Internal Tool Catalog

-

Upload

andrew-duran -

Category

Documents

-

view

257 -

download

11

description

Transcript of Internal Tool Catalog

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

INTERNAL TOOL

INTERNAL TOOL INC.

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

INTRODUCTIONINTERNAL TOOL IS HOME TO THE LARGEST COLLECTION OF UNIQUE AND HARD TOFIND CUTTING TOOLS, HAS THE LARGEST SIZE SELECTION OF COMMON TOOLS,AND CREATES REVOLUTIONARY TOOLS FAR AHEAD OF THEIR TIME.

CATALOG 2012 SERIES INDEXSERIES PAGE #04...MULTI REACH BORING BAR ........706...MULTI REACH GROOVER..............1408...ULTI REACH THREADER...............1409...MULTI REACH PROFILER...............2010...STANDARD BORING TOOL.............611...MAX BORE TOOL...............................712...CPGT INSERT BORING BAR...........29-3014...TPGT INSERT BORING BAR............24-2615...TPGT INSERTS...................................24-2616...CCGT INSERT BORING BAR...........27-2817... CCGT INSERTS.................................27-3020...GROOVING TOOLS...........................1021...MICRO ENDMILLS.............................4422...MAX GROOVE TOOLS......................1124...FULL RADIUS GROOVE TOOL........1226...INSERT GROOVE TOOL...................3127...O'RING GROOVE TOOL ....................1429...LOLIPOP CUTTERS............................6130...THREADING TOOLS..........................1531...L.H. THREADING TOOLS..................1532...ACME THREADING TOOLS.............1633...EXTERNAL ACME TOOLS.............1634...STUB ACME THREAD TOOLS........1636...INSERT THREAD TOOLS.................32-3437...THREADING INSERTS......................32-3439...EXTERNAL GROOVE TOOLS........15 &1940...REPLACMENT HEADS.....................3541 ...CARBIDE ENDMILLS.......................44-4542...QUICK CHANGE TOOLS....................8-943...I.D. CHAMFER TOOLS.......................1846...THREAD RELIEF TOOLS...................1848...BORE & GROOVE TOOLS..................1749...DRILL MILLS.........................................4650...BORE & THREAD TOOLS..................1751...O'RING DOVETAIL CUTTERS..........5852...THREAD & GROOVE TOOLS............1753...LATHE O'RING TOOLS.......................12

SERIES PAGE #54...DOUBLE EDGE BORE TOOL.. ............1855...BORE & BACK CHAMFER...................1756...PROFILE TOOLS.....................................20-2158...SPADE DRILLS........................................4759...DRILL & BORE TOOL..............................1860...DIE SINKER..............................................3761...RUNNER CUTTERS...............................3762...ENGRAVING TOOLS...............................3663...COUNTERSINKS.....................................3764...CHAMFERMILLS.....................................38-3965...EDGE BREAKERS..................................4366...CNC BACK-SPOT FACER....................1967...REVERSE CORNER ROUNDERS......4368...CORNER ROUNDERS...........................40-4169...STUB TAPERED ENDMILLS................3770...SPLIT BLANKS.........................................2271...CENTER DRILLS.....................................4772...DOUBLE CHAMFER CUTTERS...........4373...FACE GROOVERS..................................2374...LONG KEY CUTTERS............................5475...SPOTTING DRILLS.................................4776...SOLID CARBIDE KEY CUTTERS........48-5077...RETAINING RING KEY CUTTERS.......5478...CARBIDE HEAD KEY CUTTERS.........49-5179...METRIC KEY CUTTERS........................5380...FULL RADIUS KEY CUTTERS.............5681...ANGLERS..................................................5582...CONCAVE RADIUS KEY CUTTER......5684...DBL CONCAVE RADIUS CUTTER......5685...N/C COUNTER BORES..........................6786...DOVETAIL CUTTERS............................58-5988...THREADMILLS........................................6489...MULTI THREAD MILLS..........................6590...SINGLE ANGLE CUTTERS...................5491...BORING BARS FOR PLASTIC.............792...DOUBLE ANGLE CUTTERS.................62-6393...CARBIDE REAMERS.............................6694...SPLIT BUSHINGS...................................2296... FACE GROOVER HOLDER.................2398...TOOL HOLDER........................................1999...REPLACMENT SCREWS......................35

INTERNAL TOOL

INTERNAL TOOL INC.

121011918555551-5262-63565657535448-4950156171165581420-2120966354337355447222247371532-3415862-63189

19

61

ACME THREADING TOOLSACME THREAD MILLSANGLE MILLSBORE & BACK CHAMFER TOOLSBORE AND GROOVE COMBINATION TOOLSBORE & THREAD COMBINATION TOOLSBORING TOOLS SOLID CARBIDEBORING TOOLS CARBIDE TIALN COATEDBORING TOOLS INSERT DIAMOND STYLEBORING TOOLS INSERT TRIANGLE STYLEBORING TOOLS MULTI-REACHBORING TOOLS FOR PLASTICBORING TOOLS QUICK CHANGEBUSHINGSCENTER DRILLSCHAMFER MILLSCNC BACK-SPOT FACERSCORNER ROUNDING ENDMILLSCORNER ROUNDING ENDMILLS CUSTOMCONCAVE RADIUS CUTTERSCONVEX RADIUS CUTTERSCOUNTERBORESCOUNTERSINKSDIE SINKERSDOUBLE ANGLE CUTTERSDOUBLE CONCAVE RADIUS CUTTERSDOUBLE CHAMFER CUTTERSDOUBLE EDGE BORING TOOLSDOVETAIL CUTTERSDOVETAIL CUTTERS MADE TO ORDERDRILL & BORE TOOLSDRILLMILLSEDGE BREAKERSENDMILLS, MICROENDMILLSENGRAVING TOOLSEXTERNAL GROOVE TOOLSEXTERNAL THREAD TOOLSEXTERNAL ACME THREAD TOOLSFACE GROOVING TOOLSFLAT BOTTOM REAMERSGROOVE & BORE COMBINATION TOOLGROOVE & THREAD COMBINATION TOOLSGROOVING TOOLS FULL RADIUSGROOVING TOOLS INSERT STYLEGROOVING TOOLS MULTI-REACHGROOVING TOOLS MADE TO ORDER

PROFILE TOOLSPROFILE TOOLS MULTI-REACHPROFILE TOOLS QUICK CHANGEREAMERSREPLACMENT INSERT BAR HEADSREVERSE CORNER ROUNDERSRUNNER CUTTERSSCREWS, BORING BARSINGLE ANGLE CUTTERSSPADE DRILLSSPLIT BLANKSSPLIT BUSHINGSSPOTTING DRILLSTAPERED ENDMILLSTHREADING TOOLS SOLID CARBIDETHREADING TOOLS INSERT STYLETHREADING TOOLS LEFT HANDTHREADING TOOLS QUICK CHANGETHREAD MILLSTHREAD RELIEF TOOLSTOOL HOLDERS QUICK CHANGETOOL HOLDERSUNDERCUTTING ENDMILLS

ALPHABETICAL INDEX

PAGEDESCRIPTION1665551717176727-3024-26778224738-39194041565654373762-6356431858-59601846434445361515162367171712311413

DESCRIPTION PAGEGROOVING TOOLS O-RING DOVETAILGROOVING TOOLS SOLID CARBIDEGROOVING TOOLS TIALN COATEDGROOVING TOOLS QUICK CHANGEI.D. CHAMFER TOOLSKEYWAY CUTTERS 1/4 SHANKKEYWAY CUTTERS 3/8 SHANKKEYWAY CUTTERS CARBIDE HEADKEYWAY CUTTERS DOUBLE ANGLEKEYWAY CUTTERS DBL CONCAVE RADIUSKEYWAY CUTTERS FULL RADIUSKEYWAY CUTTERS MADE TO ORDERKEYWAY CUTTERS METRICKEYWAY CUTTERS SINGLE ANGLEKEYWAY CUTTERS SOFT MATERIALKEYWAY CUTTERS SOLID CARBIDELEFT HAND THREADING TOOLSLOLLIPOP CUTTERSMAX BORE TOOLSMAX GROOVE TOOLSN/C C'BORESO-RING DOVETAIL CUTTERSO-RING GROOVE TOOLS

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

1

PRODUCT INDEX

SERIES 10 Standard boring tool SERIES 11 ALTIN coated Max-Bore

APPLICATION :BORING ALL TYPES OF MATERIALS

page 6 page 7

APPLICATION :BORING TOUGH TO MACHINEMATERIALS. STAINLESS ETC.

SERIES 04 Multi-Reach boring tools

APPLICATION :DEEP HOLE BORING

page 7

SPECIALIZING IN UNIQUE AND HARD TO FIND CUTTING TOOLS

page 24-26

SERIES 14 Triangle Insert Bars

APPLICATION :ID BORING

SERIES 12 Diamond Insert Bars

APPLICATION :FOR BORING ALUMINUM page 29-30

SERIES 16 Diamond Insert Bars

APPLICATION :FOR BORING STEEL page 27-28

page 18

APPLICATION :DRILL, BORE & TURNWITH THE SAME TOOL

SERIES 54 Double edge bore tools

page 8APPLICATION :BORING ALL TYPES OF MATERIALS

SERIES 42 Quick Change boring tool

page 17

APPLICATION :BORE & THREADWITH THE SAME TOOL

SERIES 50 Bore & Thread tools

page 17

APPLICATION :BORE & GROOVEWITH THE SAME TOOL

SERIES 48 Bore & Groove tools

page 18

SERIES 59 Drill & bore tools

APPLICATION :DRILL & BOREWITH THE SAME TOOLpage 17

SERIES 55 Bore & Back chamfer tools

APPLICATION :BORE & BACK CHAMFERWITH THE SAME TOOL

page 21APPLICATION : PROFILING

SERIES 56 R.H. offset profile tools

page 20

SERIES 56 Profile tools

APPLICATION :I.D. PROFILINGpage 35

SERIES 40 Replacment Heads

APPLICATION :HEADS & SCREWS

INTERNAL TOOL

INTERNAL TOOL INC.2

PRODUCT INDEX

ITC CARBIDE: SPECIALLY BLENDED FOR OPTIMUM PERFORMANCE

SERIES 42 Quick Change groove tool

page 9

APPLICATION :GROOVING ALL TYPES OF MATERIALS

page 18APPLICATION :BORE A THREAD RELIEF

SERIES 46 Thread relief tools

APPLICATION :LEFT HAND OFFSET PROFILING

SERIES 56 L.H.offset profile tools SERIES 56 Fine point profile tools

APPLICATION :FINE POINT PROFILINGpage 21 page 21page 9

SERIES 42 Quick Change profile tool

APPLICATION :PROFILING ALL TYPES OF MATERIALS

SERIES 24 Full radius groove tools

APPLICATION :GROOVING - PROFILING

SERIES 22 ALTIN coated Max Groove

APPLICATION :GROOVING TOUGH TO MACHINEMATERIALS. STAINLESS ETC.

page 12

page 11

page 31

SERIES 26 Insert Grooving Tools

APPLICATION :INSERT GROOVE TOOL

page 13APPLICATION :SPECIAL GROOVE TOOLS

Groove Tools Made to Order

page 14

SERIES 06 Multi-Reach groove tools

APPLICATION :DEEP HOLE GROOVINGpage 20

APPLICATION :DEEP HOLE PROFILING

SERIES 09 Multi-Reach Profile Tools

SERIES 27 O-Ring groove tools

APPLICATION :GROOVING FOR O'RINGS page 14

SERIES 73 Face Grooving Tools

APPLICATION :FACE GROOVING page 23

page 20

SERIES 56 Reverse Profile tools

page 10

SERIES 20 Standard grooving tools

APPLICATION :GROOVING ALL TYPES OF MATERIAL

APPLICATION :I.D. REVERSE PROFILING

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

3

PRODUCT INDEX

page 36

page 37

page 37

page 37

QUALITY TOOLING MADE IN THE USA

SERIES 62 Engraving tools

APPLICATION :ENGRAVING, CHAMFERING, C'SINKING

SERIES 63 countersinks

APPLICATION :COUNTERSINKING

SERIES 61 Runner cutters

APPLICATION :MACHINING RUNNERS IN MOLDS

SERIES 60 Die Sinkers

APPLICATION :TAPERED BALL MILLING

page 47

SERIES 58 Spade Drills

APPLICATION :DRILLING HARD MATERIALS

APPLICATION :THREAD & GROOVEWITH THE SAME TOOL

SERIES 52 Thread & groove tools

page 17

page 32-34page 15

SERIES 31 Left Hand threading tools

APPLICATION :LEFT HAND I.D. THREADING

APPLICATION :ID INSERT THREADING

SERIES 36 Insert Threading Tools

page 15

SERIES 30 Threading tools

APPLICATION :STANDARD I.D. THREADING

page 47

SERIES 75 Spotting Drills

APPLICATION :CENTER DRILLING-C'SINK

SERIES 66 CNC Backspot facers

APPLICATION :CNC BACK SPOT FACING page 19

page 14

SERIES 08 Multi-Reach threading tools

APPLICATION :DEEP HOLE THREADING page 8

APPLICATION :THREADING ALL TYPES OF MATERIALS

SERIES 42 Quick Change thread tool

page 16APPLICATION :ACME I.D. THREADING

SERIES 32 & 34 Acme threading tools

SERIES 69 STUB TAPERS

page 37APPLICATION :TAPERED MILLING

INTERNAL TOOL

INTERNAL TOOL INC.4

page 40-41

page 43

page 43

page 51-52

PRODUCT INDEX

ITC CARBIDE: FOR EXTRA LONG TOOL LIFE

SERIES 68 Corner Rounders

APPLICATION :ROUNDING CORNERS

SERIES 67 Reverse Corner Rounders

APPLICATION :ROUNDING BACK ORINSIDE CORNERS

SERIES 65 Edge Breakers

APPLICATION :EDGE BREAKING / CHAMFERING

SERIES 78 Carbide HeadKey Cutters

APPLICATION :SLOTTING & GROOVING page 49

SERIES 78 Carbide Key Cutterswith Carbide Head Steel Shankfor Soft Material

APPLICATION :SLOTTING & GROOVINGSOFT MATERIAL ALUMINUMBRASS PLASTIC ETC

page 44

SERIES 21 & 41 micro endmills

APPLICATION :MILLING SMALL PARTS page 38-39

SERIES 64 Chamfer Mills

APPLICATION :MILLING ANGLES& CHAMFERSpage 45

SERIES 41 Endmills in speciallengths and sizes

APPLICATION :MILLING SPECIAL PARTS

page 55

page 56

SERIES 80 Full Radius Key Cutters

APPLICATION :FULL RADIUS SLOTS

SERIES 81 Anglers

APPLICATION :MACHINING LARGE ANGLES

page 46

SERIES 49 Drill-Mills

APPLICATION :DRILL & MILL WITHTHE SAME TOOL

SERIES 85 N/C C'bores

APPLICATION :C'BORING page 67

SERIES 72 double chamfer cutters

APPLICATION :chamfering both sides of a plate page 43

SERIES 93 carbide reamers

page 66APPLICATION : reaming

APPLICATION :CENTER DRILLING page 47

SERIES 71 Center Drills

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

SERIES 88 Thread Mills

APPLICATION :ID & OD THREADINGpage 54

SERIES 92 Double Angle Cutters

APPLICATION : ANGLES & CHAMFERS

page 56

page 56

page 58-59

page 60

page 62-63

page 64

page 15

5

PRODUCT INDEX

RE-DEFINING THE INDUSTRY STANDARD

SERIES 86 Dovetail Cutters

APPLICATION :DOVETAIL SLOTS & CHAMFERS

Dovetail Cutters Made to Order

APPLICATION :SPECIAL DOVETAILS

INTERNAL TOOL

SERIES 84 Dbl Concave Cutters

APPLICATION :RADIUS WORK

APPLICATION :RADIUS WORK

SERIES 82 Concave Rad Key CuttersSERIES 90 Single Angle Cutters

APPLICATION :ANGLE CUTS & CHAMFERS

page 55

SERIES 78 3/8 Shank Key Cutters

APPLICATION :FOR LIVE TOOLING page 57

Carbide Key Cutters Made to Order

APPLICATION :SPECIAL CUTTERS

page 58APPLICATION :FACE GROOVE DOVETAILS

SERIES 51 O-ring Dovetail Cutters

SERIES 39 external o'ring groove tools

APPLICATION :EXTERNAL GROOVE page 15

SERIES 39 external groove andchamfer tools

APPLICATION :EXTERNAL GROOVEAND CHAMFER

page 50 page 48

SERIES 76 Carbide Key Cuttersfor Soft Material

APPLICATION :SLOTTING & GROOVINGSOFT MATERIAL ALUMINUMBRASS PLASTIC ETC

SERIES 76 Solid CarbideKey Cutters

APPLICATION :SLOTTING & GROOVING

SERIES 89 multiple thread threadmills

page 65

APPLICATION :MILL MULTIPLE THREADS IN ONE PASS

INTERNAL TOOL

INTERNAL TOOL INC.6

MINIMUM BORE

MAXIMUM DEPTH

1/8 X 2"O.A.L.

1/8 X 2"O.A.L.

B-050-150B-050-200B-050-300B-050-400B-060-150B-060-200B-060-300B-060-400B-060-500B-080-150B-080-200B-080-300B-080-400B-080-500B-080-600B-100-150B-100-200B-100-300B-100-400B-100-500B-100-600B-100-700B-110-150B-110-200B-110-300B-110-400B-110-500B-110-600B-110-700B-120-250B-120-350B-120-500B-120-600B-120-700B-120-800B-140-250B-140-400B-140-500B-140-600B-140-700B-140-750B-140-800B-160-250B-160-400B-160-500B-160-600B-160-750B-160-900B-160-1000B-180-350B-180-500B-180-600B-180-750B-180-900B-180-1000B-180-1100B-200-400B-200-500B-200-600B-200-700B-200-800B-200-900B-200-1000B-200-1100B-200-1200B-200-1300

ORDER EDP#

1/8 X 2"O.A.L.

TOOL

IDENTIFICATION

1/4 X 2-1/2"O.A.L.

.490

3/8

X

2-1/2"

O.A.L.

1/2 X 6"O.A.L.

1/2 X 3"O.A.L.

10-133010-133510-134010-134510-135010-135510-136010-136510-137010-137510-138010-138510-139010-139510-140010-140510-141010-141510-142010-142510-143010-143510-144010-144510-145010-145510-146010-146510-147010-147510-148010-148510-149010-149510-150010-150510-151010-151510-152010-152510-153010-153510-154010-154510-155010-155510-156010-156510-157010-157510-158010-158510-159010-159510-160010-160510-161010-161510-162010-162510-1630

B-230-400B-230-500B-230-600B-230-700B-230-800B-230-900B-230-1000B-230-1150B-230-1200B-230-1250B-230-1400B-230-1500B-230-1600B-290-500B-290-600B-290-750B-290-900B-290-1000B-290-1100B-290-1250B-290-1350B-290-1500B-290-1600B-290-1750B-320-500B-320-600B-320-750B-320-900B-320-1000B-320-1100B-320-1250B-320-1500B-320-1600B-320-1800B-320-2000B-320-2500B-320-3000B-360-500B-360-600B-360-750B-360-900B-360-1000B-360-1150B-360-1250B-360-1500B-360-1600B-360-1800B-360-2000B-360-2500B-360-3000B-490-750B-490-1000B-490-1250B-490-1500B-490-2000B-490-2500B-490-2600B-490-3000B-490-3500B-490-4000B-490-4500

3/8

X

2-1/2"

O.A.L.

.320

3/8 X4" O.A.L.

.050

.140

.180

.200

.060

.080

.100

.110

.120

.160

.490

.360

.360

.320

.290

.230

1/8 X 2"O.A.L.

1/8 X 2"O.A.L.

3/16 X 2-1/2"O.A.L.

3/16 X 2-1/2"O.A.L.

3/16 X 2-1/2"O.A.L.

1/4 X 2-1/2"O.A.L.

5/16

X

2-1/2

O.A.L.

5/16

X

2-1/2

O.A.L.

TAPERED NECK AND FILLET RADIUS PROVIDE MAXIMUM RIGIDITY

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

MINIMUM BORE +.000 -.005

MAXIMUM DEPTH +.050 -.000

SERIES 10

BORING TOOLS

STANDARD BORING TOOLS

APPLICATION : BORING ALL TYPES OF MATERIALS

ITC CARBIDEmade from 4°

1.5°

10-100010-100510-101010-101510-102010-102510-103010-103510-104010-104510-105010-105510-106010-106510-107010-107510-108010-108510-109010-109510-110010-110510-111010-111510-112010-112510-113010-113510-114010-114510-115010-115510-116010-116510-117010-117510-118010-118510-119010-119510-120010-120510-121010-121510-122010-122510-123010-123510-124010-124510-125010-125510-126010-126510-127010-127510-128010-128510-129010-129510-130010-130510-131010-131510-132010-1325

.150

.200

.300

.400

.150

.200

.300

.400

.500

.150

.200

.300

.400

.500

.600

.150

.200

.300

.400

.500

.600

.700

.150

.200

.300

.400

.500

.600

.700

.250

.350

.500

.600

.700

.800

.250

.400

.500

.600

.700

.750

.800

.250

.400

.500

.600

.750

.9001.000.350.500.600.750.9001.0001.100.400.500.600.700.800.9001.0001.1001.2001.300

.400

.500

.600

.700

.800

.9001.0001.1501.2001.2501.4001.5001.600.500.600.750.9001.0001.1001.2501.3501.5001.6001.750.500.600.750.9001.0001.1001.2501.5001.6001.8002.0002.5003.000.500.600.750.9001.0001.1501.2501.5001.6001.8002.0002.5003.000.7501.0001.2501.5002.0002.5002.6003.0003.5004.0004.500

TOOL

IDENTIFICATIONMINIMUM BORE

MAXIMUM DEPTH

ORDER EDP#

SHANK &

3/8 X4" O.A.L.

1/2 X4" O.A.L.

.490

ALL TOOLS ON THIS PAGE ARE AVAILABLE IN LEFT HAND.ADD -LH TO EDP NUMBER WHEN ORDERING - EX : 10-1630-LH

OVERALL LENGTH

SHANK &OVERALL LENGTH

ITC CARBIDE: FOR THE HIGHEST PRODUCTION

LOOKING FOR SOMETHING DIFFERENT?

CHECK OUT QUICK CHANGEBORING TOOLS ON PAGE 8

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

7

MINIMUM BORE

MAXIMUM

DEPTH

MB-090-375MB-090-500MB-120-375MB-120-500MB-120-750MB-140-500MB-140-750MB-160-500MB-160-750MB-160-1000MB-180-375MB-180-500MB-180-750MB-180-1000MB-200-375MB-200-500MB-200-750MB-200-1000MB-240-500MB-240-750MB-240-1000MB-240-1250

ORDER EDP#

TOOL

IDENTIFICATION

3/8 X 2-1/2"O.A.L.

5/16 X 2-1/2"O.A.L.

1/4 X 2-1/2"O.A.L.

1/2 X 3"O.A.L.

ALTIN COATED GROUND WITH HELICAL RAKEELLIPTICAL NECK FOR GREATER STRENGTH

SERIES 11

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

MAXIMUM DEPTH +.050 -.000

MINIMUM BORE +.000 -.005

MAX-BORE BORING TOOLS2°

3°

11-120011-120511-130011-130511-131011-131111-131211-131311-131411-131611-131511-132011-132511-133011-133111-133211-133311-133411-133511-134011-134511-1350

.090

.120

.140

.160

.180

.200

.240

3/16 X 2-1/2"

1/8 X 2" O.A.L.

ALTIN COATED MAX-BORE BORING TOOLS

Max-Bore is the Ultimate in boring tools. Featuring an elliptical neck forgreater strength. A special helical flute for maximum shearing action witha better finish, and a ALTIN coating for a longer life. Max-Bore outper-forms and outlasts our competitors boring tools two to one.

APPLICATION : BORING TOUGH MATERIALS. STAINLESS, ETC.

CORNER RADIUS

SHANK &OVERALL LENGTH

ITC CARBIDE

MULTI-REACH BORING TOOLSAPPLICATION : MULTI-REACH BORING

NO LONGER LIMITED BY NECK LENGTH. ONE TOOL REPLACES A SERIES OF OTHERS.

04-1095

04-1100

04-1110

04-1120

04-1130

04-1140

ORDER EDP#

MINIMUM BORE

SHANKDIAMETER

3/16"

1/4"

5/16"

3/8"

1/2"

5/8"

.220

.280

.350

.420

.560

.700

SHANK LENGTH

4"

4"

4"

6"

6"

6"

SERIES 04

SOLID CARBIDE SHANKS PROVIDE MAXIMUM RIDGIDITY.

ITC CARBIDE

CORNER RADIUS

.005

.007

.007

.010

.010

.015

.007

.007

.007

.007

.007

.007

.007

RADIUS

.375

.500

.375

.500

.750

.500

.750

.500

.7501.000.375.500.7501.000.375.500.7501.000.500.7501.0001.250

MINIMUM BORE +.000 -.005

CORNER RADIUS

SHANK DIAMETER

THE LEADER IN INNOVATION

ALTIN COATEDORDER EDP#

04-1095-C

04-1100-C

04-1110-C

04-1120-C

04-1130-C

04-1140-C

made from

made from

.310

.360

.490

11-135511-136011-136511-137011-137511-138011-138511-139011-139511-140011-141011-141511-142011-1425

MB-310-500MB-310-750MB-310-1000MB-310-1250MB-310-1500MB-360-500MB-360-750MB-360-1000MB-360-1250MB-360-1500MB-490-750MB-490-1000MB-490-1250MB-490-1500

.500

.7501.0001.2501.500.500.7501.0001.2501.500.7501.0001.2501.500

.007

.015

.015

1/8 X 2" O.A.L.

3/16 X 2-1/2"

3/16 X 2-1/2"

1/4 X 2-1/2"O.A.L.

91-100091-101091-102091-103091-104091-105091-106091-107091-108091-109091-110091-111091-112091-113091-1140

ORDER EDP#

MINIMUM BORE

.120

.180

.240

.370

.490

PLASTIC CUTTING BORING TOOLS

MAXIMUM

DEPTHSHANK &OVERALL LENGTH

.250

.500

.800

.500

.7501.250.500.7501.250.500.7501.250.7501.0001.500

1/8 X 2"O.A.L. 3/16 X 2-1/2"O.A.L. 1/4 X 2-1/2"O.A.L.

3/8 X 2-1/2"O.A.L.

1/2 X 3"O.A.L.

APPLICATION : CLEARANCE AND RELIEF ANGELS FOR CUTTING PLASTIC

MINIMUM BORE +.000 -.005 MAXIMUM

DEPTH +.030 -.000

10°

5°

SERIES 91 ITC CARBIDEmade from

INTERNAL TOOL

INTERNAL TOOL INC.

42-097042-097542-098042-098542-099042-099542-100042-100542-101042-101542-102042-102542-103042-103542-104042-104542-105042-105542-106042-106542-107042-107542-108042-108542-109042-109542-110042-110542-111042-111542-112042-112542-113042-113542-114042-114542-115042-115542-116042-116542-117042-117542-118042-118542-119042-119542-120042-120542-121042-121542-122042-122542-123042-1235

.080

.180

.140

.120

.100

.060

.050

MINIMUM

BORE

MAX

DEPTHORDER EDP#

.160

.050

.080

.100

.150

.200

.300

.200

.300

.200

.300

.400

.500

.200

.300

.400

.500

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.800

.9001.0001.100.200.300.400.500.600.700.800.9001.0001.100

42-300042-300542-301042-301542-302042-302542-303042-303542-304042-304542-305042-305542-306042-306542-307042-307542-308042-308542-309042-309542-310042-310542-311042-311542-312042-312542-313042-313542-314042-314542-315042-3155

.080

.180

.140

.120

.100

.060

MINIMUM BORE

.160

.200

.300

.200

.300

.400

.500

.200

.300

.400

.500

.200

.300

.400

.500

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

MAX DEPTH

60°

MAX DEPTHOFFSET

MINIMUM BORE

ALL NEW SERIES OF TOOLS FROM INTERNAL TOOLFEATURING A NUMBER OF IMPROVEMENTS ON OUR STANDARD LINES:

ALL THE DETAIL AND QUALITY FROM OUR STANDARD LINE LESS EXPENSIVE QUICK CHANGE STYLE NEW FEATURE - AXIAL RAKE FOR FASTER FREER CUTTING QUICK CHANGE - REPLACE TOOLS QUICKLY AND ACCURATELY

.025

MINIMUM BORE

.025

.030

.035

.040

.045

.045

QUICK CHANGE

BORING TOOLS

QUICK CHANGE

THREADING TOOLSOFFSET

QUICK CHANGE SERIES

SERIES 42

ITC CARBIDE

SERIES 42 ITC CARBIDE

ITC CARBIDE: SPECIALLY BLENDED FOR OPTIMUM PERFORMANCE8

SHARP TIPNO RADIUS

ALTINCOATED EDP#

MAX DEPTH

ORDER EDP#

ALTINCOATED EDP#

42-3000-C42-3005-C42-3010-C42-3015-C42-3020-C42-3025-C42-3030-C42-3035-C42-3040-C42-3045-C42-3050-C42-3055-C42-3060-C42-3065-C42-3070-C42-3075-C42-3080-C42-3085-C42-3090-C42-3095-C42-3100-C42-3105-C42-3110-C42-3115-C42-3120-C42-3125-C42-3130-C42-3135-C42-3140-C42-3145-C42-3150-C42-3155-C

made from

.040

.030

.020 42-0970-C42-0975-C42-0980-C42-0985-C42-0990-C42-0995-C42-1000-C42-1005-C42-1010-C42-1015-C42-1020-C42-1025-C42-1030-C42-1035-C42-1040-C42-1045-C42-1050-C42-1055-C42-1060-C42-1065-C42-1070-C42-1075-C42-1080-C42-1085-C42-1090-C42-1095-C42-1100-C42-1105-C42-1110-C42-1115-C42-1120-C42-1125-C42-1130-C42-1135-C42-1140-C42-1145-C42-1150-C42-1155-C42-1160-C42-1165-C42-1170-C42-1175-C42-1180-C42-1185-C42-1190-C42-1195-C42-1200-C42-1205-C42-1210-C42-1215-C42-1220-C42-1225-C42-1230-C42-1235-C

made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

42-5000-C42-5005-C42-5010-C42-5015-C42-5020-C42-5025-C42-5030-C42-5035-C42-5040-C42-5045-C42-5050-C42-5055-C42-5060-C42-5065-C42-5070-C42-5075-C42-5080-C42-5085-C42-5090-C42-5095-C42-5100-C42-5105-C42-5110-C42-5115-C42-5120-C42-5125-C42-5130-C42-5135-C

.080

.180

.140

.120

.100

MINIMUM BORE

MAX DEPTH

ORDER EDP#

.160

.200

.300

.200

.300

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

42-7000-C42-7005-C42-7010-C42-7015-C42-7020-C42-7025-C42-7030-C42-7035-C42-7040-C42-7045-C42-7050-C42-7055-C42-7060-C42-7065-C42-7070-C42-7075-C42-7080-C42-7085-C42-7090-C42-7095-C42-7100-C42-7105-C42-7110-C42-7115-C42-7120-C42-7125-C42-7130-C42-7135-C42-7140-C42-7145-C42-7150-C42-7155-C42-7160-C42-7165-C42-7170-C42-7175-C42-7180-C42-7185-C42-7190-C42-7195-C42-7200-C42-7205-C42-7210-C42-7215-C42-7220-C42-7225-C42-7230-C42-7235-C42-7240-C42-7245-C42-7250-C42-7255-C42-7260-C42-7265-C42-7270-C42-7275-C42-7280-C42-7285-C42-7290-C42-7295-C

.039

.062

.048

.046

.040

.033

.018

MAX DEPTH

ORDER EDP#

.056

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.200

.300

.400

.500

.600

.700

.029

.032

GROOVE WIDTH

GROOVE WIDTH

MINIMUMBORE IS .185 MAX

DEPTH

OFFSET IS .060

TIP RADIUS

OFFSET

MINIMUM BORE

MAX DEPTH

30°5°

.005

.005

.007

.007

.007

.007

.040

.040

.050

.050

.060

.080

QUICK CHANGE

GROOVING TOOLS

QUICK CHANGE

PROFILE TOOLSOFFSET

TIPRADIUS

QUICK CHANGE SERIES

SERIES 42 ITC CARBIDE

SERIES 42 ITC CARBIDE

QUALITY TOOLING MADE IN THE USA 9

ALL TOOLS HAVE A GROUND ANGLE ON THE SHANKWHICH LOCKS IN PLACE AGAINST A LOCATING PIN,MAINTAINING AN EXACT RADIAL AND AXIAL POSITION

HOLDERS ARE AVAILABLE WITH3/8, 1/2, 5/8, & 3/4 SHANK SIZES.STANDARD STYLE3/8" SHANK EDP# 42-90001/2" SHANK EDP# 42-90055/8" SHANK EDP# 42-90103/4" SHANK EDP# 42-901522 MM SHANK EDP# 42-9020

COOLANT HOLE STYLE3/8" SHANK EDP #42-95001/2" SHANK EDP #42-95055/8" SHANK EDP #42-95103/4" SHANK EDP #42-951522 MM SHANK EDP #42-9520

EXTRA SCREW EDP# 42-8888

42-700042-700542-701042-701542-702042-702542-703042-703542-704042-704542-705042-705542-706042-706542-707042-707542-708042-708542-709042-709542-710042-710542-711042-711542-712042-712542-713042-713542-714042-714542-715042-715542-716042-716542-717042-717542-718042-718542-719042-719542-720042-720542-721042-721542-722042-722542-723042-723542-724042-724542-725042-725542-726042-726542-727042-727542-728042-728542-729042-7295

ALTINCOATED EDP#

ALTINCOATED EDP#

42-500042-500542-501042-501542-502042-502542-503042-503542-504042-504542-505042-505542-506042-506542-507042-507542-508042-508542-509042-509542-510042-510542-511042-511542-512042-512542-513042-5135

O.8 MM

1.2 MM

1.0 MM

made from

made from

INTERNAL TOOL

INTERNAL TOOL INC.10

ORDER

EDP#TOOL

ID

MIN

BOREOFFSET

GROOVE

WIDTH

MAX

DEPTH

1/4

5/16

3/8

.020

.100

.100

1/4

X

2-1/2

O.A.L.

5/16

X

2-1/2

O.A.L.

3/8

X

2-1/2

O.A.L.

ORDER

EDP#TOOL

ID

MIN

BORE

GROOVE

WIDTHOFFSET

MAX

DEPTH

G-069-4G-069-6G-069-8G-069-12G-069-16G-069-20G-087-4G-087-6G-087-8G-087-12G-087-16G-087-20G-095-8G-095-12G-095-16G-126-8G-126-12G-126-16G-093-8G-093-12G-093-16G-093-20G-093-24G-125-8G-125-12G-125-16G-125-20G-125-24G-156-8G-156-12G-156-16G-156-20G-156-24G-187-8G-187-12G-187-16G-187-20G-187-24G-250-8G-250-12G-250-16G-250-20G-250-24

20-155020-155520-156020-156520-157020-157520-158020-158520-159020-159520-160020-160520-161020-161520-162020-162520-163020-163520-164020-164520-165020-165520-166020-166520-167020-167520-168020-168520-169020-169520-170020-170520-171020-171520-172020-172520-173020-173520-174020-174520-175020-175520-1760

1/2

X

3"

O.A.L.

3/8

X

2-1/2

O.A.L.

.017/.018

.025/.026

.033/.034

.038/.039

.062/.064

.093/.095

.039/.041

.046/.048

.055/.057

.062/.064

3/8CONT.

.100

1/2 .150

.069/.071

1/43/81/23/41"1-1/41/43/81/23/41"1-1/41/23/41"1/23/41"1/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/2

.087/.089

.093/.095

.125/.127

.093/.095

.125/.127

.156/.158

.187/.189

.250/.252

SERIES 20

GROOVING TOOLS

3/16

X

2-1/2

O.A.L.

1/8

X

2"

O.A.L.

20-117020-117520-118020-118520-119020-119520-120020-120520-121020-121520-122020-122520-123020-123520-124020-124520-125020-125520-126020-126520-127020-127520-128020-128520-129020-129520-130020-130520-131020-131520-132020-132520-133020-133520-134020-134520-135020-135520-135620-135720-135820-136020-136520-137020-137520-138020-138520-139020-139520-140020-140520-141020-141520-142020-142520-143020-143520-144020-144520-145020-145520-146020-146520-147020-147520-148020-148520-149020-149520-150020-150520-151020-151520-152020-152520-153020-153520-154020-1545

G-032-3G-032-4G-032-6G-047-4G-047-6G-047-8G-064-4G-064-6G-064-8G-064-10G-018-4G-018-6G-018-8G-018-10G-026-4G-026-6G-026-8G-026-10G-031-4G-031-6G-031-8G-031-10G-061-4G-061-6G-061-8G-061-10G-017-4G-017-6G-017-8G-017-10G-025-4G-025-6G-025-8G-025-10G-030-4G-030-6G-030-8G-030-10G-060-6G-060-8G-060-10G-033-4G-033-6G-033-8G-033-12G-038-4G-038-6G-038-8G-038-12G-063-8G-063-12G-063-16G-094-8G-094-12G-094-16G-039-4G-039-6G-039-8G-039-12G-039-16G-039-20G-046-4G-046-6G-046-8G-046-12G-046-16G-046-20G-055-4G-055-6G-055-8G-055-12G-055-16G-055-20G-062-4G-062-6G-062-8G-062-12G-062-16G-062-20

1/16

.050

.031/.032

.030/.031

.046/.047

3/16

.0303/32

1/8 .062/.063

.017/.018

.025/.026

.030/.031

.062/.063

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

OFFSET

MINHOLE

MAX DEPTH+.050 / -.000

GROOVEWIDTH

2 TYP.

.040

.050

STANDARD GROOVING TOOLS

FOR RETAINING RING GROOVES & INTERNAL RELIEFS.

.062/.064

APPLICATION :

SHANK &OVERALL LENGTH

SHANK &OVERALLLENGTH

ITC CARBIDE

ITC CARBIDE: HIGH TRANSVERSE RUPTURE STRENGTH

ORDER

EDP#

20-9920

20-9930

20-9940

20-9950

20-9960

20-9970

20-9980

20-9982

20-9985

20-9990

20-9995

WIDTH+/-.25 MM

MAX

DEPTH

.5 MM (.0197)

.9 MM (.0354)

1.1 MM (.0433)

1.3 MM (.0512)

1.85 MM (.0728)

2.15 MM (.0847)

2.65 MM (.1044)

3.0 MM (.1182)

3.0 MM (.1182)

4.0 MM (.1576)

6.0 MM (.2364)

GROOVING TOOLS IN METRIC WIDTHS

6.5

(.250)

MIN

BORE

13 MM

13 MM

13 MM

13 MM

13 MM

13 MM

13MM

13 MM

19MM

19MM

19MM

TOOL

IDOFFSET

SHANK &OVERALLLENGTH

.050

.100

3/8 X 2-1/2O.A.L.

1/4 X 2-1/2O.A.L.

G-.5-13

G-.9-13

G-1.1-13

G-1.3-13

G-1.85-13

G-2.15-13

G-2.65-13

G-3.0-13

G-3.0-19

G-4.0-19

G-6.0-19

made from

3/161/43/81/43/81/21/43/81/25/81/43/81/25/81/43/81/25/81/43/81/25/81/43/81/25/81/43/81/25/81/43/81/25/81/43/81/25/83/81/25/81/43/81/23/41/43/81/23/41/23/41"1/23/41"1/43/81/23/41"1-1/41/43/81/23/41"1-1/41/43/81/23/41"1-1/41/43/81/23/41"1-1/4

.150 1/2 X 3"O.A.L.

9.5

(.375)

12.7

(.500)

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

11

MAX-GROOVE GROOVING TOOLSORDER

EDP#

TOOL

IDENTIFICATION MIN

BOREOFFSET

GROOVE WIDTH SHANK

MAX

DEPTH

MG-25-025-250MG-25-025-375MG-25-025-500MG-25-025-625

MG-25-017-250MG-25-017-375MG-25-017-500MG-25-017-625

1/4

5/16

3/8

.050

.100

.100

1/4

X

2-1/2

O.A.L.

5/16

X

2-1/2

O.A.L.

3/8

X

2-1/2

O.A.L.

ORDER

EDP#

TOOL

IDENTIFICATION MIN

BOREOFFSET

GROOVE

WIDTHSHANK

MAX

DEPTH

22-142522-143022-143522-144022-144522-1450

1/2

X

3"

O.A.L.

3/8

X

2-1/2

.017/.018

1/43/81/25/81/43/81/25/81/43/81/25/8

.025/.026

.030/.031

1/43/81/25/8

.033/.034

1/43/81/25/8

.038/.039

1/23/41"

.062/.064

1/23/41"

.093/.095

1/43/81/23/41"1-1/4

.039/.041

1/43/81/23/41"1-1/4

.046/.048

1/43/81/23/41"1-1/4

3/8CONT.

.100

1/2

.150

.069/.071

1/43/81/23/41"1-1/4

1/43/81/23/41"1-1/4

1/23/41"1/23/41"

.087/.089

.093/.095

.125/.127

.093/.095

1/23/41"1-1/41-1/21/23/41"1-1/41-1/2

.125/.127

1/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/2

.156/.158

.187/.189

.250/.252

ALTIN COATED MAX-GROOVE GROOVING TOOLS

MG-25-030-250MG-25-030-375MG-25-030-500MG-25-030-625

MG-31-033-250MG-31-033-375MG-31-033-500MG-31-033-625MG-31-038-250MG-31-038-375MG-31-038-500MG-31-038-625MG-31-063-500MG-31-063-750MG-31-063-1000MG-31-094-500MG-31-094-750MG-31-094-1000

MG-37-039-250MG-37-039-375MG-37-039-500MG-37-039-750MG-37-039-1000MG-37-039-1250MG-37-046-250MG-37-046-375MG-37-046-500MG-37-046-750MG-37-046-1000MG-37-046-1250MG-37-055-250MG-37-055-375MG-37-055-500MG-37-055-750MG-37-055-1000MG-37-055-1250

MG-25-063-250MG-25-063-375MG-25-063-500MG-25-063-625

.062/.0641/43/81/25/8

MG-25-094-250MG-25-094-375MG-25-094-500MG-25-094-625

1/43/81/25/8

.093/.095

MG-25-125-250MG-25-125-375MG-25-125-500MG-25-125-625

1/43/81/25/8

.125/.127

MG-31-125-500MG-31-125-750MG-31-125-1000

1/23/41"

.125/.127

1/43/81/23/41"1-1/4

.055/.057

MG-37-063-250MG-37-063-375MG-37-063-500MG-37-063-750MG-37-063-1000MG-37-063-1250

.062/.064

22-145522-146022-146522-147022-147522-1480

22-148522-149022-149522-150022-150522-151022-151522-152022-152522-153022-153522-154022-154522-155022-155522-156022-156522-157022-157522-158022-158522-159022-159522-160022-160522-161022-161522-162022-162522-163022-163522-164022-164522-165022-165522-1660

.062/.064

1/23/41"1-1/41-1/2

SERIES 22

MINHOLE

GROOVEWIDTH

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

MAXDEPTH +.050 /- .000

OFFSET +.020 / -.000 STRONGER ELLIPTICALLYGROUND NECK

APPLICATION :

Max-groove is the Ultimate in grooving tools. Featuring an ellipticalneck for greater strength, a special top rake for maximumshearing action with a better finish, and a ALTINcoating for a longer life.Max-Groove out performs andoutlasts our competitorsgroove tools two to one.

FOR INTERNAL GROOVING AND RELIEVING

22-110022-110522-111022-111522-112022-112522-113022-113522-114022-114522-115022-115522-116022-116522-117022-117522-118022-118522-119022-119522-120022-120522-121022-121522-122022-122522-123022-123522-124022-124522-125022-125522-126022-126522-127022-127522-128022-128522-129022-129522-130022-130522-131022-131522-132022-132522-133022-133522-134022-134522-135022-135522-136022-136522-137022-137522-138022-138522-139022-139522-140022-140522-141022-141522-1420

MG-37-069-250MG-37-069-375MG-37-069-500MG-37-069-750MG-37-069-1000MG-37-069-1250

MG-37-094-500MG-37-094-750MG-37-094-1000

MG-37-087-250MG-37-087-375MG-37-087-500MG-37-087-750MG-37-087-1000MG-37-087-1250

MG-37-125-500MG-37-125-750MG-37-125-1000

MG-50-094-500MG-50-094-750MG-50-094-1000MG-50-094-1250MG-50-094-1500MG-50-125-500MG-50-125-750MG-50-125-1000MG-50-125-1250MG-50-125-1500MG-50-156-500MG-50-156-750MG-50-156-1000MG-50-156-1250MG-50-156-1500MG-50-187-500MG-50-187-750MG-50-187-1000MG-50-187-1250MG-50-187-1500MG-50-250-500MG-50-250-750MG-50-250-1000MG-50-250-1250MG-50-250-1500

MG-50-063-500MG-50-063-750MG-50-063-1000MG-50-063-1250MG-50-063-1500

ITC CARBIDE

ALTIN: THE VERY LATEST IN

HIGH PERFORMANCE COATING

THE MOST UNIQUE LINE OF CUTTING TOOLS AVAILABLE

made from

INTERNAL TOOL

INTERNAL TOOL INC.12

ORDER

EDP#

TOOL

ID

MIN

HOLE OFFSETGROOVE

WIDTH

SHANK &OVERALLLENGTH

MAX

DEPTH

1/4

5/16

3/8

.050

.100

.100

1/4

X

2-1/2

O.A.L.

5/16

X

2-1/2

O.A.L.

3/8

X

2-1/2

O.A.L.

ORDER

EDP#TOOL

ID

MIN

HOLEOFFSET

GROOVE

WIDTH

MAX

DEPTH

R-087-4R-087-6R-087-8R-087-12R-087-16R-087-20

R-125-8R-125-12R-125-16R-125-20R-125-24

R-187-8R-187-12R-187-16R-187-20R-187-24R-250-8R-250-12R-250-16R-250-20R-250-24

R-069-4R-069-6R-069-8R-069-12R-069-16R-069-20

24-166524-167024-167524-168024-168524-169024-169524-170024-170524-1710

R-095-8R-095-12R-095-16

R-156-8R-156-12R-156-16R-156-20R-156-24

24-164024-164524-165024-165524-1660

1/2

X

3"

O.A.L.

R-126-8R-126-12R-126-16

R-093-8R-093-12R-093-16R-093-20R-093-24

24-171524-172024-172524-173024-173524-174024-174524-175024-175524-1760

.017

.018

1/43/81/25/81/43/81/25/81/43/81/25/8

1/43/81/25/83/41/43/81/23/41/23/41"1/23/41"1/43/81/25/83/41"1-1/41/43/81/23/41"1-1/41/43/81/23/41"1-1/41/43/81/23/41"1-1/4

1/2.150

1/43/81/23/41"1-1/4

1/43/81/23/41"1-1/4

1/23/41"1/23/41"

1/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/21/23/41"1-1/41-1/2

SERIES 24

MINHOLE

GROOVEWIDTH

2°TYP.

OFFSET

MAX DEPTH

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

FULL RADIUS GROOVING TOOLS

FULL RADIUS GROOVING TOOLS

APPLICATION : FULL RADIUS GROOVES AND PROFILE WORK.

SHANK &OVERALLLENGTH

ITC CARBIDE

R-017-4R-017-6R-017-8R-017-10R-025-4R-025-6R-025-8R-025-10R-030-4R-030-6R-030-8R-030-10R-060-6R-060-8R-060-10R-033-4R-033-6R-033-8R-033-10R-033-12R-038-4R-038-6R-038-8R-038-12R-063-8R-063-12R-063-16R-094-8R-094-12R-094-16R-039-4R-039-6R-039-8R-039-10R-039-12R-039-16R-039-2R-046-4R-046-6R-046-8R-046-12R-046-16R-046-20R-055-4R-055-6R-055-8R-055-12R-055-16R-055-20R-062-4R-062-6R-062-8R-062-12R-062-16R-062-20

3/81/25/8

ITC CARBIDE: THE MOST VERSATILE CARBIDE AVAILABLE

.070

.093

.103

.125

.139

.187

.210

.250

.275

.375

O-RING DOVETAIL GROOVERS SHANK DIA.x LGTH

BOTTOM RADIUS

EDPNUMBER

O-RING SIZE

DEPTH OF CUT

WIDTH

53-400053-400553-401053-401553-402053-402553-403053-403553-404053-4045

TOP RADIUS

.040

.060

.065

.082

.085

.130

.140

.173

.180

.240

.051

.075

.082

.102

.112

.154

.172

.212

.232

.317

.015

.015

.015

.031

.031

.031

.031

.062

.062

.094

.005

.010

.010

.010

.010

.015

.015

.015

.015

.020

1/8 x 2.01/8 x 2.01/8 x 2.03/16 x 2.53/16 x 2.51/4 x 2.51/4 x 2.51/4 x 2.55/16 x 2.55/16 x 2.5

SERIES 53

APPLICATION : ITC CARBIDE

SHANK SIZE

TOP RADIUS

BOTTOM RADIUS

A FLAT ON BOTH SIDES LET YOU FLIP THETOOL TO CUT BOTH SIDES OF THE SLOT

DEPTH OF CUT

WIDTH

24°

USED TO CUT-TURN 24° O-RING DOVETAILS.THEY CUT WITH BOTH TOP & BOTTOM RADIUS.

MILLING STYLE O'RING TOOLS ARE ON PAGE 58

.025

.026

.030

.031

.062

.064

.033

.034

.038

.039

.062

.064

.093

.095

.039

.041

.046

.048

.055

.057

.062

.064

.069

.071

.087

.089

.093

.095

.125

.127

24-1300-C24-1305-C24-1310-C24-1315-C24-1320-C24-1325-C24-1330-C24-1335-C24-1340-C24-1345-C24-1350-C24-1355-C24-1356-C24-1357-C24-1358-C24-1360-C24-1365-C24-1370-C24-1372-C24-1375-C24-1380-C24-1385-C24-1390-C24-1395-C24-1400-C24-1405-C24-1410-C24-1415-C24-1420-C24-1425-C24-1430-C24-1435-C24-1440-C24-1442-C24-1445-C24-1450-C24-1455-C24-1460-C24-1465-C24-1470-C24-1475-C24-1480-C24-1485-C24-1490-C24-1495-C24-1500-C24-1505-C24-1510-C24-1515-C24-1520-C24-1525-C24-1530-C24-1535-C24-1540-C24-1545-C24-1550-C24-1555-C24-1560-C24-1565-C24-1570-C24-1575-C24-1580-C24-1585-C24-1590-C24-1595-C24-1600-C24-1605-C24-1610-C24-1615-C24-1620-C24-1625-C24-1630-C24-1635-C

ALTINCOATED EDP#

ALTINCOATED EDP#

24-1640-C24-1645-C24-1650-C24-1655-C24-1660-C24-1665-C24-1670-C24-1675-C24-1680-C24-1685-C24-1690-C24-1695-C24-1700-C24-1705-C24-1710-C24-1715-C24-1720-C24-1725-C24-1730-C24-1735-C24-1740-C24-1745-C24-1750-C24-1755-C24-1760-C

.093

.095

.125

.127

.156

.158

.187

.189

.250

.252

24-130024-130524-131024-131524-132024-132524-133024-133524-134024-134524-135024-135524-135624-135724-135824-136024-136524-137024-137224-137524-138024-138524-139024-139524-140024-140524-141024-141524-142024-142524-143024-143524-144024-144224-144524-145024-145524-146024-146524-147024-147524-148024-148524-149024-149524-150024-150524-151024-151524-152024-152524-153024-153524-154024-154524-155024-155524-156024-156524-157024-157524-158024-158524-159024-159524-160024-160524-161024-161524-162024-162524-163024-1635

made from

made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

MA

XIM

UM

DE

PT

HW

IDTH

OFF

SE

T

RA

DIU

S S

HA

NK

SID

ER

AD

IUS

FR

ON

T S

IDE

FU

LL R

AD

IUS

YE

S O

R N

O ?

Quo

te in

qua

nite

s of

?T

HE

MO

RE

YO

U B

UY

TH

E C

HE

AP

ER

TH

EY

GE

T

INT

ER

NA

L S

HA

NK

D

IAM

ET

ER

TR

Y T

O K

EE

P S

AM

E S

IZE

AS

OR

LA

RG

ER

TH

AN

TH

E H

EA

D

OV

ER

AL

L L

EN

GT

H

If n

ot

sure

le

ave

bla

nk

w

e w

ill q

uo

te s

tan

da

rd

MA

JOR

DIA

ME

TE

R

Try

to

keep

sam

e si

ze

as

sha

nk o

r sm

alle

r

INT

ER

NA

L T

OO

L

DR

AW

N B

Y:

RE

V:

TO

OL

NU

MB

ER

:

DA

TE:

TO

LER

AN

CE

UN

LES

SO

THE

RW

ISE

SP

EC

IFIE

D

.X =

+

/- 1

/32

.XX

= +

/- .0

10.X

XX

= +

/- .

002

.XX

XX

= /

- .0

005

AN

GLE

S +

/- 0

.15°

RE

VIS

ION

S:

YO

UR

CO

MP

AN

Y N

AM

E:

CO

NT

AC

T :

PH

ON

E:

FA

X:

YO

UR

DIS

TR

IBU

TO

R:

QU

AN

ITY

:

Sim

ply

mak

e a

copy

fill i

n th

e in

form

atio

n be

low

and

fax

or e

mai

l to

us.

fax

# 90

9-39

2-26

27 w

e w

ill q

uote

as

soon

as

poss

ible

.

I

NF

O@

inte

rnal

tool

.com

13

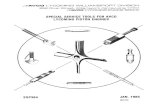

SPECIAL GROOVING TOOLS

ON THE WEB: WWW.INTERNALTOOL.COM

INTERNAL TOOL

INTERNAL TOOL INC.14

MINIMUM BORE

MAX DEPTH

27-1300

27-1305

27-1310

.500

.562

.625

O-096-8

O-141-9

O-144-10

ORDER EDP#

TOOL ID

.375

.250

SHANK

1/4 X 2-1/2 O.A.L.

3/8 X 2-1/2O.A.L.

27-1315

27-1320

27-1325

O-174-12

O-208-13

O-241-15

.750

.812

.940

OFFSET

SERIES 27

.115

.100

GROOVE WIDTH.096/.098

.141/.143

.144/.146

.174/.176

.208/.210

.241/.243

CORNER RADIUS.010/.020

.035/.045

.035/.045

.010/.020

.035/.045

.035/.045

OFFSET

5° TYP.

RADIU S TYP.

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

MINIMUM BORE

MAXIMUM DEPTH

O-RING GROOVE TOOLS

O-RING GROOVE TOOLSAPPLICATION : O-RING GROVING WITH TAPERED SIDES ITC CARBIDE

MULTI-REACH THREADING TOOLS

08-150008-150508-151008-151508-1520

MINIMUM BORE

ORDER EDP#

SHANKDIAMETER

LT-310-4LT-375-4LT-460-6LT-610-6LT-750-6

.310

.375

.460

.610

.750

SHANKLENGTH

4"4"6"6"6"

1/4"5/16"3/8"1/2"5/8"

OFFSET

.060

.060

.080

.100

.120

TOOL I.D.LARGEST PITCH

16161198

SERIES 08 APPLICATION : MULTI-REACH THREADING NO LONGER LIMITED BY NECK LENGTH. ONE TOOL REPLACES A SERIES OF OTHERS.

CARBIDE SHANKS PROVIDE MAXIMUM RIDGIDITY.

ITC CARBIDE: TESTED AND PROVEN TO BE THE BEST

MULTI-REACH GROOVING TOOLSSERIES 06

06-1200-C06-1205-C06-1210-C06-1215-C06-1220-C06-1225-C06-1230-C06-1235-C06-1240-C06-1245-C06-1250-C06-1255-C06-1260-C06-1265-C06-1270-C06-1275-C

MINIMUM BORE

ORDER EDP#TOOL I.D.

SHANKDIAMETER

1/4"

LG-310-032LG-310-063LG-310-094LG-310-125LG-390-032LG-390-063LG-390-094LG-390-125LG-475-032LG-475-063LG-475-094LG-475-125LG-620-032LG-620-063LG-620-094LG-620-125

.060

SHANK LENGTH

4"

GROOVE WIDTH OFFSET

.032

.063

.094

.125

.032

.063

.094

.125

.032

.063

.094

.125

.032

.063

.094

.125

.310

5/16"

3/8"

4"

6"

6"1/2"

.075

.100

.120

.390

.475

.620

CARBIDE SHANKS PROVIDE MAXIMUM RIDGIDITY.

ITC CARBIDE APPLICATION : MULTI-REACH GROOVING NO LONGER LIMITED BY NECK LENGTH. ONE TOOL REPLACES A SERIES OF OTHERS.

ITC CARBIDE

WIDTHS CAN BE SIZED TO YOUR SPECIFICATIONS

ALTINCOATED #

27-1300-C

27-1305-C

27-1310-C

27-1315-C

27-1320-C

27-1325-C

ALTINCOATED EDP#

06-120006-120506-121006-121506-122006-122506-123006-123506-124006-124506-125006-125506-126006-126506-127006-1275

ALTIN EDP#

08-1500-C08-1505-C08-1510-C08-1515-C08-1520-C

made from

made from

made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

15

ORDER EDP#

TOOL I.D.

MIN BORE OFFSET SHANK

MAXDEPTH

.040 1/4 X2-1/2O.A.L.

.180

.200 .045

.230 .055

.290 .070

.320 .075

.360 .085

.490 .120

1/4 X2-1/2O.A.L.

5/16 X2-1/2O.A.L.

5/16 X2-1/2O.A.L.

3/8 X2-1/2O.A.L.

3/8 X2-1/2O.A.L.

1/2 X3"O.A.L.

RIGHT HANDTHREADING TOOLS

TL-180-500TL-180-750TL-180-1000

31-120031-120531-121031-121531-122031-122531-123031-123531-1240

31-126031-126531-1270

31-124531-125031-1255

.040 1/4 X2-1/2

.500

.7501.000

.180

TL-200-500TL-200-750TL-200-1000TL-230-500TL-230-750TL-230-1000TL-290-500TL-290-750TL-290-1000TL-320-500TL-320-750TL-320-1000TL-360-500TL-360-750TL-360-1000

.500

.7501.000.500.7501.000.500.7501.000.500.7501.000.500.7501.000

.200 .045

.230 .055

.290 .070

.320 .075

.360 .085

5/16 X2-1/2

3/8 X2-1/2

LEFT HAND THREADING TOOLS

SERIES 30 SERIES 31

31-127531-128031-1285

OFFSET OFFSETMIN BORE

MIN BORE

MAXDEPTH

MAXDEPTH ALL SHANKS HAVE LOCKDOWN FLATS

FOR FASTER SETUPS

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPS

THREADING TOOLS

.060

.090

.120

.140

.020

.025

.030

.035

1/8 X 2"O.A.L. 1/8 X 2"O.A.L.

3/16 X 2-1/2O.A.L.

3/16 X 2-1/2O.A.L.

APPLICATION : LEFT HAND AND EXTERNAL THREADING.APPLICATION : RIGHT HAND ID THREADING.

ORDER EDP#

TOOL I.D.

MIN BORE SHANK

MAXDEPTH

60°

60°

OFFSET

ITC CARBIDE ITC CARBIDE

30-134030-134530-135030-135530-136030-136530-137030-137530-138030-138530-139030-139530-139630-139730-139830-139930-140030-140530-141030-141530-142030-142530-143030-143530-144030-144530-145030-145530-146030-146530-147030-147530-148030-148230-148530-149030-149530-150030-150530-150730-151030-151530-152030-152530-153030-153230-153530-154030-154230-154530-1550

T-060-150T-060-200T-060-300T-090-200T-090-300T-090-400T-120-300T-120-400T-120-500T-140-300T-140-400T-140-500T-160-400T-160-500T-160-750T-160-1000T-180-350T-180-500T-180-750T-180-1000T-200-400T-200-600T-200-750T-200-1000T-230-400T-230-600T-230-750T-230-1000T-230-1500T-290-500T-290-750T-290-1000T-290-1250T-290-1500T-290-1750T-320-500T-320-750T-320-1000T-320-1250T-320-1500T-320-1800T-360-500T-360-750T-360-1000T-360-1250T-360-1500T-360-1800T-490-750T-490-1000T-490-1500T-490-2000

.160

.150

.200

.300

.200

.300

.400

.300

.400

.500

.300

.400

.500

.400

.500

.7501.000.350.500.7501.000.400.600.7501.000.400.600.7501.0001.500.500.7501.0001.2501.5001.750.500.7501.0001.2501.5001.800.500.7501.0001.2501.5001.800.7501.0001.5002.000

.040 3/16 X 2-1/2O.A.L.

OVER 2500 TOOLS NOW AVAILABLE

ORDER

EDP# TOOL I.D. INC.

ANGLE

30°

SERIES 39

EX-30-DBL

EX-60-DBL

EX-90-DBL

EX-120-DBL

EX-031-GRV

EX-062-GRV

EX-094-GRV

EX-125-GRV

39-1000

39-1005

39-1010

39-1015

39-1020

39-1025

39-1030

39-1035

.216

EXTERNAL THREAD / GROOVE / CHAMFER TOOLS

60°

90°

WIDTH TYPE

120°

DBLANGLE

DBLANGLE

DBLANGLE

DBLANGLE

GROOVE0° .031

.062

.094

.125

0°

0°

0°

GROOVE

GROOVE

GROOVE

DEPTH

FOUR

ANGLES

TO

CHOOSE

FROM

WIDTH WIDTHDEPTH

DEPTH

3/8"

.094

.188

.281

.375

.250

.102 .190

.187 .187

.187 .108

2-1/2"

OVERALL

LENGTH

ALTINCOATED EDP#

30-1340-C30-1345-C30-1350-C30-1355-C30-1360-C30-1365-C30-1370-C30-1375-C30-1380-C30-1385-C30-1390-C30-1395-C30-1396-C30-1397-C30-1398-C30-1399-C30-1400-C30-1405-C30-1410-C30-1415-C30-1420-C30-1425-C30-1430-C30-1435-C30-1440-C30-1445-C30-1450-C30-1455-C30-1460-C30-1465-C30-1470-C30-1475-C30-1480-C30-1482-C30-1485-C30-1490-C30-1495-C30-1500-C30-1505-C30-1507-C30-1510-C30-1515-C30-1520-C30-1525-C30-1530-C30-1532-C30-1535-C30-1540-C30-1542-C30-1545-C30-1550-C

SEE HOLDERS ON PAGE 19

made from made from

1/4 X2-1/2

5/16 X2-1/2

3/8 X2-1/2

INTERNAL TOOL

INTERNAL TOOL INC.16

ORDER EDP#

MIN BORE

OFFSETTHREADS PER INCH

MAXDEPTH

.045.200

.290 .070

.360 .085

ACME THREADING TOOLS STUB ACME THREADING TOOLS

SERIES 32-34

SERIES 34

FLAT

WIDTHSHANK

.021 1/4 X2-1/2

.024 5/16 X2-1/2

3/8 X2-1/2

16

12

14

.032.490 .12010 1/2 X 3"

.028

.0418 .120.490

.0576 .120.490

.088

5 .120.490

ORDER EDP#

OFFSETTHREADS PER INCH

MAXDEPTH

34-140034-140534-141034-141534-142034-142534-143034-143534-144034-144534-145034-145534-146034-146534-147034-147534-148034-148534-149034-149534-150034-150534-151034-151534-152034-152534-153034-153534-154034-154534-155034-1555

.045.400.600.7501.000.500.7501.0001.2501.750.500.7501.0001.2501.800.7501.5002.000.7501.5002.000.7501.5002.000.7501.5002.000.7501.5002.000.7501.5002.000

.200

.290 .070

.360 .085

FLAT

WIDTHSHANK

.024 1/4 X2-1/2

.028 5/16 X2-1/2

3/8 X2-1/2

16

12

14

.037.490 .12010

.033

.0488 .120.490

.0557 .120.490

.0656 .120.490

.490 .1209 .042

.0795 .120.490

ACME AND STUB ACME THREADING TOOLS

MINBORE

29° INC.

MAXDEPTH

FLATWIDTH

OFFSET

ALL SHANKS HAVE LOCKDOWN FLATS FOR FASTER SETUPSAPPLICATION :ACME ID THREADING

SERIES 32 ITC CARBIDE ITC CARBIDE

MIN BORE

ITC CARBIDE: MAXIMUM SHEAR WITH MINIMUM WEAR

32-120032-120532-121032-121532-122032-122532-123032-123532-124032-124532-125032-125532-126032-126532-127032-127532-128032-128532-129032-129532-130032-130532-131032-131532-132032-132532-133032-133532-1340

.490 4 .150

.069

.400

.600

.7501.000.500.7501.0001.2501.750.500.7501.0001.2501.800.7501.5002.000.7501.5002.000.7501.5002.000.7501.5002.000.7501.5002.000

1/2 X 3"

1/2 X 3"

1/2 X 3"

1/2 X 3"

1/2 X 3"O.A.L.

ORDER

EDP#

TOOL

IDENTIFICATIONPITCH

TIP

WIDTH

.02116

14

12

10

8

6

SERIES 33

EX-16-ACME

EX-14-ACME

EX-12-ACME

EX-10-ACME

EX-8-ACME

EX-6-ACME

EX-5-ACME

EX-4-ACME

33-1000

33-1005

33-1010

33-1015

33-1020

33-1025

33-1030

33-1035

.024

.028

.032

.041

.057

EXTERNAL ACME THREAD TOOLS

5

EXTERNAL STUB ACME THREAD TOOLS

.069

ORDER

EDP#

TOOL

IDENTIFICATIONPITCH

TIP

WIDTH

.02416

14

12

10

8

6

EX-16-STUB

EX-14-STUB

EX-12-STUB

EX-10-STUB

EX-9-STUB

EX-8-STUB

EX-7-STUB

EX-6-STUB

EX-5-STUB

33-2000

33-2005

33-2010

33-2015

33-2020

33-2025

33-2030

33-2035

33-2040

.028

.033

.037

.042

.048

5

.055

9

7

.065

.079

SERIES 33

4 .088

TIP WIDTH

3/8" SHANK

29° INC.

ALTINCOATED EDP#

32-1200-C32-1205-C32-1210-C32-1215-C32-1220-C32-1225-C32-1230-C32-1235-C32-1240-C32-1245-C32-1250-C32-1255-C32-1260-C32-1265-C32-1270-C32-1275-C32-1280-C32-1285-C32-1290-C32-1295-C32-1300-C32-1305-C32-1310-C32-1315-C32-1320-C32-1325-C32-1330-C32-1335-C32-1340-C

34-1400-C34-1405-C34-1410-C34-1415-C34-1420-C34-1425-C34-1430-C34-1435-C34-1440-C34-1445-C34-1450-C34-1455-C34-1460-C34-1465-C34-1470-C34-1475-C34-1480-C34-1485-C34-1490-C34-1495-C34-1500-C34-1505-C34-1510-C34-1515-C34-1520-C34-1525-C34-1530-C34-1535-C34-1540-C34-1545-C34-1550-C34-1555-C

ALTINCOATED EDP#

1/2 X 3"O.A.L.

1/2 X 3"O.A.L.

1/2 X 3"O.A.L.

1/2 X 3"O.A.L.

1/2 X 3"

SEE HOLDERS ON PAGE 19

made from made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

17

ORDER

EDP# TOOL

IDENTIFICATION

MIN

BORE OFFSETTHREAD

WIDTHSHANK

MAX

DEPTH

CM-240-500CM-240-750CM-240-1000

50-110050-110550-1110

.500

.7501.000

.0501/4

.0605/16

1/4 X 2-1/2 O.A.L.

.0803/8

COMBINATION BORE & THREAD

CM-310-500CM-310-750CM-310-1000

CM-360-500CM-360-750CM-360-1000

50-111550-112050-1125

50-113050-113550-1140

.500

.7501.000

.500

.7501.000

5/16 X 2-1/2 O.A.L.

3/8 X 2-1/2 O.A.L.

ORDER

EDP# TOOL

IDENTIFICATION

MIN

BOREOFFSET

GROOVE

WIDTHSHANK

MAX

DEPTH

TG-240-500TG-240-750TG-240-1000

52-110052-110552-1110

3/32MAX

.500

.7501.000

.0501/4

1/8MAX .0605/16

.0803/8

COMBINATION THREAD & GROOVE

TG-310-500TG-310-750TG-310-1000

TG-360-500TG-360-750TG-360-1000

52-111552-112052-1125

52-113052-113552-1140

.500

.7501.000

.500

.7501.000

PLEASE SPECIFY GROOVE WIDTH WHEN ORDERING

COMBINATION TOOLS

SERIES 50

SERIES 52

.090

.065

.055

TOOL

IDENTIFICATION

ORDER

EDP#

MIN

BORE OFFSETGROOVE

WIDTH SHANKMAX

DEPTH

BG-240-500BG-240-750BG-240-1000

48-110048-110548-1110

3/32MAX

.500

.7501.000 .0501/4

1/8MAX .0605/16

5/32MAX .0803/8

COMBINATION BORE & GROOVE

BG-310-500BG-310-750BG-310-1000

BG-360-500BG-360-750BG-360-1000

48-111548-112048-1125

48-113048-113548-1140

.500

.7501.000

.500

.7501.000

SERIES 48

1/4 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

3/8 X 2-1/2 O.A.L.

5/32MAX

1/4 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

3/8 X 2-1/2 O.A.L.

MAXDEPTH

MINBORE

OFFSET

GROOVE WIDTH

MINBORE

OFFSET

MINBORE

60°

OFFSET

60°

GROOVE WIDTH

MAXDEPTH

ALL TOOLS ON THIS PAGE ARE RIGHT HAND CUTTING

APPLICATION : BORING & THREADING WITH THE SAME TOOL.

APPLICATION : THREADING & GROOVING WITH THE SAME TOOL.

APPLICATION : BORING & GROOVING WITH THE SAME TOOL.

MAX

DEPTH

ITC CARBIDE

ITC CARBIDE

ITC CARBIDE

TURN OD

THREAD OD

THREAD ID

GROOVE ID

BORE ID

GROOVE OD

THREAD OD

THREAD ID

GROOVE ID

BORE ID

GROOVE OD

TURN OD

PLEASE SPECIFY GROOVE WIDTH WHEN ORDERING

THEIR SPECIAL IS OUR STANDARD

BORE & BACK CHAMFER TOOLSAPPLICATION : BORING RELIEVING PROFILING BORE & REMOVE BURR ON BACKSIDE OF A HOLE

3/8 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

1/4 X 2-1/2 O.A.L.

1/2 X 3" O.A.L.

3/16 X 2-1/2 O.A.L.

ORDER

EDP#

MIN

BORE OFFSETWIDTH SHANK MAX

DEPTH

.050 .0451/8

3/16 .050

.0601/4

.0805/16

.1203/8

.1301/2

1/8 X 2" O.A.L.

SERIES 55

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

MAXDEPTH

WIDTH

MINBORE

OFFSET

45°

5°

4°

55-110055-110555-111055-111555-112055-112555-113055-113555-114055-114555-115055-1155

.300

.500

.400

.800

.5001.000.7501.250.7501.2501.0001.500

.060

.080

.080

.100

.110

RADIUS

.015

.015

.015

.020

.020

.030RADIUS

ALTINCOATED EDP#

55-1100-C55-1105-C55-1110-C55-1115-C55-1120-C55-1125-C55-1130-C55-1135-C55-1140-C55-1145-C55-1150-C55-1155-C

made from

made from

made from

ITC CARBIDEmade from

INTERNAL TOOL

INTERNAL TOOL INC.

18

3/8 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

1/4 X 2-1/2 O.A.L.

1/2 X 3" O.A.L.

3/16 X 2-1/2 O.A.L.

ORDER

EDP#

TOOL

IDENTIFICATION

MIN

BOREOFFSET

FLAT

WIDTH SHANK MAX

DEPTH

TR-125-300TR-125-400

46-110046-1105

.060

.300

.400.0451/8

TR-187-400TR-187-800

46-111046-1115.080 .400

.800

.050

3/16

TR-250-500TR-250-1000

46-112046-1125

.095

.5001.000

.060

1/4

TR-312-750TR-312-1250

46-113046-1135

.095

.7501.250.0805/16

TR-375-750TR-375-1250

46-114046-1145.130 .750

1.250.1203/8TR-500-1000TR-500-1500

46-115046-1155

.160 1.0001.500

.1301/2

SERIES 46

1/8 X 2" O.A.L.

MAXDEPTH

OFFSET

MINHOLE

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

FLATWIDTH

45°

THREAD RELIEF TOOLS

ORDER

EDP#

MIN

BORESHANK MAX

DEPTH

DB-240-500DB-240-750DB-240-1000DB-310-500DB-310-750DB-310-1000DB-360-500DB-360-750DB-360-1000DB-490-500DB-490-750DB-490-1000

.500

.7501.000.500.7501.000.500.7501.000.500.7501.000

1/4

5/16

3/8

SERIES 54

1/4 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

3/8 X 2-1/2 O.A.L.

MAXDEPTH

MIN.BORE

DOUBLE EDGE BORING TOOL

54-110054-110554-111054-111554-112054-112554-113054-113554-114054-114554-115054-1155

1/2 1/2 X 3" O.A.L.

APPLICATION : DRILL, BORE, ANDTURN ALL WITH THE SAME TOOL.

APPLICATION : BORE A THREAD RELIEFHELPS PREVENT THREAD TOOL BREAKAGE.

2°

ORDER

EDP# MIN

BORESHANK

MAX

DEPTH

DBO-250-500DBO-250-750DBO-250-1000DBO-312-500DBO-312-750DBO-312-1000DBO-375-500DBO-375-750DBO-375-1000DBO-500-500DBO-500-750DBO-500-1000

.500

.7501.000.500.7501.000.500.7501.000.500.7501.000

1/4

5/16

3/8

1/4 X 2-1/2 O.A.L. 5/16 X 2-1/2 O.A.L.

3/8 X 2-1/2 O.A.L.

MAXDEPTH

MINBORE

DRILL & BORE TOOL

59-120059-120559-121059-121559-122059-122559-123059-123559-124059-124559-125059-1255

1/2 1/2 X 3" O.A.L.

SERIES 59

APPLICATION : DRILL, BORE, AND TURN ALL WITH THE SAME TOOL. FEATURING A DRILL POINT FOR FASTER, STRAIGHTER CUTTING

15° POINT

TURN OD

BORE ID

ITC CARBIDE

ITC CARBIDE

ITC CARBIDE

2°

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

SPECIAL BORING & THREAD RELIEF TOOLS

ITC CARBIDE: UN-MATCHED BY ANY OTHER

3/8 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

1/4 X 2-1/2 O.A.L.

1/2 X 3" O.A.L.

3/16 X 2-1/2 O.A.L.

ORDER

EDP#

TOOL

IDENTIFICATION

MIN

BORE

NECK

DIA. FLAT

WIDTHSHANK

MAX

DEPTH

LA-115-500LA-115-750

43-200043-2005.030 .500

.750.075.115

LA-175-750LA-175-1000

43-201043-2015

.7501.00.125.175

LA-240-750LA-240-1250

43-202043-2025

.7501.250

.170.240

LA-300-750LA-300-1250

43-203043-2035

.7501.250.210.300

LA-360-750LA-360-1250

43-204043-2045

.7501.250

.250.360LA-490-1000LA-490-1500

43-205043-2055

1.0001.500

.350.490

SERIES 43

1/8 X 2" O.A.L.

MAXDEPTH

NECK DIA.

MINBORE

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

FLATWIDTH

90°

LATHE I.D. CHAMFER TOOLSAPPLICATION : INSIDE CHAMFERS

CHAMFER LENGTH

ITC CARBIDE

.030

.030

.030

.030

.030

CHAMFER

LENGTH

.040

.050

.070

.090

.110

.140

TOOL

IDENTIFICATION

TOOL

IDENTIFICATION

made from

made from

made from

made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

19

BORING / GROOVING TOOL HOLDER

Tool holder for allset screw flat type shanks

APPLICATION :A HOLDER THAT WILL HOLD OUR STANDARD SET SCREW FLAT STYLE 1/8" THRU 1/2" DIAMETER SHANK TOOLS.

Series 98 BUSHINGS

CNC BACK-SPOT FACERS

SERIES 66

ORDER EDP#

TOOL IDENTIFICATION SHANKREACH

BA-188-375BA-188-625BA-250-375BA-250-625BA-312-500BA-312-750BA-375-500BA-375-750BA-500-500BA-500-750BA-500-1000BA-625-500BA-625-750BA-625-1000BA-625-1250BA-750-500BA-750-750BA-750-1000BA-750-1250

.375

.625

.375

.625

.500

.750.225

.500

.750

.530

.500

.7501.000

3/8

5/16

1/4

1/2

3/16

.085

.100

.130

.190

.225

HEAD DIAMETER

HEAD THICKNESS

REACH

OFFSET

HEAD DIAMETER

HEADTHICKNESS

3/32

1/8

1/8

.500

.7501.0001.250

APPLICATION : USED TO CREATE A C'BORE ON THE BACK SIDE ORINSIDE OF A PART USING CIRCULAR INTERPOLATION ON A CNC MILL

OVERALL LENGTH

.500

.7501.0001.250

2-1/2

2-1/2

2-1/2

2-1/2

3"

5/32

3/16

66-110066-110566-111066-111566-112066-112566-113066-113566-114066-114566-115066-115566-116066-116566-117066-117566-118066-118566-1190

3/4

1/8

3/32

.270

.370

.435

.065

.050

5/8 3-1/2

4"

.180

.135

ITC CARBIDE

OFFSET

SERIES 98

ORDER

EDP#

BUSHING

SIZE

1/83/161/45/163/81/2

98-245098-245598-246098-246598-247098-2475

C'BORE DIAMETER

3°

1°TYP.

98-240098-2405

ORDER

EDP#

SHANK

STYLE

3/4" ROUND1" SQUARE

Series 98 HOLDERS

QUALITY TOOLING MADE IN THE USA

MAXIMUMC'BORE DIA.

.235

.310

.395

.470

.630

.815

.980

SERIES 39

39-740039-741039-742039-7430

ORDER

EDP# TO FIT IN

THIS SIZE SLOT

1/2" SQUARE5/8" SQUARE3/4" SQUARE1" SQUARE

Series 39 HOLDERS

TO FIT IN SLOT

3/8 BORE THROUGH

TWO SET

SCREWS ON TOP

ORDER

EDP# TOOL I.D.

SERIES 39

EX-030-RET

EX-035-RET

EX-041-RET

EX-047-RET

EX-056-RET

EX-068-RET

39-6000

39-6005

39-6010

39-6015

39-6020

39-6025

.075

EXTERNAL RETAING RING GROOVE TOOLsWIDTH DEPTH

DEPTH

.125

.130

.041 / .042

.072

.090

.095

.035 / .036

.030 / .031

.047 / .049

.056 / .057

.068 / .071

3/8 SHANK

2-1/2"

OVERALL

LENGTH

WIDTH

made from

INTERNAL TOOL

INTERNAL TOOL INC.20

ORDER

EDP#OFFSET

TIP

RADIUSBLANK

MAX

DEPTH

.080.180

.080

.110

.130

.160

.010

.220 .010

.300 .015

.360 .015

.490 .015

SERIES 56

ORDER

EDP#

MIN

HOLEOFFSET

TIP

RADIUS BLANK MAX

DEPTH

.080.180

.080

.110

.130

.160

.010

.220 .010

.300 .015

.360 .015

.490 .015

SERIES 56

PROFILE TOOLS

3/8 X 2-1/2

5/16 X 2-1/2

1/4 X 2-1/2

1/2 X 3"

3/16 X 2-1/2

3/8 X 2-1/2

5/16 X 2-1/2

1/4 X 2-1/2

1/2 X 3"

3/16 X 2-1/2

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

ALL SHANKS HAVE LOCKDOWN FLATSFOR FASTER SETUPS

MINHOLE

OFFSET

30° MAXDEPTH

MAXDEPTH

OFFSET

MINHOLE

30°

5°

REVERSE PROFILE TOOLS

PROFILE TOOLS

RADIUS

RADIUS

.007.120

.040

APPLICATION : REVERSE PROFILING TOOL

MIN

HOLE

56-100056-100556-101056-108056-108556-109056-110056-110556-111056-111556-112056-112556-113056-113556-114056-114556-115056-115556-116056-116556-117056-117556-1180

.200

.300

.400

.250

.500

.750

.500

.7501.000.500.7501.000.500.7501.000.500.7501.0001.250.500.7501.0001.250

.500

.7501.000.500.7501.000.500.7501.000.500.7501.0001.250.500.7501.0001.250

56-150056-150556-151056-151556-152056-152556-153056-153556-154056-154556-155056-155556-156056-156556-157056-157556-1580

ITC CARBIDE

ITC CARBIDE

MULTI-REACH PROFILE TOOLS

09-140009-140509-141009-141509-1420

.360

.420

.480

.615

.750

4"4"6"6"6"

1/4"5/16"3/8"1/2"5/8"

.100

.100

.100

.110

.125

SERIES 09 ITC CARBIDE

CARBIDE SHANKS PROVIDE MAXIMUM RIDGIDITY

MIN

HOLEORDER

EDP# OFFSETSHANK

DIAMETER

SHANK

LENGTHRADIUS

.010

.015

.015

.015

.020

APPLICATION : STANDARD PROFILING TOOL

APPLICATION : MULTI-REACH PROFILING NO LONGER LIMITED BY NECK LENGTH. ONE TOOL REPLACES A SERIES OF OTHERS.

SPECIALIZING IN UNIQUE AND HARD TO FIND CUTTING TOOLS

also see ourquick-profile tools pg. 9

LOOKING FOR SOMETHING DIFFERENT?

CHECK OUT QUICK CHANGEPROFILE TOOLS ON PAGE 9

ALTINCOATED EDP#

56-1000-C56-1005-C56-1010-C56-1080-C56-1085-C56-1090-C56-1100-C56-1105-C56-1110-C56-1115-C56-1120-C56-1125-C56-1130-C56-1135-C56-1140-C56-1145-C56-1150-C56-1155-C56-1160-C56-1165-C56-1170-C56-1175-C56-1180-C

ALTINCOATED EDP#

56-1500-C56-1505-C56-1510-C56-1515-C56-1520-C56-1525-C56-1530-C56-1535-C56-1540-C56-1545-C56-1550-C56-1555-C56-1560-C56-1565-C56-1570-C56-1575-C56-1580-C

ALTIN

COATED

EDP#

09-1400-C09-1405-C09-1410-C09-1415-C09-1420-C

.090

.080

.005

1/8 X 2"

made from

made from

1/8 X 2"

made from

INTERNAL TOOL INC.

INTERNAL TOOL

CA

TA

LO

G T

WE

NT

Y T

WE

LV

E

21

R.H. OFFSET PROFILE TOOLS

FINE POINT PROFILE TOOLS

SERIES 56

ORDER

EDP#

TOOL

IDENTIFICATION

MIN

HOLEOFFSETRADIUS SHANK

MAX

DEPTH

.020

.020

.020

.020

FIP-220-500FIP-220-750FIP-220-1000FIP-300-750FIP-300-1000FIP-360-750FIP-360-1000FIP-360-1250FIP-490-1000FIP-490-1250FIP-490-1500

.500

.7501.000.7501.000.7501.0001.2501.0001.2501.500

.220 .010

.300 .015

.360 .015

.490 .015

SERIES 56

3/8 X 2-1/2

5/16 X 2-1/2

1/4 X 2-1/2

1/2 X 3"

OFFSET & FINE POINT PROFILE TOOLS

APPLICATION : FINE POINT PROFILING TOOL.

APPLICATION : LEFT HAND OFFSET PROFILING TOOL.

SERIES 56

ORDER

EDP#

MIN

HOLEOFFSETRADIUS SHANK

.080

.110

.130

.160

.220 .010

.300 .015

.360 .015

.490 .015

SERIES 56

3/8 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

1/4 X 2-1/2O.A.L.

1/2 X 3" O.A.L.

L.H. OFFSET PROFILE TOOLS

ORDER

EDP#

TOOL

IDENTIFICATION MIN

HOLEOFFSETRADIUS SHANK

MAX

DEPTH

.080

.110

.130

.160

.220 .010

.300 .015

.360 .015

.490 .015

3/8 X 2-1/2 O.A.L.

5/16 X 2-1/2 O.A.L.

1/4 X 2-1/2O.A.L.

1/2 X 3"O.A.L.

APPLICATION : RIGHT HAND OFFSET PROFILING TOOL.

INSIDE PROFILING

OUTSIDE PROFILING

MAX DEPTH OFFSET

RADIUS

MINBORE

30° 57°

MINBORE

MAX DEPTH

OFFSET

57°

30°

MAX DEPTH

MINHOLE

23°

2°

56-131556-132056-132556-133056-133556-134056-134556-135056-136056-136556-1370

56-191556-192056-192556-193056-193556-194056-194556-195056-195556-196056-196556-197056-197556-1980

LOP-220-500LOP-220-750LOP-220-1000LOP-300-500LOP-300-750LOP-300-1000LOP-360-500LOP-360-750LOP-360-1000LOP-360-1250LOP-490-500LOP-490-750LOP-490-1000LOP-490-1250

.500

.7501.000.500.7501.000.500.7501.0001.250.500.7501.0001.250

56-181556-182056-182556-183056-183556-184056-184556-185056-185556-186056-186556-187056-187556-1880

ROP-220-500ROP-220-750ROP-220-1000ROP-300-500ROP-300-750ROP-300-1000ROP-360-500ROP-360-750ROP-360-1000ROP-360-1250ROP-490-500ROP-490-750ROP-490-1000ROP-490-1250

MAX

DEPTH

.500

.7501.000.500.7501.000.500.7501.0001.250.500.7501.0001.250

TOOL

IDENTIFICATION

ITC CARBIDE

ITC CARBIDE

ITC CARBIDE

ITC CARBIDE: SPECIALLY BLENDED FOR OPTIMUM PERFORMANCE

made from

made from

made from

INTERNAL TOOL

INTERNAL TOOL INC.

SB-125SB-187SB-250SB-312SB-375SB-437SB-500SB-125-5SB-187-5SB-250-5SB-312-5SB-375-5

22

ORDER

EDP#

SERIES 70

SPLIT

LENGTH

2"

2-1/2

2-1/2

2-1/2

2-1/2

3"

ORDER

EDP#

TOOL

IDENTIFICATION

SERIES 70

SPLIT

LENGTH DIAMETER

OVERALL

LENGTH

SP-125-SGL

SP-187-SGL

SP-250-SGL

SP-312-SGL

SP-375-SGL

SP-500-SGL

70-1100

70-1105

70-1110

70-1115

70-1120

70-1125

1/8

3/16

1/4

5/16

3/8

1/2

1-1/2"

2"

2"

2"

2"

2-1/2"

DOUBLE END SPLIT BLANKS

SINGLE END SPLIT BLANKS

OVERALLLENGTH

SPLITLENGTH

OVERALLLENGTH

SPLITLENGTH

ALL GROUND WITHSET SCREW FLATON TOP

LONG LENGTH SINGLEEND SPLIT BLANKS

ORDER

EDP#

SPLIT

LENGTH

3/8 4"

4"

4"

4"

6"

6"

3/8

3/8

1/2

1/2

5/8

SERIES 70

SPLIT BLANKS

ALL GROUND WITHSET SCREW FLATON TOP

ALL GROUND WITH SET SCREW FLAT ON TOP

APPLICATION :A BLANK THAT THE USER CAN GRIND INTO THEIR OWN SPECIAL TOOL.

OVERALL LENGTH

1/4

5/16

3/8

1/2

1/2

5/8

1/8

3/16

1/4

5/16

3/8

1/2

1/4

5/16

3/8

1/2

1/2

5/8

70-1200

70-1205

70-1210

70-1215

70-1220

70-1225

SP-125-DBL

SP-187-DBL

SP-250-DBL

SP-312-DBL

SP-375-DBL

SP-500-DBL

DIAMETER TOOL

IDENTIFICATION

OVERALL

LENGTH

70-1400

70-1405

70-1410