Instructions Manual Illustrated Parts Catalogue - … · Instructions Manual & Illustrated Parts...

-

Upload

nguyenmien -

Category

Documents

-

view

259 -

download

3

Transcript of Instructions Manual Illustrated Parts Catalogue - … · Instructions Manual & Illustrated Parts...

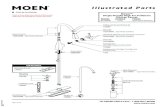

Model 7441

Single needle Extra heavy duty Large oscillating shuttle

hook Cylinder bed Compound feed lockstitch machine

(744174717461-377411RL-37)

Instructions Manual amp

Illustrated Parts Catalogue

This catalog has been prepared to guide you while operating 7441 series machines and arranged to simplify ordering spare parts

~ Before putting the machines described in this manual into service carefully read the instructions The starting of each machine is

only permitted after taking notice ofthe instructions and by qualified operators

Edition No English 20

Rights Reserved In All Countries

Printed in China

Operation Instruction

1 BRIEF INTRODUCTION --------~--------------------------------------~--------------------------------------------------- 1

2 MAIN SPECIFICATIONS --------------------------------------------------------------------------------------------------- 1

3 OPERATION PREPARATION ----------------------------------------------------------------------------------------------- 1

4 INSTALLING THE MOTOR ------------------------------------------------------------------------------------------------- 2

5 INSTALLING THE BELT GUARD ----------------------------------------------------------------------------------------- 2

6 LUBRICATION ----------------------------------------------------------------------------------------------------------------- 2

7 INSTALLING THE NEEDLE ------------------------------------------------------------------------------------------------ 2

8 CHOOSING THREAD -------------------------------------------------------------------------------------------------------- 3

9 WINDING BOBBIN THREAD --------------------------------------------------------------------------------------------- 3

10 INSTALLING AND UNINSTALLING THE BOBBIN ----------------------------------------------------------------- 3

11 THREADING NEEDLE THREAD ----------------------------------------------------------------------------------------- 3

12 ADJUSTING THREAD TENSION ---------------------------------------------------------------------------------------- 3

13 ADJUSTING STITCH LENGTH -------------------------------------------------------------------------------------------- 3

14 ADJUSTING THREAD TAKE-UP SPRING ------------------------------------------------------------------------------ 4

15 ADJUSTING THE PRESSURE OF PRESSER FOOT ----------------------------------------------------------------- 4

16 ADJUSTING THE HEIGHT OF FEED DOG ----------------------------------------------------------------------------- 4

17 THE RELATIONSHIP BETWEEN NEEDLE AND SHUTTLE ---------~-------------------------------------------- 5

18 ADJUSTING THE LIFTING AMOUNT OF ALTERNATING FOOT ----------------------------------------------- 5

19 ADJUSTING THE TIMING OF UPPER FEED -------------------------------------------------------------------------- 5

Parts Manual

A FRAME amp MISCELLANEOUS COVER COMPONENTS ----------------------------------------------------------- 1

B MAIN SHAFT COMPONENTS ------------------------------------------------------------------------------------------ 2

C NEEDLE BARmiddotUPPER FEED MECHANISM COMPONENTS------------------------------------------------------ 3-7

D PRESSURE BAR COMPONENTS ------------------------------------------------------------------------------------- 8

E FEED MECHANISM COMPONENTS -------------------------------------------------------------------------------- 9-10

F HOOK DRIVING SHAFT COMPONENTS --------------------------------------------------------------------------- 11-12

G TENSION POST COMPONENTS ----------------------------------------------------------------------------------- 13

H THREAD WINDER amp THREAD GUIDE CONPONENTS ----------------------------------------------------------14-15

I KNEE LIFTER COMPONENTS ------------------------------------------------------------------------------------------- 16

G BELT COVER COMPONENTS ----------------------------------------------------------------------------------------- 17

K THREAD STAND COMPONENTS -----------~----------------------------------~---------------------------------------- 18

L TABLE COMPONENTS -------------------------------------------------------------------------------------------------- 19

M ACCESSORIES PARTS COMPONENTS ------------------------------------------------------------------------------ 20

N SPECIAL PARTS ON REQUEST AND AGAINST EXTRA CHARGES ------------------------------------------- 21

IBrief introduction

7441 is single needle extra heavy duty large oscillating shuttle hook compound feed (bottom feed needle feed and

walking foot feed) lockstitch sewing machine for the producion of3-dimensional items used when manufacturing for

example saddles scats harness safety belts conveyor belts golf bags straps technical texties filter general leather

and upholstery products etc

The special extra large shuttle hook and bobbin capacity offers high efficiency in sewing products using extra thick

thread up to metric size 8 (including sizes 302520 128 amp V92 V128 V207 V242 V277)

7471 is top and bottom feed lockstitch machine (with additional attachments) for special purpose especially in producshy

tion ofhoses and leather goods

7461-3 7 is super long arm heavy duty compound feed lockstitch machine The cylinder shaped arm has been extended

to give approximately 940mm clearance to the right ofneedle

7441RL-37 Long arm cylinder bed transverse scam machine (Feed up the arm) is available 0 request It is a customshy

made sewing solution for products where transverse (sideways) stitching is necessary

2Main specifications

Applications Heavy and Extra-heavy weight materials

Maxsewing speed 800spm Maxstitch length Ilmm Needle bar stroke 56mm Presser foot lift 13mm by hand height 23mm by pedal Hook KSP-204N Needle DYX325 Cylinder diameter 81mm Lubrication Oiled by hand Motor power 550W

3Machine installation 31Clearing the machine

Before the head is packed all ofthe parts of the machine are coated with anti-rust greasemeanwhile the grease can harden and the dust can cover the machine surface during long time storage and shipmentsothe dust and greasemust be cleared by clean cloth with gasoline

32Examination Although every machine is conformed by strict inspection and test before deliverythe parts ofthe

machine may be loose and deformed after long distance transportation with jolt A thorough examination must be performed Turn the balance wheel slightly by hand to check if there is running obstruction parts collision uneven resis tance and abn-ormal noise If any of these existadjustment must be made accordingly before running

1

41nstalling the motor (Fig1) Move the motor C leftward or rightward to make the hand wheel belt groove A and motor pulley belt

groove B run in line

HIGHTEX n 2U

A

B

5Installing the belt guard(Fig2)

Please install the belt gurad for the safety purpose aInstall the pin supporter CD into the screw hole on the machine casting bInstall the guard reg on the casting cPut the V-belt on the hand wheel dInstall the guard regon the guard reg eFix the guard on the table with wooden screw

6Lubrication(Fig3)

Please add the oil at the places shown by arrows

7Installing the needle (Fig4) aTurn the hand wheel to lift the needle bar at its highest position bLoosen the screw CD and keep the long groove A of needle reg rightward cFully insert the needle shank up to the bottom of needle bar dTighten the screw CD

2

HIGHTEK

-

I---- dJ

Long groove leftward

4

8Choosing thread(Fig5) The needle thread should be left-twistthe bobbin threadmay be left-twist or right-twistThe way judging the

thread twisthold the thread by left handtwist it by right hand as the direction shown in the Fig5if thethread changes tightlyits left-twiston the contraryits right-twist

9Winding the bobbin thread (Fig6) a Threading the thread from thread spool and pass through ABCDthen wind thread several corcles around bobbin b eut the winding lever onto bobbin the winding pulley will press the friction pulley in the arm c Thread amount can be adjustedby screw reg the optimun capacity ofbobbin thread is fill about 80ofbobbin

outside diameterturn the screw clockwise to increase thea mounton the contrarydecrease the amount d After finishloosenthe winding lever and thread winder will stop automatically

lOInstalling and uninstalling the bobbin (Fig7) 101 Uninstalling the bobbin

Open the shuttle cover and lower the needle bar at its lowestpositioninsertthe openerreg between spring CD and bobbin casereg press the spring CDdown and draw thebobbin casereg outthe bobbin will be pulled out from bobbin case to2 Installing the bobbin

When install the bobbindraw the thread tip out and put the bobbin 4 intobobbin case thread the bobbin thread from slit CV then pass it through the hole under the tension spring The bobbin case will be locked by spring CD after being put into shuttle

5 6

D

JB~ ~ 0

0

7

l1Threading needle theard(Fig8) The sequence of threading is shown in the Fig 8 from(I)-(14)

12Adjusting thread tension(Fig9) 121Adjusting needle thread tension

Turn the nut CDclockwise to increase the needle thread tensiontum the nut counter-clockwise to decrease the needle thread tension 122Adjusting bobbin thread tension

Turn the screw regclockwise to increase the bobbin thread tensionturn the screw counter-clockwise to de crease the tension

13Adjusting stitich length(Figl 0) Turn the stitch length adjusting nut CD clockwise or counter-clockwisethe numbers ongraduation board shown

the sizes of the stitch lengthif the stitch length confirmedpleasetighten the nutreg For reverse feedlift the stitch length adjusting screw bar to performreverse sewingrelease the screw barthe forward sewing is resumed

Noteifthe screw bar becomes loose because of moving upward or downward for a long timeplease turn the screw 3 to maintain the proper tension

3

10 8 9

o

14Adjusting thread take-up spring (Figll) IChanging the stroke of thread take-up spring

a Loosen the screw CD and move the stop plate regup-ward and downward b Move thestop plate downward to increase the stroke of thread take-upmove the plateupward todecrease th stroke of thread take-up

2Adjusting the tension of thread take-up Loosen the nut turn the spring shaft counter-clockwise to increase the tension of thread take-upturn the shaft

clockwise to decrease the tension Please use a screw driver to insert the split on the spring shaft and turn the spring shaft toget the required tension

15Adjusting the pressure ofpresser foot(Fig12) The proper pressure ofpresser foot should be adjusted according to the materials to be sewn

aTum the screw CD clockwise to increase the pressureon the contrarydecrease the pressure bAfter finishtighten the nutreg

16Adjusting the height of feed dog (Fig13) The adjustment position of feed dog is higher 13-I5mm than needle plateplease adjust it as following sequence

according to sewing requi rements or after changing a new one aConfirm the highest position of feed dogthen tighten the feed dog screw CD bTemporarily adjust the height of feed

dog higher of lower compare to the standardheight according to spcial sewing situation

11 12 13-15mm

~~ ~

~

j

4

13

17The relationship between needle and shuttle (Fig 14) a confirm the height of needle bar

When the needle bar is lifted 4S-SSmm from its lowest position the tip of shuttle should locate at the center of needle bar and the clearance between the top of needle bar hole and the tip of shuttle is 2S-3mm b Confirm the position of shuttle

Loosen the crank screw reg in the bed hole CD move the crank forward or backw-ardafter adjust the position of the tip of shuttletighten the screw reg c The flank clearance between the tip of shuttle and needle bar should be OOS-3mm loosen the rear crank screw and collar screw oflower shaftmove the lower shaft leftward or rightwardafter adjustmenttighten the screws

I8Adjusting the lifting amount of alternating foot (Fig 15) The lifting amount of alternating foot can been adjsuted within a certain rangefor normal sewingthe lifting amount

ofouter presser foot is 6mmthe liftinmg amount of inner presser foot is 45mmif the other mechanism is fix the lifting amount of two feet is constant

Adjusting methodloosen the crank screw CD tum the crank upward shown in the Fig 15 to increase the lifting amount ofouter presser footon the contrarydecrease the amountafter finishtighten the screwAdjusting method of lifting amount of two feetloosen the screw reg adjust the central distance B between the screw and upper feed shaft shorten the distance B will increase the lifting amounton the contrarydecrease the amountPlease note the range of adjustment is limitedplease dont be overlarge

19 Adjusting the timing ofupper feed (Fig 16) a Ignoring CDower feedlower the presser foot lifting bar and the coarse stitch ofupper feed is realized b For 7441 loosen the screw CD adjust the relative position between reg andreg after finishtighten the screw CD c For 7471 loosen the screw tum the worm regas the direction shown in the Fig16 after finishtighten the screWreg

14 15

~s=H-+- 2S _ 3mm

4S-S5mm

5

Parts Manual

Information on using the parts catalogue

1 The last digit ofparts number 0 indicates basic parts which have been standard supplied with the machines

The last digit ofparts number from 1 to 9 indicates special parts at extra charges

2 When ordering spare parts speciafattachments additional sewing components andor assistive devices please

quote the parts number together with description

3 Please quote the tape width for binder the distance between two-needles for needle gauge sets

4 Please quote the required length in meters for electric cables and pneumatic hoses when ordering electrical

parts

5 When ordering electrical parts please spceify necessary information including voltage currency plug type and

mandatory rules amp regulations for accident prevention and environmental protection in the country

6 Should a part not be found in the spare parts list possibly due to technical alteration please describe the parts

and its function as fully as possible when ordering

7 Custom-made parts for special sewing demands are not included in this parts catalogue The sewing machines

can be equipped with a number ofother useful attachments Send us your exact requirements so that we can make you

a right solution Ifpossible included samples of the material you intend to use

8 The parts with 02 are for model 7471

6

A FRAME amp MISCELLANEOUS COVER COMPONENTS

RemarksREFNoNOTE Part No Name of part QTY

1 01 7441-01-0010 Face Plate Asm- ---1

2 02 7471-01-0020 Face Plate Asm - - - - - 1

3 7441-01-0030 Side Cover A- - - -- 2

4 01 7441-01-0040 Side Cover B- - - -- 1

5 02 7471-01-0050 Side Cover B- - - -- 1

6 01 7441-01-0060 Throat PJate- - - - - - 1

7 02 7471-01-0070 Throat Plate- - - - - - 1

8 7441-01-0080 Slide Plate- - - - - - - 1

9 7441-01-0090 Oil Pipe- - - - - - - - 3

~10 01 7441-01-0100 Rubber Plug- - - - - - 1

11 7441-01-0110 Screw 316middot28 L=8- - - 2

12 7441-01-0120 Screw 1564-28 L=21-- 2

13 7441-01-0130 Screw 9164-40 L=7- - - 3

14 7441-01-0140 Washer------ -- 2

15 7441-01-0150 Screw 1164middot40 L=9- - - 2

16 01 7441-01-0160 Throat Plate(Short)- - - 1

17 02 7471-01-0170 Throat Plate(Short)- - - 1

1

5

10

15

20

25

30

B MAIN SHAFT COMPONENTS 30

REFNoNOTE

1 2 3 4

6 01 7 02 8 9

11 12 13 14

16 17 18 19

21 22 23 24

26 27 03 28 03 29

31 32

Part No

7441-02-0010 7441-02-0020 7441-02-0030 7441-02-0040 7441-02-0050 7441-02-0060 7471-02-0070 7441-02-0080 7441-02-0090 7441-02-0100 7441-02-0110 7441-02-0120 7441-02-0130 7441-02-0140 7441-02-0150 7441-02-0160 7441-02-0170 7441-02-0180 7441-02-0190 7441-020200 7441-02-0210 7441-02-0220 7441-02-0230 7441-02-0240 7441-02-0250 7441-02-0260 7441-02-0270 7441-02-0280 7441-02-0290 7441-02-0300 7441-02-0310 7441-02-0190

Name of part QTY Remarks

MainShaft------ 1 Main Shaft Bushing Front--l Main Shaft Bushing Center- 1 Main Shaft Bushing Rear- - 1 Thread Take Up Cam- - - - 1 Needle Bar Crand Rod - - - 1 Needle Bar Crand Rod - - - 1 CrandPJate-------- 1 Needle Bar Crank Shaft - - - 1 Feed Cam---------l SidePlate---------l Hand Wheel Asm - - - - - 1 Felt----------- 3 ThrustCOller------- 1 OilWick--------- 2 Screw 1564middot28 L=15- - - - 3 Screw 14--40 L =6- - - - - 2 Tapered Pin 40X4S - - -- 1 Nut932middot28-------- 1 Screw 932middot28 L=22- - - - 2 Screw 1564--28 L=7- - - - 2 Screw 1164--40- - - - - - 2 Screw 516--24 L=21- - - - 2 Screw 14middot40L=6----- 2 Thread Take Up Lever- -- 1 RoUer---------- 1 Roller---------- 1 Roller---------- 1 Roller Stud-------- 1 Hinge Screw- - - - - - - 1 E-Shaped Snap Ring(4mm)- 1 Nut932middot28-------- 1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

Part NoREFNoNOTE

7441-03-0010

7441-03-0020

7441-03-0030

7441-03-0040

7441-03-0050

7441-03-0060

7441-03-0070

7441-03-0080

7441-03-0090

7441-03-0100

7441-03-0110

7441-03-0120

7441-03-0120

7441-03-0140

7441-03-0150

7441-03-0160

7441-03-0170

7471-05-0260

7441-03-0190

7441-03-0190

Name of part QTY

Driving Shaft - - - - - - - 1

Driving Shaft Front Metal- shy 1

Driving Shaft Rear Metalshy - 1

Driving Shaft Rod Front shy - 1

Driving Shaft Rod Rear shy - - 1

Driving Shaft Rear Arm Pin-shy 1

Frame Driving Link shy - - - - 1

HingeScrew-------- 2

Frame Driving Rod - - - - - 1

Thrust Collar D=18 W=12- 2

Screw 14-40 L=45 - - - - - 4

Screw 1564-28 L=7 - - - - - 1

Screw 1564-28 L=7----- 1

Screw 14-40 L=45 - - - - - 1

Screw 1564-28 L=145- -- 1

Screw 516-18 L=18- - - - - 1

Screw 516-18 L=24 - - - - - 1

HingeScrew-------- 2

E-Shaped Snap Ring(8mm) - - 2

ampSbaped Snap Ring(8mm) - - 2

Remarks

3

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

16

27~

fY) 5

14

19

REFNoNOTE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

24 13 12

~15

Part No Name of part QTY Remarks

NeedleBar----------l 7441-04-0020 7441-04-0010

Frame Driving Base- - - - - - 1 7441-04-0030 Needle Bar Connnection- - - - 1 7441-04-0040 Needle (794 Nm=230-4)- - - - 1 7441-04-0050 Needle Stopper- - - - - - - - 1 7441-04-0060 Pressure Plate- - - - - - - - 1 7441-04-0070 SettingShaft--------- 1 7441-04-0080 Sett PIate--------- 1 7441-04-0090 Frame OrIviog Base Shaft- - - 1 7441-04-0100 Frame Driving Base Shaft Metal- 1 7441-04-0110 Frame Driviog Base Guide- - - 1 7441-04-0120 Screw 1564-28 L=12 - - - -- 1 7441-04-0130 Screw 1564-28 L=12 - - - - - 1 7441-04-0120 Screw 1564-28 L=12----- 1 7441-04-0150 Screw 1164-40 L=7- - - -- 1 7441-04-0160 Screw 14-40 L=45- - - - - - 2 7441-04-0120 ScreW 1564-28 L=12 - - - -- 1 7441-04-0180 Screw 1564-28 L=21- - - -- 1 7441-04-0190 Screw 116tt-40 L=12-- - - - 1 7441-04-0200 Screw 1564-28 L=105- - -- 1 7441-04-0210 Oil Wlck---------- 1 7441-04-0220 Upper Peed Bar- - - - - -- 1 7441-04-0230 LLlnk----------- 1 7441-04-0240 Upper Feed Frame Driving tink- 1 7441-04-0250 Pressure Foot- - - - - - - --1 7441-04-0260 Upper Feed Bar Pln- - - - - - 1 7441-04-0270 Screw 1164-40L=7------ 1 7441-04-0280 HingeSCrew--------- 1 7441-03-0190 poundShaped Snap Rlng(8mm)- - - 1 7441-04-0300 Guide P1ate- - - - - - - -- 1 7441-04-0310 Screw 1164-40 L=45- - - - - 1

4

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

~12 19

40

REFNoNOTE Part No Name of part QTY Remarks

1 02 7471-05-0010 Needle Bar--------- 1 2 02 7471-05-0020 Needle Bar BusblngUppershy - 1 3 02 7471-05-0030 Needle Bar BusblngLower- shy 1 4 02 7471-05-0040 Needle Bar Tbread Guideshy - - 1 5 02 7471-05-0050 Needle Bar Connection - - - - 1 6 02 7441-04-0040 Needle (794 Nm=230)---- 1 7 02 7471-05-0070 Needle Bar Covershy - - - - - 1 8 02 7471-05-0080 Cover Plateshy - - - - - - --1 9 02 7471-05-0090 Screw 1564-28L=34shy - - - I 10 02 7471-05-0100 Screw 1564-28L=25 - shy - --2 11 02 7471-05-0110 Screw 1564-28L=14----- I 12 02 7471-05-0120 Screw 1l64-40L=6Sshy - - --2 13 02 7471-05-0130 Screw 1l64-40L=12shy - - - - I 14 02 7471-05-0140 Leqtbwise Feed Rocishy - - --I 15 02 7471-05-0150 DrlvlqSbaft-------- I 16 02 7441-03-0030 BuabbagRear--------1 17 02 7471-05-0170 DrlvIq Sbaft RodFront shy - - I 18 02 7471-05-0180 Ddvlq Sbaft RodRearshy - - 1 19 02 20 02

7471-05-0190 7471-05-0200

Uper Feed Control Bracklit shy - 1Sbaft----------- 1 21 02 7471-05-0210 Broek----------- I 22 02 7471-05-0220 Screw----------- I 23 02 7471-05-0230 Sbaft----------- I 24 02 7471-05-0240 Nut------------ I 25 02 7471-05-0250 Control Levershy - - - - - - - I 26 02 27 02

7471-05-0260 7471-05-0270

HlnpScrew-------- 21JusbIDI---------- I

28 02 7441-03-0100 1brust Collar D=18 w=IOshy - I 29 02 7441-03-0110 Screw l4-40L=45shy - - - - 2 30 02 7441-03-0120 Screw 1S64-28L-7- shy - - - I 31 02 7471-05-0310 Screw l4-40L=85shy - - - - I 32 02 7441-02-0170 Screw l4-40L-6shy - - - - - I 33 02 7441-04-0180 ScrewM6L=15------- I 34 02 7471-05-0340 1brust Collar D=9S3 W=IOshy I 35 02 7441-03-0120 Screw 15164-28L=7----shy 2 36 02 7471-05-0360 Srcew 15164-28(7------1 37 02 7471-05-0370 SPriDI PIn 28xI4shy - - - - - I 38 02 7471-05-0380 Screw ll64-40L=24shy - - - - 2 39 02 7471-05-0390 Nut 1l64-40-------- 2 40 02 7441-03-0190 ampShaped Suap Rlng(8mm)shy - 2

5

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

2

18 8

REFNoNOTE Part No

1 02 7471-06-0010

2 02 7471-06-0020

3 02 7471-06-0030

4 02 7471-06-0040

5 02 7471-06-0050

6 02 7471-06-0060

7 02 7471-06-0070

8 02 7471-06-0080

9 02 7471-06-0090

10 02 7471-06-0100

11 02 7471-06-0110

12 02 7471-06-0120

13 02 7471-06-0130

14 02 7471-06-0140

15 02 7471-06-0150

16 02 7471-06-0160

17 02 7471-06-0170

18 02 7441-03-0190

19 02 7441-03-0190

20 02 7471-06-0110

21 02 7471-06-0210

22 02 7441~03-0190

23 02 7471-06-0230

24 02 7471-06-0240

Name of part QTY Remarks

Rod--- ---- 1

Upper Feed Rod------ 1

Upper Feed Link A-- ---1

Upper Feed Link B- - - - - 1

Upper Feed Link Bracket- - 1

Bracket--------- 1

Supporting Plate- - - -- 1

Walking Foot (Standard) - - 1

Hinge Screw- - - - - - - 1

Hinge Screw- - - - - - - 2

Hinge Screw- - - - - - - 2

Spring Guide Bar-- - -- 1

Hinge Screw- - - - - -- 1

Adjusting Thumb Screw-- 1

Nut932-28-------- 1

Spring ---------- 1

Retaining Plate- - - - - - 1

ampShaped Snap Ring (8mm)- 2

B-Sbaped Snap Ring (8mm)- 2

Hinge Screw- - - - - - --1

Screw 1564-28L=12---- 2

B-Sbaped Snap Ring (8mm)- 2

Screw 1564-28 L=12- - - - 2

Screw 1164-40 L=95 - - - -1

6

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

REFNoNOTE Part No Name of part QTY Remarks

1 7441-07-0010 Driving Camshy ------1

2 7441-07-0020 Connecting Rod- - - - - - 1 3 7441-07-0030 Driving Shaft ArmFront - - 1 4 7441-07-0040 Driving Shaft ArmRearshy - - 1 5 7441-07-0050 Feed Rocker Shaftshy - - - shy 1 6 7441-07 -0060 BushingFrontshy - - - - shy 1

7 7441-07-0070 BushingRearshy - - - - - shy 1

8 7441-07 -0080 Rod---------- shy 1

9 7441-07-0090 Hinge Screw- - shy - - - - - 1 10 7441-07-0100 Washer---------- 1

11 7471-06-0110 HingeScrew-------- 2

12 74_41-07-0120 Screw 14middot40 L=6shy - - - --2

13 7441-04-0180 Screw m6 L=21shy - - - - shy 1

14 7441-03-0160 Screw 516-18shy - - - - - shy 1

15 7441-07-0150 Nut 1132-28--------1

16 7441-03-0120 Screw 1564-28 L=7shy - - --2

17 7441-03-0190 ampShaped Snap Ring(8mm)--2

7

D~ FRESSURE BAR COMPONENTS

2S

30 19

30

23

2 15 27 32

~

16

Name of part QtTY RemarksREFNoNOTE Part No

1 2 3 4 01 5 02 6 01 7 02 8 9 10 11 01 12 01 13 01 14 02 15 02 16 02 17 18 19 20 21 22 23 24 25 01 26 02 27 28 29 30 31 32

7441-08-0010 7441-08-0020 7441-08-0030 7441-08-0040 7471-08-0050 7441-08-0060 7471-08-0070 7441-08-0080 7441-08-0090 7441-08-0100 7441-08-0110 7441-08-0120 7441-08-0130 7471-08-0140 7471-04-0250 7471-08-0130 7441-08-0170 7441-08-0180 7441-08-0190 7441-08-0200 7441-08-0210 7441-08-0220 7441-03-0140 7471-05-0090 7441-08-0250 7441-08-0260 7441-08-0270 7441-08-0280 7441-08-0290 7441-08-0300 7441-08-0310 7441-08-0320

Presser Bar- - - - - - - - - 1 Presser Bar Bushing- -- 1 Screw----------- 1 Spring----------- 1 Spring-------- ---- 1 Presser Bar Guide Bracket -- - 1 PResser Bar GUIDE bracket- - 1 HandLifterUnk ------ 1 Hand LIfter Cam- - - - -- - 1 Hand LIfter LeVel- - - - - - 1 Pressure Foot(Smdard)Aam - - 1 Pressure Foot(Stndard)- - - - 1 Guand--------- -1 Pressure Foot(Standard)Aam - 1 Pressure Foot(Standard) - - - 1 Guand-----------l Nut------------ 1 Grlp------------l GuidePJate---------l Thrust Collar- - - - - - - - 1 RoUer Follower- - - - - - - 1 GuidePln--------- 1 Screw 1440 L==4S- - - - -- 1 Screw 1564-28L=-25 - -- -- - 1 Screw 316-18 L=11-----1 Screw 1440 L=6- -- -- -- -- -- 2 Screw 96440 L=135---- 1 Nut96440---------1 Screw 1440 L=45- -- -- - - 1 Screw 1164-40 L=9 - - - - - 2 COIIar----------- 1 Spriq Pin 30xl0- - -- - - - 1

8

E NEED MECHANISM COMPONENTS(1I2)

18 ____

16

19

20

REFNoNOTE Part No

1 7441-09-0010 2 7441-09-0020 3 7441-09-0030 4 7441-09-0040 5 7441-09-0050 6 7441-09-0060 7 1 7441-09-0070 8 2 7471-09-0080 9 1 7441-09-0090 10 7441-09-0100 11 7441-09-0110 12 7441-09-0120 13 7441-09-0130 14 7471-05-0260 15 7471-05-0260 i6 7441-09-0160 17 7441-09-0170 18 7441-04-0270 19 7441-03-0190 20 7441-09-0200 21 7441-09-0210 22 7441-03-0190 23 7441-09-0230 24 7441-09-0240 25 7441-03-0120 26 7441-09-0200 27 7441-09-0270 28 7441-09-0280

Name of part QTY

Feed Bar--------- 1 Feed Bar Unk-------- 1 Driving Shaft- - - - - - -- 1 Feed Rocker Shaft- --- I BushingFront- - -- --- I

BushingRearshy - - - - - - shy 1 Feed Rocker Shaft Cnmkshy - - 1 Feed Rocker Shaft Cnmkshy - - 1 Feed Dogshy - - - - - - - - shy 1 Feed Dogshy - - - - - - - - shy 1 Driving Shaft Metalshy - - - - - 1 Feed Bar Pressershy - - - - - - 1 Hinge Screw ---------1 HingeScrew--------- 1 HingeScrew--------- 1 Hinge Screw 0=794 L=8--- 1 Nut 14-24--------- 1 Screw 11164-40L=7------ 1 B-Shaped Snap Ring (8mm)-- 1 Screw 1564-28 L==105- - -- 1 Screw M6- - - - - - - - -- 2 B-Sbaped Snap Ring (8mm)-- 1 Screw 14-40L=35------ 4 Screw 11164-28L=6------- 2 Screw 15164-28L=7------ 1 Screw IS64-28L=105- - - - - 1 Thrust Collar 0=1472 W=10- 1 Thrust Collar 0=1111 W=10- 1

Remarks

9

14

I

K NEED MECHANISM COMPONENTS(22)

3

_-------1 _----- I

Is_~-~-~ I ~-

II I ~ I I L1r-~ ~16

~~-1i ~

8

REFNoNOTE Part No Name of part QTY

1 7441-10-0010 Rod- shy - - - - - - - - - 1 2 7441-10-0020 Feed Connecting Link- - - - 1

3 7441-10-0030 Feed Regulater- shy - - - - - 1

4 7441-10-0040 Lever- shy - - - - - - - - - 1

5 7441-10-0050 Side Cover- shy - - - - - - -1 6 7441-10-0060 Lever Gripshy - - - - - - - -1 7 7441-10-0070 Lever Shaft- shy - - - - - - 1 8 7441-10-0080 Nut- shy - - - - - - - - shy 1 9 7441-10-0090 Spring- shy - - - - - - - - 1 10 7441-10-0100 Support Plato- shy - - - - - 1 11 7441-10-0110 Ball- shy - - - - - - - - - 1 12 7441-10-0120 Hinge Screw A shy - - - - - 1 13 7441-10-0130 Hinge Screw Bshy - - - - - 1 14 7441-02-0190 Nut 932middot28- shy - - - - - - 1 15 7441-10-0150 Screw 316middot28 L=12- shy - - - 2 16 7441-10-0160 Screw 316-32 L=18shy - - - - 1 17 7441-10-0170 Screw 1564middot28 L=9- shy - - - 2 18 7441-10-0180 Nut- shy - - - - - - - - - 1

-

Remarks

10

F HOOK DRIVING SHAFT COMPONENTS(1I2) 2

5

REFNoNOTE Part No

1 7441-11-0010 2 7441-11-0020 3 7441-11-0030 4 7441-11-0040 5 7441-11-0050 6 7441-11-0060 7 7441-11-007~

8 7441-11-0080 9 7441-11-0090 10 7441-11-0100 11 7441-11-0110 12 7441-11-0120 13 7441-11-0130 14 7441-11-0140 15 7441-11-0150 16 7441-11-0160 17 03 7441-11-0170 18 03 7441-11-0180 19 03 7441-11-0190 20 7441-11-0200 21 03 7441-11-0210 22 03 7441-11-0220 23 03 7441-11-0230 24 7441-11-0240 25 7441-02-0160 26 7441-02-0160 27 7441-11-0270 28 7441-11-0280 29 7471-06-0150 30 7441-09-0270 31 7441-09-0230

Name of part QTY

Hook Driving Shaft Crank- - - 1 Crank Slide Block - - - - - - 1 Slide Block Stud- - - - - - - 1 Hook Driving Shaft - - - - - - 1 BushlngFront- - - - - - - - 1 BushingRear- - - - - - -- 1 Shuttle Driver- - - - - - - - 1 Shuttle Race Body- - - - - - 1 Bobbin----------- 1 HookCOver--------- 1 Hook Cover Spring- - - - - 2 Hook Counter Spring- - - - - 2 OUFelt----------- 2 Screw- - - - - - - - - - --2 Hinge Screw D=26 L=27- - - 2 HookCOver--------- 1 DIStance Plece- - - - - - -- 1 Distance Plece- - - - - - - - 1 DistaDce Piece- - - - - - - - 1 Distance Piece (Standard) - - - 1 Distance PleQe- - - - - - - - 1 Distance Piece- - - - - - - - 1 Distance Plece- - - - - - - - 1 SCrew----------- 2 Screw 1564-28 L=15- - - - - 1 Screw 1564-28 L=15----- 1 Thpered Pin 4OxI6- - - - - - 1 Screw M8 L=11 -------1

Nut 932-28--------- 1 Thrust Collar D=1472 W=10- 1 Screw 14-40L=35------2

Remarks

11

F HOOK DRIVING SHAFT COMPONENTS(22) 14

13- 5

I)II~ ~~- ~~

~ REFNoNOTE Part No Name of part QTY Remarks

1

2

3 4

5

6 7 8

9 10 11

12 13

14

15 16

17 18

19

20

21 22 23

7441-12-0010 7441-12-0020

7441-12-0030

7441-12-0040 7441-12-0050

7441-12-0060 7441-12-0070

7441-12-0080 7441-12-0090

7441-12-0100 7441-12-0110 7441-12-0120

7441-12-0130

7441-12-0140 7441-03-0120

7441-12-0160

7441-12-0170 7441-12-0180

7441-12-0190

7441-10-0160

7441-12-0210

7441-12-0220 7441-12-0230

Connecting Rod - - - - - - 1

Con-Rod Eccentric Cam - - 1

Cam Side Plateshy - - - - shy 1 Oscilating Rock Shaftshy - - 1

Hjnge Pinshy - - - - - - shy 1

Rock Shaft Bushingshy - - - 1 SlidePlateA------shy 1 Slide Plate Bshy - - - - - shy 1 Con-Rod Pin-------- 1

COn-RodPinWedge-----1

Cage amp RoUer ------- 1 Screw 1564-28L-15shy - - --I

Screw M81=30shy - - - - - - 2 Screw 1l64-40L=7----- 1

Screw IS64-18L=7 - - - - - 1 Oil Wlckshy - - - - - - - --1

Ping 29x32x3shy - - - - - - 1

Screw-----------l Nut 1164-40-------- 2

Screw 316-31L=18----- 1

Screw U64-28L=IO7----1 Washer---------- 1

PIN------------l 12

G TENSION POST COMPONENTS

19

REFNoNOTE

1 2

3 4

5 6

7

8 9 10

11 12 13 14

15 16 17 18

19 20

21 22 23 24 25

Part No

7441-13-0010 7441-13-0020 7441-13-0030 7441-13-0040

7441-13-0050 7441-13-0060 7441-13-0070

7441-13-0080 7441-13-0090 7441-13-0100 7441-13-0110 7441-13-0120 7441-13-0130 7441-13-0140 7441-13-0150 7441-13-0160 7471-06-0150 7441-13-0180 7441-13-0190

7441-08-0300 7441-13-0210 7441-01-0130 7441-13-0230

7441-13-0240 7441-13-0250

RemarksName of part QTY

Thread Thnsion Post- - - - - 1 Tension Disk- - - - - - -- 2

Thread Tension Stud Nut - - - 2 Thread Thhsion Spring- - - - 2 Thread Thnslon Post Bracket - - I Thread Tension Guide- - - - - 1 Thread Releasiq Plate- - - - 1 SprinsA ---------- 1 SprlDJB---------- 1 Spring Support Plate- - - -- 1 1bread Thnsion Wheel Post- - 1 Thread Thnsion Wheel- - -- 1 Wbeel Fe1t---~----- 1 Felt Support Plate--- - - - -- 1 Arm Thread GUide Jtottom Ani-I Frame 1bread Guld- - -- - - 1 Nut32-28- -~- - - - - -- 1

HJaae Screw D=OL=31- - - 1 Nut 1564-28--------- 1

Screw tr1M-40 La12 - - - -- 1

Screw 64-40 L=O- - - -- I

Screw 64-40 L=7- - - - -- 1 Sctew64-40 L=5- - - - -- 1 Screw 964-40 L=7- - - - -- 1 Thread Guide- - - - - - -- 1

13

H THREAD WINDER amp THREAD GUIDE CMPONENTS(1I2)

3

---------------L------------- shy-9 8i l- -gt

o o

I ~ o

I o

26I o

shy

l o o

--shy

-- 4

27

REFNoNOTE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

---------- I ~28 -- 13 ~

- 5 __

Part No

7441-14-0010 7441-08-0300 7441-14-0030 7441-14-0040 7441-14-0050 7441-14-0060 7441-14-0070 7441-14-0080 7441-14-0090 7441-14-0100 7441-14-0110 7441-14-0120 7441-14-0130 7441-14-0140 7441-14-0150 7441-14-0160 7441-14-0170 7441-14-0180 7441-14-0190 7441-14-0200 7441-14-0210 7441-14-0220 7441-14-0220 7441-14-0240 7441-14-0250 7441-14-0260 7441-14-0270 7441-14-0280 7441-14-0290 7441-03-0120

--shy

RemarksName of part QTY

Thread Winder Plate - - - - - 1 Screw 1164-40L=9----- 4

Thread Winder Asm - - - - - 1 Thread Winder Base- - - - - 1 Thread Winder Shaft- - - - - 1 Spacer------------ 3

Bobbin Presser- - - - - - - - 1 Bobbin Presser Spring- - - - - 1 Screw 332-56 L=33- - - - - - 2

Adjusting Screw- - - - - - - - 1 Nut 18-44---------- 1

Bobbin Winder Wheel- - - - - 1 Bobbin Winder Frame- - - - - 1 Wheel Ring--------- 1

Hinge Screw--------- 1

Bobbin Winder Tension Bracket- 1 Spring------------ 1

Bobbin Winder Spring- - - - - 1

Thread Winding Shaft Collar- - 1 Screw 1164-40 L=18-- - - - - 3

Hinge Screw D=724L=19- - - 1 Nut 1164-40--------- 1

Nut 1164-40--------- 1

Screw 1164-40 L=5- - - - - - 2 Stopper----------- 1

Screw 1164-40 L=30- - - - - 1

Thread Cut amp Clamp Plate - - - 1 Screw 18-44 L=4- - - - - - - 2 Friction Wheel-------- 1

Screw 1564-28 L=7- - - - - shy 2

14

H THREAD WINDER amp THREAD GUIDE CMPONENTS(22)

r------------i I 6

I II 3 iI 1 5

~ I

I

4

I

10 I I

11 I II I

IL___________

7J

REFNoNOTE Part No Name of part QTY Remarks

Thread Winder Guide Base Asm - 1

2

1 7441-15-0010 Thread Winder Guide Base - - - (1)

3 7441-15-0030 Tension Sping- - -- - - - - - (1)

4 7441-13-0010 Thread Tension Post- - -- -- - (1)

5 7441-13-0020 Tension Disk- - - - - - - -- (2)

6 7441-15-0060 Thread Tension Stud Nut- - --- (1)

7 7471-06-0150 Nut 932-28~ - -- -- - -- -- -- - -- (1)

8 7441-15-0080 Thread Guide- - - - - -- - - 1

9 7441-15-0090 Guide Bracket- - - -- -- - --1

10

7441-15-0020

7441-15-0100 Screw 1164middot40 L=85- - -- - -- - 1

7441-15-0110 Screw 18-44 L=6- - - - - - - 111

12 7441-01-0130 Screw 964-40 L=7- - - - - -- -- 1

Screw 1564middot28 LlO5- -- - -- - shy 27441-04-020013

15

I KNEE LIFER COMPONENTS

I

bull 18 15 6

11--__

bull 16

REFNoNOTE

1

l 3 4 5

6 7

8 9

10 11 12

13 14 15

16 17

Part No

7441-16-0010

7441-16-0020 7441-16-0030 7441-16-0040 7441-16-0050middot

7441-16-0060

7441-16-0070 7441-16-0080 7441-16-0090

7441-16-0100

7441-16-0110 7441-16-0120 7441-16-0130 7441-16-0140

7441-16-0090 7441-16-0160

7441-16-0170

Name of part QTY Remarks

Presser Bar Ufdng UDk- - - - 1 Presser Bar Ufting Sprlng- - - 1

Presser Bar Ufting Bar- - -- 1 Side Connecting Bar- - - -- 1 lJDk Base- - - - - - - -- 1

lJDk Plate- - - - - - - -- 1 lJDk Collar- - - - - - - - - 1

5------------ 1 Screw 1564-28 L=65- - - - - 2 HInpScrnD=794L=43-- 2 Hlop Screw D=794 L=43-- 1 H Screw D-794 L=43-- 1 HlDge Screw- --- - - -- 1 SpriDs Suspension - - - - -- 1 Screw 1564-28 L=65- - - - - 2 HInp ScrewD-80 L=34- - - 1 Presser Bar Lifting Link - - - 1

16

J BELT COVER COMPONENTS

2

1

1

8

RemarksREFNoNOTE Part No Name of part QTY

1 7441-17-0010 Belt Cover A - ------ 1

2 7441-17-0020 Direction Lavel- - - - - - - - 1

3 7441-17-0030 BeltCoverB--------- 1

4 7441-17-0040 Belt Cover Stud - - - - - - - - 2

5 7441-17-0050 Screw 1164middot40 L=5------ S

6 7441-16-0090 Screw IS64-28 L=6S - - - - - 2

7 7441-17-0100 Wood Screw D=83L=18- - - - 2

8 7441-17-0110 Washer SdO5x1- - - - -- 2

17

1

2

REFNoNOTE Part No Name ofpart QTY Remarks

1 2

7441-18-0010 7441-18-0020

Sbread Stand-------- 1 Wood SCrewL=8------- 3

K THREAD STAND COMPONENTS

18

L TABLE COMPONENTS

1

2

REFNoNOTE Part No Name of part QTY Remarks

1 2

7441-19-0010 7441-19-0020

Table---------shy 1 Stand--------- shy 1

19

M ACCESSORIES PARTS COMPONENTS

23~ ~ ~

2~ iii~

~ VB

1 ~9

I

REFNoNOTE Part No

1 7441-20-0010 2 7441-20-0020 3 7441-20-0030 4 7441-20-0040 5 7441-20-0050 6 7441-20-0060 7 7441-16-0070 8 7441-20-0070 9 7441-20-0080 10 7441-20-0100 11 7441-20-0110 12 7441-20-0120 13 7441-20-0130 14 7441-20-0140 15 7441-20-0150 16 7441-20-0160 17 7441-20-0170 18 7471-06-0230 19 7441-20-0190 20 7441-20-0200 21 7441-20-0210 22 7441-20-0220 23 7441-20-0230 24 7441-20-0240 25 7441-20-0250 26 7441-20-0260 27 7441-20-0270 28 7441-04-0040 29 7441-11-0090

y r1 2928fffill ~r~ bull JLJ ~

L~

~ ~

RemarksName of part QTY

Cover- --shy - --- shy - - - - - - 1 Oiler Asm - - - - - - - - --shy 1 Screw MI0 L=65- shy - - - - 4 NutMI0--------- 4 Washer llx27x2- - - --- - - - 8 Chain--- --- - --- ---- - 1 SmiddotPlug- -- --- ----1 Needle Thread Gudle Pin- - -1 Nut 316middot32- - --- ------ ----1 Oil Pot Asm - --- - --- --- - --- --- 1 Oil Pot Cover- - - - - - - - (1) OllPot---- -- - - - - --- - -(1) Frame Thread Guide- - - - - (1) Cover Stopper- - - - - --- - (1) Nut 332-56--- --- --- --- - --- - - --- (1) Screw 964-40 L=7- - - - - - (1) Pin---------------- (1) Screw 1564-28 L= 12- - - - ~ (1) Screw 964-40 L=35- --- - - - (1) Accessory Box- - - - - - - 1 Screw Driver Large- - --- --- 1 Screw Olver Small- --- --- - - 1 Hexagonal Wrencb Key(5mm)- 1 Heagonal Wrencb Key(4mm) -1 Hexagonal Wrench ~ey(3mm)- 1 Wrench(llxI4)- - - - - --- - 1 Wrencb(9xl0)- - - --- - - - 1 Needle (794 Nm=230-4)- - - 1 Bobbin---------- 3

20

N SPECIAL PARTS ON REQUEST AND AGAINST EXTRA CHARGES

ATTENTION PLEASE Below parts might be able to dramatically increase the productivity of your sewing machines and ensure excellent stitch quality even in an individual sewing task Please contact us for illustrated instruction if you need any special item

Special components on request

7441-09-0091 Non-teethed feed dog avoid marks when sewing leather goods and upholstery 7441-09-0092 Narrow feed dog work together with 7441-01-0064 for sewing very small borders on hard material like suit case furniture instrumental cases chairs etc 7441-04-0251 Center groover presser foot creates a groove in the leather and lays the stitch in that groove for a tighter pull-down stitch 7441-04-0252 Narrow center foot for sewing very small borders on hard material like suit case furniture instrumental cases chairs etc 7441-08-0121 Double-toes harness makers foot curved design allows closer stitching around edge of hardware Smooth bottom will not mark leather 7441-08-0122 Left-edge foot narrow toe foot that provides the most visibilty around the presser foot and allows you to sew along the edge ofyour leather 7441-08-0123 Right-edge foot narrow toe foot that provides the most visibilty around the presser foot and allows you to sew along the edge of your leather 7441-08-0124 Left-toe presser foot great for close stitching on right side 7441-08-0125 Right-toe presser foot great for close stitching on left side 7441-01-0061 Slotted plate Avoid mark on the underside leather for some items 7441-01-0062 Holster plate provides a raised surface and will allow you to sew right up against the left side of the machine Perfect for stitching holsters handbags pouches and even shoe welts 7441-01-0063 Stirrup plate provides a raised surface and will allow you to sew right up against the left side of the machine Ideal for covering stirrups and shoe welts

7441-01-0064 Narrow throat plate work together with 7441-09-0092 for sewing very small borders on hard material like suit case furniture instrumental cases chairs etc 7243-02-00111 Large flywheel the power balance wheel with Dia 12 inch to create more torque when sewing very heavy materials

Additional sewing equipment

HT-7243FLO I Pneumatic foot lift for clutch motor HT-7243FL02 Pneumatic foot lift for servomotor (electronic needle position motor) HT-7243BTOI Electro-pneumatic back tacking device (automatic reverse stitch) for clutch motor HT-7243BT02 Electro-pneumatic back tacking device (automatic reverse stitch) for servomotor HT-7243NCO 1 Needle cooling system to cool down the temperature ofneedle prevent breakage and thread burn in extremely sewing condition

HT-7441 SCO 1 Side cutter attachment to process cutting amp sewing in the same time great for saving labor and creates the perfectly cut edge ofa seeger on your machine HT-7441 STO 1 Adjustable pedestal type stand this new design features one straight foot pedal shaft the offer more torque at slower speeds for more control especially ideal for saddle makers harness makers and leather craftsman

Special sewing attachments

HT-MCOI Economical fabric guide easy to make sure straight seams HT-MC02 Deluxe material guide for straight stitches a l20 high roller moves in out back and forth for straight stitching close to the edge Flips up and out of the way when not in use never needs removed HT-SPO I Economical speed reducer reduces machine speed from 800 to 425 to 150 stitches per minute for greater stitching control (increase the punching power) HT-SP02 Ball bearing speed reducer allow you choose the speed ofyour sewing machine for extra torque and needle penetration HT-TAO I Table tope attachment quickly and easily increase flat work area Convert the cylinder arm sewing surface to a flat bed sewing machine to allow for better stitching with certain types of work

Sewing devices for special sewing application

HT-744I WSO I Working plate with guide attachment ideal for sewing five layers of nylon webbing four layers ofcoated webbing a nd three layers ofleather on the 7441 Also features a roller guide that perfect for stitching a scalloped piece ofleather

In addition to above a range of other special sewing devices are available Please forward samples ofmaterial and finished article when enquiring

(21)

Operation Instruction

1 BRIEF INTRODUCTION --------~--------------------------------------~--------------------------------------------------- 1

2 MAIN SPECIFICATIONS --------------------------------------------------------------------------------------------------- 1

3 OPERATION PREPARATION ----------------------------------------------------------------------------------------------- 1

4 INSTALLING THE MOTOR ------------------------------------------------------------------------------------------------- 2

5 INSTALLING THE BELT GUARD ----------------------------------------------------------------------------------------- 2

6 LUBRICATION ----------------------------------------------------------------------------------------------------------------- 2

7 INSTALLING THE NEEDLE ------------------------------------------------------------------------------------------------ 2

8 CHOOSING THREAD -------------------------------------------------------------------------------------------------------- 3

9 WINDING BOBBIN THREAD --------------------------------------------------------------------------------------------- 3

10 INSTALLING AND UNINSTALLING THE BOBBIN ----------------------------------------------------------------- 3

11 THREADING NEEDLE THREAD ----------------------------------------------------------------------------------------- 3

12 ADJUSTING THREAD TENSION ---------------------------------------------------------------------------------------- 3

13 ADJUSTING STITCH LENGTH -------------------------------------------------------------------------------------------- 3

14 ADJUSTING THREAD TAKE-UP SPRING ------------------------------------------------------------------------------ 4

15 ADJUSTING THE PRESSURE OF PRESSER FOOT ----------------------------------------------------------------- 4

16 ADJUSTING THE HEIGHT OF FEED DOG ----------------------------------------------------------------------------- 4

17 THE RELATIONSHIP BETWEEN NEEDLE AND SHUTTLE ---------~-------------------------------------------- 5

18 ADJUSTING THE LIFTING AMOUNT OF ALTERNATING FOOT ----------------------------------------------- 5

19 ADJUSTING THE TIMING OF UPPER FEED -------------------------------------------------------------------------- 5

Parts Manual

A FRAME amp MISCELLANEOUS COVER COMPONENTS ----------------------------------------------------------- 1

B MAIN SHAFT COMPONENTS ------------------------------------------------------------------------------------------ 2

C NEEDLE BARmiddotUPPER FEED MECHANISM COMPONENTS------------------------------------------------------ 3-7

D PRESSURE BAR COMPONENTS ------------------------------------------------------------------------------------- 8

E FEED MECHANISM COMPONENTS -------------------------------------------------------------------------------- 9-10

F HOOK DRIVING SHAFT COMPONENTS --------------------------------------------------------------------------- 11-12

G TENSION POST COMPONENTS ----------------------------------------------------------------------------------- 13

H THREAD WINDER amp THREAD GUIDE CONPONENTS ----------------------------------------------------------14-15

I KNEE LIFTER COMPONENTS ------------------------------------------------------------------------------------------- 16

G BELT COVER COMPONENTS ----------------------------------------------------------------------------------------- 17

K THREAD STAND COMPONENTS -----------~----------------------------------~---------------------------------------- 18

L TABLE COMPONENTS -------------------------------------------------------------------------------------------------- 19

M ACCESSORIES PARTS COMPONENTS ------------------------------------------------------------------------------ 20

N SPECIAL PARTS ON REQUEST AND AGAINST EXTRA CHARGES ------------------------------------------- 21

IBrief introduction

7441 is single needle extra heavy duty large oscillating shuttle hook compound feed (bottom feed needle feed and

walking foot feed) lockstitch sewing machine for the producion of3-dimensional items used when manufacturing for

example saddles scats harness safety belts conveyor belts golf bags straps technical texties filter general leather

and upholstery products etc

The special extra large shuttle hook and bobbin capacity offers high efficiency in sewing products using extra thick

thread up to metric size 8 (including sizes 302520 128 amp V92 V128 V207 V242 V277)

7471 is top and bottom feed lockstitch machine (with additional attachments) for special purpose especially in producshy

tion ofhoses and leather goods

7461-3 7 is super long arm heavy duty compound feed lockstitch machine The cylinder shaped arm has been extended

to give approximately 940mm clearance to the right ofneedle

7441RL-37 Long arm cylinder bed transverse scam machine (Feed up the arm) is available 0 request It is a customshy

made sewing solution for products where transverse (sideways) stitching is necessary

2Main specifications

Applications Heavy and Extra-heavy weight materials

Maxsewing speed 800spm Maxstitch length Ilmm Needle bar stroke 56mm Presser foot lift 13mm by hand height 23mm by pedal Hook KSP-204N Needle DYX325 Cylinder diameter 81mm Lubrication Oiled by hand Motor power 550W

3Machine installation 31Clearing the machine

Before the head is packed all ofthe parts of the machine are coated with anti-rust greasemeanwhile the grease can harden and the dust can cover the machine surface during long time storage and shipmentsothe dust and greasemust be cleared by clean cloth with gasoline

32Examination Although every machine is conformed by strict inspection and test before deliverythe parts ofthe

machine may be loose and deformed after long distance transportation with jolt A thorough examination must be performed Turn the balance wheel slightly by hand to check if there is running obstruction parts collision uneven resis tance and abn-ormal noise If any of these existadjustment must be made accordingly before running

1

41nstalling the motor (Fig1) Move the motor C leftward or rightward to make the hand wheel belt groove A and motor pulley belt

groove B run in line

HIGHTEX n 2U

A

B

5Installing the belt guard(Fig2)

Please install the belt gurad for the safety purpose aInstall the pin supporter CD into the screw hole on the machine casting bInstall the guard reg on the casting cPut the V-belt on the hand wheel dInstall the guard regon the guard reg eFix the guard on the table with wooden screw

6Lubrication(Fig3)

Please add the oil at the places shown by arrows

7Installing the needle (Fig4) aTurn the hand wheel to lift the needle bar at its highest position bLoosen the screw CD and keep the long groove A of needle reg rightward cFully insert the needle shank up to the bottom of needle bar dTighten the screw CD

2

HIGHTEK

-

I---- dJ

Long groove leftward

4

8Choosing thread(Fig5) The needle thread should be left-twistthe bobbin threadmay be left-twist or right-twistThe way judging the

thread twisthold the thread by left handtwist it by right hand as the direction shown in the Fig5if thethread changes tightlyits left-twiston the contraryits right-twist

9Winding the bobbin thread (Fig6) a Threading the thread from thread spool and pass through ABCDthen wind thread several corcles around bobbin b eut the winding lever onto bobbin the winding pulley will press the friction pulley in the arm c Thread amount can be adjustedby screw reg the optimun capacity ofbobbin thread is fill about 80ofbobbin

outside diameterturn the screw clockwise to increase thea mounton the contrarydecrease the amount d After finishloosenthe winding lever and thread winder will stop automatically

lOInstalling and uninstalling the bobbin (Fig7) 101 Uninstalling the bobbin

Open the shuttle cover and lower the needle bar at its lowestpositioninsertthe openerreg between spring CD and bobbin casereg press the spring CDdown and draw thebobbin casereg outthe bobbin will be pulled out from bobbin case to2 Installing the bobbin

When install the bobbindraw the thread tip out and put the bobbin 4 intobobbin case thread the bobbin thread from slit CV then pass it through the hole under the tension spring The bobbin case will be locked by spring CD after being put into shuttle

5 6

D

JB~ ~ 0

0

7

l1Threading needle theard(Fig8) The sequence of threading is shown in the Fig 8 from(I)-(14)

12Adjusting thread tension(Fig9) 121Adjusting needle thread tension

Turn the nut CDclockwise to increase the needle thread tensiontum the nut counter-clockwise to decrease the needle thread tension 122Adjusting bobbin thread tension

Turn the screw regclockwise to increase the bobbin thread tensionturn the screw counter-clockwise to de crease the tension

13Adjusting stitich length(Figl 0) Turn the stitch length adjusting nut CD clockwise or counter-clockwisethe numbers ongraduation board shown

the sizes of the stitch lengthif the stitch length confirmedpleasetighten the nutreg For reverse feedlift the stitch length adjusting screw bar to performreverse sewingrelease the screw barthe forward sewing is resumed

Noteifthe screw bar becomes loose because of moving upward or downward for a long timeplease turn the screw 3 to maintain the proper tension

3

10 8 9

o

14Adjusting thread take-up spring (Figll) IChanging the stroke of thread take-up spring

a Loosen the screw CD and move the stop plate regup-ward and downward b Move thestop plate downward to increase the stroke of thread take-upmove the plateupward todecrease th stroke of thread take-up

2Adjusting the tension of thread take-up Loosen the nut turn the spring shaft counter-clockwise to increase the tension of thread take-upturn the shaft

clockwise to decrease the tension Please use a screw driver to insert the split on the spring shaft and turn the spring shaft toget the required tension

15Adjusting the pressure ofpresser foot(Fig12) The proper pressure ofpresser foot should be adjusted according to the materials to be sewn

aTum the screw CD clockwise to increase the pressureon the contrarydecrease the pressure bAfter finishtighten the nutreg

16Adjusting the height of feed dog (Fig13) The adjustment position of feed dog is higher 13-I5mm than needle plateplease adjust it as following sequence

according to sewing requi rements or after changing a new one aConfirm the highest position of feed dogthen tighten the feed dog screw CD bTemporarily adjust the height of feed

dog higher of lower compare to the standardheight according to spcial sewing situation

11 12 13-15mm

~~ ~

~

j

4

13

17The relationship between needle and shuttle (Fig 14) a confirm the height of needle bar

When the needle bar is lifted 4S-SSmm from its lowest position the tip of shuttle should locate at the center of needle bar and the clearance between the top of needle bar hole and the tip of shuttle is 2S-3mm b Confirm the position of shuttle

Loosen the crank screw reg in the bed hole CD move the crank forward or backw-ardafter adjust the position of the tip of shuttletighten the screw reg c The flank clearance between the tip of shuttle and needle bar should be OOS-3mm loosen the rear crank screw and collar screw oflower shaftmove the lower shaft leftward or rightwardafter adjustmenttighten the screws

I8Adjusting the lifting amount of alternating foot (Fig 15) The lifting amount of alternating foot can been adjsuted within a certain rangefor normal sewingthe lifting amount

ofouter presser foot is 6mmthe liftinmg amount of inner presser foot is 45mmif the other mechanism is fix the lifting amount of two feet is constant

Adjusting methodloosen the crank screw CD tum the crank upward shown in the Fig 15 to increase the lifting amount ofouter presser footon the contrarydecrease the amountafter finishtighten the screwAdjusting method of lifting amount of two feetloosen the screw reg adjust the central distance B between the screw and upper feed shaft shorten the distance B will increase the lifting amounton the contrarydecrease the amountPlease note the range of adjustment is limitedplease dont be overlarge

19 Adjusting the timing ofupper feed (Fig 16) a Ignoring CDower feedlower the presser foot lifting bar and the coarse stitch ofupper feed is realized b For 7441 loosen the screw CD adjust the relative position between reg andreg after finishtighten the screw CD c For 7471 loosen the screw tum the worm regas the direction shown in the Fig16 after finishtighten the screWreg

14 15

~s=H-+- 2S _ 3mm

4S-S5mm

5

Parts Manual

Information on using the parts catalogue

1 The last digit ofparts number 0 indicates basic parts which have been standard supplied with the machines

The last digit ofparts number from 1 to 9 indicates special parts at extra charges

2 When ordering spare parts speciafattachments additional sewing components andor assistive devices please

quote the parts number together with description

3 Please quote the tape width for binder the distance between two-needles for needle gauge sets

4 Please quote the required length in meters for electric cables and pneumatic hoses when ordering electrical

parts

5 When ordering electrical parts please spceify necessary information including voltage currency plug type and

mandatory rules amp regulations for accident prevention and environmental protection in the country

6 Should a part not be found in the spare parts list possibly due to technical alteration please describe the parts

and its function as fully as possible when ordering

7 Custom-made parts for special sewing demands are not included in this parts catalogue The sewing machines

can be equipped with a number ofother useful attachments Send us your exact requirements so that we can make you

a right solution Ifpossible included samples of the material you intend to use

8 The parts with 02 are for model 7471

6

A FRAME amp MISCELLANEOUS COVER COMPONENTS

RemarksREFNoNOTE Part No Name of part QTY

1 01 7441-01-0010 Face Plate Asm- ---1

2 02 7471-01-0020 Face Plate Asm - - - - - 1

3 7441-01-0030 Side Cover A- - - -- 2

4 01 7441-01-0040 Side Cover B- - - -- 1

5 02 7471-01-0050 Side Cover B- - - -- 1

6 01 7441-01-0060 Throat PJate- - - - - - 1

7 02 7471-01-0070 Throat Plate- - - - - - 1

8 7441-01-0080 Slide Plate- - - - - - - 1

9 7441-01-0090 Oil Pipe- - - - - - - - 3

~10 01 7441-01-0100 Rubber Plug- - - - - - 1

11 7441-01-0110 Screw 316middot28 L=8- - - 2

12 7441-01-0120 Screw 1564-28 L=21-- 2

13 7441-01-0130 Screw 9164-40 L=7- - - 3

14 7441-01-0140 Washer------ -- 2

15 7441-01-0150 Screw 1164middot40 L=9- - - 2

16 01 7441-01-0160 Throat Plate(Short)- - - 1

17 02 7471-01-0170 Throat Plate(Short)- - - 1

1

5

10

15

20

25

30

B MAIN SHAFT COMPONENTS 30

REFNoNOTE

1 2 3 4

6 01 7 02 8 9

11 12 13 14

16 17 18 19

21 22 23 24

26 27 03 28 03 29

31 32

Part No

7441-02-0010 7441-02-0020 7441-02-0030 7441-02-0040 7441-02-0050 7441-02-0060 7471-02-0070 7441-02-0080 7441-02-0090 7441-02-0100 7441-02-0110 7441-02-0120 7441-02-0130 7441-02-0140 7441-02-0150 7441-02-0160 7441-02-0170 7441-02-0180 7441-02-0190 7441-020200 7441-02-0210 7441-02-0220 7441-02-0230 7441-02-0240 7441-02-0250 7441-02-0260 7441-02-0270 7441-02-0280 7441-02-0290 7441-02-0300 7441-02-0310 7441-02-0190

Name of part QTY Remarks

MainShaft------ 1 Main Shaft Bushing Front--l Main Shaft Bushing Center- 1 Main Shaft Bushing Rear- - 1 Thread Take Up Cam- - - - 1 Needle Bar Crand Rod - - - 1 Needle Bar Crand Rod - - - 1 CrandPJate-------- 1 Needle Bar Crank Shaft - - - 1 Feed Cam---------l SidePlate---------l Hand Wheel Asm - - - - - 1 Felt----------- 3 ThrustCOller------- 1 OilWick--------- 2 Screw 1564middot28 L=15- - - - 3 Screw 14--40 L =6- - - - - 2 Tapered Pin 40X4S - - -- 1 Nut932middot28-------- 1 Screw 932middot28 L=22- - - - 2 Screw 1564--28 L=7- - - - 2 Screw 1164--40- - - - - - 2 Screw 516--24 L=21- - - - 2 Screw 14middot40L=6----- 2 Thread Take Up Lever- -- 1 RoUer---------- 1 Roller---------- 1 Roller---------- 1 Roller Stud-------- 1 Hinge Screw- - - - - - - 1 E-Shaped Snap Ring(4mm)- 1 Nut932middot28-------- 1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

Part NoREFNoNOTE

7441-03-0010

7441-03-0020

7441-03-0030

7441-03-0040

7441-03-0050

7441-03-0060

7441-03-0070

7441-03-0080

7441-03-0090

7441-03-0100

7441-03-0110

7441-03-0120

7441-03-0120

7441-03-0140

7441-03-0150

7441-03-0160

7441-03-0170

7471-05-0260

7441-03-0190

7441-03-0190

Name of part QTY

Driving Shaft - - - - - - - 1

Driving Shaft Front Metal- shy 1

Driving Shaft Rear Metalshy - 1

Driving Shaft Rod Front shy - 1

Driving Shaft Rod Rear shy - - 1

Driving Shaft Rear Arm Pin-shy 1

Frame Driving Link shy - - - - 1

HingeScrew-------- 2

Frame Driving Rod - - - - - 1

Thrust Collar D=18 W=12- 2

Screw 14-40 L=45 - - - - - 4

Screw 1564-28 L=7 - - - - - 1

Screw 1564-28 L=7----- 1

Screw 14-40 L=45 - - - - - 1

Screw 1564-28 L=145- -- 1

Screw 516-18 L=18- - - - - 1

Screw 516-18 L=24 - - - - - 1

HingeScrew-------- 2

E-Shaped Snap Ring(8mm) - - 2

ampSbaped Snap Ring(8mm) - - 2

Remarks

3

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

16

27~

fY) 5

14

19

REFNoNOTE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

24 13 12

~15

Part No Name of part QTY Remarks

NeedleBar----------l 7441-04-0020 7441-04-0010

Frame Driving Base- - - - - - 1 7441-04-0030 Needle Bar Connnection- - - - 1 7441-04-0040 Needle (794 Nm=230-4)- - - - 1 7441-04-0050 Needle Stopper- - - - - - - - 1 7441-04-0060 Pressure Plate- - - - - - - - 1 7441-04-0070 SettingShaft--------- 1 7441-04-0080 Sett PIate--------- 1 7441-04-0090 Frame OrIviog Base Shaft- - - 1 7441-04-0100 Frame Driving Base Shaft Metal- 1 7441-04-0110 Frame Driviog Base Guide- - - 1 7441-04-0120 Screw 1564-28 L=12 - - - -- 1 7441-04-0130 Screw 1564-28 L=12 - - - - - 1 7441-04-0120 Screw 1564-28 L=12----- 1 7441-04-0150 Screw 1164-40 L=7- - - -- 1 7441-04-0160 Screw 14-40 L=45- - - - - - 2 7441-04-0120 ScreW 1564-28 L=12 - - - -- 1 7441-04-0180 Screw 1564-28 L=21- - - -- 1 7441-04-0190 Screw 116tt-40 L=12-- - - - 1 7441-04-0200 Screw 1564-28 L=105- - -- 1 7441-04-0210 Oil Wlck---------- 1 7441-04-0220 Upper Peed Bar- - - - - -- 1 7441-04-0230 LLlnk----------- 1 7441-04-0240 Upper Feed Frame Driving tink- 1 7441-04-0250 Pressure Foot- - - - - - - --1 7441-04-0260 Upper Feed Bar Pln- - - - - - 1 7441-04-0270 Screw 1164-40L=7------ 1 7441-04-0280 HingeSCrew--------- 1 7441-03-0190 poundShaped Snap Rlng(8mm)- - - 1 7441-04-0300 Guide P1ate- - - - - - - -- 1 7441-04-0310 Screw 1164-40 L=45- - - - - 1

4

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

~12 19

40

REFNoNOTE Part No Name of part QTY Remarks

1 02 7471-05-0010 Needle Bar--------- 1 2 02 7471-05-0020 Needle Bar BusblngUppershy - 1 3 02 7471-05-0030 Needle Bar BusblngLower- shy 1 4 02 7471-05-0040 Needle Bar Tbread Guideshy - - 1 5 02 7471-05-0050 Needle Bar Connection - - - - 1 6 02 7441-04-0040 Needle (794 Nm=230)---- 1 7 02 7471-05-0070 Needle Bar Covershy - - - - - 1 8 02 7471-05-0080 Cover Plateshy - - - - - - --1 9 02 7471-05-0090 Screw 1564-28L=34shy - - - I 10 02 7471-05-0100 Screw 1564-28L=25 - shy - --2 11 02 7471-05-0110 Screw 1564-28L=14----- I 12 02 7471-05-0120 Screw 1l64-40L=6Sshy - - --2 13 02 7471-05-0130 Screw 1l64-40L=12shy - - - - I 14 02 7471-05-0140 Leqtbwise Feed Rocishy - - --I 15 02 7471-05-0150 DrlvlqSbaft-------- I 16 02 7441-03-0030 BuabbagRear--------1 17 02 7471-05-0170 DrlvIq Sbaft RodFront shy - - I 18 02 7471-05-0180 Ddvlq Sbaft RodRearshy - - 1 19 02 20 02

7471-05-0190 7471-05-0200

Uper Feed Control Bracklit shy - 1Sbaft----------- 1 21 02 7471-05-0210 Broek----------- I 22 02 7471-05-0220 Screw----------- I 23 02 7471-05-0230 Sbaft----------- I 24 02 7471-05-0240 Nut------------ I 25 02 7471-05-0250 Control Levershy - - - - - - - I 26 02 27 02

7471-05-0260 7471-05-0270

HlnpScrew-------- 21JusbIDI---------- I

28 02 7441-03-0100 1brust Collar D=18 w=IOshy - I 29 02 7441-03-0110 Screw l4-40L=45shy - - - - 2 30 02 7441-03-0120 Screw 1S64-28L-7- shy - - - I 31 02 7471-05-0310 Screw l4-40L=85shy - - - - I 32 02 7441-02-0170 Screw l4-40L-6shy - - - - - I 33 02 7441-04-0180 ScrewM6L=15------- I 34 02 7471-05-0340 1brust Collar D=9S3 W=IOshy I 35 02 7441-03-0120 Screw 15164-28L=7----shy 2 36 02 7471-05-0360 Srcew 15164-28(7------1 37 02 7471-05-0370 SPriDI PIn 28xI4shy - - - - - I 38 02 7471-05-0380 Screw ll64-40L=24shy - - - - 2 39 02 7471-05-0390 Nut 1l64-40-------- 2 40 02 7441-03-0190 ampShaped Suap Rlng(8mm)shy - 2

5

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

2

18 8

REFNoNOTE Part No

1 02 7471-06-0010

2 02 7471-06-0020

3 02 7471-06-0030

4 02 7471-06-0040

5 02 7471-06-0050

6 02 7471-06-0060

7 02 7471-06-0070

8 02 7471-06-0080

9 02 7471-06-0090

10 02 7471-06-0100

11 02 7471-06-0110

12 02 7471-06-0120

13 02 7471-06-0130

14 02 7471-06-0140

15 02 7471-06-0150

16 02 7471-06-0160

17 02 7471-06-0170

18 02 7441-03-0190

19 02 7441-03-0190

20 02 7471-06-0110

21 02 7471-06-0210

22 02 7441~03-0190

23 02 7471-06-0230

24 02 7471-06-0240

Name of part QTY Remarks

Rod--- ---- 1

Upper Feed Rod------ 1

Upper Feed Link A-- ---1

Upper Feed Link B- - - - - 1

Upper Feed Link Bracket- - 1

Bracket--------- 1

Supporting Plate- - - -- 1

Walking Foot (Standard) - - 1

Hinge Screw- - - - - - - 1

Hinge Screw- - - - - - - 2

Hinge Screw- - - - - - - 2

Spring Guide Bar-- - -- 1

Hinge Screw- - - - - -- 1

Adjusting Thumb Screw-- 1

Nut932-28-------- 1

Spring ---------- 1

Retaining Plate- - - - - - 1

ampShaped Snap Ring (8mm)- 2

B-Sbaped Snap Ring (8mm)- 2

Hinge Screw- - - - - - --1

Screw 1564-28L=12---- 2

B-Sbaped Snap Ring (8mm)- 2

Screw 1564-28 L=12- - - - 2

Screw 1164-40 L=95 - - - -1

6

C NEEDLE BAR UPPER FEED MECHANISM COMPONENTS

REFNoNOTE Part No Name of part QTY Remarks

1 7441-07-0010 Driving Camshy ------1

2 7441-07-0020 Connecting Rod- - - - - - 1 3 7441-07-0030 Driving Shaft ArmFront - - 1 4 7441-07-0040 Driving Shaft ArmRearshy - - 1 5 7441-07-0050 Feed Rocker Shaftshy - - - shy 1 6 7441-07 -0060 BushingFrontshy - - - - shy 1

7 7441-07-0070 BushingRearshy - - - - - shy 1

8 7441-07 -0080 Rod---------- shy 1

9 7441-07-0090 Hinge Screw- - shy - - - - - 1 10 7441-07-0100 Washer---------- 1

11 7471-06-0110 HingeScrew-------- 2

12 74_41-07-0120 Screw 14middot40 L=6shy - - - --2

13 7441-04-0180 Screw m6 L=21shy - - - - shy 1

14 7441-03-0160 Screw 516-18shy - - - - - shy 1

15 7441-07-0150 Nut 1132-28--------1

16 7441-03-0120 Screw 1564-28 L=7shy - - --2

17 7441-03-0190 ampShaped Snap Ring(8mm)--2

7

D~ FRESSURE BAR COMPONENTS

2S

30 19

30

23

2 15 27 32

~

16

Name of part QtTY RemarksREFNoNOTE Part No

1 2 3 4 01 5 02 6 01 7 02 8 9 10 11 01 12 01 13 01 14 02 15 02 16 02 17 18 19 20 21 22 23 24 25 01 26 02 27 28 29 30 31 32

7441-08-0010 7441-08-0020 7441-08-0030 7441-08-0040 7471-08-0050 7441-08-0060 7471-08-0070 7441-08-0080 7441-08-0090 7441-08-0100 7441-08-0110 7441-08-0120 7441-08-0130 7471-08-0140 7471-04-0250 7471-08-0130 7441-08-0170 7441-08-0180 7441-08-0190 7441-08-0200 7441-08-0210 7441-08-0220 7441-03-0140 7471-05-0090 7441-08-0250 7441-08-0260 7441-08-0270 7441-08-0280 7441-08-0290 7441-08-0300 7441-08-0310 7441-08-0320

Presser Bar- - - - - - - - - 1 Presser Bar Bushing- -- 1 Screw----------- 1 Spring----------- 1 Spring-------- ---- 1 Presser Bar Guide Bracket -- - 1 PResser Bar GUIDE bracket- - 1 HandLifterUnk ------ 1 Hand LIfter Cam- - - - -- - 1 Hand LIfter LeVel- - - - - - 1 Pressure Foot(Smdard)Aam - - 1 Pressure Foot(Stndard)- - - - 1 Guand--------- -1 Pressure Foot(Standard)Aam - 1 Pressure Foot(Standard) - - - 1 Guand-----------l Nut------------ 1 Grlp------------l GuidePJate---------l Thrust Collar- - - - - - - - 1 RoUer Follower- - - - - - - 1 GuidePln--------- 1 Screw 1440 L==4S- - - - -- 1 Screw 1564-28L=-25 - -- -- - 1 Screw 316-18 L=11-----1 Screw 1440 L=6- -- -- -- -- -- 2 Screw 96440 L=135---- 1 Nut96440---------1 Screw 1440 L=45- -- -- - - 1 Screw 1164-40 L=9 - - - - - 2 COIIar----------- 1 Spriq Pin 30xl0- - -- - - - 1

8

E NEED MECHANISM COMPONENTS(1I2)

18 ____

16

19

20

REFNoNOTE Part No

1 7441-09-0010 2 7441-09-0020 3 7441-09-0030 4 7441-09-0040 5 7441-09-0050 6 7441-09-0060 7 1 7441-09-0070 8 2 7471-09-0080 9 1 7441-09-0090 10 7441-09-0100 11 7441-09-0110 12 7441-09-0120 13 7441-09-0130 14 7471-05-0260 15 7471-05-0260 i6 7441-09-0160 17 7441-09-0170 18 7441-04-0270 19 7441-03-0190 20 7441-09-0200 21 7441-09-0210 22 7441-03-0190 23 7441-09-0230 24 7441-09-0240 25 7441-03-0120 26 7441-09-0200 27 7441-09-0270 28 7441-09-0280

Name of part QTY

Feed Bar--------- 1 Feed Bar Unk-------- 1 Driving Shaft- - - - - - -- 1 Feed Rocker Shaft- --- I BushingFront- - -- --- I

BushingRearshy - - - - - - shy 1 Feed Rocker Shaft Cnmkshy - - 1 Feed Rocker Shaft Cnmkshy - - 1 Feed Dogshy - - - - - - - - shy 1 Feed Dogshy - - - - - - - - shy 1 Driving Shaft Metalshy - - - - - 1 Feed Bar Pressershy - - - - - - 1 Hinge Screw ---------1 HingeScrew--------- 1 HingeScrew--------- 1 Hinge Screw 0=794 L=8--- 1 Nut 14-24--------- 1 Screw 11164-40L=7------ 1 B-Shaped Snap Ring (8mm)-- 1 Screw 1564-28 L==105- - -- 1 Screw M6- - - - - - - - -- 2 B-Sbaped Snap Ring (8mm)-- 1 Screw 14-40L=35------ 4 Screw 11164-28L=6------- 2 Screw 15164-28L=7------ 1 Screw IS64-28L=105- - - - - 1 Thrust Collar 0=1472 W=10- 1 Thrust Collar 0=1111 W=10- 1

Remarks

9

14

I

K NEED MECHANISM COMPONENTS(22)

3

_-------1 _----- I

Is_~-~-~ I ~-

II I ~ I I L1r-~ ~16

~~-1i ~

8

REFNoNOTE Part No Name of part QTY

1 7441-10-0010 Rod- shy - - - - - - - - - 1 2 7441-10-0020 Feed Connecting Link- - - - 1

3 7441-10-0030 Feed Regulater- shy - - - - - 1

4 7441-10-0040 Lever- shy - - - - - - - - - 1

5 7441-10-0050 Side Cover- shy - - - - - - -1 6 7441-10-0060 Lever Gripshy - - - - - - - -1 7 7441-10-0070 Lever Shaft- shy - - - - - - 1 8 7441-10-0080 Nut- shy - - - - - - - - shy 1 9 7441-10-0090 Spring- shy - - - - - - - - 1 10 7441-10-0100 Support Plato- shy - - - - - 1 11 7441-10-0110 Ball- shy - - - - - - - - - 1 12 7441-10-0120 Hinge Screw A shy - - - - - 1 13 7441-10-0130 Hinge Screw Bshy - - - - - 1 14 7441-02-0190 Nut 932middot28- shy - - - - - - 1 15 7441-10-0150 Screw 316middot28 L=12- shy - - - 2 16 7441-10-0160 Screw 316-32 L=18shy - - - - 1 17 7441-10-0170 Screw 1564middot28 L=9- shy - - - 2 18 7441-10-0180 Nut- shy - - - - - - - - - 1

-

Remarks

10

F HOOK DRIVING SHAFT COMPONENTS(1I2) 2

5

REFNoNOTE Part No

1 7441-11-0010 2 7441-11-0020 3 7441-11-0030 4 7441-11-0040 5 7441-11-0050 6 7441-11-0060 7 7441-11-007~

8 7441-11-0080 9 7441-11-0090 10 7441-11-0100 11 7441-11-0110 12 7441-11-0120 13 7441-11-0130 14 7441-11-0140 15 7441-11-0150 16 7441-11-0160 17 03 7441-11-0170 18 03 7441-11-0180 19 03 7441-11-0190 20 7441-11-0200 21 03 7441-11-0210 22 03 7441-11-0220 23 03 7441-11-0230 24 7441-11-0240 25 7441-02-0160 26 7441-02-0160 27 7441-11-0270 28 7441-11-0280 29 7471-06-0150 30 7441-09-0270 31 7441-09-0230

Name of part QTY

Hook Driving Shaft Crank- - - 1 Crank Slide Block - - - - - - 1 Slide Block Stud- - - - - - - 1 Hook Driving Shaft - - - - - - 1 BushlngFront- - - - - - - - 1 BushingRear- - - - - - -- 1 Shuttle Driver- - - - - - - - 1 Shuttle Race Body- - - - - - 1 Bobbin----------- 1 HookCOver--------- 1 Hook Cover Spring- - - - - 2 Hook Counter Spring- - - - - 2 OUFelt----------- 2 Screw- - - - - - - - - - --2 Hinge Screw D=26 L=27- - - 2 HookCOver--------- 1 DIStance Plece- - - - - - -- 1 Distance Plece- - - - - - - - 1 DistaDce Piece- - - - - - - - 1 Distance Piece (Standard) - - - 1 Distance PleQe- - - - - - - - 1 Distance Piece- - - - - - - - 1 Distance Plece- - - - - - - - 1 SCrew----------- 2 Screw 1564-28 L=15- - - - - 1 Screw 1564-28 L=15----- 1 Thpered Pin 4OxI6- - - - - - 1 Screw M8 L=11 -------1

Nut 932-28--------- 1 Thrust Collar D=1472 W=10- 1 Screw 14-40L=35------2

Remarks

11

F HOOK DRIVING SHAFT COMPONENTS(22) 14

13- 5

I)II~ ~~- ~~

~ REFNoNOTE Part No Name of part QTY Remarks

1

2

3 4

5

6 7 8

9 10 11

12 13

14

15 16

17 18

19

20

21 22 23

7441-12-0010 7441-12-0020

7441-12-0030

7441-12-0040 7441-12-0050

7441-12-0060 7441-12-0070

7441-12-0080 7441-12-0090

7441-12-0100 7441-12-0110 7441-12-0120

7441-12-0130

7441-12-0140 7441-03-0120

7441-12-0160

7441-12-0170 7441-12-0180

7441-12-0190

7441-10-0160

7441-12-0210

7441-12-0220 7441-12-0230

Connecting Rod - - - - - - 1

Con-Rod Eccentric Cam - - 1

Cam Side Plateshy - - - - shy 1 Oscilating Rock Shaftshy - - 1

Hjnge Pinshy - - - - - - shy 1

Rock Shaft Bushingshy - - - 1 SlidePlateA------shy 1 Slide Plate Bshy - - - - - shy 1 Con-Rod Pin-------- 1

COn-RodPinWedge-----1

Cage amp RoUer ------- 1 Screw 1564-28L-15shy - - --I

Screw M81=30shy - - - - - - 2 Screw 1l64-40L=7----- 1

Screw IS64-18L=7 - - - - - 1 Oil Wlckshy - - - - - - - --1

Ping 29x32x3shy - - - - - - 1

Screw-----------l Nut 1164-40-------- 2

Screw 316-31L=18----- 1

Screw U64-28L=IO7----1 Washer---------- 1

PIN------------l 12

G TENSION POST COMPONENTS

19

REFNoNOTE

1 2

3 4

5 6

7

8 9 10

11 12 13 14

15 16 17 18

19 20

21 22 23 24 25

Part No

7441-13-0010 7441-13-0020 7441-13-0030 7441-13-0040

7441-13-0050 7441-13-0060 7441-13-0070

7441-13-0080 7441-13-0090 7441-13-0100 7441-13-0110 7441-13-0120 7441-13-0130 7441-13-0140 7441-13-0150 7441-13-0160 7471-06-0150 7441-13-0180 7441-13-0190

7441-08-0300 7441-13-0210 7441-01-0130 7441-13-0230

7441-13-0240 7441-13-0250

RemarksName of part QTY

Thread Thnsion Post- - - - - 1 Tension Disk- - - - - - -- 2

Thread Tension Stud Nut - - - 2 Thread Thhsion Spring- - - - 2 Thread Thnslon Post Bracket - - I Thread Tension Guide- - - - - 1 Thread Releasiq Plate- - - - 1 SprinsA ---------- 1 SprlDJB---------- 1 Spring Support Plate- - - -- 1 1bread Thnsion Wheel Post- - 1 Thread Thnsion Wheel- - -- 1 Wbeel Fe1t---~----- 1 Felt Support Plate--- - - - -- 1 Arm Thread GUide Jtottom Ani-I Frame 1bread Guld- - -- - - 1 Nut32-28- -~- - - - - -- 1

HJaae Screw D=OL=31- - - 1 Nut 1564-28--------- 1

Screw tr1M-40 La12 - - - -- 1

Screw 64-40 L=O- - - -- I

Screw 64-40 L=7- - - - -- 1 Sctew64-40 L=5- - - - -- 1 Screw 964-40 L=7- - - - -- 1 Thread Guide- - - - - - -- 1

13

H THREAD WINDER amp THREAD GUIDE CMPONENTS(1I2)

3

---------------L------------- shy-9 8i l- -gt

o o

I ~ o

I o

26I o

shy

l o o

--shy

-- 4

27

REFNoNOTE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

---------- I ~28 -- 13 ~

- 5 __

Part No

7441-14-0010 7441-08-0300 7441-14-0030 7441-14-0040 7441-14-0050 7441-14-0060 7441-14-0070 7441-14-0080 7441-14-0090 7441-14-0100 7441-14-0110 7441-14-0120 7441-14-0130 7441-14-0140 7441-14-0150 7441-14-0160 7441-14-0170 7441-14-0180 7441-14-0190 7441-14-0200 7441-14-0210 7441-14-0220 7441-14-0220 7441-14-0240 7441-14-0250 7441-14-0260 7441-14-0270 7441-14-0280 7441-14-0290 7441-03-0120

--shy

RemarksName of part QTY

Thread Winder Plate - - - - - 1 Screw 1164-40L=9----- 4

Thread Winder Asm - - - - - 1 Thread Winder Base- - - - - 1 Thread Winder Shaft- - - - - 1 Spacer------------ 3

Bobbin Presser- - - - - - - - 1 Bobbin Presser Spring- - - - - 1 Screw 332-56 L=33- - - - - - 2

Adjusting Screw- - - - - - - - 1 Nut 18-44---------- 1

Bobbin Winder Wheel- - - - - 1 Bobbin Winder Frame- - - - - 1 Wheel Ring--------- 1

Hinge Screw--------- 1

Bobbin Winder Tension Bracket- 1 Spring------------ 1

Bobbin Winder Spring- - - - - 1

Thread Winding Shaft Collar- - 1 Screw 1164-40 L=18-- - - - - 3

Hinge Screw D=724L=19- - - 1 Nut 1164-40--------- 1

Nut 1164-40--------- 1

Screw 1164-40 L=5- - - - - - 2 Stopper----------- 1

Screw 1164-40 L=30- - - - - 1

Thread Cut amp Clamp Plate - - - 1 Screw 18-44 L=4- - - - - - - 2 Friction Wheel-------- 1

Screw 1564-28 L=7- - - - - shy 2

14

H THREAD WINDER amp THREAD GUIDE CMPONENTS(22)

r------------i I 6

I II 3 iI 1 5

~ I

I

4

I

10 I I

11 I II I

IL___________

7J

REFNoNOTE Part No Name of part QTY Remarks

Thread Winder Guide Base Asm - 1

2

1 7441-15-0010 Thread Winder Guide Base - - - (1)

3 7441-15-0030 Tension Sping- - -- - - - - - (1)

4 7441-13-0010 Thread Tension Post- - -- -- - (1)

5 7441-13-0020 Tension Disk- - - - - - - -- (2)

6 7441-15-0060 Thread Tension Stud Nut- - --- (1)

7 7471-06-0150 Nut 932-28~ - -- -- - -- -- -- - -- (1)

8 7441-15-0080 Thread Guide- - - - - -- - - 1

9 7441-15-0090 Guide Bracket- - - -- -- - --1

10

7441-15-0020

7441-15-0100 Screw 1164middot40 L=85- - -- - -- - 1

7441-15-0110 Screw 18-44 L=6- - - - - - - 111

12 7441-01-0130 Screw 964-40 L=7- - - - - -- -- 1

Screw 1564middot28 LlO5- -- - -- - shy 27441-04-020013

15

I KNEE LIFER COMPONENTS

I

bull 18 15 6

11--__

bull 16

REFNoNOTE

1

l 3 4 5

6 7

8 9

10 11 12

13 14 15