Iowa Department of Natural Resources Title V Operating Permit · 92-0752 Cargill Inc, - Eddyville...

Transcript of Iowa Department of Natural Resources Title V Operating Permit · 92-0752 Cargill Inc, - Eddyville...

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

1

Iowa Department of Natural Resources Title V Operating Permit

Name of Permitted Facility: Cargill, Inc. – Eddyville, IA Facility Location: 1 Cargill Drive, Eddyville, IA 52553 Air Quality Operating Permit Number: 06-TV-006 Expiration Date: October 16, 2011 EIQ Number: 92-0752 Facility File Number: 68-09-001 ______________________________________________________________________________ Responsible Official Name: Jeff Fetterman Title: Assistant Vice President/Plant Manager Mailing Address: 1 Cargill Drive, Eddyville, IA 52553 Phone #: (641) 969-4511 Permit Contact Person for the Facility Name: David E. Olson Title: Environmental Coordinator Mailing Address: 1 Cargill Drive, Eddyville, IA 52553 Phone #: (641) 969-3563 ______________________________________________________________________________ This permit is issued in accordance with 567 Iowa Administrative Code Chapter 22, and is issued subject to the terms and conditions contained in this permit. For the Director of the Department of Natural Resources _________________________________________________________________________ Douglas A. Campbell, Supervisor of Air Operating Permits Section Date

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

2

Table of Contents I. Facility Description and Equipment List .......................................................................4 II. Plant - Wide Conditions...................................................................................................9 III. Emission Point Specific Conditions Process Group #1 – Utilities Process Group #2 – Refinery Process Group #3 – Process Process Group #4 – Feed Process Group #5 – Germ Process Group #6 – Ethanol Process Group #7 – Citric Acid Process Group #8 – Dry Products Process Group #9 – Itaconic Acid Process Group #10 – GAP IV. General Conditions G1. Duty to Comply G2. Permit Expiration G3. Certification Requirement for Title V Related Documents G4. Annual Compliance Certification G5. Semi-Annual Monitoring Report G6. Annual Fee G7. Inspection of Premises, Records, Equipment, Methods and Discharges G8. Duty to Provide Information G9. General Maintenance and Repair Duties G10. Recordkeeping Requirements for Compliance Monitoring G11. Evidence used in establishing that a violation has or is occurring. G12. Prevention of Accidental Release: Risk Management Plan Notification and Compliance Certification G13. Hazardous Release G14. Excess Emissions and Excess Emissions Reporting Requirements G15. Permit Deviation Reporting Requirements G16. Notification Requirements for Sources That Become Subject to NSPS and NESHAP Regulations G17. Requirements for Making Changes to Emission Sources That Do Not Require Title V Permit Modification G18. Duty to Modify a Title V Permit G19. Duty to Obtain Construction Permits G20. Asbestos G21. Open Burning G22. Acid Rain (Title IV) Emissions Allowances G23. Stratospheric Ozone and Climate Protection (Title VI) Requirements G24. Permit Reopenings G25. Permit Shield G26. Severability

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

3

G27. Property Rights G28. Transferability G29. Disclaimer G30. Notification and Reporting Requirements for Stack Tests or Monitor Certification G31. Prevention of Air Pollution Emergency Episodes G32. Contacts List V. Appendix A: Air Quality Policy 3-b-08 Appendix B: 40 CFR Part 60 Subpart VV Appendix C: 40 CFR Part 63 Subpart GGGG Appendix D: Predictive Emissions Monitor Plan Appendix E: 40 CFR part 63 Subpart DDDDD Appendix F: 40 CFR 63 Subpart FFFF Appendix G: Consent Decree 05-2037JMR/FLN __________________________________________________________________

Abbreviations

acfm............................actual cubic feet per minute CFR............................Code of Federal Regulation oF ................................degrees Fahrenheit EIQ.............................emissions inventory questionnaire gal/hr ..........................gallons per hour gr./dscf .......................grains per dry standard cubic foot gr./100 cf ....................grains per one hundred cubic feet IAC.............................Iowa Administrative Code IDNR..........................Iowa Department of Natural Resources MVAC........................motor vehicle air conditioner NESHAP....................National Emission Standards for Hazardous Air Pollutants NSPS..........................new source performance standard PEM ...........................Predictive Emissions Monitor ppmv ..........................parts per million by volume lb./hr ...........................pounds per hour lb./MMBtu .................pounds per million British thermal units SIC .............................Standard Industrial Classification scfm............................standard cubic feet per minute TPY............................Tons per year USEPA.......................United States Environmental Protection Agency Pollutants PM..............................particulate matter PM10 ...........................particulate matter ten microns or less in diameter SO2 .............................sulfur dioxide NOx ............................nitrogen oxides VOC ...........................volatile organic compound CO..............................carbon monoxide HAP............................hazardous air pollutant

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

4

I. Facility Description and Equipment List Facility Name: Cargill, Inc – Eddyville, IA Permit Number: 06-TV-006 Facility Description: Wet Corn Milling (SIC 2046) ______________________________________________________________________________

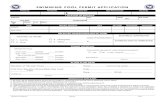

Equipment List ______________________________________________________________________________

Emission Point Number

Associated Emission Unit Number(s)

Associated Emission Unit Description

Process Group #1 - Utilities 1.001 Coal Boiler #1 1.002 Coal Boiler #2 1.039 Coal Boiler #3

1

1.052 Thermal Oxidizer #1 4 4.000 Ash Handling 30 30.000 Coal Bunker #1 31 31.000 Coal Bunker #2 32 32.000 Ash Silo 38 38.000 Coal Bunker #3 48 48.000 Coal Conveying Aspiration 51 51.000 Boiler #4

84.000 Boiler #5 84 86.000 Boiler #6 105.049 105.049 Coal Dumping Shed, Coal Crusher

Process Group #2 - Refinery 25 25.000 Chemical Tank Aspiration 27 27.000 Fructose Lime Addition 28 28.000 Fructose Precoat Unload 33 33.000 Fructose Check Filter Aid Addition 37 37.000 Carbon Furnace 1 56 56.000 Carbon Furnace 2 129 129.000 Refinery Hot Well Aspiration

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

5

______________________________________________________________________________ Equipment List (cont.)

______________________________________________________________________________

Emission Point Number

Associated Emission Unit Number(s)

Associated Emission Unit Description

Process Group #3 - Process 7 7.000 Steephouse Conveying 8 8.000 Steephouse Aspiration 1 9 9.000 Millhouse Aspiration 55 55.000 Steephouse Aspiration 2 102 102.000 Mill Aspiration 2 105.013 105.013 Gluten Loadout Conveying 1 105.103 105.103 Gluten Flash Dryer Conveying 1 105.109 105.109 Gluten Flash Dryer Conveying 2

106.062 Gluten Flash Dryer 1 106 106.901 Gluten Flash Dryer 2 119 119.000 Mill Aspiration 3 5 5.000 Corn Receiving 1 53 53.000 Corn and Solvent Extracted Meal Receiving 2 121 121.000 Process Control Backup Generator

Process Group #4 – Feed 18 18.000 Feedhouse Aspiration

104.000 Fiber Flash Dryer 104.134 Fiber Pneumatic Conveyor 1 104.135 Fiber Pneumatic Conveyor 2 104

104.136 CC/SEM Pneumatic Receiver 105.019 105.019 Feed Storage & Loadout/Rail 105.036 105.036 Feedhouse Conveyor Aspiration

105.014 Gluten Loadout Conveying 2 105.040 105.040 Feedhouse Loadout/Truck 140 140.000 Sweet Feed Loadout

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

6

______________________________________________________________________________ Equipment List (cont.)

______________________________________________________________________________

Emission Point Number

Associated Emission Unit Number(s)

Associated Emission Unit Description

Process Group #5 – Germ 67 67.000 Mineral Oil Scrubber 68 68.000 Building Aspiration 69 69.000 Extraction & DT Aspiration 70 70.000 Germ Storage Aspiration 105.090 105.090 Germ Meal Silo

107.058 Flaker/Conditioner 107.059 Expeller Aspiration 1 107.064 Cold Germ Transfer Receiver 107

107.110 Expeller Aspiration 2 107 107.060 Germ Dryer/Cooler 1 133 133.000 Meal Conveyor 137 137.000 Sweet Feed SEM Silo Receiver 139 139.000 Germ Meal Dryer/Cooler 141 141.000 Corn Oil Tank 146 146.000 Dry Germ Silo 177 177.000 Corn and Dry Feed Ingredients Storage Bin 178 178.000 Corn and Dry Feed Ingredients Storage Bin 179 179.000 Pilot Plant Aspiration Unit 180 180.000 Pilot Plant Pellet Cooler 181 181.000 Pilot Plant Extraction Process 182 182.000 Pilot Plant Meal Cooler 183 183.000 Corn Meal Products Storage Bin 184 184.000 Corn Meal Products Storage Bin 185 185.000 Corn Meal Products Loadout

Process Group #6 – Ethanol 77 77.000 RC Vent 78 78.000 Stillage Evaporator Vent 79 79.000 Ethanol Loadout 80 80.000 Ethanol Tank Farm 85 85.000 CO2 Vent

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

7

______________________________________________________________________________ Equipment List (cont.)

______________________________________________________________________________

Emission Point Number

Associated Emission Unit Number(s)

Associated Emission Unit Description

Process Group #7 – Citric Acid 41 41.000 Lime/Precoat Weigh Hopper 44 44.000 Precoat Weigh Hopper 46 46.000 Acid Tank Aspiration 50 50.000 Lime Storage Silo 83 83.000 Citric Acid Solvent Extraction 108.047 108.047 Dry Crystal Handling Aspiration 108.081 108.081 Dry Crystal Cooler 108.082 108.082 Dry Crystal Handling Aspiration 2 118 118.000 LX Shutdown Tank 120 120.000 Citric Backup Generator 172 172 Acidulants Fermenter V

Process Group #8 – Dry Products 91.000 Drying & Cooling 1 91 91.117 Conditioning Dryer 1

93 93.000 Sifter Filter Receiver 94 94.000 Air Swept Hammermill 95 95.000 Dry Sweetener Silo 97 97.000 Bulk Bagger 98 98.000 Recycle Filter Receiver 127 127.000 Sifter Filter Receiver 2

Process Group #9 – Itaconic Acid 122 122.000 Itaconic Acid Process - Flash Dryer 123 123.000 Itaconic Acid Storage Silo 124 124.000 Itaconic Acid Transfer Receiver 125 125.000 Lime Dissolve Tank Aspiration 126 126.000 Itaconic Acid Lime Storage Bin 130 130.000 BaCO3 Dissolve Tank Aspiration 131 131.000 Itaconic Acid Packaging Aspiration 132 132.000 Itaconic Acid Flash Cooler

Process Group #10 – GAP 142 142 GAP Reactors 143 143 GAP Tank Farm 144 144 GAP Packaging 145 145 GAP Dryer 175 175 Biomass Dryer 176 176 GAP Packaging

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

8

______________________________________________________________________________ Insignificant Equipment List

______________________________________________________________________________

Insignificant Emission Unit Number

Insignificant Emission Unit Description

IU 1 R&D Boiler (Natural Gas, 4.2 MMBtu/hr) IU 2 Citric B-Line Vent IU 3 Citric Drum Filters IU 4 Corn Tank Humidity Vents IU 5 Small Process Generator (<400 hp) IU 6 Engineering Building Generator (<400 hp) IU 7 Fire Pump Diesel Engine (<400 hp) IU 8 Fire Pump Diesel Tank (550 gallons)

Insignificant Activities Equipment List (Small Unit Exemption)(1)

Insignificant Emission Unit Number

Insignificant Emission Unit Description

167 Bulk HCl Tank 169 Crax Aspiration 168 Sodium Bisulfite tank 170 Extraction feed Drag Vent 173 Fiber Receiving and Handling 174 Wet Fiber Storage Bin Fan 187 Soda Ash Unloading 186 Cooling Tower Pending Gluten Vac Pumps (1) Emission Units qualify for Small Unit Exemption under 567 IAC 22.1(2)"w". Records shall be kept in accordance with 567 IAC 22.1(2)"w"(3).

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

9

II. Plant-Wide Conditions Facility Name: Cargill, Inc. – Eddyville, IA Permit Number: 06-TV-006 Permit conditions are established in accord with 567 Iowa Administrative Code rule 22.108 ______________________________________________________________________________ Permit Duration The term of this permit is: Five (5) years from permit issuance Commencing on: October 17, 2006 Ending on: October 16, 2011 Amendments, modifications and reopenings of the permit shall be obtained in accordance with 567 Iowa Administrative Code rules 22.110 - 22.114. Permits may be suspended, terminated, or revoked as specified in 567 Iowa Administrative Code Rules 22.115. ______________________________________________________________________________ Emission Limits Unless specified otherwise in the Source Specific Conditions, the following limitations and supporting regulations apply to all emission points at this plant: Opacity (visible emissions): 40% opacity Authority for Requirement: 567 IAC 23.3(2)"d" Sulfur Dioxide (SO2): 500 parts per million by volume Authority for Requirement: 567 IAC 23.3(3)"e" Particulate Matter (state enforceable only)1: No person shall cause or allow the emission of particulate matter from any source in excess of the emission standards specified in this chapter, except as provided in 567 – Chapter 24. For sources constructed, modified or reconstructed after July 21, 1999, the emission of particulate matter from any process shall not exceed an emission standard of 0.1 grain per dry standard cubic foot of exhaust gas, except as provided in 567 – 21.2(455B), 23.1(455B), 23.4(455B) and 567 – Chapter 24. For sources constructed, modified or reconstructed prior to July 21, 1999, the emission of particulate matter from any process shall not exceed the amount determined from Table I, or amount specified in a permit if based on an emission standard of 0.1 grain per standard cubic foot of exhaust gas or established from standards provided in 23.1(455B) and 23.4(455B). Authority for Requirement: 567 IAC 23.3(2)"a" (as revised 7/21/1999)

1 Pending approval into Iowa's State Implementation Plan (SIP), paragraph 567 IAC 23.3(2)"a" (as revised

7/21/1999) is considered state enforceable only.

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

10

Particulate Matter2: The emission of particulate matter from any process shall not exceed the amount determined from Table I, except as provided in 567 — 21.2(455B), 23.1(455B), 23.4(455B) and 567 — Chapter 24. If the director determines that a process complying with the emission rates specified in Table I is causing or will cause air pollution in a specific area of the state, an emission standard of 0.1 grain per standard cubic foot of exhaust gas may be imposed. Authority for Requirement: 567 IAC 23.3(2)"a" (prior to 7/21/1999) Fugitive Dust: Attainment and Unclassified Areas - No person shall allow, cause or permit any materials to be handled, transported or stored; or a building, its appurtenances or a construction haul road to be used, constructed, altered repaired or demolished, with the exception of farming operations or dust generated by ordinary travel on unpaved public roads, without taking reasonable precautions to prevent particulate matter in quantities sufficient to create a nuisance, as defined in Iowa Code section 657.1, from becoming airborne. All persons, with the above exceptions, shall take reasonable precautions to prevent the discharge of visible emissions of fugitive dusts beyond the lot line of the property on which the emissions originate. The highway authority shall be responsible for taking corrective action in those cases where said authority has received complaints of or has actual knowledge of dust conditions which require abatement pursuant to this subrule. Reasonable precautions may include, but not limited to, the following procedures. 1. Use, where practical, of water or chemicals for control of dusts in the demolition of existing

buildings or structures, construction operations, the grading of roads or the clearing of land. 2. Application of suitable materials, such as but not limited to asphalt, oil, water or chemicals

on unpaved roads, material stockpiles, race tracks and other surfaces which can give rise to airborne dusts.

3. Installation and use of containment or control equipment, to enclose or otherwise limit the emissions resulting from the handling and transfer of dusty materials, such as but not limited to grain, fertilizers or limestone.

4. Covering at all times when in motion, open-bodied vehicles transporting materials likely to give rise to airborne dusts.

5. Prompt removal of earth or other material from paved streets or to which earth or other material has been transported by trucking or earth-moving equipment, erosion by water or other means.

Authority for Requirement: 567 IAC 23.3(2)"c"

2 Paragraph 567 IAC 23.3(2)"a" (prior to 7/21/1999) is the general particulate matter emission standard currently in

the Iowa SIP.

92-0752 Cargill Inc, - Eddyville Final Permit 06-TV-006

11

______________________________________________________________________________ Compliance Plan The owner/operator shall comply with the applicable requirements listed below. The compliance status is based on information provided by the applicant. Unless otherwise noted in Section III of this permit, Cargill, Inc, – Eddyville, IA is in compliance with all applicable requirements and shall continue to comply with all such requirements. For those applicable requirements which become effective during the permit term, Cargill, Inc. – Eddyville, IA shall comply with such requirements in a timely manner. Authority for Requirement: 567 IAC 22.108(15) ______________________________________________________________________________ Consent Decree On March 3, 2006, the Federal District Court in Minnesota entered a Consent Decree between Cargill, Incorporated, U.S. EPA, Iowa Department of Natural Resources and other participating agencies. U.S. et al v. Cargill, Incorporated Civil Action Number 05-2037JMR/FLN. This Consent Decree is hereby incorporated in its entirety into this permit. During the effective period of the Consent Decree, Cargill shall comply with the specific emission reduction requirements, emission limits, operating parameters, monitoring requirements, recordkeeping requirements, and any other applicable requirements specified in the Consent Decree and applicable to this facility. Where a conflict exists, these requirements shall supersede and control over corresponding terms and conditions of this permit. A copy of this Consent Decree is included as Appendix G of this permit. Authority for Requirement: Civil Action Number 05-2037JMR/FLN 567 IAC 22.108(1)

92-0752 Cargill Inc, - Eddyville Process Group #1 – Utilities

Final Permit 06-TV-006

1

III. Emission Point-Specific Conditions Facility Name: Cargill, Inc. – Eddyville, IA Permit Number: 06-TV-006 ______________________________________________________________________________

Process Group #1 – Utilities

Emission Point Number

Associated Emission Unit Number(s)

Associated Emission Unit Description

1.001 Coal Boiler #1 1.002 Coal Boiler #2 1.039 Coal Boiler #3

1

1.052 Thermal Oxidizer #1 4 4.000 Ash Handling 30 30.000 Coal Bunker #1 31 31.000 Coal Bunker #2 32 32.000 Ash Silo 38 38.000 Coal Bunker #3 48 48.000 Coal Conveying Aspiration 51 51.000 Boiler #4 84 84.000 Boiler #5 86 86.000 Boiler #6 105.049 105.049 Coal Dumping Shed, Coal Crusher

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

2

______________________________________________________________________________ Emission Point ID Number: 1 Associated Equipment Associated Emission Unit ID Numbers: 1.001, 1.002, 1.039, 1.052 ______________________________________________________________________________

Applicable Requirements EU = Emission Unit

EU EU Description

Control Equipment

Monitoring Equipment

Raw Material Rated Capacity

1.001 Boiler #1 Coal 17 tons/hr

1.002 Boiler #2 Coal 17 tons/hr

1.039 Boiler #3

CE 1: Baghouse CE FGR: Flue Gas Recirculation

Coal 17 tons/hr

1.052 Thermal Oxidizer CE 1.052: Incinerator

ME 1: Opacity, ME 2: NOx, ME 3: CO

Natural Gas 60.00 MMBtu/hr

Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below.

EU Opacity PM-10 Particulate Matter

Sulfur Dioxide (SO2)

Nitrogen Oxides (NOx)

Carbon Monoxide (CO)

Authority for Requirement

1.001

1.002

1.039

74.9 lb/hr 0.27 lb/MMBtu 2.5 lb/MMBtu 212.1 lb/hr, 929.6 ton/yr1,2 1,100 lb/hr2 83-A-086S7, 567 IAC

23.3(2)"d", 23.3(2)"b"

1.052

40%

5.00 lb/hr 0.1 gr/scf 40.0 lb/hr 8.4 lb/hr NA 90-A-085S2, 567 IAC 23.3(2)"d", 23.4(7)

1 Total NOx from boilers 1-3, 5 & 6 shall not exceed 212.1 lb/hr (929.6 tons per twelve-month rolling period). 2 Averaging times for NOx and CO emission limits shall be 30 days rolling (each).

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

3

Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. EU's 1.001, 1.002, 1.039 Process throughput: 1. The allowable input rating for each boiler shall be 282.1 MMBtu/hr. Control equipment parameters: 1. The flue gas recirculation systems shall be operated in a manner necessary to provide the

required NOx emission reductions while minimizing the increase of CO emissions. Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Records shall be kept of the coal sulfur percentage testing done on a quarterly basis, and

Cargill shall notify the IDNR prior to combusting any coal with greater than 1.0% sulfur, by weight.

Authority for Requirement: Iowa DNR Construction Permit 83-A-086S7 Consent Decree: These emission units are subject to SO2, NOx, and CO requirements as required by the Consent Decree. Please see the "Plant-Wide Conditions" section and Appendix G of this permit for specific Consent Decree language regarding these emission units. Authority for Requirement: Civil Action Number 05-2037JMR/FLN 567 IAC 22.108(1) EU 1.052 Process throughput: 1. Oxidizer capacity of 60.0 MMBtu/hr burning natural gas. 2. This process is a member of the Utilities Group. The processing rate of corn fiber shall be

limited to the fiber from 10,100 tons of corn per day with compliance demonstrated on a 30-day rolling average basis.

3. The thermal oxidizer shall be maintained according to manufacturer's specifications.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

4

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Record the average amount of natural gas consumed (MMBtu/hr) every day of operation. 2. Estimate and record the steeping rate of corn in tons per day every day of operation. 3. Maintain a 30-day rolling average of the steeping rate of corn every day of operation. 4. Perform monthly operational status inspections of process and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents of accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 90-A-085S2 NESHAP: Boilers #1, #2, and #3 are affected sources under 40 CFR 63 Subpart DDDDD – NESHAP for Industrial, Commercial, and Institutional Boilers and Process Heaters. Per the definitions listed in Sec. 63.7575, these units fall into the existing "large solid fuel subcategory." The permittee shall comply with this subpart no later than September 13, 2007. The permittee shall also meet the notification requirements in Sec. 63.7545 according to the schedule in Sec. 63.7545 and in Subpart A of 40 CFR Part 63. (Note: Some of the notifications must be submitted before compliance with the emission limits and work practice standards are required. The initial notification was received on February 28, 2005) Authority for Requirement: 40 CFR Part 63 Subpart DDDDD

567 IAC 23.1(4)"dd" Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Characteristics Stack Height (feet): 225 Stack Diameter (inches): 106 Stack Exhaust Flow Rate (acfm): 460,000 Stack Temperature (oF): 280 Vertical, Unobstructed Discharge Required: Yes No Authority for Requirement: Iowa DNR Construction Permits 83-A-086S7, 90-A-085S2

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

5

Emission Unit Characteristics

EU Temperature (ºF) Flowrate (acfm) Authority for Requirement 1.052 450 100,000 90-A-085S2

It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Stack Testing:

To be tested with all three boilers operating at or near full capacity. Pollutant – Particulate Matter(1) Stack Test to be Completed by – October 17, 2008 Test Method – Iowa Compliance Sampling Manual Method 5 Authority for Requirement - 567 IAC 22.108(3) Pollutant – PM-10(1) Stack Test to be Completed by – October 17, 2008 Test Method – 40 CFR 51, Appendix M, 201A with 202* Authority for Requirement - 567 IAC 22.108(3) * Or approved alternative

Pollutant – Sulfur Dioxide (SO2)(2)

Test Method – 40 CFR 60, Appendix A, Method 6C Authority for Requirement – Iowa DNR Construction Permit 83-A-086S7 (1) Cargill may choose to perform one stack test to account for both PM and PM-10 emissions. This one test will satisfy the testing requirements for both pollutants. If the test results show a violation of the applicable emission limits, then the emission point will be considered to be out of compliance for both pollutants. The test method used must be approved by the Department's stack testing personnel prior to testing. (2) Required if sampled coal exceeds 1.0% sulfur by weight.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

6

Continuous Emissions Monitoring: Pollutant - Opacity Operational Specifications - 40 CFR Part 60, Appendix F Ongoing System Calibration/Quality Assurance - 40 CFR Part 60, Appendix F Reporting & Record keeping - 567 IAC 25. Submit all reports and petitions required by 567 IAC 25 to the Iowa DNR in order to demonstrate compliance with continuous emission monitoring and the 40% opacity (visible emissions) limit

Authority for Requirement – Iowa DNR Construction Permits 83-A-086S6, 83-A-087S6, 87-A-004S6, 567 IAC 25.1(1), 567 IAC 23.3(2)"d", 567 IAC 22.108(4), and 567 IAC 22.108(15)

Pollutant – Nitrogen Oxides (NOx) Operational Specifications – 40 CFR Part 60, Appendix F Date of Initial System Calibration and Quality Assurance – 2/23/96 Ongoing System Calibration/Quality Assurance – 40 CFR Part 60, Appendix F Reporting & Record keeping - 40 CFR 60.7, 567 IAC 25

Authority for Requirement - Iowa DNR Construction Permits 83-A-086S6, 83-A-087S6, 87-A-004S6, 567 IAC 25.1(1), 567 IAC 22.108(4), and 567 IAC 22.108(15)

Pollutant – Carbon Monoxide (CO) Operational Specifications – 40 CFR Part 60, Appendix F Date of Initial System Calibration and Quality Assurance – 10/28/97 Ongoing System Calibration/Quality Assurance – 40 CFR Part 60, Appendix F Reporting & Record keeping - 40 CFR 60.7, 567 IAC 25

Authority for Requirement - Iowa DNR Construction Permits 83-A-086S6, 83-A-087S6, 87-A-004S6, 567 IAC 25.1(1), 567 IAC 22.108(4), and 567 IAC 22.108(15)

The owner of this equipment or the owner’s authorized agent shall provide written notice to the Director, not less than 30 days before a required stack test or performance evaluation of a continuous emission monitor. Results of the test shall be submitted in writing to the Director in the form of a comprehensive report within 6 weeks of the completion of the testing. 567 IAC 25.1(7)

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

7

Agency Approved Operation & Maintenance Plan Required? Yes No Relevant requirements of O & M plan for this equipment: For CE 1: Baghouse Only Monitoring Guidelines The facility makes a commitment to take timely corrective action during periods of excursion where the indicators are out of range. A corrective action may include an investigation of the reason for the excursion, evaluation of the situation and necessary follow-up action to return operation within the indicator range. An excursion is determined by the averaged discrete data point over a period of time, or the presence of a monitored abnormal condition. An excursion does not necessarily indicate a violation of an applicable requirement. If the corrective action measures fail to return the indicators to the appropriate range, the facility will report the excursion to the Department and conduct source testing within 90 days of the excursion to demonstrate compliance with applicable requirements. If the test demonstrates compliance with the emission limits, then new indicator ranges must be set for monitoring and the new ranges must be incorporated in the operating permit. If the test demonstrates noncompliance with emission limits, then the facility, within 60 days, proposes a schedule to implement corrective action to bring the source into compliance and demonstrate compliance. Monitoring Methods & Corrective Actions 1. General

• Periodic Monitoring is not required during periods of time greater than one day which the source does not operate.

2. Continuous • Visible emissions: The source has an Opacity Monitor. Operation of the opacity monitor will be

conducted according to the manufacturer and regulatory requirements. Quarterly reports to DNR regarding opacity monitor operation will be submitted.

3. Monthly • The control equipment will be inspected for any obvious signs of malfunction, such as leaks,

cleaning system failure, plugging, etc. • If a pressure drop gauge is installed, it will be examined for proper operation. • All filters and emission test ports shall be inspected for proper labels. • The control equipment will be thoroughly inspected for wear, including structural components,

the housing, all welds and bolts, and the cleaning system. The results of this inspection will be recorded.

If abnormal conditions are detected the appropriate measures for remediation will be initiated within eight (8) hours. 4. Record keeping/Reporting

• Whenever maintenance; if performed on a piece of control equipment, a copy of the completed work order or similar documentation will be recorded.

• When an emission exceedence occurs, a report will be filed with IDNR. • All documentation shall be kept on file at the facility for a minimum of five (5) years.

5. Quality Control • All instruments and control equipment will be calibrated, maintained, and operated according to

the manufacturer's specifications.

Facility Maintained Operation & Maintenance Plan Required? Yes No (Required for CE FGR: Flue Gas Recirculation and CE 1.052: Incinerator) Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

8

Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

9

______________________________________________________________________________ Emission Point ID Number: 4 Associated Equipment Associated Emission Unit ID Number: 4.000 Emissions Control Equipment ID Number: CE 4 Emissions Control Equipment Description: Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 4.000 Emission Unit Description: Ash Handling Raw Material/Fuel: Ash Rated Capacity: 51 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 40 % Authority for Requirement: 567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.349 lb/hr(1)

Authority for Requirement: Iowa DNR Construction Permit 83-A-089-S3 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/dscf Authority for Requirement: Iowa DNR Construction Permit 83-A-089-S3

567 IAC 23.3(2)"a" (1) Standard is expressed as the average of 3 runs.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

10

Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 78 Stack Diameter (inches): 10 Stack Exhaust Flow Rate (acfm): 2,150 Stack Temperature (oF): 100 Discharge Type: Horizontal Authority for Requirement: Iowa DNR Construction Permit 83-A-089-S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

11

______________________________________________________________________________ Emission Point ID Number: 30 Associated Equipment Associated Emission Unit ID Number: 30.000 Emissions Control Equipment ID Number: CE 30 Emissions Control Equipment Description: DCE Vokes Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 30.000 Emission Unit Description: Coal Bunker #1 Raw Material/Fuel: Coal Rated Capacity: 17 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 0% Authority for Requirement: Iowa DNR Construction Permit 83-A-115S3

567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.129 lb/hr Authority for Requirement: Iowa DNR Construction Permit 83-A-115S3 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/scf Authority for Requirement: 567 IAC 23.3(2)"a" Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Control equipment parameters: 1. The owner or operator of this source shall ensure that fabric filters are maintained according

to manufacturer's specifications and instructions. The fabric filter shall be designed and constructed for an air to cloth ratio no greater than 12.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

12

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 83-A-115S3 Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 95 Stack Diameter (inches): 6 Stack Exhaust Flow Rate (acfm): 1,000 Stack Temperature (oF): 70 Discharge Type: Side Discharge Authority for Requirement: Iowa DNR Construction Permit 83-A-115S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Opacity: The facility shall check the opacity weekly during a period when the emission unit on this emission point is at or near full capacity and record the reading. Maintain a written record of the observation and any action resulting from the observation for a minimum of five years. Opacity shall be observed to ensure that no visible emissions occur during the material handling operation of the unit. If visible emissions are observed corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If corrective action does not return the observation to no visible emissions, then a Method 9 observation will be required. If an opacity >0 % is observed, this would be a violation and corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If weather conditions prevent the observer from conducting an opacity observation, the observer shall note such conditions on the data observation sheet. At least three attempts shall be made to retake opacity readings at approximately 2-hour intervals throughout the day. If all observation attempts for a week have been unsuccessful due to weather, an observation shall be made the next operating day where weather permits.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

13

Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

14

______________________________________________________________________________ Emission Point ID Number: 31 Associated Equipment Associated Emission Unit ID Number: 31.000 Emissions Control Equipment ID Number: CE 31 Emissions Control Equipment Description: DCE Vokes Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 31.000 Emission Unit Description: Coal Bunker #2 Raw Material/Fuel: Coal Rated Capacity: 17 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 0% Authority for Requirement: Iowa DNR Construction Permit 83-A-116S3

567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.129 lb/hr Authority for Requirement: Iowa DNR Construction Permit 83-A-116S3 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/scf Authority for Requirement: 567 IAC 23.3(2)"a" Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Control equipment parameters: 1. The owner or operator of this source shall ensure that fabric filters are maintained according

to manufacturer's specifications and instructions. The fabric filter shall be designed and constructed for an air to cloth ratio no greater than 12.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

15

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 83-A-116S3 Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 95 Stack Diameter (inches): 6 Stack Exhaust Flow Rate (acfm): 1,000 Stack Temperature (oF): 70 Discharge Type: Side Discharge Authority for Requirement: Iowa DNR Construction Permit 83-A-116S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Opacity: The facility shall check the opacity weekly during a period when the emission unit on this emission point is at or near full capacity and record the reading. Maintain a written record of the observation and any action resulting from the observation for a minimum of five years. Opacity shall be observed to ensure that no visible emissions occur during the material handling operation of the unit. If visible emissions are observed corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If corrective action does not return the observation to no visible emissions, then a Method 9 observation will be required. If an opacity >0 % is observed, this would be a violation and corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If weather conditions prevent the observer from conducting an opacity observation, the observer shall note such conditions on the data observation sheet. At least three attempts shall be made to retake opacity readings at approximately 2-hour intervals throughout the day. If all observation attempts for a week have been unsuccessful due to weather, an observation shall be made the next operating day where weather permits.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

16

Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

17

______________________________________________________________________________ Emission Point ID Number: 32 Associated Equipment Associated Emission Unit ID Number: 32.000 Emissions Control Equipment ID Number: CE 32 Emissions Control Equipment Description: UCC Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 32.000 Emission Unit Description: Ash Silo Raw Material/Fuel: Coal Ash Rated Capacity: 51 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 40 % Authority for Requirement: 567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.008 lb/hr, 0.035 ton/yr Authority for Requirement: Iowa DNR Construction Permit 83-A-117S2 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/scf Authority for Requirement: 567 IAC 23.3(2)"a" Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Control equipment parameters: 1. The owner or operator of this source shall ensure that fabric filters are maintained according

to manufacturer's specifications and instructions. The fabric filter shall be designed and constructed for an air to cloth ratio no greater than 12.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

18

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 83-A-117S2 Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 78 Stack Diameter (inches): 5 Stack Exhaust Flow Rate (acfm): 215 Stack Temperature (oF): 100 Vertical, Unobstructed Discharge Required: Yes No Authority for Requirement: Iowa DNR Construction Permit 83-A-117S2 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

19

______________________________________________________________________________ Emission Point ID Number: 38 Associated Equipment Associated Emission Unit ID Number: 38.000 Emissions Control Equipment ID Number: CE 38 Emissions Control Equipment Description: DCE Vokes Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 38.000 Emission Unit Description: Coal Bunker #3 Raw Material/Fuel: Coal Rated Capacity: 17 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 0% Authority for Requirement: Iowa DNR Construction Permit 87-A-003S3

567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.129 lb/hr Authority for Requirement: Iowa DNR Construction Permit 87-A-003S3 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/scf Authority for Requirement: 567 IAC 23.3(2)"a" Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Control equipment parameters: 1. The owner or operator of this source shall ensure that fabric filters are maintained according

to manufacturer's specifications and instructions. The fabric filter shall be designed and constructed for an air to cloth ratio no greater than 12.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

20

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 87-A-003S3 Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 95 Stack Diameter (inches): 6 Stack Exhaust Flow Rate (acfm): 1,000 Stack Temperature (oF): 70 Discharge Type: Side Discharge Authority for Requirement: Iowa DNR Construction Permit 87-A-003S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Opacity: The facility shall check the opacity weekly during a period when the emission unit on this emission point is at or near full capacity and record the reading. Maintain a written record of the observation and any action resulting from the observation for a minimum of five years. Opacity shall be observed to ensure that no visible emissions occur during the material handling operation of the unit. If visible emissions are observed corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If corrective action does not return the observation to no visible emissions, then a Method 9 observation will be required. If an opacity >0 % is observed, this would be a violation and corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If weather conditions prevent the observer from conducting an opacity observation, the observer shall note such conditions on the data observation sheet. At least three attempts shall be made to retake opacity readings at approximately 2-hour intervals throughout the day. If all observation attempts for a week have been unsuccessful due to weather, an observation shall be made the next operating day where weather permits.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

21

Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice. Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

22

______________________________________________________________________________ Emission Point ID Number: 48 Associated Equipment Associated Emission Unit ID Number: 48.000 Emissions Control Equipment ID Number: CE 48 Emissions Control Equipment Description: Howden 376 Baghouse ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 48.000 Emission Unit Description: Coal Conveying Aspiration Raw Material/Fuel: Coal Rated Capacity: 51 tons/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 0% Authority for Requirement: Iowa DNR Construction Permit 88-A-133S3

567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 0.60 lb/hr Authority for Requirement: Iowa DNR Construction Permit 88-A-133S3 Pollutant: Particulate Matter Emission Limit(s): 0.1 gr/scf Authority for Requirement: 567 IAC 23.3(2)"a" Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Control equipment parameters: 1. The owner or operator of this source shall ensure that fabric filters are maintained according

to manufacturer's specifications and instructions. The fabric filter shall be designed and constructed for an air to cloth ratio no greater than 12.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

23

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 88-A-133S3 Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 111 Stack Diameter (inches): 24 Stack Exhaust Flow Rate (acfm): 10,800 Stack Temperature (oF): 100 Vertical, Unobstructed Discharge Required: Yes No Authority for Requirement: Iowa DNR Construction Permit 88-A-133S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Stack Testing: Pollutant – PM-10 Stack Test to be Completed by – October 17, 2008 Test Method – 40 CFR 51, Appendix M, 201A with 202* Authority for Requirement - 567 IAC 22.108(3) * Or approved alternative. The owner of this equipment or the owner’s authorized agent shall provide written notice to the Director, not less than 30 days before a required stack test or performance evaluation of a continuous emission monitor. Results of the test shall be submitted in writing to the Director in the form of a comprehensive report within 6 weeks of the completion of the testing. 567 IAC 25.1(7)

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

24

Opacity: The facility shall check the opacity weekly during a period when the emission unit on this emission point is at or near full capacity and record the reading. Maintain a written record of the observation and any action resulting from the observation for a minimum of five years. Opacity shall be observed to ensure that no visible emissions occur during the material handling operation of the unit. If visible emissions are observed corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If corrective action does not return the observation to no visible emissions, then a Method 9 observation will be required. If an opacity >0 % is observed, this would be a violation and corrective action will be taken as soon as possible, but no later than eight hours from the observation of visible emissions. If weather conditions prevent the observer from conducting an opacity observation, the observer shall note such conditions on the data observation sheet. At least three attempts shall be made to retake opacity readings at approximately 2-hour intervals throughout the day. If all observation attempts for a week have been unsuccessful due to weather, an observation shall be made the next operating day where weather permits. Agency Approved Operation & Maintenance Plan Required? Yes No Relevant requirements of O & M plan for this equipment: Monitoring Guidelines The facility makes a commitment to take timely corrective action during periods of excursion where the indicators are out of range. A corrective action may include an investigation of the reason for the excursion, evaluation of the situation and necessary follow-up action to return operation within the indicator range. An excursion is determined by the averaged discrete data point over a period of time, or the presence of a monitored abnormal condition. An excursion does not necessarily indicate a violation of an applicable requirement. If the corrective action measures fail to return the indicators to the appropriate range, the facility will report the excursion to the Department and conduct source testing within 90 days of the excursion to demonstrate compliance with applicable requirements. If the test demonstrates compliance with the emission limits, then new indicator ranges must be set for monitoring and the new ranges must be incorporated in the operating permit. If the test demonstrates noncompliance with emission limits, then the facility, within 60 days, proposes a schedule to implement corrective action to bring the source into compliance and demonstrate compliance. Monitoring Methods & Corrective Actions 1. General

• Periodic Monitoring is not required during periods of time greater than one day which the source does not operate.

2. Monthly • The control equipment will be inspected for any obvious signs of malfunction, such as leaks,

cleaning system failure, plugging, etc. • If a pressure drop gauge is installed, it will be examined for proper operation. • All filters and emission test ports shall be inspected for proper labels. • The control equipment will be thoroughly inspected for wear, including structural components,

the housing, all welds and bolts, and the cleaning system. The results of this inspection will be recorded.

If abnormal conditions are detected the appropriate measures for remediation will be initiated within eight (8) hours.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

25

3. Record keeping/Reporting • Whenever maintenance; if performed on a piece of control equipment, a copy of the completed

work order or similar documentation will be recorded. • When an emission exceedence occurs, a report will be filed with IDNR. • All documentation shall be kept on file at the facility for a minimum of five (5) years.

4. Quality Control • All instruments and control equipment will be calibrated, maintained, and operated according to

the manufacturer's specifications. Facility Maintained Operation & Maintenance Plan Required? Yes No Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

26

______________________________________________________________________________ Emission Point ID Number: 51 Associated Equipment Associated Emission Unit ID Number: 51.000 Emissions Control Equipment ID Number: CE 51 Emissions Control Equipment Description: Low NOx Burner, Flue Gas Recirculation Continuous Emissions Monitors ID Numbers: ME 51: NOx ______________________________________________________________________________

Applicable Requirements Emission Unit vented through this Emission Point: 51.000 Emission Unit Description: Boiler #4 Raw Material/Fuel: Natural Gas Rated Capacity: 230 MMBtu/hr Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 40 %1 Authority for Requirement: Iowa DNR Construction Permit 89-A-210S4

567 IAC 23.3(2)"d" 1 Per DNR Air Quality Policy 3-b-08, Opacity Limits, an exceedance of the indicator opacity of 25% will require the owner/operator to promptly investigate the emission unit and make corrections to operations or equipment associated with the exceedance. The permit holder shall also file an “indicator opacity exceedance report” with the DNR field office and keep records as required in the policy. If exceedances continue after the corrections, the DNR may require additional proof to demonstrate compliance (e.g., stack testing). Pollutant: PM-10 Emission Limit(s): 2.30 lb/hr2

Authority for Requirement: Iowa DNR Construction Permit 89-A-210S4 Pollutant: Sulfur Dioxide (SO2) Emission Limit(s): 500 ppmv Authority for Requirement: 567 IAC 23.3(3)"e" Pollutant: Nitrogen Oxides (NOx) Emission Limit(s): 46.000 lb/hr2

Authority for Requirement: Iowa DNR Construction Permit 89-A-210S4 2 Standard is expressed as the average of 3 runs.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

27

Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Process throughput: 1. This boiler is limited to a maximum capacity of 230 MMBtu/hr. 2. This boiler shall only operate on natural gas. Control equipment parameters: 1. The low NOx burner shall be maintained according to the manufacturer’s specifications and

instructions. Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Record the average amount of natural gas consumed (MMBtu/hr) every day of operation. 2. Perform monthly operational status inspections of process and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observation of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permit 89-A-210S4 Consent Decree: This emission unit is subject to NOx requirements as required by the Consent Decree. Please see the "Plant-Wide Conditions" section and Appendix G of this permit for specific Consent Decree language regarding these emission units. Authority for Requirement: Civil Action Number 05-2037JMR/FLN 567 IAC 22.108(1) NESHAP: This unit is an affected source under 40 CFR 63 Subpart DDDDD – NESHAP for Industrial, Commercial, and Institutional Boilers and Process Heaters. According to Sec. 63.7506(b), existing large gaseous fuel and existing large liquid fuel units are only subject to the initial notification requirements in Sec. 63.9(b). As specified in Sec. 63.7545(b), an initial notification must be submitted no later than 120 days after November 12, 2004 (Received February 28, 2005). The initial notification must include the information listed in Sec. 63.7545(b)(1) and (b)(2), as applicable. Authority for Requirement: 40 CFR 63 Subpart DDDDD

567 IAC 23.1(4)"dd"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

28

Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Height (feet): 159 Stack Diameter (inches): 120 Stack Exhaust Flow Rate (acfm): 68,300 Stack Temperature (oF): 300 Vertical, Unobstructed Discharge Required: Yes No Authority for Requirement: Iowa DNR Construction Permit 89-A-210S4 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Continuous Emissions Monitoring:

Pollutant – Nitrogen Oxides (NOx) with O2 monitor Operational Specifications – 40 CFR Part 60, Appendix B Performance Specifications

2 & 3, 40 CFR Part 60, Appendix F Date of Initial System Calibration and Quality Assurance – 9/9/94 Ongoing System Calibration/Quality Assurance – 40 CFR Part 60, Appendix F Reporting & Record keeping - 40 CFR 60.7, 567 IAC 25

Authority for Requirement - Iowa DNR Construction Permit 89-A-210S3, 567 IAC 25.1(1), 567 IAC 22.108(4),

and 567 IAC 22.108(15) The owner of this equipment or the owner’s authorized agent shall provide written notice to the Director, not less than 30 days before a required stack test or performance evaluation of a continuous emission monitor. Results of the test shall be submitted in writing to the Director in the form of a comprehensive report within 6 weeks of the completion of the testing. 567 IAC 25.1(7) Agency Approved Operation & Maintenance Plan Required? Yes No Facility Maintained Operation & Maintenance Plan Required? Yes No Facility operation and maintenance plans must be sufficient to yield reliable data from the relevant time period that are representative of the source’s compliance with the applicable requirements. Facility operation and maintenance plans are to be developed by the facility within six(6) months of the issuance date of this permit and the data pertaining to the plan maintained on site for at least 5 years. The plan and associated recordkeeping provides documentation of this facility’s implementation of its obligation to operate according to good air pollution control practice.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

29

Good air pollution control practice is achieved by adoption of quality control standards in the operation and maintenance procedures for air pollution control that are comparable to industry quality control standards for the production processes associated with this emission point. Authority for Requirement: 567 IAC 22.108(3)"b"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

30

______________________________________________________________________________ Emission Point ID Number: 84 Associated Equipment Associated Emission Unit ID Number: 84.000, 86.000 ______________________________________________________________________________

Applicable Requirements EU= Emission Unit

EU EU Description

Control Equipment

Raw Material

Monitoring Equipment

Rated Capacity

84.000 Boiler #5 CE 84: Low NOx Burner, Flue Gas Recirculation Natural Gas 182.1 MMBtu/hr

86.000 Boiler #6 CE 86: Low NOx Burner, Flue Gas Recirculation Natural Gas

ME 84: NOx PEM 182.1 MMBtu/hr

Emission Limits (lb./hr, gr./dscf, lb./MMBtu, % opacity, etc.) The emissions from this emission point shall not exceed the levels specified below. Pollutant: Opacity Emission Limit(s): 40 % Authority for Requirement: 567 IAC 23.3(2)"d" Pollutant: PM-10 Emission Limit(s): 1.82 lb/hr (each) Authority for Requirement: Iowa DNR Construction Permits 92-A-227S3, 92-A-228S3 Pollutant: Particulate Matter Emission Limit(s): 0.6 lb/MMBtu Authority for Requirement: 567 IAC 23.3(2)"b" Pollutant: Sulfur Dioxide (SO2) Emission Limit(s): 500 ppmv Authority for Requirement: 567 IAC 23.3(3)"e" Pollutant: Nitrogen Oxides (NOx) Emission Limit(s): 18.20 lb/hr (each)1

Authority for Requirement: Iowa DNR Construction Permits 92-A-227S3, 92-A-228S3 567 IAC 23.1(2)"ccc" 40 CFR Part 60 Subpart Db 1 Total NOx emissions from boilers 1-3, 5 & 6 shall not exceed 212.1 lb/hr, based on a 30-day rolling average of CEM data.

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

31

Operational Limits & Requirements The owner/operator of this equipment shall comply with the operational limits and requirements listed below. Process throughput: 1. Natural Gas boiler capacity of each boiler shall not exceed 182.1 MMBtu/hr. 2. Each boiler shall only operate on natural gas. Control equipment parameters: 1. Low NOx

burner shall be maintained according to manufacturer's specifications and instructions.

Reporting & Record keeping: Records shall be kept on site for at least five years and shall be available for inspection by the Department. 1. Record the average amount of natural gas consumed (MMBtu/hr) every day of operation. 2. Perform monthly operational status inspections of processes and control equipment that is

important to the performance of the capture system (i.e., pressure sensors, dampers and damper switches). This inspection shall include observations of the physical appearance of the equipment (e.g., presence of holes in ductwork or hoods, flow constrictions caused by dents or accumulated dust in ductwork, and fan erosion). Any deficiencies shall be noted and proper maintenance performed. Any variance on these operating limits shall be noted and appropriate action taken.

Authority for Requirement: Iowa DNR Construction Permits 92-A-227S3, 92-A-228S3 Consent Decree: These emission units are subject to NOx requirements as required by the Consent Decree. Please see the "Plant-Wide Conditions" section and Appendix G of this permit for specific Consent Decree language regarding these emission units. Authority for Requirement: Civil Action Number 05-2037JMR/FLN 567 IAC 22.108(1) NSPS: 1. These boilers are each subject to the provisions of 40 CFR Part 60 Subpart Db ( Standards of

Performance for Industrial/Commercial/Institutional Steam Generating Units) and Subpart A (General Provisions).

NESHAP: Boilers #5 and #6 are affected sources under 40 CFR 63 Subpart DDDDD – NESHAP for Industrial, Commercial, and Institutional Boilers and Process Heaters. According to Sec. 63.7506(b), existing large gaseous fuel and existing large liquid fuel units are only subject to the initial notification requirements in Sec. 63.9(b). As specified in Sec. 63.7545(b), an initial notification must be submitted no later than 120 days after November 12, 2004 (Received February 28, 2005). The initial notification must include the information listed in Sec. 63.7545(b)(1) and (b)(2), as applicable. Authority for Requirement: 40 CFR 63 Subpart DDDDD

567 IAC 23.1(4)"dd"

92-0752 Cargill Inc, - Eddyville Process Group #1 - Utilities

Final Permit 06-TV-006

32

Emission Point Characteristics The emission point shall conform to the specifications listed below. Stack Characteristics Stack Height (feet): 149 Stack Diameter (inches): 72 Stack Exhaust Flow Rate (acfm): 106,000 Stack Temperature (oF): NA Vertical, Unobstructed Discharge Required: Yes No Authority for Requirement: Iowa DNR Construction Permits 92-A-227S3, 92-A-228S3 Emission Unit Characteristics

EU Temperature (ºF) Flowrate (acfm) Authority for Requirement

84.000 332 53,000 92-A-227S3

86.000 332 53,000 92-A-228S3 It shall be the owner’s responsibility to ensure that construction conforms with the emission point characteristics stated above. If it is determined that any of the emission point characteristics are different than stated above, the owner must notify the Department and obtain a construction permit amendment, if required. Periodic Monitoring Requirements The owner/operator of this equipment shall comply with the periodic monitoring requirements listed below. Continuous Emissions Monitoring: ME 84 (PEM)

Pollutant – NOx Operational Specifications – "Example Specifications and Test Procedures for Predictive

Emission Monitoring Systems"(1)

Date of Initial System Calibration and Quality Assurance – 02/99 Ongoing System Calibration/Quality Assurance - "Example Specifications and Test

Procedures for Predictive Emission Monitoring Systems"(1)