INFUB Conference Industrial Furnaces Boilers, INFUB · INFUB ‐11th European Conference on...

Transcript of INFUB Conference Industrial Furnaces Boilers, INFUB · INFUB ‐11th European Conference on...

Technology for a better society

1

INFUB ‐ 11th European Conference on Industrial Furnaces and Boilers, INFUB‐11

Francisco Carrasco‐Maldonadoa , Jørn Bakkenb, Mario Ditarantob, Nils E. L. Haugenb, Øyvind Langørgenb, Simon Grathwohla, Jörg Maiera

aIFK, University of Stuttgart, Pfaffenwaldring 23, 70569 Stuttgart, GermanybSINTEF Energy Research, Trondheim, Norway

Oxy‐fuel burner investigations for CO2 capture in cement plants

Technology for a better society

2

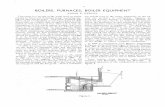

Raw meal

Cyclonepreheater

Flue gas

Calciner

Tertiary air duct

Cooler exhasut gas

Fuel/air

Fuel

Cooler

Cooling air

Rotary kiln 2000 °C

300 ‐ 350 °C

700 ‐ 1000 °C

200 °C ‐ 350 °C

850 °C

700 ‐ 1000 °C

Clinker

60 % Material CO2

40 % Fuel CO2CaCO3, SiO2, Al2O3, Fe2O3

Cement emissionsrepresent 5% of

total anthropogenicCO2 emissions

CO2 emissions in the cement industry

Source: ECRA

Technology for a better society

3

The need for CCS in Cement productionWithout reduction measures: 2.4 Gt/a in 2050BLUE MAP scenario (with CCS): max 1.6 Gt/a in 2050

Increase of energy efficiencyAlternative fuels useReduction of clinker share

Reduction by:

CCS

2.5

2.0

1.5

Global CO2em

issions ofthe

cemen

tind

ustryin Gt/a

0.0

2010 2030 2050

44 %

56 %

Source: IEA Cement Roadmap

• IEA target for 2050: 50 % of all cement plants in Europe, Northern America, Australia and East Asia apply CCS

• Cement plants typically have a long lifetime (30‐50 years or more) and very few (if any) are likely to be built in Europe→ Retrofit

Technology for a better society

5

Technologies to be tested ‐ oxyfuelCalciner test rigExisting <50 kWth entrained flow calciner (USTUTT) to be used for oxyfuel calcination tests

Clinker cooler To be designed and built for on‐site testing at HeidelbergCement in Hannover

Partners: USTUTT, VDZ, IKN, CTG

Partners: IKN, HeidelC, VDZ

Partners: USTUTT, TKIS, SINTEF‐ER

Oxyfuel burner Existing 500 kWth oxyfuelburner at USTUTT to be modified for CEMCAP

Source: ECRA

Technology for a better society

6

1. Validation of CFD models for oxy‐fuel combustion.

2. Adaptation of test facility for cement kiln burner investigations.

3. Preliminary results of oxy‐fuel investigations.

Outline

Technology for a better society

7

7

Simulation of USTUTT Combustion facility:

1. Validation of CFD models for oxy‐fuel combustion.

Bottomash

ID fanESPSCR

StoragetanksFD/ RG fan

O2

CO2

Stack

AirO2 CO2

Gasdistribution

APH

Coal feeding

Burnerwindbox

Air

By-passes

Bottomash

ID fanESPSCR

StoragetanksFD/ RG fan

O2

CO2

Stack

AirO2 CO2

Gasdistribution

APH

Coal feeding

Burnerwindbox

Air

By-passes

Technology for a better society

8

8

Simulation of oxy‐fuel test at USTUTT Combustion facility with IFK burner:

1. Validation of CFD models for oxy‐fuel combustion.

Test case O2 in oxidizer[vol‐% wet]

Stoichiometricratio

O2 in stack[vol‐% dry]

Fuel input[kW]

Air 21 1,15 2,8 305

OF29 29,5 1,15 4,5 305

Technology for a better society

9

9

South African coal:

1. Validation of CFD models for oxy‐fuel combustion.

0.002.004.006.008.0010.0012.0014.0016.0018.0020.0022.0024.0026.0028.0030.00

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

1.00 10.00 100.00 1000.00

Vol

ume-

%

Particle size [um]

CD

D[v,0.5](um)

BD

Water

[%]

Ash[%]

Volatiles

[%]

Cfix[%]

C[%]

Htot

[%]

H[%]

N[%]

S[%]

O[%]

an 1,65 14,36 27,22 56,77 67,83 4,77 4,59 1,77 0,44 9,35raw 8,94 13,30 25,20 52,56 62,80 5,25 4,25 1,64 0,41 8,66wf - 14,61 27,67 57,72 68,97 4,67 4,67 1,80 0,45 9,51

Ho,v[J/g]

Hu,p[J/g]

an 27.383 26.355raw 25.444 24.316wf 27.942 26.943waf 32.721 31.551Ho,v = HHV and Hu,p = LHV

Technology for a better society

10

10

1. Validation of CFD models for oxy‐fuel combustion.

Primary/ coal

Secondary

Natural Gas

Technology for a better society

11

11

CFD input

1. Validation of CFD models for oxy‐fuel combustion.

Ansys Fluent models

Code Fluent 17.02D‐Axisymmetric swirl

Mesh, number of cells 113757 (structured mesh)

Turbulence k‐epsilon, realizable, standard wall functionsk‐omega SST

Chemistry Species transport, Finite rate/Eddy Dissipation, 2‐step reaction

Radiation P1 with particle‐radiation interaction

Furnace wall temperature Profile calculated from IFK experiments. Implemented by an UDF

Inlets Velocity inlet (constant velocity)

Outlet Pressure outlet

Technology for a better society

12Temperature profile – Air Case

Temperature profile – Oxy‐fuel Case

Technology for a better society

15

Source: ThyssenKrupp

a) Design of a prototype oxy‐fuel burner for cement kilns.

Source: ThyssenKrupp‐ POLFLAME

2. Adaptation of test facility for cement kiln burner investigations.

• Scaling factor of 100 between industrial and pilot burner.

Technology for a better society

16

16

• Primary Gas (nozzles)o Velocity ca. 250 m/so 8 nozzleso Angle: 0‐40°

• Carrier gas (outer coal channel)o Transport air velocity ca. 15 m/s

2. Adaptation of test facility for cement kiln burner investigations.

Technology for a better society

17

17

b) Adapt test facility for oxy‐cement processing

2. Adaptation of test facility for cement kiln burner investigations.

Clinker cooler

Cement kiln

Secondary Gas 700‐100°C

Primary and carrier gas

• Preheating of secondary gas• Dry secondary gas

Technology for a better society

18

18

level no.

12345

6789

10

1112131415

1617181920

21

22

23

24

25

26

27

28

29

30

31

Continue gas measurements

Bottomash

ID fanESPSCR

StoragetanksFD/ RG fan

O2

CO2

Stack

AirO2 CO2

Gasdistribution

APH

Coal feeding

Burnerwindbox

Air

By-passes

Bottomash

ID fanESPSCR

StoragetanksFD/ RG fan

O2

CO2

Stack

AirO2 CO2

Gasdistribution

APH

Coal feeding

Burnerwindbox

Air

By-passes

In-flameMeasurements:• Gas emissions• Gas temperature• Heat flux• Radiation, etc.

Air/Flue gas

Test facility: 500 kWth KSVA (Pulverized Coal Combustion Plant)

Burn out

2. Adaptation of test facility for cement kiln burner investigations.

Technology for a better society

19

19Bottom Ash

ID fanESPSCR

Storage Tanks

Carrier gasCO2

Stack

O2 CO2

Coal feeding

Air

By-passes

CO2, O2

Air

Air

CO2, O2

Primary gas

Secondary gas

Preheaters

• Secondary gas flow lines• Gas storage tanks• Quenching system• Head of combustion chamber• Preheater system• Radiation probes

2. Adaptation of test facility for cement kiln burner investigations.

Technology for a better society

20

20

Source: ECRA CCS Project

3. Preliminary results of oxy‐fuel investigations.

Longer flame. Altered temperature

profile. Altered heat flux

profile to material bed.

Previous results published by ECRA:

Technology for a better society

22

22

3. Preliminary results of oxy‐fuel investigations.

Ho,v[J/g]

Hu,p[J/g]

an 33.077 32.237wf 34.657 33.894Ho,v = HHV and Hu,p = LHV

Water[%]

Ash[%]

Volatiles[%]

Cfix[%]

C[%]

Htot

[%]

H[%]

N[%]

S[%]

Cl[%]

an 4,56 2,12 11,3 82,0 77,0 3,91 3,40 1,47 3,03 0,074wf ‐ 2,22 11,9 85,9 80,7 3,56 3,56 1,57 3,17 0,078

Fuel characterization: Petcoke

Technology for a better society

23

23

Primary gas (nozzles)

Coal + Carrier gas

482 kW

Secondary gas

T = 740 °C

v = 4,5 m/s

O2 = 21%

N2 = 79%

λ = 1,12

O2 = 2,2% vol,dry

CO2= 16,5% vol,dry

NOx = 536 ppm, dry

Flue gas

CC Shell radiation

PG = 21%

Primary gas (nozzles)

Coal + Carrier gas

482 kW

O2 = 53%

CO2 = 47%CO2 =100%

Secondary gas

Flue gas

CC Shell radiation

AIR CASE OXY‐27

T = 712 °C

v = 3 m/s

O2 = 21%

CO2 = 79%

λ = 1,13

O2 = 3,4% vol,dry

CO2= 84,6% vol,dry

NOx = 770 ppm, dry

Swirling 40°

PG = 24%

Technology for a better society

24

24

3. Preliminary results of oxy‐fuel investigations.

Air Case Oxy-fuel

Fuel burnout 98,0 98,3

Technology for a better society

25

25

Summary

• First simulation of test rig. Validation vs Experimental data was successful.• Two turbulence models were tested, K‐Omega produced better results.• Test facility was adapted for relevant oxy‐cement tests.• Burner prototype was designed and tested.• Demonstration tests evinced suitability to obtain similar radiation profiles

under oxy‐fuel conditions.

Further Steps• Additional testing with a higher volatile fuel.• Simulation of additional oxy‐fuel cases not investigated in facility.

Technology for a better society

2626

AcknowledgementsThis project has received funding from the European Union's Horizon 2020

research and innovation programme under grant agreement no 641185

This work was supported by the Swiss State Secretariat for Education, Research and Innovation (SERI) under contract number 15.0160

www.sintef.no/cemcapTwitter: @CEMCAP_CO2