Hydro Vise

Transcript of Hydro Vise

Design and fabrication of Hydro Pneumatic

Vise

ST. PETER`S UNIVERSITYAVADI, CHENNAI – 600 054

Faculty of Mechanical Engineering

Project Guide : Mr. P. BHAGAT SINGH M.E,

Project Members :

ASHWIN KANNA.K SARAVANA PRABU. N UDHAYA SHANKAR. K

VISWANATHAN. K

Introduction: This is a work holding device, which can be operated by the application of both hydraulic and pneumatic power applied together. It in turns provides a great scope of application to overcome the conventional methods.

Difficulties in conventional methods :

• In case of Pneumatic work holding device :-

* The Working pressure is limited to certain value, and in case of the requirement of pressure above the level, the vise is not suitable.

• In case of Hydraulic work holding device :-

* The components are quite noisy, and huge number of Fluid is required for the operation.

* The operation is little expensive comparing pneumatic systems. Though the power is negligible.

In order to overcome the difficulties of the conventional systems. We have designed a new system, which can solve the power and expenses problems.

Initially in this vise pneumatic components acts as a booster to the hydraulic and operation is thus achieved providing the required power, which is boosted from a optimum power.

Evolution of the Design

Hydro Pneumatic Vise – 2D diagram

Pneumatic circuit diagram

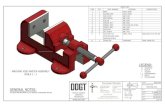

Basic Components of the Hydro Pneumatic Vise

• Base Plate• Cylinder Cap• Cylinder Cover• Cylinder Housing• Cylinder Mounting jacket• Fixed Jaw• Flange• Hydro operated cylinder• Intensifier Unit (Bottom plate, Connecting Rod, Piston)• Moving Jaw

Cylinder Cap

Base Plate

Cylinder Housing

Cylinder Cover

Fixed Jaw

Cylinder Mounting

Bracket

Moving Jaw

Hydro Operated

Cylinder

IntensifierTop Plate

Intensifier Bottom Plate

Intensifier assembly unit

MACHINING OF COMPONENTSFixed jaw & Movable jaw : * Raw material i.e M.S. of dimension 100 x 50 x 100 is purchased. * Milling M/C is used to machine the surface to achieve the required size of the component (78 x 50 x 70). Base Plate: * M.S plate of dimension 300 x 100 x 16. * Shaper M/C is used for the process.

Cylinder mounting bracket: * M.S of dimension 50 x 40 x 100 is machined using milling & drilling machines, where milling reduces the size and drilling used to drill the holes and to bore at the centre of the component.

Hydro operated cylinder: * M.S Rod of Ø42 x 150 is machined using lathe. Facing and turning operation is carried out. Boring is carried out at centre to make a bore.

Flange : * M.S. Rod Ø70 x 15 is machined using drilling M/C for making a drill and a bore.

S.NO PART NAME MATERIAL REQUIRED MATERIAL SIZE PURCHASED MATERIAL SIZE

1 Fixed Jaw M.S 78 x 50 x 70 100 x 50 x 100

2 Movable Jaw M.S 78 x 50 x 70 100 x 50 x 100

3 CYL Mounting Bracket M.S 50 x 30 x 70 50 x 40 x 100

4 Base Plate M.S 290 x 90 x 16 300 x 100 x 16

5 Cylinder Cap S.S Ø40 x 20 Ø40 x 20

6 Cylinder Cover AL Ø40 x 80 Ø40 x 80

7 Piston Rod AL Ø20 x 80 Ø20 x 80

8 KM-6 Lock Nut M.S Standard Standard

9 Intensfier Bottom Plate C.I 110 x 110 x30 110 x 110 x 40

10 Intensfier Top Plate C.I 110 x 110 x35 110 x 110 x 40

11 Intensfier Piston AL Ø96.5 x 30 Ø100 x 30

12 Intensfier Connecting Rod AL Ø18 x 185 Ø20 x 190

13 Hydraulic Operated Cylinder M.S Ø42 x 148.5 Ø45 x 150

14 Flange M.S Ø70 x 14 Ø70 x 15

15 Intensfier Cylinder Housing S.S Ø103 x 190 Ø105 x 200

16 M10 Screw rod M.S 270 270

17 M10 lock nut M.S Standard Standard

18 FRL Unit Standard Standard Standard

19 5/2 solenoid valve Standard Standard Standard

20 Oil Reservoir Agralic Standard Standard

21 R2 Type Hose R2 Standard Standard

22 Poly Tube Polyurithene Standard Standard

23 1/2" 6mm Hose Connector Standard Standard Standard

24 1/4" 6mm Male Stud Coupling Standard Standard Standard

25 1/8" 6mm Male Stud Coupling Standard Standard Standard

26 Pressure Gauge Standard Standard Standard

27 Lip Seal Nitrale Rubber Standard Standard

28 U Seal Nitrale Rubber Standard Standard

29 O Ring Nitrale Rubber Standard Standard

30 Fasteners

BILL OF MATERIALS

*ALL DIMENSIONS ARE IN mm.

WorkingWhen the air from the compressor enters the air cylinder through the inlet. It boost up the hydraulic fluid with the ratio about 30 :1.

Such that when an air pressure of 100 psi is sent , it may be boosted upto 150 bar by the hydraulic system thus provided.

About 200 ml oil is enough for the process., whereas a regular hydraulic system requires minimum of 5 liters for the actuation.

ADVANTAGES

It is more economical. High power can be obtained No such complications in assembly. Used to hold, rectangular , circular, and

square components. Highly reliable.

Applications•Can be used in Milling machine to hold the job.

•Can be used in drilling machines.

•Can be used in CNC machines.

Thank you