Hybrid circuit breaker

-

Upload

vishal-bhimani -

Category

Education

-

view

2.912 -

download

2

description

Transcript of Hybrid circuit breaker

L. E. College, Morbi

GUJARAT TECHNOLOGICAL UNIVERSITY

“HYBRID CIRCUIT BREAKER”

A Product survey Report On

SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE

AWARD OF THE DEGREE OF

BACHELOR OF ENGINEERING

Electrical Engineering

SUBMITTED TO:

L. E. COLLEGE, MORBI

SUBMITTED BY

Student Name Enrollment No.

1. Bhimani Vishal R. 100310109056

2. Patel Priyesh B. 100310109059

GUIDED BY:-

Prof. S. N. Purohit

Assi. Prof. Electrical Department

October 2013

1L.E. COLLEGE - MORBI

Lukhdhirji Engineering College, Morbi

Gujarat Technological University

CERTIFICATE

This is to certify that

1. Bhimani Vishal R. (100310109056)

2. Patel Priyesh B. (100310109059)

of final year Electrical Engineering students have satisfactorily and accurately completed

their project work entitled “Product survey on Hybrid Circuit Breaker” for the subject

code 170001 Project I in the 7th semester of academic year 2013-14 for the partial fulfilment

of the award of the Bachelor of Engineering in Electrical Engineering at Gujarat

Technological University.

DATE:-

PROF. S. N. PUROHIT PROF. A. K. JOSHI

PROJECT GUIDE HEAD OF DEPARTMENT

2L.E. COLLEGE - MORBI

ACKNOWLEDGEMENT

We owe a great many thanks to a great many people who helped and

supported us during the writing of this report. Our deepest thanks to

S.N.Purohit the Guide of the project for guiding and correcting various

documents of ours with attention and care. He has taken pain to go through the

project and make necessary correction as and when needed. We express our

gratitude to our head of the Department Prof A.K.JOSHI for his invaluable

support and encouragement at every stage. We also express our thanks to the

Principal Prof. P. C. Vasani , Lukhdhirji Engineering College, Morbi-2, for his

constant support and encouragement. We would also thank our Institution and

the faculty members without whom this project would have been a distant

reality.

Name Sign

Bhimani Vishal R.

Patel Priyesh B.

3L.E. COLLEGE - MORBI

ABSTRACT:

High Voltage Circuit Breaker (CB) is important electrical equipment used in the power

system network to isolate the faulty section from the healthy network and thus ensure safe

operation of the electrical system. Vacuum Circuit Breakers and SF6 Circuit Breakers are

widely used depending upon the power rating of the transmission line. The merits and

demerits of the two are reviewed and the need for hybrid model is analyzed.

The hybrid circuit breaker has at least two series-connected arcing chambers, which are

operated by a common drive via a transmission connected upstream from it. It is intended to

be possible to assemble this transmission easily in the interior of the hybrid circuit breaker.

This is achieved in that the transmission is formed from at least two transmission parts which

can be plugged together, with a first transmission part being firmly connected to the at least

one first arcing chamber and a second transmission part being firmly connected to the at least

one second arcing chamber. The transmission also has means which allow the movements of

the at least two arcing chambers to be technically suitably matched to one another and to be

optimized with respect to the time sequence and switching speed thereof.

A hybrid circuit breaker consists of a series-connected vacuum interrupter and sulfur

hexafluoride interrupter wherein the contacts of each are simultaneously operated. The sulfur

hexafluoride interrupter is of the type in which an arc is rapidly rotated through a relatively

static volume of sulfur hexafluoride. In one embodiment of the invention, the vacuum

interrupter is replaced by a second sulfur hexafluoride interrupter in which the arc gap

between the electrodes receiving the final arc to be interrupted is relatively smaller than the

corresponding arc gap in the other sulfur hexafluoride interrupter.

4L.E. COLLEGE - MORBI

INDEX: PAGE NO.

CHAPTER 1: INTRODUCTION…………………………………………….7

CHAPTER 2: HYBRID CIRCUIT BREAKER (AC)……………………….9

2.1:-DESIGN

2.2:-METHOD OF OPERATION

2.3:-CURRENT INTERRUPTION IN HYBRID MODES

2.4:-REQUIREMENTS AND OBJECTIVE

CHAPTER 3: HYBRID CIRCUIT BREAKER (HVDC)………………….14

3.1:-DESIGN OF HYBRID HVDC CIRCUIT BREAKER

3.2:-CIRCUIT DIAGRAM OF HYBRID CIRCUIT BREAKER

3.3:-PROTOTYPE DESIGN OF TH HYBRID HVDC C.B.

CHAPTER 4: TESTING OF HYBRID HVDC BREAKER………………19

4.1:-TEST RESULTS OF MAIN BREAKER

4.2:-TEST RESULTS OF HYBRID HVDC C.B.

CHAPTER 5: NEEDS OF HYBRID CIRCUIT BREAKER

AND SPECIFICATION………………….……………...24

5.1:-NEEDS OF HYBRID CIRCUIT BREAKER

5.2:-SPECIFICATION

5L.E. COLLEGE - MORBI

CHAPTER 6: ABOUT OF INVENSION…………………………………...27

6.1:-THE OBJECT OF INVENSION

6.2:-SUMMERY OF INVENSION

CHAPTER 7: ADVAMTAGES, DISADVANTAGES, AND COST

OF HYBRID CIRCUIT BREAKER………………………29

7.1:-ADVANTAGES

7.2:-DISADVANTAGES

7.3:-COST

CHAPTER 8: PHOTO OF HYBRID BREAKER…..…….……………....31

CONCLUSION

REFERANCE

6L.E. COLLEGE - MORBI

CHAPTER 1: INTRODUCTION

For many years various investigators have explored different approaches to develop a high

voltage direct current circuit breaker. Recently a joint effort by the Bonneville Power

Administration (BPA), Electric Power Research Institute (EPRI) and Brown Boveri

Corporation (BBC) resulted in the successful development and field testing of a practical,

500 kV, 2000A air - blast HVDC breaker. The primary focus of all HVDC breaker

development has been overcoming the problem of dc systems having no natural current zero.

In the familiar high voltage ac circuit breaker, the interruption process depends on the

naturally occurring cyclic instances of current zero. The breaker will typically arc through

high current periods making no attempt to clear until or about the current zero point,

whereupon it will then isolate the circuit. To obtain similar isolation in a dc circuit, it is

necessary to create a current zero point. Most of these methods create a current zero by active

or passive commutation of the direct current.

Active commutation methods have a capacitor, typically pre-charged, inserted across the

main interrupter element through some switching device. The surge current caused by the

insertion of this capacitor quickly drives the direct current in the interrupter to zero.

The present invention relates to a hybrid circuit breaker, comprising a first circuit that

comprises: a main current path which comprises a mechanical switch element, and at least

one commutation path arranged in parallel with the main current path and comprising a

controllable semi-conductor switch element. The invention also relates to an electric power

supply system comprising a hybrid circuit breaker according to the invention. The breaker is

an electric current breaker. In particular, it may form part of an AC electric power system. In

particular, it may form part of a medium or high voltage electric power system, medium or

high voltage being referred to as a voltage of 400 V or above. However, lower voltage

applications are not excluded. The mechanical switch element may comprise any type of

mechanical switch comprising first and second contact elements that are movable in relation

7L.E. COLLEGE - MORBI

to each other in connection to the switching operation thereof. Typically, the mechanical

switch comprises a mechanical circuit breaker.

Electric ships with Integrated Power Systems (IPS) can benefit from dc distribution

architectures that allow bi-directional power flow. One drawback has been the lack of

suitable dc circuit breakers that can operate at medium to high voltages and operate fast

enough to limit peak fault currents to acceptable levels.

General Atomics (GA) has developed a novel high voltage hybrid dc circuit breaker, Fig. that

employs a fast mechanical interrupter in parallel with a solid-state commutation circuit to

achieve short interrupt times for medium to high voltage systems.

The controllable semi-conductor switch element may be any kind of solid-state breaker based

on semi-conductor technology and of controllable character such as a controllable thyristor,

an IGBT (Insulated Gate Bipolar Transistor), an IGCT (Insulated Gate-Commutated

Thyristor) or a GTO, all well known within this field of technology. The expression

"controllable" indicates that the element in question opens or closes as soon as an appropriate

control is applied to it. Accordingly, in this regard, the controllable semi-conductor element

is an active element, or at least not passive.

8L.E. COLLEGE - MORBI

CHAPTER 2: HYBRID CIRCUIT BREAKER (AC)

2.1:-DESIGN:

The interrupter is fundamentally a very high performance pneumo-electromechanical device.

Aside from the initial magnetic impulsive force and the reclose/contact pressure operation,

the interrupter is essentially a passive device.

However, achieving the specified voltage breakdown recovery in the specified time depends

on a complex set of coupled nonlinear actions including:

The drive circuit energy store must have sufficient energy and the drive coil must

magnetically couple to the piston in a manner that propels the piston to establish an

adequate electric gap in the specified time.

The gas specie and initial gas pressure must fill the electric gaps in the specified time

with sufficient pressure to achieve the specified breakdown strength.

The inner cylinder volume and check valve design must dissipate the kinetic energy

of the piston to arrest and latch the piston open.

And, the gas system must allow for piston reclose on command and the establishment

of an adequate contact pressure to achieve low insertion loss.

A thorough understanding of all these actions is essential to ensuring that the interrupter is

properly designed and can meet the objective requirements. The design development was

necessarily model & simulation driven, relied heavily on finite element analysis (FEA) and

computational fluid dynamic (CFD) techniques and consisted of four key analytical efforts.

1. Piston Opening Dynamics

2. Electrostatic & Voltage Recovery Analysis

3. Piston Arrest & Latch Dynamics

4. Piston Structural & Friction Analysis

9L.E. COLLEGE - MORBI

Fig. Hybrid Circuit Breaker (AC)

2.2:-METHOD OF OPERATION:

When the interrupter receives a signal to “Open”, the interrupter controller sends a command

to the drive circuit triggering an electric discharge into the drive coil. The electric pulse in the

drive coil couples to the conducting face of the pistons which are accelerated away from the

electrodes under the Lorentz forces at very high speeds. As the contactor piston moves away

from the electrodes, the pressure builds in the inner cylinder until the check-valve opens

venting gas from the inner cylinder to the outer cylinders.

“close”, the interrupter controller signals the gas system to pump gas from the outer cylinder

to the volume of the inner cylinder between the check-valve and piston. The piston is pushed

toward the electrodes under gas pressure until

seated. When the contactor pistons are seated against the electrodes, the interrupter controller

signals the gas system to restore and maintain a specified pressure to ensure a good electrical

contact between the pistons and the electrodes.

The interrupter is now “closed” and ready to resume normal operations. The closing

sequence is illustrated in Fig. 4 „Closing Sequence‟ a-e.

10L.E. COLLEGE - MORBI

Fig. High-speed Interrupter Open/Close Sequence

11L.E. COLLEGE - MORBI

2.3:-CURRENT INTERRUPTION IN HYBRID MODEL:

The minimum arc duration are shorter in a vacuum interrupter as compared to the SF6

interrupter by several milliseconds. Hence it is preferable to open the SF6 interrupter initially

followed by the opening of vacuum interrupter with some delay of a few milliseconds. Since

there are two interrupters connected together therefore the currents can be interrupted by

each of the interrupters.

Interruption Initially By Vacuum Interruption:

In this case, current is first interrupted by the vacuum interrupter. This mode of operation is

observed at the highest current. Vacuum interrupter first transmits initial recovery voltage

peak value and the latter higher peak value is shared by SF6 interrupter as highlighted in fig.

As can be seen in fig. ,the vacuum arc extinguishes at current zero while the SF6 arc

continues to operate for the next 5usec and then after current zero 8 A post arc current flows

in the vacuum interrupters.

When the vacuum post arc current decays to zero then only the SF6 post arc current is

forcibly chopped to zero. Due to this, the arc voltage and current do not cross zero

simultaneously and the arc voltage is initially of opposite polarity.

Interruption Simutaneously By Vacuum And Sf6 Interrupter:

In this case, current is simultaneously interrupted by both vacuum and SF6 interrupters. This

mode of operation is typically observed in conditions in which current is less than maximum

current. Here, the performance of SF6 circuit breaker is reduced deliberately but it is

sufficient to do the job alone.SF6 post arc current is much smaller as compared to the

vacuum CB, so the SF6 interrupter stops the flow of vacuum arc charge. The post arc

vacuum charge remains trapped. This prevents the Transient Recovery Voltage (TRV) to

build up in vacuum interrupter until all the charges disappear Therefore the complete TRV is

carried by SF6 interrupter. The above operation can be easily seen in fig below. The

performance of the hybrid circuit breaker in the first mode is better than that in second mode.

12L.E. COLLEGE - MORBI

Fig. SF6 and vacuum interrupt simultaneously

2.4:-REQUIREMENTS AND OBJECTIVES:

In 2011, GA proposed to the US Department of Energy’s Advanced Research Projects

Agency (ARPA-e) and was awarded a contract to develop a high-speed, high voltage, low

insertion loss hybrid circuit breaker. The objective of the project was to develop a circuit

breaker that could achieve or exceed the technical performance measures listed in Table 1

and full circuit breaker open/latch/reclose functionality.

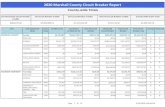

Table 1: Interrupter Requirements Description

Description Units Requirement

Normal Current: A 500

Interrupt Current, Max: kA < 3.5

Interrupt Time: s < 250

Rated Voltage: kV 125

Insertion Loss: W 1,000

13L.E. COLLEGE - MORBI

CHAPTER 3: HYBRID HVDC CIRCUIT BREAKER

3.1:-DESIGN OF HYBRID CIRCUIT BREAKER:

Recent studies focus on designing a hybrid circuit breaker operation mechanism with strong

controllability property and low dispersion degree. The former researchers have adopted an

operation mechanism that connects the two interrupters with the help of a connection rod or a

spring. This mechanism led to weak controllability property and low dispersion degree.

Depicts a hybrid circuit breaker based on fiber control vacuum CB connected in series with

SF6 CB.

A synchronized coordinate operation control unit which adjusts the coordination movements

of the two interrupters in microseconds is utilized in this scheme. The top bus terminal of

vacuum circuit breaker is connected with the bus input, and the end bus terminal box is

linked with top bus terminal of SF6 circuit breaker. The end bus terminal of SF6 circuit

breaker is connected to bus output, its operation mechanism and synchronization unit are

placed at low potential. The synchronization unit of hybrid circuit breaker receives system

control signal and perform synchronized operation to operate the vacuum circuit breaker and

SF6 circuit breaker respectively.

3.2;-CIRCUIT DIAGRAM OF HYBRID HVDC BREAKER:

As presented in Figure, the hybrid HVDC breaker consists of an additional branch, a bypass

formed by a semiconductor-based load commutation switch in series with a fast mechanical

disconnector. The main semiconductor-based HVDC breaker is separated into several

sections with individual arrester banks dimensioned for full voltage and current breaking

capability, whereas the load commutation switch matches lower voltage and energy

capability. After fault clearance, a disconnecting circuit breaker interrupts the residual

current and isolates the faulty line from the HVDC grid to protect the arrester banks of the

hybrid HVDC breaker from thermal overload.

14L.E. COLLEGE - MORBI

Fig. hybrid HVDC circuit breaker

During normal operation the current will only flow through the bypass, and the current in the

main breaker is zero. When an HVDC fault occurs, the load commutation switch

immediately commutates the current to the main HVDC breaker and the fast disconnector

opens. With the mechanical switch in open position, the main HVDC breaker breaks the

current.

The mechanical switch isolates the load commutation switch from the primary voltage across

the main HVDC breaker during current breaking. Thus, the required voltage rating of the

load commutation switch is significantly reduced. A successful commutation of the line

current into the main HVDC breaker path requires a voltage rating of the load commutation

switch exceeding the on-state voltage of the main HVDC breaker, which is typically in the

kV range for a 320 kV HVDC breaker. This

result in typical on-state voltages of the load commutation switch is in the range of several

volts only. The transfer losses of the hybrid HVDC breaker concept are thus significantly

reduced to a percentage of the losses incurred by a pure semiconductor breaker, i.e. 0.01% of

the transmitted power.

The mechanical switch opens at zero current with low voltage stress, and can thus be realized

as a disconnector with a lightweight contact system. The fast disconnector will be exposed to

the maximum pole-to-pole voltage defined by the protective level of the arrester banks after

15L.E. COLLEGE - MORBI

first being in open position while the main HVDC breaker opens. Thomson drives result in

fast opening times and compact disconnector design using SF6 as insulating media.

Proactive control of the hybrid HVDC breaker allows it to compensate for the time delay of

the fast disconnector, if the opening time of the disconnector is less than the time required for

selective protection. As shown in Figure, proactive current commutation is initiated by the

hybrid HVDC breaker`s built-in overcurrent protection as soon as the HVDC line current

exceeds a certain overcurrent level. The main HVDC breaker delays current breaking until a

trip signal of the selected protection is received or the faulty line current is close to the

maximum breaking current capability of the main HVDC breaker.

To extend the time before the self-protection function of the main HVDC breaker trips the

hybrid HVDC breaker, the main HVDC breaker may operate in current limitation mode prior

to current breaking. The main HVDC breaker controls the voltage drop across the HVDC

reactor to zero to prevent a further rise in the line current. Pulse mode operation of the main

HVDC breaker or sectionalizing the main HVDC breaker as shown in Fig. will allow

adapting the voltage across the main HVDC breaker to the instantaneous HVDC voltage

level of the HVDC grid. The maximum duration of the current limiting mode depends on the

energy dissipation capability of the arrester banks.

On-line supervision allowing maintenance on demand is achieved by scheduled current

transfer of the line current from the bypass into the main HVDC current breaker during

normal operation, without disturbing or interrupting the power transfer in the HVDC grid.

Fast backup protection similar to pure semiconductor breakers is possible for hybrid HVDC

breakers applied to HVDC switchyards. Due to the proactive mode, over-currents in the line

or superior switchyard protection will activate the current transfer from the bypass into the

main HVDC breaker or possible backup breakers prior to the trip signal of the backup

protection. In the case of a breaker failure, the backup breakers are activated almost

instantaneously, typically within less than 0.2 ms. This will avoid major disturbances in the

HVDC grid, and keep the required current-breaking capability of the backup breaker at

16L.E. COLLEGE - MORBI

reasonable values. If not utilized for backup protection, the hybrid HVDC breakers

automatically return to normal operation mode after the fault is cleared.

3.3:-PROTOTYPE DESIGN OF THE HYBRID HVDC BREAKER:

The hybrid HVDC breaker is designed to achieve a current breaking capability of 9.0 kA in

an HVDC grid with rated voltage of 320 kV and rated HVDC transmission current of 2 kA.

The maximum current breaking capability is independent of the current rating and depends

on the design of the main HVDC breaker only. The fast disconnector and main HVDC

breaker are designed for switching voltages exceeding 1.5 p.u. in consideration of fast

voltage transients during current breaking.

The main HVDC breaker consists of several HVDC breaker cells with individual arrester

banks limiting the maximum voltage across each cell to a specific level during current

breaking. Each HVDC breaker cell contains four HVDC breaker stacks as shown in Figure.

Two stacks are required to break the current in either current direction.

HVDC breaker cell

FIG. DESIGN OF 80KV MAIN HVDC BREAKER CELL

Each stack is composed of up to 20 series connected IGBT (insulated gate bipolar transistor)

HVDC breaker positions. Due to the large di/dt stress during current breaking, a mechanical

17L.E. COLLEGE - MORBI

design with low stray inductance is required. Application of press pack IGBTs with 4.5 kV

voltage rating enables a compact stack design and ensures a stable short circuit failure mode

in case of individual component failure. Individual RCD snubbers across each IGBT module

ensure equal voltage distribution during current breaking. Optically powered gate units

enable operation of the IGBT HVDC breaker independent of current and voltage conditions

in the HVDC grid. A cooling system is not required for the IGBT stacks, since the main

HVDC breaker cells are not exposed to the line current during normal operation.

For the design of the load commutation switch, one IGBT HVDC breaker module for each

current direction is sufficient to fulfill the requirements of the voltage rating. Parallel

connection of IGBT modules increases the rated current of the hybrid HVDC breaker. Series

connected, redundant IGBT HVDC breaker modules improve the reliability of the load

commutation switch. A matrix of 3x3 IGBT positions for each current direction is chosen for

the present design. Since the load commutation switch is continuously exposed to the line

current, a cooling system is required. Besides water cooling, air-forced cooling can be

applied, due to relatively low losses in the range of several tens of kW only.

18L.E. COLLEGE - MORBI

CHAPTER 4: TESTING OF HYBRID CIRCUIT

BERAKER

4.1:-TEST RESULTS MAIN BREAKER:

During the design of the hybrid HVDC breaker prototype, different tests were performed in

order to verify expected performance. The first test setup reported earlier focuses mainly on

the control of semiconductor devices and their current breaking capability. The second test

setup verifies both the voltage and current capability of one cell of the main HVDC breaker.

The ongoing extension of this test setup will focus on the overall performance of the hybrid

HVDC breaker. Due to big differences in voltage levels in the test setup, construction of the

test circuits is quite different but the test procedure is similar.

A scaled-down prototype of the main breaker cell with three series connected IGBT modules

and a common arrester bank was used to verify the current-breaking capability of 4.5 kV

StakPak IGBTs in the first test circuit as shown in Figure . A fourth IGBT module was

connected in opposite primary current direction to verify the functionality of the incorporated

anti-parallel diode. Discharge of a capacitor bank by a thyristor switch, limited only by a

minor DC reactor, represents pole-to-ground faults in the HVDC grid. The HVDC voltage

level prior to the fault and after fault clearance is less critical, since the voltage stress across

the IGBT HVDC breaker positions during current breaking depends on the applied arrester

bank only.

Fig. DC breaker Component test Circuit

19L.E. COLLEGE - MORBI

As shown in Figure, the maximum current breaking capability of the IGBT HVDC breaker

cell is determined by the saturation current of the applied IGBT modules rather than the safe

operation area (SOA) as is typical in voltage source converter applications. The series

connected HVDC breaker IGBT positions commutate the line current within 2 s

(microseconds) into the RCD snubber circuits, which limits the rate of rise in voltage across

the positions to 300 V/s. Zero voltage switching reduces the instantaneous switching losses

and ensures equal voltage distribution independent of the tolerances in the switching

characteristics of the applied IGBT modules.

The line current commutates from the RCD snubbed circuit into the arrester path after the

common voltage across the IGBT HVDC breaker positions reaches the protective level of the

arrester bank. The IGBT HVDC breaker positions passed the stress tests for breaking

currents below 10 kA. For higher currents, the IGBT saturation current level is reached by

the internal current limitation in the breaker, causing an immediate voltage drop across the

IGBT modules. During a purposely destructive test, the resulting internal heat dissipation

within the IGBT module destroys the encapsulated IGBT chips. Due to the use of press pack

IGBTs, a reliable short circuit without mechanical destruction of the failed IGBT module is

enabled. Since only one of the IGBT modules failed during the test, the fault can still be

cleared by the two other modules.

The nominal HVDC voltage per IGBT HVDC breaker cell is 80 kV. Due to the high voltage

level, the second test setup requires a significantly larger space. In Figure 7, the test circuit

for the hybrid HVDC breaker concept is shown. A ±150 kV HVDC switchyard supplies the

containerized test equipment to verify the functionality of the main IGBT HVDC breaker

represented by two series connected IGBT HVDC breaker stacks and a common arrester

bank. The desired HVDC voltage level is built up by charging the capacitor bank C1. The

reactor L1 is selected to give the expected current derivative (di/dt) during a short-circuit

fault. The short-circuit fault is initiated by the triggered spark gap Q5.

20L.E. COLLEGE - MORBI

Fig. DC Breaker Test Circuit

Figure, shows a typical test result. A maximum breaking current of over 9 kA is verified. The

voltage across the HVDC breaker cell exceeds 120 kV during current commutation. The

breaking capability of one 80 kV HVDC breaker cell thus exceeds 1 GVA. Furthermore,

equal voltage distribution with a maximum voltage drop of 3.3 kV and a spread of less than

10 percent was only observed for the individual IGBT HVDC breaker positions in the HVDC

breaker cell.

21L.E. COLLEGE - MORBI

4.2:-TEST RESULTS HYBRID HVDC BREAKER:

The main breaker test setup described in Section 5 and reported earlier was expanded to

verify the complete hybrid HVDC breaker concept. A second capacitor bank and large

reactors were installed to limit the rate of line current rise to typical HVDC grid values. The

ultra-fast disconnector and load commutation switch are included in the system

configuration.

Successful verification testing at device and component level has proven the performance of

the components. The complete hybrid HVDC breaker has now been verified in a

demonstrator setup at ABB facilities. The diagram in Figure 9 shows a breaking event with

peak current 9 kA and 2 ms delay time for opening the ultra-fast disconnector in the branch

parallel to the main breaker. The maximum rated fault current of 9 kA is the limit for the

existing generation of semiconductors. The next generation of semiconductor devices will

allow breaking performance of up to 16 kA. The purpose of the tests was to verify switching

performance of the power electronic parts, and the opening speed of the mechanical ultra-fast

disconnector. The test object consisted of one 80 Kv unidirectional main breaker cell, along

with the ultra-fast disconnector and load commutation switch. The higher voltage rating is

accomplished by connecting in series, several main breaker cells, but the switching stress per

cell is the same as in the demonstrator. This series connection approach is also used to test

conventional HVDC Light and HVDC Classic valves. Tests have not only been carried out

for normal breaking events, but also for situations with failed components in the breaker, in

order to verify reliable detection and safe operation in such cases.

22L.E. COLLEGE - MORBI

Fig, Verification of the hybrid HVDC breaker system

23L.E. COLLEGE - MORBI

CHAPTER 5: NEED OF HYBRID CIRCUIT BREAKER

AND SPECIFICATION

5.1:-NEEDS OF HYBRID CIRCUIT BREAKER

The ongoing research in the field of High Voltage Engineering focuses on the modeling of

Hybrid circuit breakers, which in the future have the potential to take over SF6 circuit

breakers. The vacuum interrupters have the ability to recover the dielectric strength across

the interrupting gap at the time of current zero. In case of vacuum arc mode, the dielectric

recovery is the fastest. Figure 1 indicates the comparison of dielectric strength recovery

speed between SF6 interrupter and vacuum interrupter when the gap is 6.35mm breaking

current 1600A, 180A vapor pressure. The rate of rise of vacuum recovery voltage is 20kV/us

which is faster than SF6. This type of CB has the following shortcomings:

Random dielectric breakdown across the open contacts of the CB can occur under

continuous voltage stress which can lead to energizing the system to be isolated. This

breakdown occurs for about one cycle of the system frequency.

The butt contacts of the CBs, may bounce or close. Due to the multiple make and

break operations occurring in the circuit, the voltage produced may reach above the

insulation level of the system and the equipment.

Vacuum interrupters have the tendency to chop the current as it reaches zero during

circuit interruption .High voltages comparable to the system voltage but less than the

insulation level are generated due to chopping .

The interrupting gap in SF6 CBs has high dielectric recovery capability along with

thermal recovery and high dielectrics withstand capability under continuous voltage

stress. This characteristic helps to prevent the random breakdown of the gap by

isolating the vacuum CB from the system. SF6 has wiping contacts of tulip and

24L.E. COLLEGE - MORBI

bayonet type. SF6 arc resistance is higher than that of vacuum arc resistance. Thus in

the hybrid model SF6 CB bears the main voltage drop and works in conjunction with

vacuum CB to complete current interruption. These contacts make the circuit without

any bounce and thus no multiple system energisations will occur.

The hybrid circuit breaker has the following advantages over SF6 and vacuum CBs:

This type of breaker has the capability of switching short line faults at high voltage.

High operating force is not required and the size and the cost of the breaker reduces

Various standard design of this type are available which can be applied to free

standing breakers and compact substation breakers.

It has an excellent capability to deal with the steep-rising transient recovery voltage

(TRV).

A basic interrupting module can be formed which is rated at 145kV or more.

Fig. the comparison of dielectric recovery speed between

SF6 interrupter and vacuum interrupter

25L.E. COLLEGE - MORBI

5.2:-SPECIFICATION

Table 3: Specification of hybrid circuit breaker

System Voltage Interrupter Opening Time Breaker Interrupt Time

325 Kv 240 s 340 s

125 130 230

50 85 185

7 65 165

26L.E. COLLEGE - MORBI

CHAPTER 6: ABOUT OF THE INVENTION

6.1:-OBJECT OF THE INVENSION

It is an object of the present invention to present a hybrid circuit breaker which works on the

principle of keeping the voltage across a mechanical switch thereof sufficiently low to

prevent arcing between the contacts of the mechanical switch in connection to its switching

operation.

A hybrid circuit breaker which can be used in an electrical high-voltage network. This hybrid

circuit breaker has two series-connected arcing chambers, a first of which is filled with

sulfahexafluoride gas as a quenching and insulating medium, and a second of which is in the

form of a vacuum interrupter chamber. The second arcing chamber is surrounded by

sulfahexafluoride gas on the outside. The main contacts of the two arcing chambers are

operated simultaneously by a common drive via a simple lever transmission. Both arcing

chambers have a power current path, in each of which the erosion-resistant main contacts are

located and, in parallel with this, a rated current path, with this rated current path having only

a single interruption point. During disconnection, the rated current path is always interrupted

first of all, after which the current to be disconnected commutates onto the power current

path. The power current path then continues to carry the current until it is definitively

disconnected.

Simple lever transmissions such as these are comparatively difficult to match to the

movement profiles required in hybrid circuit breakers. Furthermore, the bearing points are

subject to mechanically very severe stresses, which results in the bearing points having a

complex and expensive design, as a result of which the hybrid circuit breaker price is

increased. If this configuration of the bearing points is dispensed with, then the time penalty

for the maintenance work which is then required more frequently restricts the availability of

the hybrid circuit breaker in a disadvantageous manner. Furthermore, the complexity for

27L.E. COLLEGE - MORBI

installing the lever transmission in the interior of the hybrid circuit breaker is comparatively

great, owing to the restricted accessibility in this area.

6.2:-SUMMARY OF THE INVENTION

The invention, as it is characterized in the independent claims, achieves the object of

providing a hybrid circuit breaker having a transmission, which can be joined together easily

in the interior of the hybrid circuit breaker.

The hybrid circuit breaker has at least two series-connected arcing chambers, which are

operated by a common drive. These arcing chambers are preceded by a common

transmission. This transmission has at least two transmission parts, which are designed such

that they can be plugged together, with the first transmission part being firmly connected to

the at least one first arcing chamber, and the second transmission part being firmly connected

to the at least one second arcing chamber. The transmission has means which allow the

movements of the at least two arcing chambers to be technically sensibly matched to one

another and to be optimized with respect to the time sequence and switching speed thereof. It

has been found to be particularly advantageous for the transmission to be designed such that

it is self-locking both in the connected position and in the disconnected position since this

means that there is no need for any additional locking apparatus or catches. Furthermore, the

drive does not need to apply any particular holding forces in the two limit positions, so that a

simple and particularly low-cost drive can be used here.

The longitudinal axes of the two arcing chambers in one preferred embodiment of the hybrid

circuit breaker lie in one plane and are inclined at an angle α to one another, with the angle α

being less than 90°, and preferably being in the range between 68° and 800°. This

arrangement of the arcing chambers makes it possible to produce a hybrid circuit breaker

which has a comparatively short extent in the axial direction, so the space required for this

hybrid circuit breaker is particularly small.

The further refinements of the invention are the subject matter of the dependent claims.

28L.E. COLLEGE - MORBI

The invention, its development and the advantages which can be achieved by it are explained

in more detail in the following text with reference to the drawing, which illustrates only one

possible embodiment approach.

CHAPTER 7: ADVANTAGES, DISADVANTAGES,

AND COST OF HYBRID BREAKER

7.1:-ADAVANTAGES

1. Arc-less interruption

2. Required fault current handling capability of the mechanical contacts can be

reduced.

3. Turn-on at lower fault current compared with the conventional hybrid breaker

4. Lower turn-off current.

5. The solid-state device must handle (dissipate) comparably lower energy.

6. Compact solution, the solid-state device is not as bulky as in the case of the

conventional hybrid breaker.

7. Lower temperature rise in the solid-state device due to lower peak current.

8. Current limiting ability

9. Can be used in both AC and DC current interruptions.

10. Lower varistor rating is required.

11. Overall turn-off process completes earlier.

12. Comparably lower commutation time possible.

13. Possible reduction of the conduction time of the solid-state breaker.

14. The connected network components don't need to be rated with respect to short-

time very high fault current-handling capability.

29L.E. COLLEGE - MORBI

7.2:-DISADVANTAES

High cost

Complex design

Construction under process

7.3:-COST OF HYBRID CIRCUIT BREAKER

No. Capacity rating Prize(Rs)

1 Up to 11 kv 2000

2 Up to 121 11,000

3 Up to 500 kv 22,000

4 Up to 2000 A 50,000 (around)

30L.E. COLLEGE - MORBI

CHAPTER 8: PHOTO OF HYBRID CIRCUIT

BREAKER

LIST OF DESIGNATIONS:

1 First longitudinal axis

2 Second longitudinal axis

3 Drive linkage

4 Bolt

5 Contact rod

6 Enclosure

7 Slot

8 Roller

9 Bolt

10 Rotation axis

11 Surface

31L.E. COLLEGE - MORBI

12 Slotted guide disk

13 Bolt

14 Guide enclosure

15 Slot

16 Rotation axis

17, 18 Insulating enclosure

19 Bolt

20 Double lever

21 Bolt

22 Drive rod

23 Flange

24 Stop part

24a, 24b Shoulder

25 Collar

26 Cup spring pack

27 Step

28 Arrow

29 Transmission

30, 31, 32 Arrow

33 Curved surface

34 Planar surface

35 Guide tube

36 Slot

37 Collar

38 Slotted guide part

39 Slot

40 Guide slot

41 Bolt

42 Dashed line of action

42a, 42b Section

43 Holder

32L.E. COLLEGE - MORBI

44 Union nut

a Angle

b Angle

R Radius of curvature

CONCLUSION

From the testing it is observed that the initial peak of the transient recovery voltage falls

across the vacuum interrupter and the later much higher peaks are taken by the SF6

interrupter. In this way both the SF6 interrupter and the vacuum interrupter assist each other.

The vacuum interrupter capability to withstand the steep rate of rise of recovery voltage

reduces the pressure of SF6 gas in SF6 interrupter. Hence it can be concluded that the

breaking capacity of the hybrid circuit breaker is more than that of the SF6 circuit breaker. In

the future, it can be seen as a great alternative of SF6 circuit breaker in high voltage

applications.

33L.E. COLLEGE - MORBI

REFERANCE:

[1] E. Koldby, M. Hyttinen “Challenges on the Road to an Offshore HVDC Grid,” (Nordic

Wind Power Conference, Bornholm, Sept. 2009)

[2] Å. Ekström, H. Härtel, H.P. Lips, W. Schultz “Design and testing of an HVDC circuit

breaker,” (Cigré session 1976, paper 13-06)

[3] C.M. Franck “HVDC Circuit Breakers: A Review Identifying Future Research Needs,”

(IEEE Trans. on Power Delivery, vol. 26, pp. 998-1007, April 2011)

[4] J. Magnusson, O. Hammar, G. Engdahl “Modelling and Experimental Assessment of

Thomson Coil Actuator System for Ultra Fast Mechanical Switches for Commutation of

Load Currents,” (International Conference on New Actuators and Drive Systems, Bremen,

14-16 Juni 2010)

[5] G. Asplund “HVDC switch for current limitation in a HVDC transmission with voltage

source converters,” (European Patent EP0867998B1)

[6] S. Eicher, M. Rahimo, E. Tsyplakov, D. Schneider, A. Kopta, U. Schlapbach, E. Caroll

“4.5kV Press Pack IGBT Designed for Ruggedness and Reliability,” (IAS, Seattle, October

2004)

[7] M. Rahimo, A. Kopta, U. Schlapbach, J. Vobecky, R. Schnell, S. Klaka “The Bi-mode

Insulated Gate Transistor (BiGT) A potential technology for higher power applications,”

(Proc. ISPSD09, p. 283, 2009)

[8] J. Häfner, B. Jacobson, ” Proactive Hybrid HVDC Breakers - A key innovation for

reliable HVDC grids,” (Cigré Bologna, Paper 0264, 2011)

34L.E. COLLEGE - MORBI

[9] J . J . V i t h a y a t h i l , "HVdc Breaker and i t s Application", Proceedings o f the I n t e

r n a t i o n a l Symposium on HVdc Technology, Rio de Janeiro, B r a z i l , March 20-25,

1983

[10] B. Bachmann, G. Mauthe, E. Ruoss, H.P. Lips, J.W. Porter and J.J. V i t h a y a t h i l ,

"Development o f a 500 kV A i r b l a s t HVdc C i r c u i t Breaker", IEEE Transactions on

Power Apparatus and Systems, Vol. 104, No. 9, September 1985, pp. 2460-2466.

[11] J.J. V i t h a y a t h i l , A.L. Courts, W.G. Peterson, N.G. Hingorani, S . Nilson and J.W.

Porter, "HVdc C i r c u i t Breaker Development and F i e l d Tests", IEEE Transactions on

Power Apparatus and Systems, Vol. 104, No. 10, October 1985, pp, 2693-2705.

[12] A, Lee, P.G. Slade, K.H. Yoon, J. Porter and J. V i t h a y a t h i l , "The Development o

f a HVdc sF6 Breaker", IEEE Transactions on Power Apparatus and Systems, Vol. 104, No.

10, October 1985, pp. 2721-2729.

[13] D. Goldsworthy and J.J. V i t h a y a t h i l , "EMTP Model o f an HVdc Transmission

System", Proceedings of the IEEE Montech '86 Conference on HVdc Power Transmission,

September 29 - October 1, 1986, pp. 39-46.

[14] J.D. Cobine, "Gaseous Conductors, Theory and Engineering Applications", Dover Pub1

i c a t i o n s , Inc. New York. pp. 344-348.

[15] K. Ragaller, A. Plessl, W. Hermann, W. Egli, "Calculation Methods f o r ,;he Arc

Quenching System o f Gas Circuit-Breakers , CIGRE Report 13-03, 1984.

[16] E. Bross, H. Schubert, "The DLF Range o f High Voltage A i r b l a s t C i r c u i t

Breakers; Design Performance, Applications", Brown Boveri Review 65,1978

WEBSITE:

www.sumobrain.com/patents/wipo/Hybrid-circuit-breaker/WO2011044928.html

www.freepatentsonline.com/6727453.html

www.siemens.com/energy

35L.E. COLLEGE - MORBI