Interface reaction analysis of La O /SiC upon annealing by ... presen.pdf · • Effective...

Transcript of Interface reaction analysis of La O /SiC upon annealing by ... presen.pdf · • Effective...

Interface reaction analysis of La2O3/SiC

upon annealing by ATR-FTIR

Tokyo Tech. FRC 1, Tokyo Tech. IGSSE 2, Mitsubishi Electric Corp.3, ○Y. M. Lei 1, S. Munekiyo 1, K. Kakushima 2,T. Kawanago 2, Y. Kataoka 2, A. Nishiyama 2, N.

Sugii 2, H. Wakabayashi 2, K. Tsutsui 2, K. Natori 1, H. Iwai 1, M.Furuhashi 3, N.Miura 3 and S. Yamakawa 3

Tokyo Insititute of Technology

An issue for SiC MOSFETs

Most report

http://jstshingi.jp/abst/p/10/1

018/naist1.pdf

Improvement of

channel mobility

is necessary

Mobility limits the on-resistanceRelationship of mobility and Dit

http://www.iisb.fraunhofer.de/de/mobisic.html

Inverse proportional relationship of

mobility with interface state density

Reduction of Dit is critical to make low loss SiC power devices

Approaches for interface improvement

NO,N2O gas annealing

• Effective passivation of interface trap by annealing the gate

oxide in NO,N2O gas.

SiO2/LaSiOx gate oxides on SiC

• Recently a passivation of interface trap on SiC has been found

by forming LaSiOx interface layer on SiC substrate.

Drain

LaSiOx

SiO2

TaN/W

sicSource

Interface improvement can

be achieved by reaction of

La2O3 and SiC!

[1] X. Yang, et al., ICSCRM Th-2B-5 (2013).

4

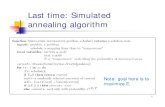

Purpose and outline of this presentation

Investigate the interface reaction of La2O3 with 4H-nSiC to find the best process for gate dielectric application

1.Introduction2.Interface reaction model for La2O3 on Si substrates3.Interface reaction of La2O3 on 4H-nSiC substrates4.SiN barrier layer for La-silicate dielectrics5.Conclusions

1.Introduction2.Interface reaction model for La2O3 on Si substrates3.Interface reaction of La2O3 on 4H-nSiC substrates4.SiN barrier layer for La-silicate dielectrics5.Conclusions

6

1837184018431846

Binding energy (eV)

Inte

nsit

y (

a.u

)

300 oC

annealing

Si sub.

La-silicateas depo.

500 oC

annealing

Si substrate

La2O3

La-silicate

W

500 oC, 30 min

1 nm

k=8~14

k=23

La2O3+Si+nO2 → La2SiO5, La10(SiO4)6O3

La9.33Si6O26, La2Si2O7, etc.

XPS (Si 1s)TEM

Supply of oxygen atoms triggers silicate reactionThicker silicate layer with higher temperature

(XRD database)

(アモルファス)

High T

Interface reaction of La2O3 on Si

kT

Ert a

silicate

2exp)(0

0 200 600 800 1000

Annealing temprature (oC)

0.0400

0.4

1.2

1.6

2.0

0.8

0.0

2.0

1.0

3.0

EO

T (

nm

)

tsilic

ate

(nm

)

La2O3

La-silicate

Si

La-silicate

La-silicate

SiLa2O3500oC

300oC

T

zCzC

exp)( 0

C(z)(a.u.)

Distance from Si interface (a.u.)

500oC 300oC350oC400oC450oC

(773K)

(573K)

La2O3

La-silicate

Si

La-silicate

La-silicate

SiLa2O3500oC

300oC

T

zCzC

exp)( 0

C(z)(a.u.)

Distance from Si interface (a.u.)

500oC 300oC350oC400oC450oC

(773K)

(573K)

0(r) : oxygen ionic conduction in La-silicate (r: La conc.)Ea : activation energy for r)

Ea=0.3 eV

Thickness of silicate can be modeled by simple equation

(tsilicate: silicate層の膜厚)

Composition of silicate is assumed to be constant

Interface reaction model

8

200 300 400 500 600 700 800 900 1000

アニール温度(oC)

30min 2s

0

0.2

0.4

0.6

0.8

1

1.2

1.4

EO

T(n

m)

W/La2O3(3.5nm)/n-Si

Annealing temperature (oC)

Equ

ival

ent

oxi

de

th

ickn

ess

(n

m)

La2O3+Si+nO2

→ La2SiO5, La10(SiO4)6O3

La9.33Si6O26, La2Si2O7

-controlling the oxygen atoms supply

-controlling the annealing time

(it may reach to thermal equilibrium)

1. SiO2, La2O3: solid solution

(glass structure)

2. k-value depends on Si conc.

silicate growth(from XRD database)

Silicate reaction can be controlled by

Amount of interface reaction

9

10 15 25 30

-2 (deg)20

Inte

nsity (

a.u

.)

Si sub.h=15keV, GIXD

900oC

500oC

544 540 532 528

Binding energy (eV)536

La-O-LaLa-O-SiSi-O-Si

700oC

as-depo.

300oC

500oC

5.54eV

5.58eV

5.52eV

6.17eV

hex-La2O3

Eg (eV) structure

La2O3 5.5~5.6 hexagonal

La-silicate 6.2 amorphous

La-silicate is amorphous

C(20nm)/La2O3(4nm)/n-Si

(at least with semeconductor processes)

Properties of La-silicate

10

Structrue of La-silicate (amorphous)

La atoms act as network modifier to relax the SiO4 network

Si

O O

O

O

Si

O O

O

OO

OO

O

SiBO

BO

Si Si

Si

BO: bridging oxygen atom

NBO:non-bridging oxygen atom

Si

O O

O

O

Si

O O

O

OO

O

O

O

La NBO

BO

Si Si

La

BO

BO

NBO

BO

La atomBO

NBOSiO4-tetrahedron

SiO4-tetrahedoron network with La atoms

Si-O-Si bonding

La-O-Si bonding

Atomic configuration of La-silicate

1.Introduction2.Interface reaction model for La2O3 on Si substrates3.Interface reaction of La2O3 on 4H-nSiC substrates4.SiN barrier layer for La-silicate dielectrics5.Conclusions

n-SiC(0001)substrate

La2O3 Deposition(EB)

FTIR measurement

Oxidation(5%O2/95%N2)

TEM analysis

Substrate cleaning(SPM, HF)

Sample preparation La2O3/SiC

FTIR measurement n-SiC substrate

La2O3 (2nm)

n-SiC substrate

Sample 1

(control)

Sample 2

500oC

1000oC

SiC(without La2O3))

5%O2 anneal:500oC—1000oC

12501300 1200 11001150 1050 1000

wavenumbers(cm-1)

Ab

sorb

an

ce (

a.u

.)

(a)

1000oC

600oC

La2O32nm/SiC)

Ab

sorb

an

ce (

a.u

.)12501300 1200 11001150 1050 1000

wavenumbers(cm-1)

(b)5%O2 anneal:500oC—1000oC

1000oC

950oC

900oC

Oxidation on SiC substrate was enhanced by La2O3 film

Accompanied by La-silicate formation

Si-O-SiLa-O-Si

Si-O-Si

9

FITR spectra of oxidized SiC surface

(SiO2)

(SiO2)

(La-silicate)

SiO2

SiC

La-silicate

SiC

SiO2

Might be due to radical oxygen generation by La atoms

sample:La2O3 (2nm)/SiC

10

SiC(0001) SiC(0001)50nm 10nm

La-silicateSiO2

TEM image of La2O3/SiC oxidized at 1000oC

• Agglomeration of La-silicates above SiO2/SiC interface• La-silicate grains positioned at bunches of SiC substrate (4o)• Thick SiO2 of 11nm is formed (enhanced oxidation rate)

Enhanced growth rate over thermal oxidation

SiC(0001) 10nm

11.8nm

sample:La2O3 (2nm)/SiC

after oxidation in 1000℃ 5%O2 30min

K. Kita, et al., ECS Trans, vol. 61(2), p. 135-142 (2014).

Higher oxidation rate of 1.5 order of magnitude can been

achieved by La2O3 capped oxidation

However, rough interface/surface may degrade reliability

This study

100

10-1

10-2

10-3

1300oC 1200oC 1100oC 1000oC

Gro

wth

rat

e co

nst

ate(

nm

/min

)

Temperature(oC)

SiO2 Growth rate of thermal oxidation

Oxidation rate comparison

1.Introduction2.Interface reaction model for La2O3 on Si substrates3.Interface reaction of La2O3 on 4H-nSiC substrates4.SiN barrier layer for La-silicate dielectrics5.Conclusions

n-SiC substrate

La-silicate

n-SiC substrate

SiO2

SiO2

n-SiC substrate

La2O3

SiN

La2O3 /SiC reaction

La2O3 /SiN reaction

n-SiC substrate

La2O3

SiN barrier layer against agglomeration

La-silicate formation by reaction of La2O3 and SiN layer(SiN: oxygen barrier to suppress oxidation of SiC)

n-SiC(0001)substrate

EB-La2O3 deposition

FTIR measurement

FTIR measurement

SPM,HF cleaning

PECVD-SiN deposition

XPS, TEM analysis

PECVD-SiO2 deposition

annealing

(5%O2/95%N2)

FTIR

TEM

La2O3(4nm)

SiN(2nm, 1.5nm, 0nm)

n-SiC

substrate

La2O3(4nm)

SiN(2nm)

TEOS

n-SiC

substrate7

Sample preparation with SiN barrier

annealing

(5%O2/95%N2)

La2O3 4nm/SiC)

Ab

sorb

an

ce (

a.u

.)

12501300 1200 11001150 1050 1000

wavenumbers(cm-1)

(C)O2 anneal:500oC—1000oC

1000゜C

950゜C

900゜C

La2O3 4nm/SiN2nm/SiC)

Ab

sorb

an

ce (

a.u

.)

12501300 1200 11001150 1050 1000

wavenumbers(cm-1)

(A)O2 anneal:500oC—1000oC

1000゜C

950゜C

900゜C

La2O3 4nm/SiN1.5nm/SiC)

Ab

sorb

an

ce (

a.u

.)

12501300 1200 11001150 1050 1000

wavenumbers(cm-1)

(B)O2 anneal:500oC—1000oC

1000゜C

950゜C

900゜C

Formation of La-silicate confirmed above 900oC

Slight suppression of SiO2 with thicker SiN

La-O-Si-O

Si-O-Si

SiN 2nmSiN 1.5nmWithout SiN

8

Si-O-Si

La-O-Si-OLa-O-Si-O

FTIR spectra of La2O3/SiN/SiC

10 20 30

10

20

30

40

50

80

60

70

Sputter time (min)

Ato

mic

co

nce

ntr

atio

n (

%)

0 10 20 30

10

20

30

40

50

80

60

70

Sputter time (min)

Ato

mic

co

nce

ntr

atio

n (

%)

0

O

O

SiSi

Si

C

La

NC

O

O

SiSi

Si

C

La

NC

SiO2(40nm)/La2O3 (4nm)/SiN (2nm)/SiC sub.

Annealing temperature:500oC

LaSiON layer broadens with higher temperature

Concentration of nitrogen decrease with annealing9

XPS depth profile on annealing temperature

Annealing temperature:800oC

• Suppression of agglomeration by SiN barrier layer

• Some protrusion of La-silicates presented at the interface

SiC(0001) SiC(0001)

Sample: SiO2/La2O3 4nm/SiN 2nm/SiC

50nm 10nm

10

Annealing temperature:1000oC

SiO2La-silicate

La2O3/SiN/SiC interface section TEM image

protrusion

0 5 10 15 20 25 30 35

Intensity[a.u.]

Distance[nm]

N-K

O-K

La-M

EELS analysis location(ADF-STEM image)

11

EELS spectra of the protrusion

N La

O

• No nitrogen at the protrusion• Failure of barrier to oxidize SiC substrate

Annealing time, temperature to preserve N atoms at the interface

13

Conclusion

• Oxidation with La2O3 capped SiC substrate• Enhanced oxidation rate with radical oxygen atoms

generated by La atoms• Grain growth, agglomeration of La-silicates• Surface roughness due to step enhanced oxidation

• SiN barrier layer for La2O3/SiC substrates• Formation of LaSiON interface layer• Some protrusion from substrates presumably due to

lack of nitrogen atoms at the interface