IO Center - NTNUreport+2009.pdfdemonstration of integrated drilling simulator with virtual wellbore...

Transcript of IO Center - NTNUreport+2009.pdfdemonstration of integrated drilling simulator with virtual wellbore...

Annu

al Re

port

2009

IO CenterCenter for Integrated Operations in the petroleum industry

Established by the Research Council of Norway

•DevelopnextgenerationIOsolutionsforPeople,Processes

andTechnologytoimprovesafetyandeconomicvalue

•GivethepartnersacompetitiveedgeinIOcomplianceand

operationalperformance

•BringnewIOtechnologytothepetroleumindustryasawholeVISI

ON

Introduction to Integrated Operations

INtegrated OperatIONSisanewwayofoptimizingtheoperationofoilandgasfieldsbymakingsmarterdecisionsthrough

• integrationofpeoplewithdifferentexpertise• integrationofworkprocesses• Integrationofinformationandcommunicationsystemsfromdifferentdomains

Throughthelastdecades,thetraditionaloperationalstrategyforoilandgasfieldwastodivideacomplexoperationinto“silos”(reservoirandproduction,drilling,operationandmaintenance,logistics,HSE)inordertoorganizetheworkprocesses,organizationalstructuresandinformationtechnology.Thedecisionprocesseswereconfinedwithinthelimitationsofeachsilo.Obviously,thisstrategydidnottakefulladvantageofthesynergiesandinterdependenciesbetweenthefunctions.Byputtingthesetogetherinintegratedoperationstheexpectedresultissmarterdecisionsleadingtooptimizationoftheentireoperation.

Inthenearfuturedecisionswillbemadebyvirtualteamsoperatingacrossorganizational,functionalandgeographicaldomains.Expertsfromanywhereintheglobalnetworksoftheoilcompaniesandtheirsupplierswillworktogethertosolvespecificproblemsofagivenasset.Thevirtualteamswillhaveattheirhandsrealtimeanalyzedinformationcollectedfromavarietyofinformationsystemswhichpreviouslydidnotcommunicateeasily.

Thisfutureperspectiveisraisingseveralissuesregardingnewbusinessprocesses,humancommunicationandculture,collaborationenvironment,advancedmathematicalmodelsanddatacommunication,justtomentionafew.AllthoughtheoilcompaniesandservicesuppliersalreadyhaveembarkedonimplementingIntegratedOperations,therearestillmanychallengesleft,wherefurtherresearchanddevelopmentisneeded.ThisisthemotivationforestablishingtheIOCenter.

IO Center AnnualReport2009 www.ntnu.no/iocenter

2

ASSETS

Reservoir Wells Process system

INFORMATION SYSTEMS

ANALYSIS & VISUALIZATION

DECISION & PLANNING PROCESS

BUSINESS OBJECTIVES

INCREASED PRODUCTION

REDUCED COSTS

ENHANCED OIL

AND GASIMPROVED

HSE

Integrated interpretation and decision process

Integrated data acquisition and information systems

Integrated modelling and analysis tools

Data processing, modeling, prediction

Decision support

Data acquisition Communication

VisualizationCommunication

Smarter decisions

Integrated planning and execution

Decision processes across disciplines and

organizational boundaries

Integrated operations is about smarter decisions

Integration at all levels, from data capture to decision

Key elements in Integrated Operations

www.ntnu.no/iocenter IO Center AnnualReport2009

3

Success Criteria and Goals for the IO Center

ReSeaRChLong-term industrial research of a high international calibreWorldclassresearch 2-4Internationalbreakthroughareasthrough5yearsGeneratenewideas/solutions 2newsolutions/methodologiesperyearPhDprojects 15PhDcandidatesthrough5yearsPublishing 5Level2journalpapersand10conferencespapersperyearInternationalco-operation Co-authoringofpapersandexchangeofscientistsIncreasedR&Damongpartners NewR&Dprojectsinitiatiedbyindustrialpartners

INNOVaTIONValue for increased production, enhanced oil recovery, reduced costs and improved hSe,Value for supplier industry through new competitive products and servicesUseoftechnology Useofprojectresultsinindustrialpartners’businessprocessesPilotprojects 1pilotforeachpartnerthrough5yearsTransferofknowledge 10userseminars/workshops/coursesperyearMobilityofpersonnel 2researchersfromIOCenterworkingonindustrialsiteseveryyearSupporttoimplementation/innovation ScientistsfromtheIOCentercontributetoimplementationprojectsNewenterprises Driveforestablishmentofnewenterprisesbasedonprojectresults

eDUCaTIONProviding IO-competent people to the industryMasterstudents 25IOMasterstudentsperyear.Summerinternshipsandmasterprojectsinthe industry.Continuededucation 50participantsoncontinuededucationcoursesperyear

NeTWORKING INDUSTRY – ReSeaRCharenas for co-operation and networkingIndustry-researchnetwork AnnualSMEInnovationForumandoneopenseminaryearlyStrategicthinktank StrategicdiscussionsinBoardInternationalConference AnnualIOconference

Key f igures for the IO Center in 2009

human resourcesResearchScientists 62ResearchScientist,manyears 16GuestResearchScientists 4PhDstudents(partialorfullfunding) 16AssociatedPhDstudents 4Postdoctoratestudents 2Masterstudents(graduated2009) 16

Results Journalpapers 5Conferencepapers 29Technicalreports 13Workshops,internalseminars 10

Funding and costs (1.000 NOK) FundingResearchCouncilofNorway 8344Industrialpartners 26250Researchpartners 5681Operating costs 40274

4

IO Center AnnualReport2009 www.ntnu.no/iocenter

PaRTNeRS

Center for Integrated Operations in the Petroleum Industry

Established by the Research Council of Norway

OVERVIEW OF PROGRAMS AND SUB PROJECTSOverview of programs and sub projects

Research partners

Industrial partners

International cooperation partners

www.ntnu.no/iocenter IO Center AnnualReport2009

5

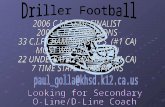

demonstration of integrated drilling simulator with virtual wellbore

TheIntegrateddrillingsimulatorisanewinformationsystemprovidingadvancedrealtimedatawhiledrilling,enablingmoreefficientandsafedrillingwithlessriskofnon-productivetime.

Theinformationcoversmeasuredandcalculatedvaluesrelatedtowellborestability,porepressure,mudcirculation,rateofpenetrationanddrillstringvibrations.

AcompletedatabasefortheGullfaksfieldhasbeenbuiltthisyear,providingavirtuallaboratoryforintegratedtestingofrockmechanics,basinpropertiesanddrillingoperations.

Anewporepressurepredictionmodelhasbeenintegratedwithwiththedrillingsimulator.Promisingresultsfromaninitialtesthavebeenpresentedat2009SPEAnnualTechnicalConferenceandExhibitionheldinNewOrleans,Louisiana,USA,4-7October2009.

Theheavemotionoffloatingdrillingrigsandvessels,andtheconsequencesfordrillstringmotionsisamajorchallengeformonitoringandcontrollingthedrillingprocess.Amethodtocompensatefortheheavemotionwasdemonstratedfollowedbyatestonafloatinginstal-lationduringdrillingofachallenginghighpressure/hightemperaturewell(HPHT).Realtimemodelsforwellstabilityandporepressurepredictionwereapplied,todemonstratehowsuchtoolscanbesuchusedinarealtimeworkingenvironment.

APh.D.projectisstudyingdrillstringvibrationsandoptimizationoftheRateofPenetration

program 1 DrillingandWellConstructionautomated Interpretation, diagnostics and advisory in real timean example: early warning of stuck pipeReal-timeanalysisofpressurereadingsanddrillstringtorquepickupearlyindicationsofbadholecleaningthatmaynotbevisibletothedriller.Thenewalgorithmproducesfewerfalsealarmsthanexistingmethods.Advice for the drillerThedrillerwillhavetheopportunitytoadjustdrillingparametersandcleantheholebeforetheproblemescalates,leadingtolessNonProductiveTimeThe development processHistoricaldatamadeavailabletousbyIOcentreindustrypartnersformedthebasisformethoddevelopment.Methodhasbeentestedonthesehistoricaldatawithgoodresults.PublishedinSPE123374.Afieldtestisplannedfor2010.Fieldtestsmayrevealhowthedrillermakesuseofthenewinformationandhowitfitsintoexistingworkprocessesorevenalterthem.Fieldtestsarethereforeimportantforacompleteassessmentofthestuckpipedetection.

6

IO Center AnnualReport2009 www.ntnu.no/iocenter

Wired to drill Investigating the potential of Wired drill pipe

Wireddrillpipeisnowaproventechnologythatletsusretrievemassiveamountsofdatafromdownhole,bothfromthenear-bitareaandalongtheentiredrillstring.Thisismadepossiblethroughasignalcableembeddedinthedrillpipe.Thenewtechnologyexceedsthetechnologyitreplacessoradicallythatanewwayofthinkingaboutdrillingisrequired.Thenewtechnologydemandsthatroutinesforworkprocessesanddecisionmakingmustbereconsidered.

Theprojectlooksathowwecanmakeuseofsuchafuturistictechnologytoday.Theprojecthasanalyzeddatarecordedwhiletestingwireddrillpipeandwearedevelopingexcitingideasastohowthedatacanbeused.Manyoftheideasarenottotallynew;wehavedreamedofdoingthissortofthingforalongtime,wireddrillpipejustturnsdreamsintoreality.

Animportanthurdlewehavetoovercomeisdataquality.Becausethedataissentthroughanadvancedcommunicationsystem,doesn’tmeanthedataisalwayscorrect.Sensorsfail,calibrationcandrift.WeareadaptingourDataQualitymethodstothewireddrillpipescene.

OthermethodsweseeaspartofIntegratedDrillingOperationswillmakeuseofthenewlyavailabledata.Methodsarebeingadaptedintheareasofdrillingoptimization,wellcontrol,andproblemdetection.

Anewandexcitingsub-projectisfocusingonmakinguseofboreholeseismicdatatogetherwithrealtimemeasurementsofformationparameterstoforma“picture”oftheunderground.Thisactivityisacooperativeeffortbetweendrilling,seismicandreser-voirresearchers.Applicationsrangefromoptimalplacementofthewellbore,improvedreservoirdrainage,andproductionplanning.

Theprojecthasgeneratedareportoutliningthepotentialofwireddrillpipe.Reportsofimprovedmethodsmakinguseofwireddrillpipeareintheworks.Theprojectwillcontinuetocollectwireddrillpipedataasitbecomesavailabletohaveabasisfortestingnewmethods.

Work processes related to Integrated Operations in drilling

Theprojectdevelopsknowledge,methodsandguidelinesforintegratedworkprocessindrillingteams,supportedbyadvancedcollaborationanddecisionsupporttoolsandfacilitatedthroughcollectivelearning.NewworkprocessescombinedwithuseofintegrateddrillingsimulatorweretestedduringdrillingofawellontheHildfield(Total)andthereportSurvey 1 – Implementation of eDrilling on Hildhasbeenissued.ASPEpaperwaspresentedforThe2009SPEAsiaPacificHealth,Safety,SecurityandEnvironmentConferenceandExhibition(APHSSEC),4-6August2009,JakartaIndonesia,onthetopicresilienceandcollectivelearningindrillingoperations.AsecondpaperwassubmittedtoSPEIntelligentEnergyConfer-ence2010:Creating an Intelligent Energy Organization through Collective Learning,withfindingsonanewmethodforenhancingCollectiveIntelligenceindrilling:Why-,WhatandHow-learning.ThethreelearningdimensionsofHow,WhatandWhyinteractinadynamicwayimplyingthatabalancemustbeestablishedinordertopursueanoptimalenvironmentforcollaborativedecision-makingindrillingteamscreatingsaferandmoreefficientoperations.

Themethoddistinguishesbetweenstructuringandenablingparametersthattogetherarebelievedtomakeacompre-hensivefunctionalcharacterizationofcollectivereflection.Earlyfindingsindicatethatexistingtoolsandarenasarebiasedtowardsoneofthedimensions,attimes

Task performance

Processes &Roles &

Decision types

SuccessFactors

Performancecriteria

Vision/purpose

Information and information sourcesBounded object

Attention Perception Knowledge ActionCommunication

ManagementAbility to execute

WhatHow Why

IntelliServ Drill String Telemetry Network

Telemetry Drill Pipe

IntelliLink™ Measurement Nodes

Telemetry BHA MWD/DD Tool String

Data Speed: 57.6kbps one way / 28.8kbps both ways Potentially 2MbpsTemperature = 302ºF/150ºC, Pressure = 25,000psi/1,725barDownward Communication: InstantaneousLength/Fluid Restrictions: NoneData Acquisition Locations: Up to 256 distributed nodes

Courtesy to National Oilwell Varco

www.ntnu.no/iocenter IO Center AnnualReport2009

7

program 2 ReservoirmanagementandProductionOptimizationa large portion of the IO value potential lies in reservoir management. Our guiding principle is the concept of closed loop reservoir management and the application of mathematical optimization. This includes work flows for assisted history matching and production optimization. We try to develop fast, reliable and transparent methods. Further, our aim is to challenge the dominant silo approach and bring IO to a next level through integration of models and optimization applications.

rOOKIe – a unique teaching environmentTheROOKIEprojectuseslivedataandisaone-of-a-kindcompetencedevelopmentplatformforstudentsandresearchers

WehavedevelopedanoperationslabatNTNUwherestudentshaveaccesstolivedataandremotecontrolofgaswellsinOklahoma.Thesewellsarepronetoliquidloadingamongstotheroperationalchallenges.CurrentlyonewellisfullyaccessiblethroughaLabview®interface.Thismeansthatdataandvideofeedareavailableonlineinrealtime.Further,

storeddataisavailablefordataanalyses,forinstancemodelvalidation.Onefeature,whichisimportantinaneducationalsetting,isthefactthatstudentscanchangetheproductionchokeremotely,fromtheoperationslaboranyotherplacewithInternetaccess,toexplorethebehaviorofawell.

Currentlyonewellisonline.Asecondwellwillcomeonlinesoontogetherwiththeabilitytoremotelyoperatethepumpinadditiontotheproductionchokeoneachwell.

TestsshowthatROOKIEiswellreceivedbystudents.

Norne benchmark caseTheNornefieldcaseoffersindustryandresearchauniqueenvironmentforcomparingtechnologiesforclosedloopreservoirmanagement

TheNornefieldcaseprovidesuserswithabenchmarkbasedonrealsubsurfacedata.Thiswillbeanextensiontocurrentbenchmarkcaseswhichareallbasedonsyntheticdata.TheNornefieldontheNorwegianContinentalShelfisoperatedbyStatoil,andincludesthelicensepartnersENIandPetoro.Aninterestingfeatureofthebenchmarkishighquality4Dseismicdata,wherethedepletionofthereservoirismonitoredthroughseismicmeasurementsfrompermanentlyinstalledseabottomsensors.Thisisanewtechniqueforincreasingtherecoveryfromoilandgasfields,usedonafewfieldsaroundtheworld.TheIOCenterdevelopsnewanalysistoolstoextractinformationonthedepletionhistorytounderstandbetterthereservoirbehaviorandoptimizethepositioningandoperationofnewproductionandinjectionwells.Thepurposeistoestablishthiscaseasakeybenchmarkforthepetroleumindustries.Itwillbeusedtoevaluateandtocomparemathematicalmethodsforhistorymatchingandclosed-loopreservoirmanagement.Further,theNornedataoffersanopportunitytouserealdataforeducationalpurposes,incourses,semesterprojectsandmasterthesiswork.CurrentlyresearchersatStanfordUniversity,TUDelftandNTNUareusingthesedata.

8

IO Center AnnualReport2009 www.ntnu.no/iocenter

production optimization on a daily basisAnewconceptforproductionoptimizationhasbeendeveloped.Testingonrealdataindicatesasignificantpotentialforthismethodology.

Thedailyworkflowforaproductionengineertypicallystartswithareviewofproductionandindividualwellperformance.Productionengineersneedtoanalyzethecurrentsituationandrecommendafutureproductionstrategy.Hence,adecisionsupporttoolisoftendesiredforallocatingandroutingproductionfromindividualwells.Wehavedevelopedanoveldecompositionandmodelingmethodwhichishighlyefficient,partlybecauseitmaybeimplementedinaparallelcomputerarchitecture.ItusesDantzig-Wolfedecomposi-tionandprovidestheuserwithtransparentresultsofvaluetoanyknowledgeableuser.Thisincludesthecostofscarceresources(forinstanceadownstreamgascapacityconstraint)andameasureofthequalityofarecommendation.

OneofourPhDstudentsspent6monthsonanexchangevisitasaproductionengineeratTrollB&C.Hence,wehavehadtheopportunitytoassesstheproposedmethodologyonrealdatawithencouragingresults.OtheractivepartnersareFMCTechnologiesASandIBM.

Anumberofscientificpublicationsareavailablewhichanalyzesanddescribesthemethodology.

I-Opt – integrated modeling and optimization

Theintegratedbenchmarkwillchallengeindustryviewsonthebusinesspotentialofvaluechainintegration.Integratedmodelingofmulti-fieldassets,fromsubsurfacetomarket,ischallengingduetothecomplexityoftheproblem.Wehavedevelopedanindustrybenchmarkasameanstoassessthepotentialbusinessvalueofintegratingapplicationsalongthevaluechainfromreservoirtoexport.

ThebenchmarkbuildsonSPE121252,andincludestwofull-fieldcompositionalmulti-wellmodelsandonefull-fieldmodelundergoingmiscibleWAGinjection.Further,acommonfield-widesurfaceprocessingfacilityismodeledwithemphasisonwaterhandling,NGLextraction,sales-gasspec,andgasreinjection.Thesurfaceprocessmodelinteractswiththethreereservoirmodelsthroughwater-andgas-handlingconstraints,andbydistributionofavailableproducedgasforreinjection.Aneconomicmodelwithcostfunctionsforallmajorcontrolvariables(e.g.numberofwells,surfacefacilityselectionandoperatingconditions)isincluded.Allpara-metersarecarefullyselectedtoensurerealism.

Thebenchmarkiswellsuitedtoquantifythepotentialbenefitofintegratedoptimizing(meaningapplicationswhichinclude

reservoirs,pipelinesandprocessfacilities)comparedtoasiloapproachwithseparateupstreamanddownstreamapplica-tions.Hence,itshouldchallengethecurrentmindsetintermsofbusinessvalue.

Thebenchmarkwillbeprovidedtoindustryandacademiathroughawebinterface,applicationdatafiles,workshopsandscientificpublications.

www.ntnu.no/iocenter IO Center AnnualReport2009

9

program 3 OperationandMaintenance

Condition based maintenance; extracting meaning from a sea of raw dataTheMímirplatformisatoolforprocessingrawdataandtransformingitintomeaningfulinformationformaintenanceandoperationalplanning.Itisbasedonacceptedindustrystandardsandaimsatprovidingastandardizedandexpandablesetoftoolsthatcanbeeasilycombinedtoquicklyimplementanddeployadvanceddecisionsupportfunctionsandbusinesssolutions.

During2009apre-releaseversionofMímirhasbeenmade,including:• TheMímir BuilderforthedefinitionandassemblyofMímirmodulesintoconditionmonitoringanddataanalysisapplications• TheMímir Run-Time Managerforthereal-timeexecutionofMímirapplications• TheimplementationofarangeofMímirmodules(e.g.implementingdifferentregressiontechniques)• Theimplementationofdemonstrationapplicationsincluding: -Signalvalidationapplication -NOxemissionmonitoringapplication -Falsealarmavoidancesystemforkickdetectionsupport

Program3alsoconductsresearchonnovelRemaining Useful Life(RUL)modelswhicharecentraltotheprognosticsandcondition-basedmaintenancetechnologiesthatarebeingdeveloped.2009hasseenthestartofexpandingthecurrentsetofRULinfluencingfactorstoincludepredictedopera-tionalandenvironmentalconditions,withthefinalaimofreducingtheuncertaintiesinRULcalculations.

TheMímir Builderisusedtoassembleaconditionmonitoringsystemmadeofanetworkofpredefinedstandardmodules.

Next Step: PilotimplementationoftheMímirplatform.DevelopmentofRULprinciples.

Condition Monitoring Integrated planning

pilot projects

Detection

Diagnosis

Prognosis

Maintenance planning

10

IO Center AnnualReport2009 www.ntnu.no/iocenter

Improved condition monitoring of process equipment

Theimportanceofbeingabletomonitortheconditionofoffshoreequipment,suchasseparators,safetycriticalvalves,andheatexchangersisemphasizedinsub-project3.2.Differentmethodsfornon-intrusiveinspection(NII)arebeingtestedandevaluatedtoexpandcapabilities(e.g.probabilityofdetection).

During2009therehasbeenanemphasisonNIIforproductionseparatorsandextensivetestprogramsusingacousticdetection,gammarayandneutronbackscattertechnologieshavebeenrun.Adedicatedlabsetupisusedfortestingthedifferenttechnolo-gies.Thisprovidesexcellentconditionsfordescribingthedetectioncapabilities.Basedonthisitispossibletoplanextendedteststoverifythesuitabilityofthesetechnologiesforfielduse.

Integrated planning – IpL

BasedonfindingsfromtheearlyphaseoftheprojecttheIPLprojectisdrawingmoreandmoreattentiontoworkprocessesanddoinglessresearchdirectlyrelatedtoICTtools.

During2009theprojecthasbeenreorientedtowardsaholisticunderstandingoftheplanningprocess.Thisin-cludesanoverviewoftheinformationflow,dependen-ciesinthesystemandallactorsinvolved.Itisneces-sarytoidentifycriticalinterfacesbetweenindividuals,groupsanddifferentinformationandcommunicationtools.Itisalsoessentialtomaptheneedforcoopera-tionandcommunicationincludingmoreefficientuseofexistingICTtoolsortheneedfornewtoolstopresentandsharerelevantinformation.

BasedonthisreorientationtheIPLprojecthasdevelopedapreliminarymodelforintegratedplanningasabestpracticetool.Themodelisillustratedinthefigurebelow.TheintentionistousethismodelasastartingpointfordiscussingIPLwithdifferentorgani-zations.

Next Step: DevelopIPLbestpracticemodelincooperationwithIOindustrypartners.

Next Step: Fromlabtothefield:Fieldtestingofnewmethodsforconditionmonitoringofseparatorsandsafetycriticalvalves.Cantheyprovideusefulinformationinabusyandclutteredoperationalenvironment?

IPLPractice

Agility &Resilence

Communicativecapabilities

Organizationallearning

Mindfulnes

MAINTENANCE

MODIFICATIONS

MAJOR PROJECTS

SUPPLY CHAIN

WELLINTERVENTION

DRILLING

PLANNING&ADJUSTING

PLANNING EXECUTION

Strategic &TacticalPlanning

NotificationsUnexpected EventsWeather

Strategic &TacticalPlans

IntegratedPlan

OFFSHORE PRODUCTION

RESULTSProductionProfit, HSE

www.ntnu.no/iocenter IO Center AnnualReport2009

11

program 4 NewWorkProcessesandEnablingTechnologies

Future Collaboration environments; Case study on risk impact of maintenance operations

In 2009 the project has conducted studies on collaboration surfaces to support risk informed decisions in maintenance and modification planning. A test-bed, called the IO Maintenance and modification planner (IO MAP) was developed in close colla-boration with partners and tested at several Statoil locations, as well as at ENI Norge, GdF SUEZ E&P Norge and Shell.

Ideally,onewouldselectandshapetechnologiestoactivelyenabledesiredworkpractices.Inreality,technologyconstraintsandpossibilitiesoftenshapetheworkpracticesinstead,sometimeswithunforeseeneffects.Technologyimposedchangeisonlypurposefulifitcontributestoalignmentwiththeorganisation’sstrategiesandthestandardsoftheindustry.Onesetofsuchstandardsandstrategiesarethosethatpertaintosafetyrisks.ThepurposeoftheIOMAPstudiesistoinvestigatetechnologycharacteristicsthatmayimproveriskidentification.

ThesoftwaredesignisinspiredbylocationbasedgeographicalinformationsystemsandisbasedonIFE’sInformationRichDesignconcept.IO-MAPcontainseasilycomprehensibleoverviewsofworkinvariousstagesofplanningandofconditionsinaworkarea.Usersmayvisuallyidentifyanddescribesafetyrisk.

Someearlyfindings:• IOMAPfillsanimportantfunctioninvisualizingrisksinconnectionwithtasksandlocation,offeringextrahighlightsand

remindersofrisksonthemap• Plannerswithoff-shoreplanningexperiencehaveanadvantageinidentifyingrisksconnectedtojobsatanearlystage

becauseoftheiroff-shoreknowledge• ItalsoseemsthatIOMAPmayhelpplannerswhoneverworkedoff-shoretogetashareoftheexperiencedplanners’

“gutfeeling”throughvisualizations• Feedbackindicatesthatalimitednumberofadditionstothesystemwillturnitintoagroupwarefordistributed

collaboration

Testuserquote:“I thought you were bringing just another ICT tool, but this is actually about our real work”

Discussing risk impact of maintenance operations.

12

IO Center AnnualReport2009 www.ntnu.no/iocenter

Organizational factors and Integrated OperationsIn 2009 the project addresses how organizational factors impact on the successful implementation of Integrated Operations, with a focus on operations, maintenance, and production optimization. Examples of organizational factors include: leadership, organizational structure, organizational culture, roles and responsibilities, teamwork, KPIs, and training. The project is carried out in close cooperation with Shell Norway, where we have previously developed and tested a team training concept for operations and production optimization teams.

Someimportantfindings:• Leadershipbehaviorhasastrongimpactonthedegree

ofsuccessofanorganization’sIOimplementation.TosuccessfullyimplementnewtechnologiesandnewworkprocessesthatenableIO,clearcommitmentandexpec-tationsfromleadersareessential.

• Thequalityofthecollaborationbetweenanoperationssupportcenterandaproductionfacilitydependsonthequalityoftheco-locatedcollaborationwithintheopera-tionssupportcenterandwithintheproductionfacility.Inotherwords:Goodintegrationacrosslocationsdependsongoodintegrationacrossdisciplines/functionsinthelocationsinvolved.

• Geographicallydistributed(virtual)teamscaneasilybecomepolarizedacrosslocations,thatis,belockedinto“usandthem”patterns.Bybeingawareofthistendency,virtualteamswillbeinabetterpositiontoavoidtheproblem.

• Clearlydefinedrolesandresponsibilitiesareimportantforeffectivedecisionmakingandcoordinationinteams.However,teamsmaylosesomeoftheirflexibilityifrolesandresponsibilitiesbecometoorigidlydefined.

IO and Safety – More resilient organisations by new approaches to emergency managementBased on an interview study performed in 2008, the project performed observation studies of emergency exercises in addition to arranging a workshop on future emergency management in 2009. The aim of the activities was to study how new technology and work processes influence emergency preparedness and handling

Byreal-timeinformation;accesstoexperts;sharingofinformation;anddistributedactors,integratedoperationsisanenablerforshiftingfocusinemergencymanagementfromonlyrescueandresettingsystemstoabroaderperspectivethatincludesanticipationandresponsetotheprecedingeventsthatleaduptotheaccident.Experiencesfromaccidentinvestigationsshowthatacommoncontri-butingfactortoaccidentsintheindustryislackofriskanticipation,itcanthusbeclaimedthatthereisaneedtoexpandthefocusinemergency.

Basedonthefindingsinthestudiesthefollowingrecommendationsregardingfutureemergencymanagementareproposed:• Amoreproactivefocusinemergencyhandlingbyutilizingearlywarningstomonitorandanticipatedeviations,andthus

preventemergenciesfromhappeninginthefirstplaceaswellasestablishingtheemergencyorganizationfaster.• Consideruseofrichercollaborationtechnologyinemergencyhandling.Shouldbeperformedcarefully,asoneneedto

trusttechnologyinemergencyhandling• Identifyactorsandinteractionsbetweentheseatdifferentverticalandhorizontallevelsinvolvedinemergencyhandling,

andplanandtrainaccordingly.

www.ntnu.no/iocenter IO Center AnnualReport2009

13

Indicating Value of IO

TheIOValuationMethodisaresearchbasedpracticalassessmentmethodforvaluationofIOinvestmentinfields,technologiesandorganizationsfocusingattheprojectlevel.Themethodisameansto:• Understandsourceofvalue→helpstofocuson

criticalsuccessfactors;• ComparealternativeIOprojectsandsolutions→

improvedNPV;• Calculatemonetaryvalue→motivationtofasterIO

implementation.Year2009wasaproductiveyearfortheprojectthatresultedinfourreportsandtwopapers.OnepaperreceivedtheBestPaperAwardattheBusinessInformationSystems2009conference.PartsofthemethodhavebeenfurtherenhancedthroughcollaborationwithassociatedmembersoftheprojectfromSintef,Marintek,UniversityofStavangerandinternationalexpertsfromoverseas.

Implementationofaprototypetoolandothermetho-dologicalinstrumentshadbeenstartedbasedonthedevelopedvaluationmethod.ThatallowedtorunapilotstudyonIntegratedPlanningatConocoPhillipsandtotestpartsofthemethod.

TwoworkshopsfortheindustrialpartnersofIOCenterwereheldin2009.Internationalexpertsparticipatedinbothworkshops.Apositivefeedbackwasreceivedfromtheindustrypartners(ConocoPhillips,ENI,Statoil,Shell,TotalE&P)andTechnicalCommitteeofIOCenter.

CrYStaL BaLL

Courtesy to National Museum of Natural History, Washington D.C. USA

Looking into the future of IO

• Explorationanddescriptionofscenariosfor2ndand3rdgenerationIOworkprocesses

IdentificationofradicalR&DideasforIO;Challengecurrentthinking

• Transferofexperiencefromotherindustries(aerospace,defense,health,processindustry)

• Studyofneworganizationalstructuresandbusinesstasks

-Networkbasedstructures -Newmanagementroles -Newconceptsforbusinessprocessesand

operator/suppliercooperation

• Studyofnewtechnology -Wirelesssensors -Upscalingofdataamounts,needfornewdata

reductionmethods -Deeperintegrationofinformationsystems

The use of the results • Developmentofstrategiesforfutureimplementation

ofIOintheindustry• Selectionoffutureareasforresearch

Next Step: Casestudiestovalidatethemethodandidentifybestpractices.Developtrainingseminarsfortheindustrialpartnersinordertotransferexperience.

5. general projects

VALUE

KPIs analysis• Oil & gas recovery• Production• Cost• HSE

Extrapolation &simulation

ScenarioAnalysis

DecisionAnalysis

1. Preparation 2. Analysis 3. Valuation

Qualitative assessment(pre & post)• Teamwork • Process• Technology • Organization

Fieldcharacteristics

Commercialimplications

Local consideration

Scope ofIO project

Org. goals

Financial Analysis

a. P

erfo

rman

ce

mea

sure

men

tsb.

Val

ue

est

imat

ion

14

IO Center AnnualReport2009 www.ntnu.no/iocenter

petrONaS Seminar on IO 2009TheIOCenterandPetradincooperationwithPetronasandtheCCOPSecretariatorganizedatailormade3dayseminaronIOinKualaLumpurfortheemployeesofPetronas10-12February.Therewereabout100participants.TheNorwegianam-bassadortoMalaysiaopenedtheseminar.18speakersfromtheIOCenterandPetronassharedresentdevelopmentandsolutionsinintegratedoperationswithcasesbothfromMalaysiaandtheNorthSea.Thesemi-naralsoorganizedfourworkinggroupsonthecriticalareasindrilling,reservoirmanagement,productionoptimizationandworkprocesses.OperationandmaintenanceandenvironmentalmonitoringandIOwerealsotopicsfordiscussions.TheseminarwaswellreceivedatPetronasandthedelegatesdiscussedstrategiesforfollowupprojectsbetweenMalaysiaandNorway.

IO 09 International Conference on Integrated Operations; Science and practiceThe5thinternationalconferenceonintegratedoperationsinthepetroleumindustry-IO09ScienceandPractice-wasarrangedbytheIOCenter29-30September.Themaintopicwas“Intelligentpetroleumfieldsandintegratedoperationsforbetterproductivityandsafety”.TheIOConferenceisaninternationalmeetingplaceonIOwhereindustryandresearchshareknowledgeandexperienceandbuildnetwork.Theconferencereviewstrendsandopportunitiesforresearchandbusinessandisaplacewherescienceandpracticemeet.IO09had300participantsand34speakers.IO09hadaverygoodinternationalattendanceandthiswillbeexpandedinthefuture.TheconferencemanagementcooperateswiththeAdvisoryBoardwithrepresentativesfromSaudiAramco,Petrobras,PetronasandQatarPetroleumaswellastheinternationaloilcompaniesthatsupporttheIOCenteraspartners.TheIO09cooperatedwithIOintheHighNorthandIndustrialGamingandbothorganizationschairedtheirspecialparallelsession.AYoungProfessionalProgramwith8postersessionswasorganizedaswellasawellattendedexhibitionplace.TheIO09alsoorganizedthreeexcursionsanddemosessionsduringtheconference.ItisanobjectivefurthertodevelopthesciencepartinthefutureconferenceswithPh.DpresentationsofrecenttrendsanddevelopmentwithinIOfromtheuniversitiesinNorwayandabroadincludingtheYoungProfessionalForumandeducationforthefutureleadership.IO 10 6th International Conference on Integrated Operations in the Petroleum Industry is scheduled for 28-29 September, 2010.www.ioconf.no

International IO Conferences organized by the IO center

educationMaster studentsRecruitmentofmasterstudentswithbackgroundinIO-relatedsubjectsisaveryimportant“result”forourindustrialpartners.ThesecandidateswillenterimportantpositionsintheindustryandcontributetoimplementationofIOfromtheveryfirstworkingday.ManyofthestudentsprojectsareconductedincooperationwiththeindustrypartnersintheIOCenter.

16masterstudentsbeingaffiliatedwiththeIOCenterhavegraduatedin2009.Themajorityofthestudentshavebeenrecruitedbyservicesuppliersandoilcompanies.

30newstudentsstartedtheirmasterpreprojectinthefall2009,andwillgraduatespring2010.

Continued education15workshops/seminars/continuededucationcoursesarrangedforindustryparticipation

15

www.ntnu.no/iocenter IO Center AnnualReport2009

InnovationThegoalforinnovationintheIOCenteristhattheindustrypartnersshallimprovetheirbusinessprocesses,productsandservicesthroughimplementingresultsfromthecenter.

drilling technologyAnintegrateddrillingsimulatorhasbeenfieldtestedinStatoil,ConocoPhillipsandTotal,demonstratingcapabilitytodetectdrillingproblemsatanearlystage.Newworkprocesseshavebeendevelopedtotakefulladvantageofthesimulator.Thetechnologyhasbeencommercializedthroughanewcompany,eDrillingSolutions.

SMe Innovation Forum 2009TheIOCenterhasasagoaltostimulateSMEsintheIOfieldtodevelopnewproductsandservicesrelatedtoIO,andtofindcustomerrelationsamongcompaniesinsideandoutsidetheIOCenter.The2ndSMEInnovationForumwasorganizedinconnectionwiththeIO09Conference.TheobjectiveoftheSMEInnovationForum2009wastodiscusshowsuppliersandoilcompaniescouldcooperatetomeetthechallengeofproactiveenvironmentalmonitoringandcontrolbydeployingtheideasofintegratedoperations.Wehadabout70participantsfromoilcompanies,majorsuppliers,SMEcom-paniesandR&Dcompanies.TheForumwaswellreceivedandStatoilsupportedthisyear’seventbyusingtheforumasakick-offmeetingfordiscussionoffuturesolutionsforenvironmentalmonitoringandcontrolandtheinnovationcooperationbetweensuppliersandoilandgascompanies.

Watson Research Center

Master students, summer

internships

Common data bases for field dataYearly symposions

and workshops

Co‐authoring of papers

Guest researchers

PhD students,exchange visits

International collaboration

production optimizationResultsfromthepilotprojectonproductionoptimizationonTroll(Statoil)incollaborationwithFMCKongsbergwillcon-tributetothedevelopmentofanewgenerationofthe”FlowManager”systemprovidedbyFMC.APhDcandidatewasoutplacedatStatoil,Trolltodeployresearchresultsindailyoperation.

associated projectsAssociatedprojectshavebeencarriedoutbytheresearchpartnersoftheIOCenterforGdFSuezontrainingprogramsandintegratedplanning,andforEni/GoliatonConditionmonitoringsystemengineering.

16

IO Center AnnualReport2009 www.ntnu.no/iocenter

the BOard

Brage SandstadConocoPhillips

Gregor hendersonShell

Nora BergsethEniNorgeAS

Fridtjov Øwre,InstituteforEnergyTechnology

espen RokkeFMCKongsberg

Kjell arne JacobsenSINTEFPetroleumResearch

erik ØstbyDetNorskeVeritas

Tore BøTotalE&PNorge

Rebecca ChristensenGdFSuez

Ingvald StrømmenNTNU

Øystein haukvikAkerSolutions

Vidar hepsøStatoil

Trond WebergKongsbergMaritime

Jon LippeNTNU,SecretaryoftheBoard

Jon KleppeNTNU,Chair

Svein Ivar SagatunStatoil

Jon StærkebyeIBM

Tor Petter JohnsenResearchCouncilofNorway(observer)

Organization and governance Model

Theorganizationchartandgovernancemodelisshowninthefigurebelow.

TheBoardandtheTechnicalCommitteemeetstwiceayear.BoardandTCmemberscanaccessreportsandotherprojectinformationthroughawebsite.

ThesubprojectteamsarepopulatedbyresearchersfromNTNU,SINTEFandIFE,andguestresearchersfromfourinter-nationalcooperatinguniversities.ResearchisperformedatfivelocationsinNorway;Trondheim,Oslo,Halden,BergenandStavanger,inadditiontothepilotprojectsitesonshoreandoffshoreandattheinternationaluniversities.Communicationinternallyandacrossactivitiesisorganizedthroughphysical

andvirtualmeetings,useofacommonprojectdatabaseandemailcommunication.

ThePhDstudentsarrangeregularcolloquia.ThePhDstudentswork25%oftheirtimeasresearchersinthesubprojects,inordertogetexposedtoindustrialprocessesandapplicationsofnewtechnology.

Collaborationwiththeindustryisorganizedthrough15pilotprojectsandabout10workshopsperyearfortransferofknowledge.

gender distribution

Category % Female Target actual PhDstudents 30 25ResearchScientists 30 13Subprojectmanagers 30 23Board 30 13

InconnectionwithrecruitmentofPhDstudents,theannouncementshavestimulatedwomentoapplyforpositions.Femaleparticipationhasalsobeenoneofthecriteriaforhiringsubprojectmanagersandprogrammanagers.How-ever,inbothcaseswehaveexperiencedproblemswithfindingasufficientnumberoffemalecandidates.

Center ManagementCenter Manager: Jon Kleppe, NTNU

OperationalManager: Jon Lippe, NTNUProject Coordinator; Solveig Johnsen, NTNU

Technical CommitteeAppr. 35 representatives from

the industrial and academic partners

Board14 members, one for each partner

Program 1Drilling and WellConstruction

Tor Stein Ølberg, SINTEF

Program 2Rreservoir Management and Production Optimization

Bjarne Foss, NTNU

Program 3Operation and Maintenance

Anders Valland, MARINTEK

Program 4 New Work Processes andEnabling Technologies

Jon Kvalem, IFE

Core Team

15 Sub Projects15 Sub Projects15 Sub Projects

Sub Projects

Pilot projects and cooperationwith industrial partners

15 Sub Projects15 Sub Projects15 Sub Projects

Sub Projects

15 Sub Projects15 Sub Projects15 Sub Projects

Sub Projects

15 Sub Projects15 Sub Projects15 Sub Projects

Sub Projects

ORGANIZATION CHART

www.ntnu.no/iocenter IO Center AnnualReport2009

17

roald Kluge1.1.IntegratedDrill.SimulatorSINTEF

Jon KleppeCentermanagerNTNU

asgeir tomasgardIOValuationModelNTNU

tor Stein ØlbergProgram1:DrillingandWellConstructionSINTEF

aud Marit Wahl3.3IntegratedplanningMARINTEK

delfina goviaGovia&Associates,LLC

Bernt aadnøyUniversityofStavanger

davide roverso3.1ConditioningbasedMonitoringandMaintenancesupport,IFE

thor Ole gulsrud1.2.DiagnosticToolSINTEF

Stein Krogstad2.1ReservoirmanagementSINTEF

Jon LippeOperationalmanagerNTNU

Solveig JohnsenProjectCoordinatorNTNU

arild N. NystadAdvisorPetromanagementAS

roar Nybø1.2DiagnosticToolSINTEFfromSept2009

prof. erikhollnagelEcoledeMines/Armines

david echeverria CiaurriStanfordUniversity

darijus StrasunskasNTNU

prof. erik YdstieCarnegieMellonUniversity

anders VallandProgram3:OperationandmaintenanceMARINTEK,fromNov.2009

andrew gibsonProgram3:OperationandmaintenanceMARINTEK

torbjørn Korsvold1.3WorkProcessesandExperienceTransfer

george W. halsey1.4UtilizationofIncreasedbandwidthfromboreholeSINTEF

torgeir Brurok3.2ConditioningMonitoringMARINTEK

Bjarne FossProgram2:ReservoirManagementandProductionOptimizationNTNU

Jon KvalemProgram4:NewWorkProcessesandEnablingTechnologiesIFE

grete rindahl4.1FutureCollaborationEnvironmentsIFE

Sjur Larsen4.2WorkProcessesandDecisionMakingStudioApertura

eirik albrechtsen4.3IntegratedOperationsandSafetySINTEF

18

IO Center AnnualReport2009 www.ntnu.no/iocenter

Center Management

people in the IO Center

Visiting researchers postdoctoral researchers

program Managers

Sub project Managers

eka SuwartadiNTNU

are hauganIFE

erik hennieMARINTEK

Lone ramstadMARINTEK

Johannes tjønnås SINTEF

Martin LandrøNTNU

torgeir haavikNTNU,Associated

Odd FalmyrIFE

Knut BjørkevollSINTEF

espen NystadIFE

Knut andreas LieSINTEF

asgeir drøivoldsmoIFE

Lisbeth hanssonSINTEF

Stig Ole JohnsenNTNU

harald SleireMARINTEK

richard rwechunguraNTNU

Kristin halvorsenNTNU

Johnny FrøyenSINTEF

Michael WartmannCarnegieMellonUniversity

Vahid azizUiS

alexey StovasNTNU

Camilla tveitenNTNU

pratichi VaidyaNTNU

per Morten SchiefloeNTNU

Jørn VatnNTNU

harald p. J. thunem IFE

Magnhild Kaarstad IFE

hans Martin helset SINTEF

Margit hermundsgardIFE

Matthias BelloutNTNU

gisle andresenNTNU

alexander JuellNTNU

aminul Islam NTNU,Associated

Mario hoffmannIFE

Curtis WhitsonNTNU

Svein hovland MARINTEK

Sture holmstrøm SINTEF•Michael golan NTNU•Jaising hitesh SINTEF

ann Britt SkjerveIFE

Svein NilsenIFE

agus I hasanNTNU

geir guttormsenNTNU,Associated

Karsten OpelIFE

terje BodalIFE

Silvya dewi rahmawatiNTNU

petter almklovNTNU

hans Olav randemIFE

Bjørn emil MadsenSINTEF

Ingrid SchjølbergSINTEF

Vidar gunnerudNTNU

Mohsen dadasphourNTNU

Øystein VelandNTNU

tor arne reinenSINTEF

Sizarta Sarshar IFE

anders lauvsnesSINTEF

tone BergSINTEF

19

www.ntnu.no/iocenter IO Center AnnualReport2009

research Scientists

ph.d students

Center for Integrated Operations in the petroleum industryTheIOCenterwasestablishedin2006,byleadinginternationaloilcompanies,systemsuppliers,academicinstitutionsandtheResearchCouncilofNorway,withtheobjectivetoundertakeresearch,innovationandeducationonintegratedoperations.

Contact persons

Professor Jon Kleppe, Ph.D, Center Manager Phone: + 47 918 97 300, + 47 73 59 49 33Email: [email protected] Postal address: Department of Petroleum Engineering and Geophysics, S. P. Andersens v. 15, 7491 Trondheim, Norway

Jon Lippe, Operational ManagerPhone: + 47 918 97 033, + 47 73 59 02 33Email: [email protected] address: Department of Petroleum Engineering and Geophysics, S. P. Andersens v. 15, 7491 Trondheim, Norway

arild N. Nystad, Ph.D, Innovation & industrial relationsPhone: + 47 913 22 497, + 47 51 56 71 11Email: [email protected] PetroManagement AS, P.O.Box 252 Sentrum, Haakon VII’s gt. 8 (10th floor), 4002 Stavanger, Norway

IO CenterS. P. Andersens v. 15, 7491 Trondheim, NorwayTelephone: +47 73 59 49 25Telefax: +47 73 94 44 72

www.ntnu.no/iocenter

Industrialpartners

Internationalcooperationpartners

Researchpartners

The IO Center team with Researchers from NTNU, Sintef and IFE.

Established by the Research Council of Norway

Nas

jona

lt se

rtifi

kat:

1660

Prod

uksj

on: T

apir

Uttr

ykk