INVESTIGATION OF EFFECT OF CUTTING PARAMETERS AND … Thesis Full...iii DECLARATION I declare that...

Transcript of INVESTIGATION OF EFFECT OF CUTTING PARAMETERS AND … Thesis Full...iii DECLARATION I declare that...

INVESTIGATION OF EFFECT OF CUTTING

PARAMETERS AND TOOL NOSE RADIUS ON

CUTTING FORCES AND SURFACE ROUGHNESS IN

FINISH HARD TURNING OF AISI D2 STEEL WITH

CBN TOOL

A Thesis submitted to Gujarat Technological University

for the Award of

Doctor of Philosophy

in

Mechanical Engineering

By

Vallabhbhai Dahyabhai Patel

Enrollment No.129990919013

under supervision of

Dr. Anishkumar H. Gandhi

GUJARAT TECHNOLOGICAL UNIVERSITY

AHMEDABAD

[June-2018]

i

INVESTIGATION OF EFFECT OF CUTTING

PARAMETERS AND TOOL NOSE RADIUS ON

CUTTING FORCES AND SURFACE ROUGHNESS IN

FINISH HARD TURNING OF AISI D2 STEEL WITH

CBN TOOL

A Thesis submitted to Gujarat Technological University

for the Award of

Doctor of Philosophy

in

Mechanical Engineering

By

Vallabhbhai Dahyabhai Patel

Enrollment No.129990919013

under supervision of

Dr. Anishkumar H. Gandhi

GUJARAT TECHNOLOGICAL UNIVERSITY

AHMEDABAD

[June-2018]

ii

© Vallabhbhai Dahyabhai Patel

iii

DECLARATION

I declare that the thesis entitled “Investigation of effect of cutting parameters and tool

nose radius on cutting forces and surface roughness in finish hard turning of AISI D2

steel with CBN tool” submitted by me for the degree of Doctor of Philosophy is the record

of research work carried out by me during the period from October-2012 to June- 2018

under the supervision of Dr. Anishkumar. H. Gandhi and his has not formed the basis for

the award of any degree, diploma, associateship, fellowship, titles in this or any other

University or other institution of higher learning.

I further declare that the material obtained from other sources has been duly acknowledged

in the thesis. I shall be solely responsible for any plagiarism or other irregularities, if

noticed in the thesis.

Signature of the Research Scholar: Date: ………………..

Name of Research Scholar: Vallabhbhai Dahyabhai Patel

Place: Ahmedabad

iv

CERTIFICATE

I certify that the work incorporated in the thesis title as Investigation of effect of cutting

parameters and tool nose radius on cutting forces and surface roughness in finish

hard turning of AISI D2 steel with CBN tool submitted by Vallabhbhai Dahyabhai

Patel was carried out by the candidate under my supervision/guidance. To the best of my

knowledge: (i) the candidate has not submitted the same research work to any other

institution for any degree/diploma, Associateship, Fellowship or other similar titles (ii)

the thesis submitted is a record of original research work done by the Research Scholar

during the period of study under my supervision, and (iii) the thesis represents

independent research work on the part of the Research Scholar.

Signature of Supervisor: Date: ……………….

Name of Supervisor: Dr. Anishkumar H. Gandhi

Place: Ahmedabad

v

Originality Report Certificate

It is certified that PhD Thesis titled “Investigation of effect of cutting parameters and

tool nose radius on cutting forces and surface roughness in finish hard turning of

AISI D2 steel with CBN tool” by Mr. Vallabhbhai Dahyabhai Patel has been examined

by us. We undertake the following:

a. Thesis has significant new work / knowledge as compared already published or

are under consideration to be published elsewhere. No sentence, equation,

diagram, table, paragraph or section has been copied verbatim from previous

work unless it is placed under quotation marks and duly referenced.

b. The work presented is original and own work of the author (i.e. there is no

plagiarism). No ideas, processes, results or words of others have been

presented as Author own work.

c. There is no fabrication of data or results which have been compiled /

analyzed.

d. There is no falsification by manipulating research materials, equipment or

processes, or changing or omitting data or results such that the research is not

accurately represented in the research record.

e. The thesis has been checked using https://turnitin.com (copy of originality

report attached) and found within limits as per GTU Plagiarism Policy and

instructions issued from time to time (i.e. permitted similarity index

<=25%).

Signature of the Research Scholar: Date: ….…………..…

Name of Research Scholar: Vallabhbhai Dahyabhai Patel

Place: Ahmedabad

Signature of Supervisor: Date: ………………...

Name of Supervisor: Dr. Anishkumar H. Gandhi

Place: Ahmedabad

vi

vii

PhD THESIS Non-Exclusive License to

GUJARAT TECHNOLOGICAL UNIVERSITY

In consideration of being a PhD Research Scholar at GTU and in the interests of the

facilitation of research at GTU and elsewhere, I, Vallabhbhai Dahyabhai Patel having

Enrollment No.129990919013 hereby grant a non-exclusive, royalty free and perpetual

license to GTU on the following terms:

a) GTU is permitted to archive, reproduce and distribute my thesis, in whole or in part,

and/or my abstract, in whole or in part (referred to collectively as the “Work”)

anywhere in the world, for non-commercial purposes, in all forms of media;

b) GTU is permitted to authorize, sub-lease, sub-contract or procure any of the acts

mentioned in paragraph (a);

c) GTU is authorized to submit the Work at any National / International Library, under

the authority of their “Thesis Non-Exclusive License”;

d) The Universal Copyright Notice (©) shall appear on all copies made under the

authority of this license;

e) I undertake to submit my thesis, through my University, to any Library and Archives.

Any abstract submitted with the thesis will be considered to form part of the thesis.

f) I represent that my thesis is my original work, does not infringe any rights of others,

including privacy rights, and that I have the right to make the grant conferred by this

non-exclusive license.

g) If third party copyrighted material was included in my thesis for which, under the terms

of the Copyright Act, written permission from the copyright owners is required, I have

obtained such permission from the copyright owners to do the acts mentioned in

paragraph (a) above for the full term of copyright protection.

h) I retain copyright ownership and moral rights in my thesis, and may deal with the

copyright in my thesis, in any way consistent with rights granted by me to my

University in this non-exclusive license.

viii

i) I further promise to inform any person to whom I may hereafter assign or license

my copyright in my thesis of the rights granted by me to my University in this non-

exclusive license.

j) I am aware of and agree to accept the conditions and regulations of PhD including

all policy matters related to authorship and plagiarism.

Signature of the Research Scholar: Date: ….…………..…

Name of Research Scholar: Vallabhbhai Dahyabhai Patel

Place: Ahmedabad

Signature of Supervisor: Date: ….…………..…

Name of Supervisor: Dr. Anishkumar H. Gandhi

Place: Ahmedabad

Seal:

ix

THESIS APPROVAL FORM

The viva-voce of the PhD Thesis submitted by Shri Vallabhbhai Dahyabhai Patel

(Enrollment No.129990919013) entitled Investigation of effect of cutting parameters

and tool nose radius on cutting forces and surface roughness in finish hard turning of

AISI D2 steel with CBN tool was conducted on …………………….………… (day and

date) at Gujarat Technological University.

(Please tick any one of the following option)

The performance of the candidate was satisfactory. We recommend that

he/she be awarded the PhD degree.

Any further modifications in research work recommended by the panel after 3

months from the date of first viva-voce upon request of the Supervisor or

request of Independent Research Scholar after which viva-voce can be re-

conducted by the same panel again.

(briefly specify the modifications suggested by the panel)

The performance of the candidate was unsatisfactory. We recommend that

he/she should not be awarded the PhD degree.

(The panel must give justifications for rejecting the research work)

Name and Signature of Supervisor with Seal

1) (External Examiner 1) Name and Signature

2) (External Examiner 2) Name and Signature

3) (External Examiner 3) Name and Signature

x

ABSTRACT

Because of its excellent wear and abrasion properties, AISI D2 steel is widely used as a

material for bearing races, forming dies, punches, forming rolls, etc. Understanding of the

mechanics of oblique turning of hardened materials is important to industries

manufacturing components like bearings, dies and tools. This research describes

investigation of effect of cutting parameters (cutting speed, feed), tool geometries (tool

nose radius) on cutting forces (cutting force, radial force and axial force) and surface

roughness of AISI D2 steel using cubic boron nitride (CBN) tool. Experiments were

conducted based on full factorial design of experiment. Results shows influence of

different cutting conditions on cutting forces and surface roughness. Forces in axial, radial

and cutting directions vary with the different values of cutting speed, feed and nose radius

at constant depth of cut during hard turning. Initially, force model is developed based on

cutting parameters (i.e. cutting speed and feed) and tool nose radius and further it is

extended by considering progressive flank wear. Empirical model of cutting forces shows

best fits with cutting conditions (i.e. cutting speed and feed) and tool geometries (i.e. tool

nose radius, inclination angle and rake angle). Experimental observation shows that feed

is most significant parameter affecting cutting force, radial force and axial force followed

by nose radius and cutting speed. Cutting forces are linearly proportional to feed and nose

radius whereas, it is inversely proportional to cutting speed. A linear exponential model of

surface roughness shows simultaneous effect of cutting speed, feed and nose radius. Feed

contributes significantly to surface roughness than tool nose radius and cutting speed.

Empirical models of forces and surface roughness are validated with new set of

experiments and found to be with reasonable accuracy of prediction within limits of

cutting parameters and tool geometry considered.

xi

ACKNOWLEDGEMENT

I would like to take an opportunity to express my sincere gratitude who have contributed

to this research work and supported me during this journey.

Firstly, I am extremely grateful to my honorable Supervisor Dr. Anishkumar H.

Gandhi, for his continuous guidance, motivation, encouragement and support for

throughout my research work. His guidance helped me in all the time of research and

writing of this thesis, I could not have imagined having a better advisor and mentor for

my research work.

Besides my advisor, I would like to appreciate to my Doctoral Progress Committee

Members Dr. H. K. Raval, Professor, SVNIT, Surat and Dr. D. I. Lalwani, Associate

Professor, SVNIT, Surat for their rigorous examinations and precious suggestion during

my research. Their valuable suggestions and constructive criticisms from time to time

enabled me to complete my work successfully.

I am thankful to Dr, Akshai Aggarwal, Ex. Vice Chancellor, Dr. Navin Sheth, Vice

Chancellor, Shri J. C. Lilani, Registrar and all staff members of PhD Section, GTU.

I would also like to acknowledge guidance and support provided for experimental work by

Mr. I M Hakim, Turner, ITI, Gandhinagar. I would also thankful to Mr. J. D. Patel and

other staffs of workshop instructors of L D R P Institute of Technology and Research,

Gandhinagar, for their valuable support.

Finally, I would like to thanks my father Mr. Dahyabhai Patel and my mother Mrs.

Shantaben Patel for supporting me spiritually during the hard time of this journey. I

would also like to thank my beloved wife Falguni Patel, my son Jils and my daughter

Navya for their unconditional love and moral support.

xii

Table of Content

CHAPTER - 1 Introduction ..................................................................................................... 1

1.1 Overview. .............................................................................................................................. 1

1.2 Hardened workpiece materials and their specific applications ............................................. 2

1.3 Cutting tools used in hard turning......................................................................................... 3

1.4 Cutting conditions, orientation of three dimensional forces, surface roughness and wear

of cutting tool pertaining to machining of hardened materials ............................ 4

1.5 Organization of thesis ........................................................................................................... 7

References…. ..... ……………………………………………………………………………….9

CHAPTER - 2 Literature review .......................................................................................... 10

2.1 Introduction ......................................................................................................................... 10

2.2 Literature on surface roughness of hardened materials ...................................................... 10

2.3 Literature on cutting forces in hard turning ........................................................................ 12

2.4 Literature on tool wear ........................................................................................................ 14

2.5 Literature on development of models of crater wear, flank wear and cutting forces

during turning of hardened materials ................................................................. 19

2.5.1 Literature on modeling of tool wear .......................................................... 19

2.5.2 Literature on analytical modeling of cutting forces .................................. 23

2.6 Findings of literature review ............................................................................................... 28

2.7 Definition of the problem ................................................................................................... 29

2.8 Objectives and scope of study ............................................................................................ 29

2.9 Significance of Study .......................................................................................................... 29

2.10 Research Methodology ..................................................................................................... 31

References…. ... ……………………………………………………………………………….32

CHAPTER - 3 Design of experiment and experimental work ............................................ 36

3.1 Overview. ............................................................................................................................ 36

3.2 Design of experiment .......................................................................................................... 36

xiii

3.3 Experimental work .............................................................................................................. 38

3.3.1 Workpiece ................................................................................................. 38

3.3.2 Cutting tools .............................................................................................. 40

3.3.3 Machine tool .............................................................................................. 41

3.3.4 Surface roughness tester ............................................................................ 42

3.3.5 Tool maker’s microscope for tool wear measurement .............................. 43

3.3.6 Lathe tool dynamometer for measurement of cutting forces .................... 43

3.3.7 Experimental procedure ............................................................................ 44

CHAPTER - 4 Results and discussion .................................................................................. 50

4.1 Overview. ............................................................................................................................ 50

4.2 Experimental results based on various cutting conditions .................................................. 50

4.2.1 Percentage contribution of cutting variables on cutting forces ................. 53

4.3 Influence of cutting conditions on surface roughness ........................................................ 55

4.3.1 Percentage contribution of cutting variables on surface roughness .......... 57

4.4 Tool flank wear at optimum cutting condition ................................................................... 58

References…. ... ……………………………………………………………………………….64

CHAPTER - 5 Model development of three dimensional forces and surface roughness

for hard turning ................................................................................................ 65

5.1 Overview. ............................................................................................................................ 65

5.2 Modeling of cutting forces .................................................................................................. 65

5.2.1 Modeling of cutting forces based on cutting conditions ........................... 66

5.2.2 Modeling of forces considering progressive flank wear of tool ................ 71

5.2.3 Evaluation of total cutting forces and its comparison with predicted

values….. ............................................................................................................ 74

5.3 Modeling of surface roughness ........................................................................................... 76

5.3.1 Modeling of surface roughness based on cutting conditions and

geometry………………………..……… ........................................................... 77

5.3.2 Determination of constants and validation of surface roughness model ... 79

xiv

References…. …………………………………………………………………………………81

CHAPTER - 6 Conclusions and future scope ...................................................................... 83

6.1 Conclusions ......................................................................................................................... 83

6.2 Future scope ........................................................................................................................ 85

Appendices… .. ……………………………………………………………………………….86

List of publications .................................................................................................................. 90

xv

List of Abbreviation

Pa : Hardness of the abrasive particle

Pt : Tool hardness

T : Average temperature

KQ : Constant related with activation energy for diffusion

Kabrasion : Process related dimensionless abrasive wear coefficient

Kadhesion : Process related adhesive wear coefficient

Kdiff : Process related diffusive wear coefficient

α, αn : Rake/chamfer angle, taken as a positive value for simplicity

γ : Clearance angle

D : Coefficient of diffusion

σ, : Normal shear stress

τs : Shear stress in the shear plane

KT : Tool crater wear depth

n : Dimensionless constant

R : Radius of the tool crater arc

F : Friction force

αe : Effective rake angle

Φe : Shear plane angle, angle between the shear plane and cutting

velocity

i : Inclination angle

β : Friction angle

t1 : Depth of cut/ undeform chip thickness

b : Width of cut

N : Normal force

FH : Principal component of the cutting force

Ft : Thrust force

Vs : Sliding velocity

Ψ : Apex angle of the stagnation zone

k : Material shear flow stress

xvi

θ : Slip line angle

Cs : Side cutting edge angle

ηc : Chip flow angle

Fwcutting, Fwaxial,

Fwradial : Forces due to wear in cutting, axial and radial direction

P1 , P2 , P3 : Forces in cutting, axial, and radial directions

Kn, Kf : Cutting pressure coefficients

Acutting : Cutting cross sectional area

* : Equivalent pertaining angles (e.g. i*= equivalent inclination angle)

Fr : Radial force (N)

Fa : Axial force (N)

Fc : Cutting force (N)

d : Depth of cut (mm)

v : Cutting speed (m/min)

f : Feed (mm/rev)

r : Tool nose radius (mm)

Vb : Tool flank wear length (mm)

Fcw : Force in the cutting direction due to flank wear (N)

Faw : Force in the axial direction due to flank wear (N)

Frw : Force in the radial direction due to flank wear (N)

δFcw : Cutting force component due to wear (N)

δFarw : Resultant wear force component of Fcw and Faw (N)

τw : Shear stress along the flank face (N/mm2)

σw : Normal stress along the flank face (N/mm2)

a0, a1, a2, a3 : Constants depend on radial force and cutting conditions

b0, b1, b2, b3 : Constants depend on axial force and cutting conditions

c0, c1, c2, c3 : Constants depend on cutting force and cutting conditions

Fct : Total cutting force in cutting direction (N)

Fat : Total axial force in feed direction (N)

Frt : Total radial force in radial direction (N)

Ra exp : Experimental value of average surface roughness of machined part

(μm)

Ra pred : Average surface roughness prediction based on all possible factors

(μm)

xvii

Ra vfr : Average surface roughness based on v, f, and r (μm)

c0,c1,c2, c3 : Constants corresponding to cutting conditions and tool geometry

xviii

List of Figures

FIGURE 1.1: Atoms of boron nitride changes from hexagonal to cubic structure .................... 4

FIGURE 1.2: Direction of cutting force, radial force and axial force on cutting tool insert ..... 5

FIGURE 1.3: Different wear phenomenon on single point cutting tool .................................... 7

FIGURE 2.1: Geometrical nomenclature of crater wear of CBN tool used in turning of

hard materials ..................................................................................................... 22

FIGURE 2.2: Material removal concept based on extended Lee and Shaffer’s model using

negative rake angle tool ...................................................................................... 25

FIGURE 2.3: Orientation of cutting forces based on progressive wear of flank face of tool

in hard turning .................................................................................................... 27

FIGURE 2.4: Flow chart of applied research methodology ................................................... 32

FIGURE 3.1: (a) Detailed drawing of workpiece (AISI D2 steel) to perform full factorial

design of experiments (all dimensions are in mm) ............................................ 40

(b) Detailed drawing of workpiece (AISI D2 steel) for flank wear

measurement at optimum cuttingconditions (all dimensions are in mm) .......... 40

FIGURE 3.2: CBN cutting tool insert of 0.4, 0.8 and 1.2 mm nose radius .............................. 41

FIGURE 3.3: Work piece material AISI D2 steel after heat treatment .................................... 44

FIGURE 3.4: Flow diagram of complete experimental work .................................................. 45

FIGURE 3.5: Prefinal size of AISI D2 steel round bar before starting of experiment ............ 45

FIGURE 3.6: Finish hard turning at different cutting conditions ............................................ 46

FIGURE 3.7: Experiment set up of lathe tool dynamometer ................................................... 46

FIGURE 3.8: Measurement of surface roughness with the help of surface roughness tester

SJ210 .................................................................................................................. 47

FIGURE 3.9: Turning up to 65 mm cutting length for flank wear measurement .................... 47

FIGURE3.10:Flank wear measurement with suitable fixture using Tool maker’s

microscope……. .......................................................................................... …..48

xix

FIGURE 4.1: Influence of feed (f) and nose radius of tool (r) on axial (Fa), radial (Fr) and

cutting (Fc) force at cutting speed (v) = 80 m/min and depth of cut (d) = 0.2

mm ...................................................................................................................... 52

FIGURE 4.2: Influence of feed (f) and tool nose radius (r) on axial (Fa), radial (Fr) and

cutting (Fc) force at cutting speed (v) = 116 m/min and depth of cut (d) = 0.2

mm ...................................................................................................................... 52

FIGURE 4.3: Influence of feed (f) and tool nose radius (r) on axial (Fa), radial (Fr) and

cutting (Fc) force at cutting speed (v) = 152 m/min and depth of cut (d) = 0.2

mm ...................................................................................................................... 53

FIGURE 4.4: Effect of cutting speed (v) and feed (f) on surface roughness at tool nose

radius (r) = 0.4 mm and depth of cut (d) = 0.2 mm ........................................... 55

FIGURE 4.5: Effect of cutting speed (v) and feed (f) on surface roughness at tool nose

radius (r) = 0.8 mm and depth of cut (d) = 0.2 mm ........................................... 56

FIGURE 4.6: Effect of cutting speed (v) and feed (f) on surface roughness (Ra) at tool nose

radius (r) = 1.2 mm and depth of cut (d) = 0.2 mm ........................................... 56

FIGURE 4.7: Effect of flank wear on cutting forces at optimum cutting conditions (cutting

speed (v) = 152 m/min, feed (f) =0.04 mm/rev and tool nose radius (r) = 1.2

mm) .................................................................................................................... 60

FIGURE 4.8: Effect of flank wear on surface roughness at optimum cutting conditions

(cutting speed (v) = 152 m/min, feed (f) =0.04 mm/rev and tool nose radius

(r) = 1.2 mm) ...................................................................................................... 60

FIGURE 4.9: Correlation of surface roughness and cutting forces at optimum cutting

conditions (cutting speed (v) = 152 m/min, feed (f) =0.04 mm/rev and tool

nose radius (r) = 1.2 mm) ................................................................................... 61

FIGURE 4.10: Effect of flank wear on resultant cutting forces at optimum cutting

conditions (cutting speed (v) = 152 m/min, feed (f) =0.04 mm/rev and tool

nose radius (r) = 1.2 mm) as per Table 4.6 ........................................................ 62

FIGURE 4.11: Effect of resultant cutting forces on surface roughness at optimum cutting

conditions (cutting speed (v) = 152 m/min, feed (f) =0.04 mm/rev and tool

nose radius (r) = 1.2 mm) as per Table 4.6 ........................................................ 62

xx

FIGURE 5.1: Experimental and predicted value of cutting force based on different cutting

conditions (cutting speed (v), feed (f) and nose radius (r) as reported in Table

5.2) ...................................................................................................................... 69

FIGURE 5.2: Experimental and predicted value of radial force based on different cutting

conditions (cutting speed (v), feed (f) and nose radius (r) as reported in Table

5.2) ...................................................................................................................... 70

FIGURE 5.3: Experimental and predicted value of axial force based on different cutting

conditions (cutting speed (v), feed (f) and nose radius (r) as reported in Table

5.2) ...................................................................................................................... 70

FIGURE 5.4: Tool flank wear geometry; (a) cutting force component in z direction, (b)

effective flank and nose wear, (c) resultant force component of x and y

direction .............................................................................................................. 72

FIGURE 5.5: Cutting forces in cutting (Fcw), radial (Frw) and axial (Faw) directions due to

tool flank wear evaluated based on progressive flank wear modeling ............... 74

FIGURE 5.6: Comparison of total cutting force (Fct) considering flank wear (Vb) ................. 75

FIGURE 5.7: Comparison of total radial force (Frt) considering flank wear (Vb) ................... 75

FIGURE 5.8: Comparison of total axial force (Fat) considering flank wear (Vb) .................... 76

FIGURE 5.9: Experimental and predicted value of surface roughness based on different

cutting conditions (cutting speed (v), feed (f) and nose radius (r) as

reported in Table 5.4) ........................................................................................ 80

xxi

List of Tables

TABLE 1.1: Comparisons of hard turning and grinding ............................................................ 2

TABLE 2.1: Different cutting conditions used in various literatures during hard turning ....... 18

TABLE 3.1: Values of input parameters for turning experiments ........................................... 37

TABLE 3.2: Experimental design using full factorial design of experiment ........................... 37

TABLE 3.3: Chemical composition of AISI D2 steel in percentage ........................................ 39

TABLE 3.4: Physical properties of AISI D2 steel .................................................................... 39

TABLE 3.5: Specifications of lathe (NH 22 HMT make) ........................................................ 41

TABLE 3.6: Specifications of surface roughness tester SJ210 ................................................ 42

TABLE 3.7: Specifications of tool maker’s microscope .......................................................... 43

TABLE 3.8: Specifications of lathe tool dynamometer ........................................................... 43

TABLE 4.1: Experimental readings of axial (Fa), radial (Fr) and cutting (Fc) force and

surface roughness (Ra) ....................................................................................... 51

TABLE 4.2: Percentage contribution of nose radius, cutting speed and feed attributes to

cutting force ........................................................................................................ 54

TABLE 4.3: Percentage contribution of nose radius, cutting speed and feed attributes to

radial force .......................................................................................................... 54

TABLE 4.4: Percentage contribution of nose radius, cutting speed and feed attributes to

axial force ........................................................................................................... 54

TABLE 4.5: Percentage contribution of nose radius, cutting speed and feed attributes to

surface roughness ............................................................................................... 58

TABLE 4.6: Experimental readings of tool flank wear, surface roughness and cutting

forces at optimum cutting conditions ................................................................. 59

TABLE 5.1: Model constants evaluated using 27 experimental readings as per Table 4.1 ..... 68

TABLE 5.2: Experimental value of cutting (Fc exp), radial (Fr exp) and axial (Fa exp) force at

different cutting conditions ................................................................................ 68

TABLE 5.3: Model constants evaluated based on 27 experimental results as per Table 4.1 ... 79

xxii

TABLE 5.4: Experimental values of surface roughness (Ra exp) using different sets of

cutting conditions ............................................................................................... 79

xxiii

List of Appendices

Appendix A : Calculation of percentage contribution of variable cutting and geometry

parameters on cutting forces .............................................................................. 86

Appendix B : Calculation of percentage contribution of variable cutting and geometry

parameters on surface roughness ........................................................................ 88

Overview

1

CHAPTER – 1

Introduction

In this chapter, concept of hard turning is defined. Benefits of hard turning over grinding

are discussed. Application of various hardened steel material grades especially hardened

AISI D2 steel is discussed. Various tool materials for turning of hardened steel material

grades along with their characteristics are discussed. Various machining parameters, tool

geometry parameters and machining conditions affecting mechanism of cutting are

discussed.

1.1 Overview

Turning of steel materials with hardness value above 45 HRC (Rockwell hardness) is

defined as hard turning. Hard turning with single point cutting tool is very complex when

hardness of workpiece is in the range of 55-68 HRC [1-3]. Hardness of material, tools

which are used for cutting and mechanism of chip formation differ the hard turning from

conventional turning. Hard turning is an economic and an efficient alternative to grinding

which converts raw materials into desired shape. If complex components could be

manufactured using hard turning, production costs could be decreased up to 70 % [4].

Surface quality can be achieved up to the level of grinding in hard turning. Quality

improvement, cost reduction and reduce setup duration is very challenging in today‘s

market. This scenario enforces the manufacturer to increase quality of product and

efficiency. Turning of materials can be effectively done after heat treatment is the major

benefit over traditional techniques like finish grinding operation [5]. Benefits of hard

turning over grinding are shown in Table 1.1.

Highly precise parts, made up of advanced hardened alloys used in aerospace industries are

manufactured using metal removal processes. Hard components like roller bearings, dies,

tools, automotive parts like crank pins and hydraulic parts have been widely manufactured

using hard turning technology. Cutting fluid and lubricants are not used in hard turning,

thus storage, maintaining and disposal of cutting fluid is eliminated and it may favor the

Ch. 1 Introduction

2

health of machine operators [2]. It has other benefits such as flexibility, higher material

removal rate and reduced machining time [6].

TABLE 1.1

Comparisons of hard turning and grinding [6]

Though hard turning is advantageous over grinding process, it also possesses certain

limitations as described. For example, residual stresses are produced beneath the surface of

turned part due to high temperature and high pressure induces during metal removing.

Also, tool wear is critical phenomenon which deteriorates the surface finish of machined

part.

1.2 Hardened Workpiece Materials and Their Specific Applications

Different workpiece materials are hardened up to 68 HRC and used for specific

applications. Recently, various industries pertaining to machining of hardened materials

commonly use different steels like AISI H11, AISI H13, AISI D2, AISI D3, AISI M2,

AISI M42, AISI T1, AISI T4 and AISI T5. AISI D2 steel is known as high carbon, high

chromium steel. It is used for manufacturing of various parts due to its specific properties

like high strength, high fatigue strength and high wear resistance. Machinability and

toughness of AISI D2 steel are considered to be low [6]. Its specific applications in

industries are mentioned below:

Tools for heavy duty hot forming process like dies, mandrels etc.

Extrusion of rod and tube

Tools for hot impact extrusion

Various tools for production of nuts, screws, rivets, bolts and hollow bodies

Various dies of press machine

Sr. No. Description Hard turning Grinding

1 Rate of metal removal 150 – 1500 mm3/min 10 - 60 mm

3/min

2 Flexibility Very flexible Low flexibility

3 Cutting process Stable Tendency to jerk

4 Accuracy 0.2 micron Ra Better than 0.2 micron Ra

5 Pre-machining duration Less More

6 Effect on atmosphere Material removal

without cutting fluid

Material removal with cutting

fluid

Cutting tools used in hard turning

3

Different dies of casting

Dies of forming process

Cutting blades of hot shearing

1.3 Cutting Tools Used in Hard Turning

All hard machining operations require specific cutting tool materials which can withstand

against the critical conditions produced during machining. Performance of cutting tools are

affected due to tool wear (crater and flank wear), thrust and temperature developed during

machining. Some special characteristics require for tool materials are high wear resistance,

high hardness and chemical stability [7]. Various tool materials like cemented tungsten

carbide, ceramics, cubic boron nitride (CBN) and diamond are commonly preferred for

metal cutting. At elevated temperature hardness of cemented carbide decreases with

decrease in binder content. So, special powder preparation and processing techniques are

required to minimize the grain growth and provide adequate strength. Some improvements

in the toughness of ceramic tools have been achieved recently by alloying alumina with

TiC or with stabilized ZrO2 and by new processing techniques such as hot pressing and hot

isostatic pressing. A significant increase in fracture toughness accomplished with SIALON

based tool materials, though SIALON is not so hard enough. Diamond is one of the hardest

materials which can be used for hard machining, but it is very expensive. In contrast to

diamond, CBN (cubic boron nitride) is more preferable for machining of hardened

workpiece. CBN is chemically more stable than diamond when it is used for machining

ferrous alloys. It has good thermal stability; up to around 800 °C, this temperature can be

further increased by decreasing the impurity content with special processing techniques.

CBN tool is better than carbide and ceramic tools. It can perform 5 to 100 times better in

terms of longer tool life and / or higher removal rate than carbide or ceramic tools.

Proportionate harder cutting materials are required for machining of hardened workpiece.

Development of higher hardness materials like PCBN (polycrystalline cubic boron nitride)

has great importance to machining of hardened materials [4]. Ammonia and boron chloride

form a compound of Boron nitride (BN) as per following reaction:

BCL3 + NH3 → BN + 3HCL (1.1)

Boron nitride (BN) has hexagonal structure like graphite. Hexagonal structure of

hexagonal boron nitride can be transformed in to cubic structure under high temperature

Ch. 1 Introduction

4

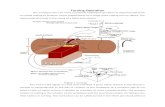

and pressure and form a cubic boron nitride (CBN). This transformation is shown in Fig.

1.1.

FIGURE 1.1

Atoms of boron nitride changes from hexagonal to cubic structure [4]

Bonding strength of CBN is higher due to large amount of binders available in the cubic

structure of boron nitride. High wear resistance of CBN tool is observed, when machining

of hardened steel [6].

1.4 Cutting Conditions, Orientation of Three Dimensional Forces,

Surface Roughness and Wear of Cutting Tool Pertaining to Machining of

Hardened Materials

In process of turning, depth of cut, cutting feed and cutting speed are main cutting factors

affecting the performance of tool. Single point tool geometries like main cutting edge

angle, rake angle and tool nose radius have equal importance. Other input cutting

conditions like workpiece hardness and rigidity of machine tool need to be considered for

efficient machining. During turning, various forces are inducing on cutting tools. For

example, forces exerted in cutting direction, radial direction and feed direction are known

Cutting Conditions, Orientation of Three Dimensional Forces, Surface Roughness and

Wear of Cutting Tool Pertaining to Machining of Hardened Materials

5

as cutting (Fc), radial (Fr) and axial force (Fa) respectively. Three dimensional forces

relating to cutting tool insert are presented in Fig. 1.2.

FIGURE 1.2

Direction of cutting force, radial force and axial force on cutting tool insert

Cutting forces and stresses are continuously induced during the machining of metallic and

nonmetallic materials. Manufacturing industries are constantly focusing to increase

efficiency. There are many investigations pertaining the study of parameters and geometry

of tool on the forces of cutting for different metals [7]. Determination of appropriate

variables of cutting based on material removal rate and tool life has been carried out.

Moreover, morphology of chip, wear of tool, development of tool life equation, three

dimensional forces of cutting and their variations need to be analyzed [6].

Performance of finish hard turning is evaluated based on surface roughness of machined

component which is one of the vital output parameter of the process using different range

of cutting variables [8]. Also, preparation of cutting tool edge and nose radius of tool are

significantly important to obtain lower surface roughness [9].

Ch. 1 Introduction

6

A tool wear mechanism produced during hard turning has been investigated for better

machining and tool selection criteria. CBN is widely used tool as it has comparatively

higher wear resistance [4]. White layer formation and wear of tool are significantly

affected by cutting variables like depth of cut, feed and cutting speed [9]. Some analysis

was studies based on microstructure of steel and worn faces of tool flank and detected that

various particles of hard carbides present in material of workpiece produces grooves on

tool flank face by abrasion. Different wear rates were observed based on the degree of

hardness of carbides in the steels [6]. Wear of tool occurs due to combined or individual

effect of five wear mechanism like abrasion, adhesion, diffusion, fatigue and tribochemical

process. Abrasion and adhesion are referred as mechanical wear. Flank wear formation is

very critical and affects performance of machining more significantly. Flank wear

increases rapidly at initial stage of machining or at last stage of machining for three equal

stage of cutting length. Flank and crater wear are formed due to rubbing of workpiece and

sliding of chips on flank and rake faces of cutting tool [4, 10]. Shortly, individual as well

as simultaneous or coexistence effect of abrasion, adhesion, and diffusion may affect the

wear of CBN tool in hard turning [4].

Relative motion of workpiece and cutting tool is continuous and in great proportion which

is responsible for inducing high cutting tool forces, high temperature and friction at tool

workpiece interface in hard turning. This is the reason for wearing of tool faces which

damages the surface quality and reduces the precision in machined part. Wear is generated

by physicochemical mechanism and it is very complex to differentiate. Commonly, tool

wear occurs during severe cutting conditions in hard turning. It means variation of tool

geometry, tool forces and temperature produced in machining deteriorate surface quality of

workpiece material. Wear on all active faces of tool depends on the machining conditions

[4]. Figure 1.3 shows various wear produced on single point cutting tool during turning.

Cutting forces are induced during machining and affect the performance such as surface

roughness, wear of tool, temperature, vibration etc. Understanding of phenomena of

cutting force is an important in machining as it plays primary role to evaluate power

consumption, tool and material deflections. In hard turning, higher amount of cutting

forces are produced because of high hardness of material this affects the performance of

cutting tool [7].

Organization of Thesis

7

FIGURE 1.3

Different wear phenomenon on single point cutting tool [4]

However, geometries of tool like nose radius and inclination angle make the chip

formation process as a critical oblique cutting process. Some theory has been developed

which contains the geometry of tool along with cutting conditions to evaluate temperature

and forces [11].

AISI D2 steel which can be hardened up to 68 HRC is used in many engineering

applications. CBN possess certain advantages over other tool materials like diamond,

tungsten carbide, ceramic etc. Research related to turning of AISI D2 steel investigating

influence of tool geometries and different input cutting variables on surface roughness of

component, cutting forces and tool wear may be of great interest to machining industry.

This has provided motivation to take up this research with specific objectives as reported

in chapter – 2.

For clarity of presentation, content of the thesis is organized in different chapters as per the

detail given in following section.

1.5 Organization of Thesis

Thesis contains six chapters to address the objectives of research work. Outline of various

chapters is discussed below;

Ch. 1 Introduction

8

CHAPTER 1 describes back ground of hard turning, tool materials, workpiece materials,

cutting parameters, tool geometries, mechanism of cutting forces, science of tool wear and

surface roughness of machined part.

CHAPTER 2 emphasizes review of specific literatures attribute to analysis of surface

finish, cutting forces and wear of tool for turning of hardened material. It covers complex

mechanism of oblique cutting, impact of cutting variables and geometries of tool on

performance of machining. It also deals with the extensive modeling of three dimensional

forces of cutting, surface roughness and wear of tool studied by various authors. Finally,

overall findings of various literatures, objectives, scope of work and their significance are

presented.

CHAPTER 3 reports design of experiment and experimental work. It explains detail

experimental planning for hard turning experiments. It also mentions the details of

instruments used in experimentation and methods of measurement of output variables.

CHAPTER 4 shows experimental readings of three dimensional forces of cutting, surface

roughness of machined component and wear of tool. Also, influence of different cutting

variables on three dimensional forces of cutting, surface roughness and wear of tool are

analyzed in this chapter.

CHAPTER 5 demonstrates empirical modeling of surface roughness and forces in axial,

radial and cutting directions based on various cutting conditions to reveal correlation of

outcome with input variables in hard turning. It also shows the comparison between test

results and predicted outcome for validation of models of forces of cutting and surface

roughness.

CHAPTER 6 depicts summary of the important conclusions derived based on results of

presented research work and scope of future work.

References

9

References

[1] Pardeep Kumar SD, Aman Agarwal (2011) HARD TURNING VERSUS GRINDING, National

Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering.

[2] de Oliveira AJ, Diniz AE, Ursolino DJ (2009) Hard turning in continuous and interrupted cut with PCBN

and whisker-reinforced cutting tools, Journal of Materials Processing Technology, 209, 5262-5270.

[3] Bartarya G, Choudhury S (2012) State of the art in hard turning, International Journal of Machine Tools

and Manufacture, 53, 1-14.

[4] Huang Y, Chou YK, Liang SY (2007) CBN tool wear in hard turning: a survey on research progresses,

The International Journal of Advanced Manufacturing Technology, 35, 443-453.

[5] Davim JP (2011) Machining of hard materials, Springer Science & Business Media.

[6] Arsecularatne JA, Zhang LC, Montross C, Mathew P (2006) On machining of hardened AISI D2 steel

with PCBN tools, Journal of Materials Processing Technology, 171, 244-252.

[7] Kamely MA, Noordin MY (2011) The impact of cutting tool materials on cutting force, World Academy

of Science, Engineering and Technology, 51, 903-906.

[8] Bartarya G, Choudhury SK (2012) Effect of cutting parameters on cutting force and surface roughness

during finish hard turning AISI52100 grade steel, Procedia CIrP, 1, 651-656.

[9] Özel T, Karpat Y, Figueira L, Davim JP (2007) Modelling of surface finish and tool flank wear in turning

of AISI D2 steel with ceramic wiper inserts, Journal of materials processing technology, 189, 192-198.

[10] Thamizhmanii S, Hasan S (2009) Investigation of surface roughness and flank wear by CBN and PCBN

tools on hard Cr-Mo steel, Proceedings of the World Congress on Engineering, pp. 5.

[11] Arsecularatne JA, Fowle RF, Mathew P (1996) Nose radius oblique tool: cutting force and built-up edge

prediction, International Journal of Machine Tools and Manufacture, 36, 585-595.

Ch. 2 Literature Review

10

CHAPTER – 2

Literature Review

2.1 Introduction

Introduction to hard turning including its complexity, applications, cutting tools, cutting

conditions and its influence on three dimensional forces of cutting, surface finish and wear

of tool etc. is discussed in chapter 1. Out of the large amount of reported research available

related to hard turning, some important literatures based on the scope of this research work

are identified and discussed in this chapter.

Literatures addressing use of numerical, analytical and experimental methods for analysis

of hard turning of wide range of workpiece materials with different tool materials are

reviewed. It has been tried to report the literature exploring effect of cutting variables on

cutting forces, surface finish of machined part and mechanism of wear development during

turning of hardened materials. Range of cutting parameters used for hard turning with

different materials of workpiece and cutting tools are explored. Work reported depending

on contents of literatures are scrutinized and discussed in four different sub sections

namely; surface roughness of hardened materials, three dimensional forces of cutting in

hard turning, wear of tool, modeling of wear and cutting forces. After discussion on the

literature, overall findings based on literature reviewed, definition of the problem,

objective and scope of study and significance of study is reported.

2.2 Literature on Surface Roughness of Hardened Materials

Surface roughness of machined component is key factor for effectiveness of any machining

process. All factors considered in hard turning affect surface quality of workpiece in

different proportions. Most influencing parameters affecting surface roughness values are

feed, cutting speed and tool nose radius [1]. Moreover, built up edge formation [2] and

wear of tool phenomenon [3] affect the surface quality.

Literature on Surface Roughness of Hardened Materials

11

Various authors have investigated various aspects of hard turning and drew conclusions

regarding the surface roughness of machined part based on varying amount of cutting

conditions. Munoz-Escalona and Cassier [4] reported experimental work to study the

variation of smoothness of machined surface of workpiece for different nose radius of tool

and different cutting parameters. In addition, turning of various steel round bars (AISI

1020, 1045, 4140, D2) with different hardness was used to study the influence of

workpiece hardness on surface irregularity of machined components. Conclusion was

drawn by authors that surface roughness decreases with increase of nose radius of tool,

increase of cutting speed and reduction in feed.

Özel et al. [5] performed machining of hardened steel (AISI D2 steels, 60 HRC) with

ceramic tools of different nose radius. Full factorial design of experiments were applied to

perform experiments using three values of feed, cutting speed and cutting time with their

three levels and analyzed their influence on surface roughness. In the results, lower range

of surface roughness (around 0.18 – 0.20) µm was measured at low feed and highest

cutting speed. In addition, better tool life was obtained at lowest feed.

Many literatures pertaining to effectiveness of CBN tool used in machining of different

steels of high hardness along with different cutting parameters are studied. Özel et al. [6]

performed turning of hardened AISI H13 round bar (51.3, 54.7 HRC) using CBN tool.

Three different values of feed; 0.05, 0.1 and 0.2 mm/rev and two different values of cutting

speed; 100 and 200 m/min were used to analyze surface roughness. Also, they developed

functional relationship of surface roughness with feed, cutting speed and workpiece

hardness using regression analysis and artificial neural network. Authors obtained higher

surface roughness at high value of feed and hardness.

Bouacha et al. [7] performed hard turning using different cutting speed (125 - 246 m/min),

feed (0.08 - 0.16 mm/rev) and depth of cut (0.15 - 0.45 mm) with CBN tool. RSM

(response surface methodology) was used for analysis to study the influence of various

parameters to surface finish in machining of AISI 52100 steel having hardness of 64 HRC.

They observed that feed was most affecting parameter for variation of surface roughness

while depth of cut had very marginal effect on surface roughness. Conclusion also shows

that cutting speed has negative influence on surface roughness.

Ch. 2 Literature Review

12

Aouici et al. [8] carried out turning of AISI H11 round bar of three different hardness (40,

45 and 50 HRC) with CBN tool using varying amount of depth of cut (0.15 - 0.45 mm),

cutting speed (120 - 240 m/min) and feed (0.08 - 0.16 mm/rev) to analyze their effect on

surface finish. Results of surface roughness were measured in the range of 0.34 - 0.83 µm.

Authors studied effect of two-factor interactions like hardness of component and cutting

speed, depth of cut and feed, cutting speed and depth of cut, hardness of component and

feed on finish. They concluded that interaction of feed and hardness of component

significantly affects surface roughness. They also concluded that high cutting speed and

lower feed showed lower surface roughness.

Bartarya and Choudhury [9] performed hard turning to study the influence of different

parameters on surface roughness. CBN tool was utilized for turning of AISI 52100 steel

(60±2 HRC). Regression equation of surface roughness was formulated based on full

factorial design of experiment using range of input parameters 167-261 m/min, 0.075–0.15

mm/rev and 0.1–0.2 mm for cutting speed, feed and depth of cut respectively. Average

value of surface roughness was achieved from 1.11 µm to 6.19 µm. Depth of cut, feed and

their interaction had significant contribution. On increasing of feed at low depth of cut,

surface roughness first decreases and then increases. Cutting speed had less influence on

surface roughness.

Besides variation of cutting parameters and tool geometries, some phenomenon like tool

wear greatly influence the performance of machining. Rech and Moisan [10]

experimentally investigated influence of cutting speed, feed and tool wear on surface

quality of 27MnCr5 steel while turning. They stated that feed and tool wear significantly

affect surface roughness in comparison to cutting speed. However, surface roughness

increases suddenly at high cutting speed between 200–250 m/min. It might be due to

sudden wearing of tool during turning.

2.3 Literature on Cutting Forces in Hard Turning

In material removing process, cutting forces are induced on tool in radial, axial and cutting

directions. In hard turning, it is important to give proper attention on mechanism of cutting

forces as it is essential for taking decision for selection of tool geometry and its material.

Investigation of tool performance is reported by different researchers [11-13] and observed

that it depends on many variables like depth of cut, feed, cutting speed, wear of tool and

Literature on Cutting Forces in Hard Turning

13

cutting forces. Various researchers reported the effect of cutting conditions, material

hardness and geometries of tool on three dimensional cutting forces.

Bartarya and Choudhury [9] investigated variation of three dimensional forces in cutting

based on depth of cut, feed and cutting speed in turning of hardened steel of AISI 52100

(60±2 HRC) using CBN tool. Experiments were performed using full factorial design of

experiment for three different values of depth of cut (0.1, 0.15 and 0.2 mm), feed (0.075,

0.113 and 0.15 mm/rev) and cutting speed (167, 204 and 261 m/min). Combined effect of

machining parameters on cutting forces was also investigated. Forces in cutting, radial and

axial directions were more sensitive with depth of cut than feed. Cutting speed had least

contribution to radial and axial force. Authors also reported development of cutting forces

model based on regression analysis.

Few researchers also investigated effect of workpiece hardness on cutting forces along

with effect of main cutting parameters. Aouici et al. [8] reported hard turning mechanism

to show influence of different variables on three dimensional forces in cutting with the

variable depth of cut 0.15-0.45 mm, feed 0.08-0.16 mm/rev, cutting speed 120-240 m/min

and hardness of materials 40, 45 and 50 HRC. Experiments were carried out on AISI H11

steel using CBN tool. Results of tangential, axial force and thrust force were measured in

the range of 59.76–302.28 N, 41.13–166.95 N and 99.71–369.35 N respectively. Results

showed that depth of cut influenced cutting force components significantly followed by

workpiece hardness. Contribution of depth of cut towards cutting and axial force was

found to be 31.50 % and 56.77 % respectively. While, cutting speed had lower

contribution (0.14 %) on forces. Authors also concluded that lower axial force was

obtained at lower feed and moderate amount of cutting speed. Interaction effect of depth of

cut and hardness of workpiece material influenced the axial force. It was observed that

lower axial force was obtained at lower depth of cut and lower hardness of workpiece

material.

Cutting forces also varied with radius provided at cutting edge of tool and had significant

impact on three components of cutting forces in turning of hard metal. Liu et al. [14] performed turning of hardened JIS-SUJ2 steel and investigated the influence of nose radius

of CBN tool on cutting forces under dry condition. Experiment was performed at depth of

cut of 0.1 and 0.2 mm, constant feed of 0.1 mm/rev and constant cutting speed of 120

Ch. 2 Literature Review

14

m/min. Authors concluded that progressive increase of nose radius increases the thrust

force.

Arsecularatne et al. [15] performed turning of hardened AISI D2 steel (62 HRC hardness)

with PCBN cutting tool. Various values of three dimensional forces induced in cutting

were reported during machining which was carried out at different values of cutting speed

(70–120 m/min), feed (0.08–0.20 mm/rev) and 0.5 mm constant depth of cut. From

graphical representation of cutting force, radial force and axial force components, they

found that axial forces was the smallest force, cutting force was the largest force and radial

force lied between axial and cutting force.

Tönshoff et al. [16] studied relationship between cutting forces and material hardness.

Turning of AISI 4030 round bar was performed using constant depth of cut, feed and

cutting speed of 0.15 mm, 0.9 mm/rev and 90 m/min respectively. They analyzed forces

and concluded that hardness of material affect the cutting forces. Cutting forces for cutting

of soft material were high and observed to be decreasing with increase in workpiece

hardness. While cutting forces were observed to be increasing with increase the hardness

of material above 50 HRC. This increase amount of cutting forces raised temperature at

work area due to energy consumption resulted in increase of thermal load in hard turning. Authors selected low feed and small depth of cut to reduce mechanical and thermal loads

on tool. Moreover, increases of tool wear due to increase in cutting time affected cutting

force component greatly.

2.4 Literature on Tool Wear

Extensive research work is reported addressing prediction of wear of tool in turning of

hardened materials as it is the measure of tool failure.

Various authors described different reasons for development of tool wears in metal cutting

operations. Waydande et al. [17] studied phenomenon of tool wear produced during hard

turning. They concluded that constant heat is generated due to continuous shear and

friction during turning and as a results high temperature is induced at tool and chip

interface. They reported different types of wears observed at tool faces due to combine

effect of adhesion, abrasion and diffusion. Amongst that; wear of crater, flank and notch

were commonly observed in turning of hardened material. They concluded that friction

Literature on Tool Wear

15

produced between flank face and workpiece was responsible for flank wear. Wear land of

flank face was observed along the major and minor cutting edges of tool due to abrasion

between cutting tool and workpiece component. Crater wear was observed on rake surface

as a result of adhesion and diffusion of chip particles and small elements of rake face.

Chemical or metallurgical wear was induced due to mechanical friction along the major

cutting edge. Authors also described notch wear due to combination of wears of rake and

flank surface besides to intersection point between primary cutting edge and workpiece. Previous passes during cutting and mechanical thrust which was induced due to wear

caused surface hardening of workpiece.

Anthony et al. [18] reported wear pattern which was created due to adhesion with

continuous machining. Adhesion was produced due to high temperature and pressure

created at shear zone and it joins rake face and chip temporarily. As a result, lose particles

removes from soft surface. Adhesion was commonly found in aluminium alloys, but it was

not usual in hard turning. They also reported softening of materials at high temperature,

notching and diffusion and their resultant effect on wear of tool. However, it was difficult

to obtained tool life equation based on cutting variables like cutting parameters and

geometries of tool as well as properties of tool and workpiece materials. They reported

some critical problems occurred due to shortage of relevant details, high temperature and

high rate of strain. Also, various factors influenced tool life like material of workpiece and

tool, machine tool, geometries of tool and cutting parameters.

Arsecularatne et al. [19] concentrated on various literatures pertaining to flank wear and

tool life while machining with WC (tungsten carbide), PCBN (poly-crystalline cubic boron

nitride) and PCD (poly-crystalline diamond) tool materials. Authors described dominant

wear pattern of PCBN and tungsten carbide tool. Wear mechanism due to abrasion,

adhesion, micro-cracking and fatigue was used to explain wear of PCD tool. But,

unfortunately wear of PCD tool was not understood due to non-availability of experimental

results. Authors concluded that chemical wear found to be main wear phenomenon for

PCBN tool. They also reported that diffusion was the dominant wear mechanism for WC

tool and steel combination. Moreover, progressive flank wear was observed on tool flank

face and it was useful to define tool life. Flank wear progression caused increase in the

wear land. Also, surface quality and dimensional accuracy of machined part get affected

after certain level of flank wear.

Ch. 2 Literature Review

16

Liu et al. [14] reported the influence of tool nose radius on flank wear of CBN tool in hard

turning of JIS-SUJ2 bearing steel under dry condition. Experiment was performed using

depth of cut of 0.1 and 0.2 mm. Cutting speed and feed kept constant and were 120 m/min

and 0.1 mm/rev respectively. Authors concluded that friction produced at tool–workpiece

interface significantly contributed to flank wear. Friction developed between tool and

workpiece increases with increase of tool flank wear and resulted in increase of cutting and

thrust force on cutting tool. Also, residual tensile stresses at machined workpiece increased

remarkably with increase of tool wear.

Remadna and Regal [20] applied different methods to perform experimental work. In first

method experiment was performed with constant cutting speed, while in the second

method, variable cutting speed from 100-300 m/min was introduced in turning.

Measurements of tool wear at regular interval were recorded to scrutinize the phenomenon

of wear along tool faces. They concluded that shape of wear developed in cutting was

attributed to geometry of tool, cutting parameters and workpiece material. However, wear

of CBN tool did not affect the quality of surface directly. Wear progression affected

cutting force which altered the functioning of system because of inter-relationship between

workpiece and cutting tool.

Ozel et al. [5] used different combinations of feed (0.05, 0.10 and 0.15 mm/rev) and

cutting speed (80, 115 and 150 m/min) to perform turning of hardened AISI D2 steels

having hardness of 60 HRC. Experiment was carried out using 0.2 mm depth of cut and

tool having ceramic material to obtain model of tool life. Predictive model of tool wear

was developed using neural network and multiple linear regression method. After

machining for around 15 minutes at high cutting speed, tool flank wear was observed 0.15

mm and it was considered as tool life criterion. They concluded that lowest cutting speed

and feed combination results into best life of tool.

Turning of AISI D2 steel with 62 HRC hardness was performed by Arsecularatne et al.

[15] with PCBN tools at different range of cutting speed (70–120 m/min) and feed (0.08-

0.20 mm/rev) combinations. Flank wear was used as criteria for deciding tool life. Lowest

speed (70 m/min) results into highest tool life among the selected tool and workpiece

combination. Most appropriate feeds for roughing and finishing operation were observed

0.20 mm/rev and 0.14 mm/rev respectively. Authors used Taylor tool life equation which

was used to define correlation of cutting parameters with tool life.

Literature on Tool Wear

17

Zhou et al. [21] reported the influence of chamfer angle on wear of flank face of PCBN

tools in turning of hardened 100Cr6 steel having hardness of 60-62 HRC. Finish hard

turning was performed using depth of cut, feed and cutting speed as 0.5 mm, 0.05 mm/rev

and 160 m/min respectively. Various tools with varying amount of chamfer angles between

00 and 30

0 were selected along with other geometries like constant cutting edge radius of

0.01 mm and 0.1mm chamfer width. It could be observed that tool life increases and

reached maximum when chamfer angle increases from 00 to 15

0.

Kishawy and Elbestawi [22] described influenced of flank wear on surface roughness of

machined component. Workpiece material AISI D2 having 62 HRC hardness was used to

perform turning to analyze the surface roughness of machined component using different

range of cutting speed, feed and depth of cut of 140-500 m/min, 0.05-0.2 mm/rev and 0.2-

0.6 mm respectively. PCBN tools having honed nose radius of 0.0125 mm and sharp

chamfer of 200×0.1 mm were used. Authors concluded that tool wear rate was increased

with increasing the value of cutting speed above 350 m/min. So, it deteriorated the surface

finish of machined component and this caused the material side flow during machining.

Moreover, feed and cutting speed combination was found to be main cause of micro cracks

and cavities. Due to phase transformation during machining, machined surface found

thermally affected and white layer was formed especially with chamfered or worn tools.

Tool life of different tools depends on wear rate of different materials. Sahin [23]

compared the tool life of cubic boron nitride (CBN) cutting tools and ceramics tools while

turning of hardened bearing steels. Performance of CBN tool was reasonably good than

ceramic tool. Also, investigation of effect of feed, cutting speed and hardness of cutting

tools on the life of tool was carried out based on the L9 orthogonal array in Taguchi

method. It could be seen from the results that the cutting speed had major contribution

which influenced wear of tool than hardness of workpiece and feed. Optimum cutting

conditions were evaluated based on tool life using signal to noise ratio. For effective

prediction, regression model was applied to develop exponential model. ANOVA

performed at 90% confidence level revealed different contribution of variables which

affected tool life. The contribution of feed, cutting speed and hardness of material was

observed to be 25.22 %, 41.63 % and 32.68 % respectively.

Various authors have performed turning of hardened materials using different cutting

parameters, tool geometries and different hardness of workpiece. It is important for

Ch. 2 Literature Review

18

machinist to work in appropriate range of various cutting conditions to improve

performance of turning. Here, efforts have been made to accumulate such technical data

specifically for hard turning and reported in Table 2.1.

TABLE 2.1

Different cutting conditions used in various literatures during hard turning

Table 2.1 shows different hardened materials used in turning process which was performed

with the various range of depth of cut, feed, cutting speed, nose radius of tool and tool

materials.

Here, it is necessary to identify contribution of all input factors on the performance of

turning as they are functionally related with each other. In oblique cutting system it is very

difficult to develop relationship which shows interaction effect of various parameters on

output. As per above reported literatures, force and wear draws attention towards the

performance of hard turning as it influenced surface roughness, design of tool and power

consumption. Various authors have developed models based on empirical and analytical

methods for cutting forces and tool wear which are described in successive section.

Sr.

No

Workpiece material

(hardness) r (mm) Tool material v (m/min) f (mm/rev)

d

(mm)

1 JIS SUJ2 (60 HRC) [14] 0.4, 0.8,

1.2 CBN 120 0.1

0.1,

0.2

2 AISI 52100 (60-62 HRC)

[24]

0.8, 1.6,

2.4

Alumina, titanium-

carbide

composite

120 – 180 0.05 – 0.6 0.2

3 H13 steel (56 HRC) [25] 0.4 CBN 144.26,

288.52 0.172 0.2

4 AISI D2 (60 HRC) [26] 0.8 CBN, Ceramic 100, 140,

200 0.06 0.4

5 AISI D2 (60±1 HRC) [5] 0.8 Ceramic 80, 115,

150

0.05, 0.10,

0.15 0.2

6 AISI D2 (62HRC) [15] 0.8 CBN 70, 95, 120 0.08, 0.14,

0.20 0.5

7 AISI D2 (58 HRC) [27] 0.8 Mixed alumina 80–150,

220

0.05–0.10

and 0.15 0.2

8 AISI D2 (60 HRC) [28] 0.8 Ceramic tool 80, 150,

220

0.05, 0.10,

0.15 0.2

9 AISI D2 (54HRC) [29] 0.8 CBN 120, 180,

230 0.08, 0.12 0.2

Literature on Development of Models of Crater Wear, Flank Wear and Cutting Forces During Turning of

Hardened Material

19

2.5 Literature on Development of Models of Crater Wear, Flank Wear

and Cutting Forces During Turning of Hardened Materials

Various models were developed and utilized by many authors to optimize performance of

hard turning. In this section, different models have been reviewed for turning of hardened

materials using CBN (cubic boron nitride) tool. Here, efforts are made to describe

appropriate empirical and analytical models. Different models pertaining to crater and

flank wear model, model of oblique cutting force, Usui‘s wear model, force model of

extended Lee and Shaffer, morphology of chip and flank wear progression are reported

here to recognize the relationship of different parameters and geometries of tool with

forces and wear developed in machining. Different methods are reported to scrutinize the

influence of cutting variables on forces and wear of tool developed during experiments.

Various modeling of cutting forces and tool wear are reported here. So, suitable model can

be applied as per necessity of industries of manufacturing of hard components.

2.5.1 Literature on Modeling of Tool Wear

Many authors reported literatures on modeling of tool wear and its influence with cutting

forces and surface roughness. Özel et al. [5] stated that tool crater wear and flank wear

directs the tool life and were main factors contributing to dimensional variation and

reduction of surface quality of materials. Additionally, reported research shows that

inaccuracy and instability of tool motion during machining was produced as a consequence

of wear of tool and hence cutting forces [5, 30, 31].

Different approaches for development of cutting force model in association with chip

morphology had been applied based on different numerical, empirical and analytical

method. Chang [32] analyzed the forces in cutting, radial and axial directions considering

effect of tool wear. Many authors [8, 33, 34, 35] investigated the effect of different

material hardness (50-64 HRC) on tool wear under moderate feed, cutting speed and lower

depth of cut for hard turning. Huang and Liang [36] developed model of tool wear using

analytical approach and finite element method (FEM).

Huang et al. [37] reported extensive survey on wear of CBN tool in turning of hardened

component. They described causes of wear and its influence on performance of hard

Ch. 2 Literature Review

20

turning. Commonly, interaction effect of diffusion, adhesion and abrasion was found to be

major factors affecting wear of CBN tool during turning of hardened materials. However,

authors concluded that discrete wear phenomenon was dependent on type of material of

workpiece and tool, tool-workpiece orientation, cutting parameters, geometry of tool,

properties of CBN tool such as grain size, binder phase and content of CBN. Apart from

main wear mechanism like flank, crater and nose wear; some wear was observed due to

notching and micro-chipping on CBN tool during hard turning. But authors drew final

conclusion that only flank and crater wear required greater attention for research as it has

greater influence on metal cutting performance. Bouchelaghem et al. [33] developed

mathematical models to evaluate the relationship between cutting speed and life of CBN

tool. Authors concluded that tool wear was key variable for performance evaluation as it

affected surface quality of machined component. Also they stated that consistency of

process were reliant on tool wear phenomenon. Also, surface finish and precision of the

machined work piece reduced due to tool wear. Authors stated that mechanism of wear is