INSULATORS FOR ICING AND POLLUTED …...INSULATORS FOR ICING AND POLLUTED ENVIRONMENTS MASOUD...

Transcript of INSULATORS FOR ICING AND POLLUTED …...INSULATORS FOR ICING AND POLLUTED ENVIRONMENTS MASOUD...

-

INSULATORS FOR ICING AND POLLUTED ENVIRONMENTS

MASOUD FARZANEHUniversité du Québec à Chicoutimi, Chicoutimi, Québec, Canada

WILLIAM A. CHISHOLMKinectrics, Toronto, Ontario, Canada

A JOHN WILEY & SONS, INC., PUBLICATION

InodataFile Attachment9780470496244.jpg

-

INSULATORS FOR ICING AND POLLUTED ENVIRONMENTS

-

BOOKS IN THE IEEE PRESS SERIES ON POWER ENGINEERING

Principles of Electric Machines with Power Electronic Applications, Second Edition M. E. El -Hawary

Pulse Width Modulation for Power Converters: Principles and PracticeD. Grahame Holmes and Thomas Lipo

Analysis of Electric Machinery and Drive Systems, Second Edition Paul C. Krause, Oleg Wasynczuk, and Scott D. Sudhoff

Risk Assessment for Power Systems: Models, Methods, and ApplicationsWenyuan Li

Optimization Principles: Practical Applications to the Operations of Markets of the Electric Power IndustryNarayan S. Rau

Electric Economics: Regulation and DeregulationGeoffrey Rothwell and Tomas Gomez

Electric Power Systems: Analysis and ControlFabio Saccomanno

Electrical Insulation for Rotating Machines: Design, Evaluation, Aging, Testing, and RepairGreg Stone, Edward A. Boulter, Ian Culbert, and Hussein Dhirani

Signal Processing of Power Quality DisturbancesMath H. J. Bollen and Irene Y. H. Gu

Instantaneous Power Theory and Applications to Power ConditioningHirofumi Akagi, Edson H. Watanabe, and Mauricio Aredes

Maintaining Mission Critical Systems in a 24/7 EnvironmentPeter M. Curtis

Elements of Tidal -Electric EngineeringRobert H. Clark

Handbook of Large Turbo -Generator Operation and Maintenance, Second Edition Geoff Klempner and Isidor Kerszenbaum

Introduction to Electrical Power SystemsMohamed E. El -Hawary

Modeling and Control of Fuel Cells: Distributed Generation ApplicationsM. Hashem Nehrir and Caisheng Wang

Power Distribution System Reliability: Practical Methods and ApplicationsAli A. Chowdhury and Don O. Koval

Insulators for Icing and Polluted EnvironmentsMasoud Farzaneh and William A. Chisholm

FACTS Controllers: Theory, Modeling, and Applications for Electronic Transmission SystemsKalyan K. Sen and Mey Ling Sen

-

INSULATORS FOR ICING AND POLLUTED ENVIRONMENTS

MASOUD FARZANEHUniversité du Québec à Chicoutimi, Chicoutimi, Québec, Canada

WILLIAM A. CHISHOLMKinectrics, Toronto, Ontario, Canada

A JOHN WILEY & SONS, INC., PUBLICATION

-

IEEE Press445 Hoes Lane

Piscataway, NJ 08854

IEEE Press Editorial BoardLajos Hanzo, Editor in Chief

R. Abari T. Chen B. M. HammerliJ. Anderson T. G. Croda O. MalikS. Basu M. El-Hawary S. NahavandiA. Chatterjee S. Farshchi W. Reeve

Kenneth Moore, Director of IEEE Book and Information Services (BIS)

Technical ReviewersAnthony Baker, K-Line Insulators

Andrew E. Schwalm, Victor Insulators, Inc.

Copyright © 2009 by the Institute of Electrical and Electronics Engineers, Inc.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey. All rights reserved.Published simultaneously in Canada

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at http://www.wiley.com/go/permission.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifi cally disclaim any implied warranties of merchantability or fi tness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor author shall be liable for any loss of profi t or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging-in-Publication Data is available.

ISBN 978-0-470-28234-2

Printed in the United States of America

10 9 8 7 6 5 4 3 2 1

http://www.copyright.comhttp://www.wiley.com/go/permissionhttp://www.wiley.com

-

v

CONTENTS

PREFACE xxi

ACKNOWLEDGMENTS xxv

1. INTRODUCTION 1

1.1. Scope and Objectives / 11.1.1. Problem Areas / 21.1.2. Problem Characteristics / 41.1.3. Intended Audience / 4

1.2. Power System Reliability / 61.2.1. Measures of Power System Reliability / 61.2.2. Achieving Reliability with Redundant

Components / 101.2.3. Achieving Reliability with Maintenance / 101.2.4. Cost of Sustained Outages / 111.2.5. Cost of Momentary Outages / 111.2.6. Who Is Responsible for Reliable Electrical

Systems? / 131.2.7. Regulation of Power System Reliability / 16

1.3. The Insulation Coordination Process: What Is Involved? / 161.4. Organization of the Book / 171.5. Précis / 20 References / 20

-

vi CONTENTS

2. INSULATORS FOR ELECTRIC POWER SYSTEMS 23

2.1. Terminology for Insulators / 232.1.1. Electrical Flashover / 242.1.2. Mechanical Support / 242.1.3. Insulator Dimensions / 242.1.4. Interpretation of Terminology for Winter

Conditions / 292.2. Classifi cation of Insulators / 30

2.2.1. Classifi cation by Ceramic or Polymeric Material / 312.2.2. Classifi cation by Station or Line Application / 322.2.3. Classifi cation by Nature of Mechanical Load / 34

2.3. Insulator Construction / 352.3.1. Ceramic Materials / 352.3.2. Polymeric Materials / 442.3.3. End Fittings / 462.3.4. Other Materials in Series or Parallel with

Insulators / 472.4. Electrical Stresses on Insulators / 48

2.4.1 Power Frequency Electrical Stresses / 492.4.2. Impulse Electrical Stresses / 502.4.3. Major Electrical Factors in Freezing Conditions / 51

2.5. Environmental Stresses on Insulators / 522.5.1. Major Environmental Factors in Temperate

Conditions / 522.5.2. Major Environmental Factors in Freezing

Conditions / 532.6. Mechanical Stresses / 54

2.6.1. Important Factors in Temperate Conditions / 542.6.2. Important Factors in Freezing Conditions / 54

2.7. Précis / 55 References / 56

3. ENVIRONMENTAL EXPOSURE OF INSULATORS 59

3.1. Pollution: What It Is / 593.2. Pollution Deposits on Power System Insulators / 62

3.2.1. Typical Sources / 623.2.2. Deposit Processes / 633.2.3. Monitoring Methods for Site Pollution Severity / 63

-

CONTENTS vii

3.2.4. Short-Term Changes in Pollution Levels / 653.2.5. Cleaning Processes and Rates / 693.2.6. Long-Term Changes in Pollution Levels / 703.2.7. Other Factors in Pollution Problems / 71

3.3. Nonsoluble Electrically Inert Deposits / 723.3.1. Sources and Nature of Nonsoluble Deposits / 723.3.2. Direct Measurement Method for NSDD / 723.3.3. Indirect Measurement Methods for NSDD / 733.3.4. Role of NSDD in Insulator Surface Resistance / 753.3.5. Case Studies: NSDD Measurements / 75

3.4. Soluble Electrically Conductive Pollution / 783.4.1. Electrical Utility Sources / 783.4.2. Other Fixed Sources / 833.4.3. Conductance of Electrolytes / 91

3.5. Effects of Temperature on Electrical Conductivity / 943.5.1. Equivalent Conductance of Ions / 943.5.2. Effect of Temperature on Liquid Water

Conductivity / 953.5.3. Effect of Temperature on Ice Conductivity / 97

3.6. Conversion to Equivalent Salt Deposit Density / 1003.6.1. Insulator Case Study: Mexico / 1013.6.2. Insulator Case Study: Algeria / 1033.6.3. Insulator Case Study: Japan / 1033.6.4. Surface Resistance of Insulator / 1033.6.5. Insulator Leakage Current: Case Studies / 1063.6.6. Estimating ESDD from Environmental Measures for

Corrosion / 1063.6.7. Statistical Distribution of the Conductivity of Natural

Precipitation / 1103.6.8. Mobile Sources / 112

3.7. Self-Wetting of Contaminated Surfaces / 1223.8. Surface Wetting by Fog Accretion / 124

3.8.1. Fog Measurement Methods / 1243.8.2. Typical Observations of Fog Parameters / 1253.8.3. Fog Climatology / 1273.8.4. Fog Deposition on Insulators / 1283.8.5. Heat Balance Between Fog Accretion and

Evaporation / 1303.8.6. Critical Wetting Conditions in Fog / 131

-

viii CONTENTS

3.9. Surface Wetting by Natural Precipitation / 1323.9.1. Measurement Methods and Units / 1333.9.2. Droplet Size and Precipitation Conductivity / 1363.9.3. Effects of Washing on Surface Conductivity / 1373.9.4. Rain Climatology / 137

3.10. Surface Wetting by Artifi cial Precipitation / 1393.10.1. Tower Paint / 1393.10.2. Bird Streamers / 1393.10.3. Dam Spray / 1393.10.4. Irrigation with Recycled Water / 1413.10.5. Cooling Pond Overspray: Freshwater Makeup / 1423.10.6. Cooling Tower Drift Effl uent / 1443.10.7. Cooling Water Overspray: Brackish or Saltwater

Makeup / 1453.10.8. Manurigation / 145

3.11. Précis / 147 References / 148

4. INSULATOR ELECTRICAL PERFORMANCE IN POLLUTION CONDITIONS 155

4.1. Terminology for Electrical Performance in Pollution Conditions / 1554.1.1. Terms Related to Pollution and Its

Characterization / 1554.1.2. Terms Related to In-Service Environment / 1574.1.3. High-Voltage Measurement Terminology / 157

4.2. Air Gap Breakdown / 1594.2.1. Air Breakdown in Uniform Field / 1594.2.2. Air Breakdown in Nonuniform Field / 1614.2.3. Breakdown of Clean and Dry Insulators / 1624.2.4. Breakdown of Clean and Wet Insulators / 164

4.3. Breakdown of Polluted Insulators / 1654.3.1. Breakdown Process on a Contaminated Hydrophilic

Surface / 1654.3.2. Breakdown Process on a Contaminated Hydrophobic

Surface / 1674.3.3. Complications in the Process for Real

Insulators / 1684.4. Outdoor Exposure Test Methods / 169

4.4.1. Field Observations of Leakage Current Activity / 169

-

CONTENTS ix

4.4.2. Field Observations of Flashover Performance / 1704.4.3. Field Observations of Other Variables / 1714.4.4. Observations at Croydon, United Kingdom,

1934–1936 / 1714.4.5. Observations at Croydon, United Kingdom,

1942–1958 / 1724.4.6. Observations at Brighton, United Kingdom / 1754.4.7. Observations at Martigues, France / 1764.4.8. Observations at Enel Sites in Italy / 1764.4.9. Observations at Noto, Akita, and Takeyama,

Japan / 1764.5. Indoor Test Methods for Pollution Flashovers / 178

4.5.1. Comparison of Natural and Artifi cial Pollution Tests / 180

4.5.2. Power Supply Characteristics for Pollution Tests / 1814.5.3. Electrical Clearances in Test Chamber / 184

4.6. Salt-Fog Test / 1854.6.1. Description of Salt-Fog Test Method / 1854.6.2. Validation of Salt-Fog Test Method / 1854.6.3. Quick Flashover Voltage Technique / 187

4.7. Clean-Fog Test Method / 1874.7.1. Precontamination Process for Ceramic

Insulators / 1884.7.2. Precontamination Process for Nonceramic

Insulators / 1904.7.3. Artifi cial Wetting Processes / 1924.7.4. Validation of Clean-Fog Test Method / 1934.7.5. Rapid Flashover Voltage Technique / 195

4.8. Other Test Procedures / 1964.8.1. Naturally Polluted Insulators / 1974.8.2. Liquid Pollution Method / 1974.8.3. Dust Cycle Method / 1984.8.4. Dry Salt Layer Method / 1984.8.5. Cold-Fog Test Method / 1994.8.6. Tests of Polymeric Insulator Material

Endurance / 2004.8.7. Summary of Pollution Test Methods / 201

4.9. Salt-Fog Test Results / 2034.9.1. ac Salt-Fog Test Results / 2034.9.2. dc Salt-Fog Test Results / 204

-

x CONTENTS

4.10. Clean-Fog Test Results / 2054.10.1. ac Clean-Fog Tests / 2054.10.2. dc Clean-Fog Tests / 2074.10.3. Impulse Voltage Clean-Fog Tests / 209

4.11. Effects of Insulator Parameters / 2114.11.1. Leakage Distance and Profi le / 2114.11.2. Effect of Small Diameter : Monofi laments and

ADSS / 2124.11.3. Infl uence of Average Insulator Diameter / 2144.11.4. Infl uence of Insulator Form Factor / 2194.11.5. Infl uence of Surface Material / 221

4.12. Effects of Nonsoluble Deposit Density / 2234.13. Pressure Effects on Contamination Tests / 224

4.13.1. Standard Correction for Air Density and Humidity / 224

4.13.2. Pressure Corrections for Contamination Flashovers / 227

4.14. Temperature Effects on Pollution Flashover / 2294.14.1. Temperatures Above Freezing / 2294.14.2. Temperatures Below Freezing / 231

4.15. Précis / 233 References / 234

5. CONTAMINATION FLASHOVER MODELS 241

5.1. General Classifi cation of Partial Discharges / 242

5.1.1. Discharges in the Presence of an Insulating Surface / 243

5.2. Dry-Band Arcing on Contaminated Surfaces / 2465.2.1. Wetted Layer Thickness and Electrical

Properties / 2465.2.2. Surface Impedance Effects / 2475.2.3. Temperature Effects Leading to Dry-Band

Formation / 2475.2.4. Dry-Band Formation / 2485.2.5. Arcing and Enlargement of Dry Bands / 2495.2.6. Nuisance Factors from Discharges on Wetted

Pollution Layers / 2505.2.7. Stabilization or Evolution to Flashover / 255

5.3. Electrical Arcing on Wet, Contaminated Surfaces / 255

-

CONTENTS xi

5.3.1. Discharge Initiation and Development / 2565.3.2. Arc V–I Characteristics in Free Air / 2565.3.3. Arc V–I Characteristics on Water or Ice

Surfaces / 2595.3.4. Dynamics of Arc Propagation / 261

5.4. Residual Resistance of Polluted Layer / 2625.4.1. Observations of Series Resistance of Pollution

Layer / 2625.4.2. Mathematical Functions for Series Resistance of

Pollution Layer / 2655.4.3. Resistance of Arc Root on Conducting Layer / 268

5.5. dc Pollution Flashover Modeling / 2715.5.1. Analytical Solution: Uniform Pollution Layer / 2715.5.2. Analytical Solution Using Insulator Form

Factor / 2735.5.3. Numerical Solution: Nonuniform Pollution

Layer / 2745.5.4. Comparison of Different Models for Pollution

Layer / 2745.5.5. Introduction of Multiple Arcs in Series / 2765.5.6. dc Arc Parameter Changes with Pressure and

Temperature / 2775.6. ac Pollution Flashover Modeling / 278

5.6.1. ac Arc Reignition / 2785.6.2. ac Reignition Conditions Versus Ambient

Temperature / 2815.6.3. Mathematical Model for Reignition Condition / 2825.6.4. Comparison of dc and ac Flashover Models / 283

5.7. Theoretical Modeling for Cold-Fog Flashover / 2845.8. Future Directions for Pollution Flashover Modeling / 2855.9. Précis / 286 References / 287

6. MITIGATION OPTIONS FOR IMPROVED PERFORMANCE IN POLLUTION CONDITIONS 291

6.1. Monitoring for Maintenance / 2926.1.1. Insulator Pollution Monitoring / 2926.1.2. Condition Monitoring Using Leakage Current / 2966.1.3. Condition Monitoring Using Corona Detection

Equipment / 301

-

xii CONTENTS

6.1.4. Condition Monitoring Using Remote Thermal Monitoring / 303

6.2. Cleaning of Insulators / 3056.2.1. Doing “Nothing” / 3056.2.2. Insulator Washing: Selecting an Interval / 3066.2.3. Insulator Washing: Methods and Conditions / 3076.2.4. Case Study: Southern California Edison,

1965–1976 / 3096.2.5. Insulator Washing Using Industry Standard

Practices / 3106.2.6. Insulator Washing: Semiconducting Glaze / 3136.2.7. Insulator Washing: Polymer Types and RTV

Coatings / 3146.2.8. Insulator Washing: Procedures in Freezing

Weather / 3166.2.9. Insulator Cleaning: Dry Media / 316

6.3. Coating of Insulators / 3196.3.1. Oil-Filled Insulators / 3196.3.2. Greases / 3196.3.3. Silicone Coatings / 321

6.4. Adding Accessories / 3246.4.1. Booster Sheds / 3246.4.2. Creepage Extenders / 3256.4.3. Animal, Bird or “Guano” Guards / 3276.4.4. Corona Rings / 3296.4.5. Arcing Horns / 331

6.5. Adding More Insulators / 3326.6. Changing to Improved Designs / 334

6.6.1. Anti-Fog Disk Profi le with Standard Spacing and Diameter / 334

6.6.2. Aerodynamic Disk Profi le / 3356.6.3. Alternating Diameter Profi les / 3376.6.4. Bell Profi le with Larger Diameter and Spacing / 3386.6.5. Anti-Fog Disk Profi les with Larger Diameter and

Spacing / 3406.6.6. Station Post and Bushing Profi les / 342

6.7. Changing to Semiconducting Glaze / 3436.7.1. Semiconducting Glaze Technology / 3436.7.2. Heat Balance: Clean Semiconducting Glaze

Insulators / 345

-

CONTENTS xiii

6.7.3. Heat Balance: Contaminated Semiconducting Glaze Insulators / 348

6.7.4. On-Line Monitoring with Semiconducting Glaze Insulators / 349

6.7.5. Role of Power Dissipation in Fog and Cold-Fog Accretion / 350

6.7.6. Considerations for Semiconducting Insulators in Close Proximity / 351

6.7.7. Application Experience / 3526.8. Changing to Polymer Insulators / 3526.8.1. Short-Term Experience in Contaminated

Conditions / 3536.8.2. Long-Term Performance in Contaminated

Conditions / 3546.8.3. Interchangeability with Ceramic Insulators / 3556.8.4. Case Study: Desert Environment / 357

6.9. Précis / 357 References / 358

7. ICING FLASHOVERS 363

7.1. Terminology for Ice / 3647.2. Ice Morphology / 365

7.2.1. Crystal Structure / 3657.2.2. Supercooling / 3667.2.3. Lattice Defects from Pollution / 367

7.3. Electrical Characteristics of Ice / 3677.3.1. Conductivity of Bulk Ice / 3687.3.2. Conductivity of Ice Surface / 3687.3.3. High-Frequency Behavior of Ice / 371

7.4. Ice Flashover Experience / 3737.4.1. Very Light Icing / 3747.4.2. Light Icing / 3777.4.3. Moderate Icing / 3807.4.4. Heavy Icing / 381

7.5. Ice Flashover Processes / 3847.5.1. Icing Flashover Process for Very Light and Light Ice

Accretion / 3857.5.2. Icing Flashover for Moderate Ice Accretion / 3867.5.3. Icing Flashover Process for Heavy Ice

Accretion / 387

-

xiv CONTENTS

7.6. Icing Test Methods / 3887.6.1. Standard Electrical Tests of Insulators / 3897.6.2. Standard Mechanical Ice Tests for Disconnect

Switches / 3907.6.3. Natural Icing Tests in Outdoor Test Stations / 3907.6.4. History of Laboratory Ice Testing / 3917.6.5. Recommended Icing Test Method / 3987.6.6. Recommended Cold-Fog Test Method / 402

7.7. Ice Flashover Test Results / 4037.7.1. Outdoor Text Results / 4037.7.2. Laboratory Tests with Very Light Icing / 4037.7.3. Insulators with Light Ice Accretion / 4067.7.4. Insulators with Moderate Ice Accretion / 4087.7.5. Insulators Fully Bridged with Ice / 4157.7.6. Arresters Under Heavy Icing Conditions / 4227.7.7. Ice Flashover Under Switching and Lightning

Surge / 4227.7.8. Effect of Diameter on ac Flashover for Heavy

Icing / 4257.7.9. dc Flashover Results for Heavy Icing / 427

7.8. Empirical Models for Icing Flashovers / 4317.8.1. The Icing Stress Product for ac Flashover Across

Leakage Distance / 4327.8.2. The Icing Stress Product for ac Flashover across Dry

Arc Distance / 4347.8.3. Implementation of ISP Model for dc Flashover

Under Heavy Ice Conditions / 4397.8.4. Comparison of Ice Flashover to Wet Flashover / 440

7.9. Mathematical Modeling of Flashover Process on Ice-Covered Insulators / 4417.9.1. dc Flashover Modeling of Ice-Covered

Insulators / 4427.9.2. Infl uence of Insulator Precontamination on dc

Flashover of Ice-Covered Insulators / 4487.9.3. ac Flashover Modeling of Ice-Covered

Insulators / 4507.9.4. Application Details: Flashover Under Very Light

Icing / 4577.9.5. Application Details: Flashover Under Light Icing

Conditions / 459

-

CONTENTS xv

7.9.6. Application Details: Flashover Under Moderate Icing Conditions / 461

7.9.7. Application Details: Flashover Under Heavy Icing Conditions / 463

7.10. Environmental Corrections for Ice Surfaces / 4657.10.1. Pressure Correction for Heavy Ice Tests / 4657.10.2. Arc Parameter Variation with Temperature and

Pressure / 4677.10.3. Heat Transfer and Ice Temperature / 467

7.11. Future Directions for Icing Flashover Modeling / 4697.11.1. Streamer Initiation and Propagation on Ice

Surfaces / 4707.11.2. Dynamics of Arc Motion on Ice Surfaces / 4707.11.3. Dynamic Model for Ice Temperature / 471

7.12. Précis / 472 References / 472

8. SNOW FLASHOVERS 481

8.1. Terminology for Snow / 4818.2. Snow Morphology / 4828.3. Snow Electrical Characteristics / 484

8.3.1. Electrical Conduction in Snow, dc to 100 Hz / 4878.3.2. Dielectric Behavior of Snow, 100 Hz to 5 MHz / 4898.3.3. Products of Electrical Discharge Activity / 490

8.4. Snow Flashover Experience / 4908.5. Snow Flashover Process and Test Methods / 493

8.5.1. Snow Flashover Process / 4948.5.2. Snow Test Methods / 4958.5.3. General Arrangements for Snow Tests / 4968.5.4. Snow Deposit Methods / 4978.5.5. Evaluation of Flashover Voltage for Snow Tests / 498

8.6. Snow Flashover Test Results / 5008.6.1. Outdoor Tests Using Natural Snow Accretion / 5008.6.2. Outdoor Tests Using Artifi cial Snow Deposit / 5038.6.3. Indoor Tests Using Natural Snow Deposits / 5038.6.4. Snow Flashover Results for dc / 5058.6.5. Snow Flashover Under Switching Surge / 5058.6.6. Snow Flashover Results for Long Insulator

Strings / 508

-

xvi CONTENTS

8.7 Empirical Model for Snow Flashover / 5088.7.1. Conversion of Test Results to Snow Stress

Product / 5098.7.2. Comparison of Snow Flashover to Ice and Cold

Fog / 5118.7.3. Comparison of Snow Flashover to Normal Service

Voltage / 5128.8. Mathematical Modeling of Flashover Process on Snow-

Covered Insulators / 5138.8.1. Voltage–Current Characteristics in Snow / 5148.8.2. dc Flashover Voltage / 5178.8.3. ac Reignition Condition and Flashover Voltage / 5188.8.4. Switching and Lightning Surge Flashover / 519

8.9. Environmental Corrections for Snow Flashover / 5208.9.1. Pressure / 5208.9.2. Temperature / 520

8.10. Case Studies of Snow Flashover / 5208.10.1. In-Cloud Rime Accretion: Keele Valley, Ontario / 5208.10.2. Temporary Overvoltage Problem: 420-kV Breaker in

Norway / 5228.10.3. Snow Accretion on Surge Arresters / 524

8.11. Précis / 525 References / 525

9. MITIGATION OPTIONS FOR IMPROVED PERFORMANCE IN ICE AND SNOW CONDITIONS 529

9.1. Options for Mitigating Very Light and Light Icing / 5309.1.1. Semiconducting Glaze / 5329.1.2. Increased Leakage Distance / 5359.1.3. Coating of Insulators with RTV Silicone / 5399.1.4. Change for Polymer / 5439.1.5. Insulator Pollution Monitoring and Washing / 5449.1.6. Case Study: SMART Washing / 548

9.2. Options for Mitigating Moderate Icing / 5509.2.1. Use of Profi les with Greater Shed-to-Shed

Distance / 5529.2.2. Increased Dry Arc Distance / 5539.2.3. Insulator Orientation / 5559.2.4. Semiconducting Glaze / 555

-

CONTENTS xvii

9.2.5. Polymer Insulators / 5599.2.6. Corona Rings / 5619.2.7. Condition Monitoring Using Remote Thermal

Measurements / 5619.2.8. Silicone Coatings / 562

9.3. Options for Mitigating Heavy Icing / 5649.3.1. Increasing the Dry Arc Distance / 5649.3.2 Changing to Semiconducting Glaze / 5669.3.3. Adding Booster Sheds / 5689.3.4. Changing to Polymer Insulators / 5729.3.5. Ice Monitoring Using Leakage Current / 5739.3.6. Ice Stripping in Freezing Weather / 5759.3.7. Corona Rings and Other Hardware / 5769.3.8. Increasing Shed-to-Shed Distance / 5779.3.9. Coating of Insulators with RTV Silicone / 577

9.4. Options for Mitigating Snow and Rime / 5809.4.1. Increased Dry Arc Distance / 5809.4.2. Insulator Profi le / 5809.4.3. Insulators in Parallel / 5819.4.4. Polymer Insulators / 5829.4.5. Surface Coatings / 5839.4.6. Use of Semiconducting Glaze / 5839.4.7. Use of Accessories / 583

9.5. Alternatives for Mitigating Any Icing / 5849.5.1. Doing “Nothing” / 5849.5.2. Voltage Reduction / 5859.5.3. Post-Event Inspection Using Corona Detection

Equipment / 5859.6. Précis / 585

References / 586

10. INSULATION COORDINATION FOR ICING AND POLLUTED ENVIRONMENTS 591

10.1. The Insulation Coordination Process / 59210.1.1. Classifi cation of Overvoltage Stresses on

Transmission Lines / 59210.1.2. High-Voltage Insulator Parameters / 59410.1.3. Extra-High-Voltage Insulator Parameters / 595

-

xviii CONTENTS

10.1.4. Design for an Acceptable Component Failure Rate / 596

10.1.5. Design for an Acceptable Network Failure Rate / 598

10.2. Deterministic and Probabilistic Methods / 59910.3. IEEE 1313.2 Design Approach for Contamination / 60410.4. IEC 60815 Design Approach for Contamination / 60610.5. CIGRE Design Approach for Contamination / 60710.6. Characteristics of Winter Pollution / 611

10.6.1. Days Without Rain in Winter / 61210.6.2. Rate of Increase of ESDD / 61210.6.3. Effect of Road Salt / 615

10.7. Winter Fog Events / 61710.8. Freezing Rain and Freezing Drizzle Events / 618

10.8.1. Measurement Units / 61810.8.2. Frequency of Occurrence / 61910.8.3. Time of Day and Time of Year of Freezing

Precipitation Occurrence / 62210.8.4. Severity of Freezing Rain Occurrence / 62210.8.5. Electrical Conductivity of Freezing

Rainwater / 62310.9. Snow Climatology / 625

10.9.1. Standard Methods for Snow Measurements / 62510.9.2 Snow Accumulation and Persistence / 62510.9.3. Snow Melting / 628

10.10. Deterministic Coordination for Leakage Distance / 62910.11. Probabilistic Coordination for Leakage Distance / 63010.12. Deterministic Coordination for Dry Arc Distance / 631

10.12.1. Dry Arc Distance Requirements for Icing Conditions / 631

10.12.2. Dry Arc Requirements for Snow Conditions / 632

10.13. Probabilistic Coordination for Dry Arc Distance / 63410.14. Case Studies / 635

10.14.1. Ontario 500 kV / 63510.14.2. Ontario 230 kV / 63710.14.3. Newfoundland and Labrador Hydro / 640

10.15. Précis / 641 References / 642

-

CONTENTS xix

APPENDIX A: MEASUREMENT OF INSULATOR CONTAMINATION LEVEL 645

APPENDIX B: STANDARD CORRECTIONS FOR HUMIDITY, TEMPERATURE, AND PRESSURE 651

APPENDIX C: TERMS RELATED TO ELECTRICAL IMPULSES 659

INDEX 661

-

xxi

PREFACE

There are many causes of power system interruption. Breakdown of self - restoring air insulation is one of the most frequent. In a former analog world, the tolerable frequency and duration of supply interruptions was much greater: our grandparents were amazed that a power system worked at all, and our parents never took it for granted the way our children do.

Many causes of power system interruption have an obvious relation to adverse weather. Lightning fl ashes, either to overhead groundwire protection systems or to phase conductors, are the most frequent cause of transmission system insulation breakdown at many utilities. Ice loading on power lines can lead in extreme cases to excess overturning moment and tower failures, as was shown in the 1998 ice storm that devastated the province of Qu é bec. Conductors and insulators buzz when there is heavy rain or fog, producing higher levels of electromagnetic interference and audible noise. In some cases, partial dis-charges in these conditions can develop into full electrical breakdown across insulator surfaces.

Electric power systems are carefully designed to withstand mechani-cal forces associated with wind and ice loads. The mechanical design speci-fi cation, fully developed in standards, gives good results in climates with a wide range of icing risks. There is no equivalent quantitative, standards - based design process for electrical insulation performance in the same conditions. This book allows utility engineers, consultants, researchers, and students to evaluate the risks of electrical fl ashover in cold weather. The authors hope that this treatment will also serve as a suitable introduction to the insulation

-

xxii PREFACE

coordination process for other adverse - weather conditions and for other risk factors.

There were few problems with insulator choices in winter conditions at high - voltage transmission levels up to 230 kV, with the exception of pole fi res on distribution systems. The insulation problems were recognized more quickly as extra - high - voltage (EHV) lines moved out of remote areas with limited development and low pollution. Problems with switching overvoltages were anticipated on EHV systems but improved switchgear and surge arrest-ers mitigated the problems effi ciently in the 1960s and 1970s. This led to the use of reduced insulation levels that exposed some utilities to low levels of reliability in a specifi c set of weather conditions, usually including ice accret-ing in thin or thick layers, melting temperature at 0 ° C (32 ° F), and some form of environmental pollution, either in precipitation or in surface deposits that accumulate over time. With the widespread use of EHV equipment in urban and suburban winter environments, the special case of winter fl ashovers at the melting point has now become an important design constraint in several areas. The public is less tolerant of this kind of fault because it is rare and relatively well tolerated by other systems, such as transportation. In many cases, as will be shown, the utility is caught in a trap because winter deicing treatments that ensure ice - free roads in the winter are a root cause of their electrical fl ashovers.

The duration of exposure to pollution buildup in winter can be similar to that found in typical desert exposure. Symptoms of this problem also show up when drift overspray from cooling towers condenses onto cold insulators or when unfavorable wind direction blows road salt spray directly onto insulators. The study of electrical fl ashover on iced or polluted and frosted insulators is also an interesting and accessible introduction to more diffi cult problems of insulation coordination for the electrical utility engineer or student in engi-neering or risk management. Much of the work described here also describes aspects of the general insulation coordination process. The specifi c reliability evaluations set out here also serve as working models for a coordinated risk management plan to treat other weather - related reliability issues in electrical power system installations.

After reading the appropriate parts of this book, technicians and environ-mental specialists will be able to carry out appropriate insulator contamination measurements, understand how these readings change with time and weather, and work out how the readings compare with the upper limits set by insulator dimensions in their existing stations. Design engineers will be able to assess the likely maximum pollution and icing limits at a substation or along an overhead line, and then select insulators that have appropriate withstand margins. Regulators will understand why modest ice accretion at a moderate 0 ° C temperature on one occasion can qualify as a major reliability event day, while many similar days pass without power system problems. Educators will understand why the ice surface fl ashover is well behaved compared to the

-

PREFACE xxiii

conventional pollution fl ashover, making it much more suitable for demonstra-tions, modeling, and analysis by students.

Masoud Farzaneh William A. Chisholm

Chicoutimi, Qu é bec, Canada

Toronto, Ontario, Canada

July 2009

-

xxv

ACKNOWLEDGMENTS

This book, with a provisional title “ Fire in the Ice, ” was originally scoped on the back of a napkin at Ù Flek ù after a seminal meeting of the CIGRE Task Force, Infl uence of Ice and Snow on the Flashover Performance of Outdoor Insulators , hosted by Vaclav Sklenicka in Prague in 1999. At that time, there were too many unknowns to complete important sections of the outline. Members of the CIGRE Task Force and the corresponding IEEE Task Forces on Icing Test Methods and Selection of Insulators for Reliable Winter Performance have supported and contributed to the free sharing and consoli-dation of experiences that now allows a cohesive presentation.

The authors have been surprised and delighted by the success of the CIGELE program at the Universit é du Qu é bec à Chicoutimi (UQAC). This chair has been sponsored by the governments of Canada (NSERC and CRC) and Qu é bec, by electrical utilities in Canada, the United States, and France, and by manufacturers in the United States and Canada. This program, now in its third fi ve - year mandate, has engaged more than 40 graduate students in various aspects of electrical fl ashover modeling. Each student has found some-thing of value and interest in the electrical performance of cold insulators and in return has left new fi ndings and insight that expand our understanding exponentially.

During the writing process, we have received encouragement and positive feedback from anonymous reviewers for IEEE Press and also from the editors, Steve Welch, Mo El - Hawary, Lisa Van Horn, and Jeanne Audino. We were also encouraged by the helpful and detailed reviews of chapters and the entire text by several colleagues, notably Tony Baker, Jeff Burnham, Tony Carreira, Ed Cherney, Hiroya Homma, Ray Lings, Bill Meier, Farouk A. M. Rizk, Andy Schwalm, Mike Southwood, Jerry Stewart, and Jianhui Zhang.

-

xxvi ACKNOWLEDGMENTS

Permission to use previously published material is gratefully acknowledged as noted in the references. We especially note the staff of Kinectrics, the former Research Division of Ontario Hydro, and of Hydro - Qu é bec, for their collabo-ration starting from basic fi eld studies and culminating in the release of many new test results presented here.

Finally, the authors acknowledge the help and support of their wives and families.

M. F. W. A. C.

-

Insulators for Icing and Polluted Environments. By Masoud Farzaneh and William A. ChisholmCopyright © 2009 the Institute of Electrical and Electronics Engineers, Inc.

1

INTRODUCTION

1.1. SCOPE AND OBJECTIVES

Electric power systems are carefully designed to withstand mechanical forces associated with wind and ice loads. The mechanical design specifi cation, fully developed in standards, gives good results in a wide range of climates. There is no equivalent quantitative, standards - based design process for electrical insulation in winter conditions.

There were occasional problems with insulators operating in winter condi-tions at high - voltage transmission levels up to 230 kV, along with hazards of pole fi res on distribution systems that made use of wood insulation. The insulation problems were recognized more quickly as extra - high - voltage (EHV) lines moved out of remote areas with limited development and low pollution. With the widespread use of EHV equipment in urban and subur-ban winter environments, and the challenges of ultra - high - voltage (UHV) engineering, the special case of winter fl ashovers at air temperature close to the melting point has now become an important design constraint in several areas.

This book is mainly about the electrical performance of power system insulators when coated with various forms of ice or snow. The roles of insula-tor precontamination and pollution in natural precipitation are important, so

CHAPTER 1

-

2 INTRODUCTION

there is some overlap with the many studies of electrical performance of insulators in salt - fog and clean - fog conditions. The authors recognize that when conductors are weighted down by ice and snow, there are extreme loads on the insulators, towers, and poles, and that the low temperatures also affect the mechanical strength of the components. However, electrical prob-lems with fl ashovers resulting from modest ice accretion on insulators are far more frequent than line collapse under heavy ice loads.

1.1.1. Problem Areas

The number of single - phase faults in transmission networks in winter increases substantially during and after accretion of cold precipitation, fol-lowed by a rise in air temperature above 0 ° C. Farzaneh and Kiernicki [1995] reviewed problems from 11 countries. A detailed review of the North American experience, leading to signifi cant event reports to the National Electric Reliability Council (NERC), was consolidated by Chisholm [1997] . Eighteen countries reported ice and snow electrical fl ashover problems in a 2005 CIGRE survey [Yoshida and Naito, 2005 ]. The fl ashover problems plagued 35 utilities with 400 - to 735 - kV transmission systems on both line and station insulators.

Worldwide, ice and snow test methods have been developed to a high degree of sophistication in Canada, Sweden, Japan, and China, with movement toward standardization in IEEE PAR 1783 [2008] . The topic has also been covered in panel sessions and papers at general conferences on insulation and high voltage such as:

• IEEE Power and Energy Society ( PES ). • IEEE Dielectrics and Electrical Insulation Society ( DEIS ). • Conseil Internationale des Grands Resaux Electriques ( CIGRE ). • International Symposium on High Voltage Engineering ( ISH ).

Specialized conferences on icing such as the International Workshop on Atmospheric Icing of Structures ( IWAIS ) have also focused sessions on elec-trical fl ashover problems.

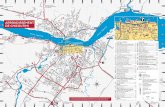

Geographically, the K ö ppen – Geiger World Climate Classifi cation of cold regions, based on vegetation, can provide a good initial indication of where in the world there will be problems with electrical fl ashovers on insulators. The group - D (continental) climates are the ones having an average temperature above 10 ° C in summer and below − 3 ° C in winter. There are few areas in the Southern Hemisphere, for example, highland New Zealand, that have this classifi cation, so icing fl ashover problems are mainly the domain of the north-ern regions, shown in Figure 1 - 1 .

There are two other aspects to the classifi cation in Figure 1 - 1 . The second letter in the D x y code has the following meanings: