Information Systems & Technologies VG KARIER fileVIST Group MISSION Increasing – Operations...

Transcript of Information Systems & Technologies VG KARIER fileVIST Group MISSION Increasing – Operations...

VIST Group MISSION

Increasing – Operations efficiency and safety– Control of equipment usage– Labor productivity– Sustainability– Safety

Decreasing– Operation costs – Negative staff influence– Maintenance costs

Developing and deploying Hi-Tech solutions in key sectors of the industry

SOLUTIONS BY INDUSTRIES AND BRANCHES

• Mining

• Mining Equipment Manufactories

• Railway

• Transport

• Construction

VIST Group:Headquarter - MoscowBranch Offices- Kemerovo, Mezhdurechensk, Stary Oskol, Apatity, Zheleznogorsk, Magnitogorsk Subsidiary companies

-VISTGroup Tekhnicheskiy Centr, Kryvyi Rih (Ukraine)-VIST Sensor, Minsk (Belarus)-BV International, Danvers, Mass., (USA)

Kemerovo

Mezhdurechensk

Kryvyi Rih(Ukraine)

Minsk (Belarus)

MoscowApatiti

ZheleznogorskStary Oskol

Magnitogorsk

Danvers (USA)

VIST Group STRUCTURE

VG KARIER Mine Fleet Management System

More than 20 years in the market

Own development of Software and Hardware

More than100 high qualified employees involved in design,

development, deployment and support

More than 50 Mine Fleet Management Systems

deployments

Russian Government Award for VG Karier

Mine Fleet Management System

in 2009

Member or the Russian Silicon Valley Skolkovo

with the Intelligent Mine project

Flexible solutions with guarantee

quality

BENEFITS FROM CHOOSING VIST Group

VG KARIER Mine Fleet Management System

VIST Group PARTNERS• Belorussian Autoworks “BELAZ”• OMZ Group (Mining Excavator Producer)• GPFK• BV International• Oracle• Cisco Systems• Motorola• Aplicom Oy• Tamtron Oy• Vulcan• OMZ - Group• NAVIS• ROHDE&SCHWARZ• HP• IBM• Skolkovo• Association GLONASS/GNSS Forum• Saint Petersburg State Mining University

VG KARIER Mine Fleet Management System

• Severstal

• Magnitogorsk Iron and Steel Works

• LUTEK

• Siberian Coal Energy Company (SUEK)

• SDS

• SDS - AGRO

• EVRAZ

• METALLOINVEST

• ArcelorMittall

• Joint Venture "ERDENET“

• Mechel

• POLIMETALL (Gold)• Eurochem• ENRC• SSGPO• KuzbassRazrezUgol• Metinvest• POLUS Gold• NLMK• DGK• UGMK• EN+• SMR

SOME VIST Group CLIENTS

VG KARIER Mine Fleet Management System

KARIER Benefits

Increased Mining Fleet Productivity

Reduced operational costs and fuel consumption

Increased Mining Machine Durability and Life Cycle

Increased Safety of Mining Works

Improved Mineral Quality Control

VG KARIER Mine Fleet Management System

KARIER Economic Benefits

The average efficiency of VG Karier calculation is based

on approved statistics from mining enterprises

•Fleet and excavators efficiency and productivity

increase by 5-12%

•Operation costs decrease by 2,5 – 7%

•Fuel consumption decrease by 10-15% (fuel

economy and improper use)

VG KARIER Mine Fleet Management System

Data from one of the customer (Gold Mine)

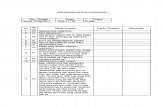

Costs item Estimation of cost decreasing Real achievement

Trucks Share parts 0,95 0,59

Tires 0,90 0,89

Fuel 0,93 0,91

Liquids 0,83 0,81

KARIER Economic Benefits

They haul the same value with less trucks (18 instead of 20)

after 1 year of VG Karier deployment

VG KARIER Mine Fleet Management System

Specific costs for the items

Specific costs1 st half of

20082 nd half of

2008

9 months of 2009

12 months of 2009

RUR/ м3*km 11,26 10,54 10,02 9,81

RUR/ t*km 5,12 4,68 4,47 4,35

Costs decreasing

• For hauling of one м3*km is 12%• For transportation one t*km is 15%.

KARIER Economic BenefitsData from one of the customer (Gold Mine)

VG KARIER Mine Fleet Management System

KARIER Economic Benefits

ArcelorMittal Kryvyi Rih, UkraineKARIER System First Year Usage Allowed:

• 12 % Fleet Efficiency Increase

• 7 % Fuel Consumption Decrease

• Increase Staff Responsibility and

Discipline

• Increase Sustainability and Truck

Technical Rate of Availability

• Eliminate Fuel Theft and Fleet Misuse

VG KARIER Mine Fleet Management System

KARIER Features

Automatic Dispatching and Optimization

Down Time Minimization

Payload Optimizing

Real-Time Management

Formal Business Messages Support

High Precision Machine Guidance

Time of Equipment Availability Increasing

Increased Mining Fleet Productivity

Use less trucks for the same hauling volumes

VG KARIER Mine Fleet Management System

KARIER Features

Increased Mining Equipment Durability and Life Cycle

Breach Monitoring and Management

Operating Parameters Control (speed, load, slope etc.)

Road quality monitoring

Servicing Planning

Equipment Health Monitoring

VG KARIER Mine Fleet Management System

KARIER Features

Improved Mineral Quality Control

Optimization with quality criteria

High Precision Machine Guidance

Drill Navigation and Sensor Monitoring

Bench Elevation and Bucket Positioning

Stockpile Management

Geological System Integration

VG KARIER Mine Fleet Management System

KARIER Features

Reduced operational costs and fuel consumption

Fuel Consumption Reducing

Exclude Fuel Theft

Down Time Minimization

Real-Time Reporting

Operating Parameters Control (speed, load, slope etc.)

Servicing Planning

Automatic Dispatching

Real time statistics is corresponds with surveyor measurements – full and real accounting of operations

VG KARIER Mine Fleet Management System

KARIER System Architecture

Mining EquipmentSensors,Health monitoring

systems System Server

GLONASSGPS

Control Center

ERP, MES, EAM, Geological etc.

EAMMine

Headquarter

Функционал

ERP

Geological systems

VG Holding

VG Fleet VG MineTruck

VG Skarex

VG Railway

VG Drill

VG Karier

VG Orders and Safety

KARIER Position in enterprise

VG KARIER Mine Fleet Management System

Motorola MESH

WiFi

WiMax

GSM

PTP and MTP links

Satellite Communications

KARIER Wireless Communication Systems

Enterprise Area

Public Roads

Railways

COMBINING

VG KARIER Mine Fleet Management System

KARIER On-Board Equipment

Industrial Rugged PCwith LCD Touch Screen

Wireless Communication Unit

Sensors, Diagnostic and Control Systems

Navigation System

Trucks

Excavators

Loaders

Drills

Trains

Dozers

Refuellers

Auxiliary Transport

VG KARIER Mine Fleet Management System

BENEFITS and FEATURES

KARIER On-Board EquipmentVIST Group Load, Fuel & Tire Pressure Monitoring System

•Load measuring•Fuel level and consumption measuring•Trip counting•Tire pressure control•Intuitive driver graphical interfaces•Three level payload light signaling to excavatoroperator•Data storage•Hydraulic cylinders charging assistance

SustainabilityMore than 4500 systems IN USETrucks manufacturer BELAZ approvalIndustrial Rugged Design

Can be installed to CAT, Komatsu, Hitachi, Terex etc or connected to their own system

VG KARIER Mine Fleet Management System

KARIER On-Board EquipmentVIST Group Truck Integral Diagnostic System

•Integral Multifunctional LCD Display•Truck Systems Health Control (engine, electric drives, hydraulic system, liquid system etc.)•Distributed Data Collection from Analog/Digital Sensors •Driver Video Assistance System•Load, Fuel & Tire Pressure Control System

BENEFITS and FEATURES

VG KARIER Mine Fleet Management System

KARIER On-Board EquipmentVIST Group Diagnostic and Control System VG SKAREX for EKG Excavator

•Integral Multifunctional LCD Display•Electrical Parameters Monitoring (currents, voltages, consumption etc.)•Mechanical Parameters Monitoring (vibrations, temperatures, inclinations etc.)•Digging Cycle Counting•Operation and Idle Time Counting•Excavator Systems Health Monitoring (engine, electric drives, hydraulic system, liquid system etc.)•Analog/Digital Sensors Readings •Operator Video Assistance System

BENEFITS and FEATURES

VG KARIER Mine Fleet Management System

KARIER Software Architecture

ERP, MES, EAM, Geological etc.

On-board PC Software

OracleDataBase

Enterprise KARIER Server

Applications Server Web-Server

Headquarter KARIER Server

Control CenterFat Client +

WEB- Interface

ALL USERSWEB-Interface

VG KARIER Mine Fleet Management System

KARIER Holding Structure

REMOTE OFFICESystem Users

Control CenterSystem Server and

System Users

ROUTER

MANAGEMENT OFFICESystem Users

ENTERPRISE

HEADQUATERSystem Users

GLONASSGPSSatellite

Communications

REMOTE ENTERPRISE

VG KARIER Mine Fleet Management System

KARIER Mine Fleet Management

Mapping

•Different Map Types Support (vector, bitmap)•Automatic Map Updating from Geological System•Configurable Graphics•Objects, Routes, Zones Creating and Editing•Playback option

Control Center Map

Web-interface map

KARIER Mine Fleet ManagementBusiness messages

Business MessagingSoftware

Driver – Voice and Text Messages

Low fuel level

Dispatch Manager

•Stop reasons•Breakages•Directions

•Notifications•Filling

•Automatic dispatching

•etc

Operator– Voice and Text Messages

Engineers

VG KARIER Mine Fleet Management System

KARIER Truck Management

Truck Plan Performance Real-Time Report

VG KARIER Mine Fleet Management System

KARIER Truck Management

Excavators Plan Performance Real-Time Report

VG KARIER Mine Fleet Management System

Existing diagnostic systems can be connected (Cummins, Siemens,

MTU, Lincoln etc.)

KARIER Equipment Health Monitoring

VG KARIER Mine Fleet Management System

KARIER Mine Fleet Management

Fleet Technical Condition and Repair Planning

VG KARIER Mine Fleet Management System

KARIER Mine Fleet Management

Dozer Shift Ordering and Operation Control

VG KARIER Mine Fleet Management System

KARIER Mine Fleet Management

Automatic Road Quality Monitoring

Roads Defects Marks

Превы шение нормативны х значений угла наклона

0

20

40

60

80

100

120

10 110 210 310 410 510 610 710 810 910 1010

Маршрут (м)

Про

мил

ле

Roads Slopes Monitoring

VG KARIER Mine Fleet Management System

KARIER Mine Fleet Management

Auxiliary Transport Ordering and Operation Management

Waybill – Print Form

Real-time Management

VG KARIER Mine Fleet Management System

KARIER Fuel ManagementFilling Optimization

Fuel Optimization Software and

business messages

Get ready

Low fuel level

Direction

VG KARIER Mine Fleet Management System

Full Cycle Fuel Monitoring

Fuel Depot

Refueller

Vehicles

LevelOutput/

ConsumptionTemperature

DensityVolume

Monitoring

KARIER Fuel Management

VG KARIER Mine Fleet Management System

KARIER Full Cycle Fuel Monitoring

FUEL Monitoring

Fuel Report – Print Form

Fuel Consumption Analyzing

VG KARIER Mine Fleet Management System

KARIER Railway Management

Train Work Diagram

User SW Form Print Form

VG KARIER Mine Fleet Management System

KARIER Railway Management – Station Control System

BENEFITS and FEATURES

E-counting System of Rail Axes

Railway Arrows Management with Electrical Drives

Railway Traffic Lights Management

Route Control Mode

Station Dispatch Office

Station Dispatch Office

VG KARIER Mine Fleet Management System

KARIER Improved Mineral Quality Control

BENEFITS and FEATURES

•Actual shift planning using mineral quality needs •Visual confirmation of material type andquality while loading trucks - eliminates theneed for staking and ribbon boundaries.• Calculation of load grade on the trucks –provides ability to dispatch according to material quality, providing accurate blending of material and eliminating misrouted loads.• Automatic record of shovel progress into theface• Real-time dispatching and blending - basedon high precision data.• Elevation control feature - allows operator tobuild smooth bench floors thereby reducing wear and tear on vehicles and promoting faster cycle times.

VG KARIER Mine Fleet Management System

KARIER Improved Mineral Quality Control

WORK SCHEME

High Precision GNSS and Sensors

Shift planning (contours work off order) Real time position, shift order

and geological model visualization to operator

Excavator

Minerals Quality Control and Accounting

Automatic control of shovel progress into the face

VG KARIER Mine Fleet Management System

KARIER Improved Mineral Quality Control

BURDEN PREPARATION

Actual Warehouse State

Minerals Quantity and Quality Diagrams

VG KARIER Mine Fleet Management System

KARIER Improved Drill Management – VG Drill

BENEFITS and FEATURES

•Automated Drill Guidance using

High Precision GNSS

•Digital Map Shift Order Showing to Operator

•Operation Parameters Control and Visualization

(depth, penetration rate, production and utilization

statistics such as cumulative meterage,

number of holes drilled, time spent drilling, propelling between holes,

and rod handling)

VG KARIER Mine Fleet Management System

KARIER Improved Drill Management – VG Drill

WORK SCHEME

High Precision GNSS and Sensors

Drill

Real time position, digital map and guidance prompts

visualization to operator

Shift planning (holes order and parameters) Drill Operation Parameters

Control

Calculating the Parameters of Blasting

Hole Charges

VG KARIER Mine Fleet Management System

KARIER Truck Optimization Algorithm

BENEFITS and FEATURES

•Improved truck distribution on the route / route group•Reduced truck and shovel waiting time•Increased productivity•Automatic Visual Truck Driver Changes Notification

Real-time Truck Management

Dynamic Optimization Static Optimization

Statistics and forecasting

Optimization Criteria

VG KARIER Mine Fleet Management System

KARIER Truck Optimization Algorithm

OPTIMIZATION CRITERIA

Production rates for the crushers, stockpiles, and/or dumps

Shovel priorities and shovel rates or production

Multiple shovel groups or combinations of groups and shovels working in fixed assignment

Locking of trucks to a particular shovel or destination

Restricting trucks from particular shovels and destinations

VG KARIER Mine Fleet Management System

KARIER Truck Optimization Algorithm

User Optimization SW

Excavators

Unloading points

Optimization Groups

Trucks

VG KARIER Mine Fleet Management System

Real time routs distribution qaulity

KARIER Truck Optimization Algorithm

Preliminary meeting and offer

Technical visit on site and Technical project – 1-1,5 month

Manufacturing and shipping - up to 4 month

Installation and training – up to 2 month

Maintenance and Support

6-9

mon

ths

KARIER deployment

BASE Support Contract -• Answering the customers’ questions either by phone or by e-mail• Access to special service WEB-application• Access to software updates and new software versions

Additional features• 24/7 multilingual phone support • On-site engineer or region service engineer• System audit every month/quarter/half year/year (on-sight visit and a

report that includes necessary changes for increasing the productivity)• Supply of the critical staff and services to site at short notice• Additional staff training • Personal manager• Remote software management• Region stock with share parts• Developing of customer-specific software/reports

Free for 12 month

KARIER Maintenance and support

Intelligent mine – key features

Technologies developing to create Intelligent mine:• GPS/GLONASS satellite navigation• Wireless broadband communications• Software• Robotics • Microelectronics

Intelligent mine is based on VIST Group Mine Fleet Management System VG Karier, which was awarded by the russian goverment in field of scince and technics

Intelligent mine allow to process unmanned mining works and:

•Increase mining operation productivity (15-25%)•Process mining works at harsh climatic conditions and remote regions•Solve the scarcity of labor problem in mining regions

•Wireless systems•Wire optical systems•Voice and video wireless systems

Communication system

•High precision GLONASS/GPS •3D vision system based on lidars, radars and digital cameras•On-board hardware and software for remote management and autonomous movement•Wireless system

Navigation system:

Onboard equipment

•Central system server for mine remote and autonomous management and process monitoring•Mining works analyze and management office

Software

Intelligent mine components

What is done

2010. Remote managed robotized mining truck based on BelAZ 75137 was successfully

shown at Belaz Autoworks

Nearest future:

2012. First robotized area in Siberia at coal mining enterprise will be developed

High precision navigation

Wireless system

Remote Control Center

Collision avoidance system

Remote Control hardware and

software

VIST Group107078, Dokuchaev pereulok, 3/1, Moscow, Russia

Tel.: + 7 (499) 975-2217, 975-3394, Fax: + 7 (499) 975-1846

http://eng.vistgroup.ru/

e-mail: [email protected]

Thank you for your attention!