Impact of Transient Simulations on Plunger Lift Operation

Transcript of Impact of Transient Simulations on Plunger Lift Operation

Impact of Transient Simulations on Plunger Lift Operation

Rahel Yusuf, Schlumberger

Kees Veeken, Shell

Bin Hu, Schlumberger

Outline

• Introduction

• Candidate well and flow model

• Results and Discussion

• Conclusions

Slide 2

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

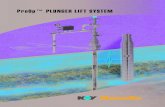

• Plunger lift is an artificial lift method mostly used to deliquify gas wells

• Plunger lift operation involves opening and closing of wellhead valveaccording to an optimum frequency to facilitate movement of plungerto surface alongwith liquid trapped above the plunger

• Low capital and maintenance cost

• Easy to install and operate

• Difficult to model as a transient modelling approach is required

Slide 3

Plunger Lift

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

Candidate Well

• Onshore gas well with inflow@ 2790 mAH

Slide 4

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

Transient Multiphase Flow Model

• A comprehensive transient multiphase simulator (OLGA) is used in the present work

• Simulator is based on three fluid model

• Solves five mass conservation equation and three momentum conservation equations

• Model has strong heat transfer calculations and solves a single energy balance for the fluid mixture

• Model extensively verified against laboratory and field data*

Slide 5

*Nossen, J., Shea, R. and Rasmussen J.: “New Developments in Flow Modeling and Field Data Verification”, 2nd North American Conference on Multiphase Technology, Banff, Canada, 21-23 June, 2000

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

Key Modeling Parameters

Slide 6

• 3.5” tubing to 2706 m, 7” liner to 2790 m

• Plunger between “launch” @ 2631m and “trap” @ 0

(Wellhead) and 93 m (SCSSV)

• A standing valve (SV) is placed at the plunger LAUNCH

position to prevent liquid escaping below the LAUNCH

position.

• Inflow @ 2790 , A=5.0 bara/(e3m3/d)

• Pres=15-18 bara, WGR=40-80 m3/e6m3,

• Wellhead pressure = 8 bara

• Plunger weight = 7.5 kg with zero leakage

• Plunger modelled as a PIG

• 10 plunger cycles with 2 hr flow, and1 hr shut-in

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

7

Temporal variation of different parameters for 10 plunger cycles

WGR=40, Pres=18, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

8

Temporal variation of different parameters for Cycle#9

WGR=40, Pres=18, Trap @SCSSV

Plunger Launched Plunger Trapped Well Shut-in

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

9

Profile plot of Tubing Holdup and Pressure@ 25.96 h

WGR=40, Pres=18, Trap @SCSSV

Standing Valve location

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

10

Profile plot of Tubing Holdup and Pressure@ 26.07 h

WGR=40, Pres=18, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

11

Profile plot of Tubing Holdup and Pressure@ 26.13 h

WGR=40, Pres=18, Trap @SCSSV

Standing Valve location

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

12

Profile plot of Tubing Holdup and Pressure@ 27.0 h

WGR=40, Pres=18, Trap @SCSSV

Standing Valve locationStanding Valve location

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

13

Profile plot of Tubing Holdup and Pressure@ 28.03 h

WGR=40, Pres=18, Trap @SCSSV

Standing Valve location

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

14

Profile plot of Tubing Holdup and Pressure@ 28.4h

WGR=40, Pres=18, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

15

Temporal variation of pressure at upstream and downstream of standing valve for

Cycle#9 with backpressure valve disabled

WGR=40, Pres=18, Trap @SCSSV

2.2bar

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

16

Temporal variation of gas rate and liquid content for different backpressure

threshold settings on backpressure valve: WGR=40, Pres=18, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

17

Zoomed in profile of tubing holdup at 28.9 h (cycle#9) with two

differential threshold pressure settings on backpressure valve

Standing Valve location

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

18

Temporal variation of different parameters for 10 plunger cycles

WGR=40, Pres=18, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

19

Temporal variation of different parameters for 10 plunger cycles

WGR=40, Pres=15, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

20

Temporal variation of different parameters for 10 plunger cycles

WGR=80, Pres=15, Trap @SCSSV

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

21

Temporal variation of different parameters for 10 plunger cycles

WGR=80, Pres=15, Trap @WH

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

Conclusions

• Transient multi-phase flow model produces credible results andprovides valuable insight into influence of well parameters andbackpressure valve settings on plunger performance

• Plunger needs to travel to top of tubing to deliver maximumvalue i.e. liquid slug cannot bridge large “gap”

• Gas production during upward travel must deliver minimumplunger velocity and will diminish as slug size increases

• Further explore the influence of plunger launch position,wellbore (plus annulus) volume, inflow performance

Slide 22

Rahel Yusuf for 9th European Gas Well Deliquification Conference & Exhibition in Groningen (Netherlands) on 22-24 September 2014

![THREE-DIMENSIONAL SIMULATIONS OF TRANSIENT ...people.sabanciuniv.edu/syesilyurt/papers/fc/IMECE2007...in the transient analysis [5-7]. Here, we present time-dependent three-dimensional](https://static.fdocuments.net/doc/165x107/60b83134af6790465d416b3a/three-dimensional-simulations-of-transient-in-the-transient-analysis-5-7.jpg)