) Install a jumper wire between cavity 6 of clus-ter connector and a good ground. Connect batterynegative cable. Turn ignition switch to ON. Lampshould light. If OK, remove jumper wire and go tonext step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect batterynegative cable and unplug cluster connector. Checkfor continuity between cavity 6 of cluster connectorand a good ground. There should be no continuity. IfOK, go to next step. If not OK, repair short circuit asrequired.

(4) Check continuity between cavity 6 of clusterconnector and cavity 52 of ABS control module con-nector (Fig. 6). There should be continuity. If OK, re-fer to Group 5 - Brakes for diagnosis of ABS controlmodule. If not OK, repair open circuit as required.

BRAKE WARNING LAMPThe diagnosis found here addresses an inoperative

lamp condition. If the brake warning lamp stays onwith the ignition switch in the ON position and theparking brake released, refer to Group 5 - Brakes fordiagnosis. If no service brake or parking brake prob-lem is found, the following procedure will help locatea short circuit or faulty switch.

(1) Unplug parking brake switch connector. Turnignition switch to START position. Lamp shouldlight. Release ignition switch to ON position. Lampshould go off. If OK, go to step 10. If not OK, go tonext step.

(2) Unplug brake warning switch connector. Installa jumper wire between two cavities of connector.Turn ignition switch to START. Lamp should light.Remove jumper wire and lamp should go off. If OK,replace brake warning switch. If not OK, removejumper wire and go to next step.

(3) Turn ignition switch to ON position. Install ajumper wire between brake warning switch connector

cavity for circuit G9 and a good ground. Lamp shouldlight. If OK, go to step 5. If not OK, go to next step.

(4) Turn ignition switch to OFF. Remove jumperwire and disconnect battery negative cable. Removeleft instrument cluster bezel and main cluster. Installa jumper wire between cavity 1 of cluster connectorand a good ground. Connect battery negative cableand turn ignition switch to ON. Lamp should light. IfOK, repair open in circuit to brake warning switch. Ifnot OK, replace bulb.

(5) Turn ignition switch to OFF and removejumper wire. Disconnect battery negative cable.Check for continuity between brake warning switchconnector cavity for circuit G11 and a good groundwith ignition switch in START position. There shouldbe continuity. If not OK, go to next step.

(6) Turn ignition switch to OFF and removejumper wire. Unplug ignition switch connectors.Check for continuity between ignition switch connec-tor cavity for G11 circuit and a good ground. Thereshould be no continuity. If OK, go to next step. If notOK, repair short circuit between ignition switch andbrake warning switch connectors as required.

(7) Check for continuity between ignition switchconnector cavity for G11 circuit and brake warningswitch connector cavity for G11 circuit. There shouldbe continuity. If OK, go to next step. If not OK, re-pair open circuit as required.

(8) Check for continuity between metal steeringcolumn jacket and a good ground. There should becontinuity. If OK, go to next step. If not OK, refer toGroup 19 - Steering to check steering column groundclip installation.

Fig. 6 ABS Control Module Connector

8E - 32 INSTRUMENT PANEL AND GAUGES—YJ J

(9) Turn ignition switch to START position andhold there. Check for continuity between terminal forcircuit G11 of ignition switch and a good ground.There should be continuity. If not OK, replace igni-tion switch.

(10) Unplug brake warning switch connector.Check for continuity between parking brake switchconnector and a good ground. There should be nocontinuity. If OK, go to next step. If not OK, repairshort circuit as required.

(11) Check for continuity between parking brakeswitch connector and brake warning switch connectorcavity for circuit G11. There should be continuity. IfOK, replace parking brake switch. If not OK, repairopen circuit to brake warning switch as required.

FOUR-WHEEL DRIVE INDICATOR LAMP(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switchoperation, replace if bad. If bulb is OK, repair opento indicator.

HEADLAMP HIGH BEAM INDICATOR LAMP(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer toGroup 8L - Lamps for diagnosis of headlamp system.