HTS Rotating Machines 050303

Transcript of HTS Rotating Machines 050303

-

7/29/2019 HTS Rotating Machines 050303

1/63

11

The State of SuperconductingThe State of Superconducting

TechnologyTechnologyPresented atPresented at

US Naval Graduate SchoolUS Naval Graduate School

Monterey, CaliforniaMonterey, California3 March 20053 March 2005

Dr. Swarn Kalsi

American Superconductor Corporation

Westborough, MA 01581

-

7/29/2019 HTS Rotating Machines 050303

2/63

22

ContentsContents

Enabling Technologies

Applications

-Magnets

- Power Cables

- FCL and Transformers

-

Rotating Machines Future

-

7/29/2019 HTS Rotating Machines 050303

3/63

33

Enabling TechnologiesEnabling TechnologiesStatus of Wire: SuperconductorsStatus of Wire: Superconductors

Discovered in 1911

Perfect conductors of electricity

Require cryogenic cooling

Low Temperature Superconductor (LTS) metallicwires used in MRI near 4 K

New, ceramic HTS material discovered in 1986

HTS requires less cooling

operation at >77K at low field

30-40K in motor applications

< 1/10 the energy required for 4K refrigeration

HTS enhances commercial economics

-

7/29/2019 HTS Rotating Machines 050303

4/6344

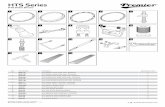

Enabling TechnologiesEnabling TechnologiesWire ArchitecturesWire Architectures

Generation IGeneration I Generation IIGeneration II

BiBi22SrSr22CaCa11CuCu22OO YY11BaBa22CuCu33OO

0.0100.010

0.160.16

Multi-Filamentary Composite

(AMSC commercial, in production)

Coated Conductor Composite

(AMSC second generation, under development)

Second Generation Goal: Form-Fit-Function replacement at same performance,

with 2-5x lower cost

-

7/29/2019 HTS Rotating Machines 050303

5/6355

Enabling TechnologiesEnabling Technologies1G HTS Wire Fabrication Process1G HTS Wire Fabrication Process

Heat TreatmentRolling

Deformation

Deformation

Deformation

DeformationPowder Production Sealing in Billet Deformation

Rebundling

Part 1:

PrecursorFabrication

Part 2:Microstructure

Engineering

Multi-DieDeformation

-

7/29/2019 HTS Rotating Machines 050303

6/6366

Enabling TechnologiesEnabling TechnologiesStatus of Wire: Generation IStatus of Wire: Generation I

Stainless Steel

HTS insert tape

Solder

Filament

Silver

{

abr

abt

c-axis

z Key Application Requirements

Performance ~ 15,000 A/cm2 (insert)

Strain Tolerance > 0.2% (design for 0.015%)

Field

1.25-3.5 T c

2.5-6 T abt

Fatigue Tolerant

Temperature ~35K

Other Factors - 100% testedz Status

Laminated Bi2223

available as a 100% tested material

4.85 x 0.305 mm

Fatigue validated by NRL and NHMFL

Bi2223

Gen I

Gen I wire meets todays needs

-

7/29/2019 HTS Rotating Machines 050303

7/6377

Enabling TechnologiesEnabling TechnologiesCoated Conductor Fabrication ProcessCoated Conductor Fabrication Process

Substrate Production

Buffer Deposit ion

YBCO FormationYBCO Precursor

Coating

-

7/29/2019 HTS Rotating Machines 050303

8/6388

Enabling TechnologiesEnabling TechnologiesStatus of Wire: Future DevelopmentsStatus of Wire: Future Developments

SuperconductorCoating

BufferLayer

AlloySubstrate

Coated Conductor

Gen II

Generation II Wires can bemanufactured by low costprocesses

Form Fit Function replacementfor Generation I wire

Gen II wire will further reduce system cost

-

7/29/2019 HTS Rotating Machines 050303

9/6399

Enabling TechnologiesEnabling TechnologiesLeading in HTS Wire ManufactureLeading in HTS Wire Manufacture

Worlds first commercial HTS wire plantnow in operation

First sales of HTS wire from new plantin J anuary 2003

Currently facilitated for 1,400,000 m per

year with 20,000,000 m ultimate annualcapacity

Designed to meet high volume demandat minimum cost

Volume upgradeable with small capitalinvestment

Devens HTS Wire Plant

Orders for over 700,000 meters received since January 2003

-

7/29/2019 HTS Rotating Machines 050303

10/63

1010

Enabling TechnologiesEnabling Technologies

1 G Wire Composite Critical Current Surface1 G Wire Composite Critical Current Surface

20

35

64

50

77

70

0

1

2

3

4

5

6

0 0.5 1 1.5 2 2.5

Magnetic F ield (Tesla)

Ic(T,

B)/Ic(77K,

0T)

77 K

70 K

64 K

50 K35 K

20 K

The crit ical current improves as the temperature decreases

NormalizedCurrentCapac

ity

-

7/29/2019 HTS Rotating Machines 050303

11/63

1111

Enabling TechnologiesEnabling TechnologiesCooling the New SuperconductorsCooling the New Superconductors

Temperature, Kelvin Scale

Relative

Cost ofCooling

20 40 60 800

LTS HTS

COTS Refrigerators

HTS Motors and Generators

HTS enables reliable and cost effective cool ing

E bli T h l iE bli T h l i

-

7/29/2019 HTS Rotating Machines 050303

12/63

1212

Winding operating temperature ~ 20-40Kprovides optimal cost/performance balance.

Gifford McMahon cryocooler output at 30 K has

improved by nearly a factor of 4 over the past 5years.

MTBF of similar GM coolers exceeds 9 years

Enabling TechnologiesEnabling TechnologiesRefrigerationRefrigeration

762mm

610mm

610mm

Electrical Line

Water

Lines

Gas Lines

To Cold Head 762mm

610mm

610mm

Electrical Line

Water

Lines

Gas Lines

To Cold Head

High Capacity Single Stage GM Cooler

Cold Head

Compressor

Heat ExchangerBlock

Vacuum Flange

Cold Head

Bellows Seal

Tension BoltGas LineCouplings

Heat ExchangerBlock

Vacuum Flange

Cold Head

Bellows Seal

Tension BoltGas LineCouplings

CryoMechCryoMech

-

7/29/2019 HTS Rotating Machines 050303

13/63

1313

HTS TransformersHTS Transformers

-

7/29/2019 HTS Rotating Machines 050303

14/63

1414

Waukesha/SuperPower ObjectivesWaukesha/SuperPower Objectives

Phase II is now completePhase II is now complete

-

7/29/2019 HTS Rotating Machines 050303

15/63

1515

Other ProgramsOther Programs

Other transformer programs are;

- CAS/TBEA (China)

-BHEL (India)

- Condumex (Mexico)

-

7/29/2019 HTS Rotating Machines 050303

16/63

1616

HTS MagnetsHTS Magnets

-

7/29/2019 HTS Rotating Machines 050303

17/63

1717

HTS Magnet Progress OverviewHTS Magnet Progress Overview

HTS Mi i M tHTS Mines eeping Magnet

-

7/29/2019 HTS Rotating Machines 050303

18/63

1818

HTS Minesweeping MagnetHTS Minesweeping Magnet1818--in Bore x 36in Bore x 36--in Longin Long

Largest HTS magnet in size

Light weight and highestmagnetic moment were maindrivers

Coil generates a peak field of ~1 tesla in the bore whileoperating at ~ 35 K

Conduction cooled with acryocooler

Field can be varied at 1 Hz

continuously

This prototype magnet was delivered to Navy in 2002

Magnetic Separation MagnetMagnetic Separation Magnet

-

7/29/2019 HTS Rotating Machines 050303

19/63

1919

Magnetic Separation MagnetMagnetic Separation MagnetWarm bore magnetWarm bore magnet

BSCCO-2223 magnet designedfor continuous operation

HTS magnet generates ~ 3tesla field in warm bore whileoperating at ~ 35 K

Conduction cooled with acryocooler

Magnet can be used forcleaning ballast water beforedischarging in to the sea

Factory tested magnet was delivered to Du Pont in March 2004

-

7/29/2019 HTS Rotating Machines 050303

20/63

2020

Other HTS Magnet ProgramsOther HTS Magnet Programs

Central J apan Railway - Maglev (J apan)

Brookhaven - Accelerator (USA)

FZK - Research (Germany) Nuclear Science Centre - Ion Source (India)

National Institute for Fusion Science - Fusion (J apan)

Pantechnik - Ion source (France)

Tai-Yang Research - NASA (USA)

Wang NMR - NMR insert (USA)

Cryomagnetics - Defense (USA)

HTS-110 - Defense (New Zealand)

CESI - Research (Italy)

CERN - Current Leads (Switzerland)

-

7/29/2019 HTS Rotating Machines 050303

21/63

2121

HTS Electric Power CablesHTS Electric Power Cables

500 m Cable Test Site in500 m Cable Test Site in YokosukaYokosuka, Japan, Japan

HTS Power CablesHTS Power CablesHTS Power Cables

-

7/29/2019 HTS Rotating Machines 050303

22/63

2222

HTS Power CablesFeaturesHTS Power CablesHTS Power CablesFeaturesFeatures

Power Carrying Capabilities 3x to 9x Greaterthan Copper Cables

HTS Wire Enables a Core Geometry that

Provides Low Conductor Resistance

Low Inductance

Environmental Compatibility

Underground Placement

No Electromagnetic Field

Thermally Independent of Environment

Nitrogen Cooling Fluid (Inert) No Oil

XLPE Cables

1000A 5000A2000A 3000A 4000AAC CURRENT

AC High Capacity VLI Cables

HTS Power CablesHTS Power CablesHTS Power Cables

-

7/29/2019 HTS Rotating Machines 050303

23/63

2323

HTS Power CablesLIPA Project DataHTS Power CablesHTS Power CablesLIPA Project DataLIPA Project Data

Long Island Power Authority East Garden City Substation

Electrical Operating Characteristics

Operating Voltage/Current 138kV/2400A ~ 600MVA

Design Fault Current 69,000A @ 15 line cycles (250ms) Physical Characteristics

Length 610m

HTS Conductor Length 128km

Cold Dielectric Design Hardware Deliverables

Three 610m long Phase Conductors

Six 161kV Outdoor Terminations & Accessories

One 161kV Splice One Refrigeration System + Pulse Tube System

Commissioning - 2005

Worlds First Installation of a Transmission Voltage HTS Cable in the World

-

7/29/2019 HTS Rotating Machines 050303

24/63

2424

Other HTS Power Cable ProgramsOther HTS Power Cable Programs

IGC/SEI - Albany

AMSC/Nexans - Long Island

Ultera - Columbus

KERI/LG Cable - S. Korea

Condumex- Mexico City

CAS/Chang Tong - China InnoPower - China

KEPRI/SEI - S. Korea

KERI/LG Cable #2 - S. KoreaTratos - Italy

Nexans 2G Cable - Spain

-

7/29/2019 HTS Rotating Machines 050303

25/63

2525

HTS Fault Current LimitersHTS Fault Current Limiters (FCL)(FCL)

Limit fault current during a shortLimit fault current during a short--circuitcircuit

HTS Fault Current LimitersHTS Fault Current Limiters

-

7/29/2019 HTS Rotating Machines 050303

26/63

2626

HTS Fault Current LimitersHTS Fault Current LimitersApplicationsApplications

Fault current limiting at:- Bus-tie

- IPP interconnection

- Transformer

-Feeder

- Closing open loop

In-rush current controller for self-start induction and synchronousmotors

IPP

Bus-tieFCL

138 kV

30 MVA

15 kV

HTS FCLs have many potential applications

HTS Fault Current LimitersHTS Fault Current LimitersHTS Fault Current Limiters

-

7/29/2019 HTS Rotating Machines 050303

27/63

2727

HTS Fault Current LimitersAn HTS FCL Concept for 15 kVHTS Fault Current LimitersHTS Fault Current Limiters

An HTS FCL Concept for 15 kVAn HTS FCL Concept for 15 kV

1250 A steady-state current

2G wire with high normal resistivity

YBCO

AMSC/Siemens joint development program

CB

LI MI TER

CABLE

CB

RT RESI STANCE

HTS

LI MI TER

CABLE

FCLFCLAssemblyAssembly

ShuntShunt

SeriesSeries

-

7/29/2019 HTS Rotating Machines 050303

28/63

2828

Other FCL ProgramsOther FCL Programs

IGC/Nexans

AMSC/Siemens

CAS/Beijing Superconductor (China)

Yonsei University (Korea)

KEPRI (Korea)

Bar Ilan/Ricor (Israel)

HTS Rotating MachineryHTS Rotating Machinery

-

7/29/2019 HTS Rotating Machines 050303

29/63

2929

g yg yProgress Towards CommercializationProgress Towards Commercialization

Rockwell/Reliance MotorRockwell/Reliance Motor0.7 MW, 1800 rpm0.7 MW, 1800 rpm

Siemens MotorSiemens Motor

0.45 MW, 1500 rpm0.45 MW, 1500 rpm

AMSC MotorAMSC Motor3.5 MW, 1800 rpm3.5 MW, 1800 rpm

AMSC Sh ip MotorAMSC Sh ip Motor5 MW, 230 rpm5 MW, 230 rpm

Test

GE GeneratorGE Generator1.8 MVA, 3600 rpm1.8 MVA, 3600 rpm

AMSC Synchronous CondenserAMSC Synchronous Condenser8 MVA, 1800 rpm8 MVA, 1800 rpm

AMSC Ship MotorAMSC Ship Motor

36.5 MW, 120 rpm36.5 MW, 120 rpm

Siemens GeneratorSiemens Generator4 MW, 3000 rpm4 MW, 3000 rpm

GE GeneratorGE Generator100 MVA, 3600 rpm100 MVA, 3600 rpm

1999 2000 2001 2002 2003 2004

Advantages: 2-4x reduced size/weight, 2x better efficiency, 2-4x higherreactive power, high overload, low noise

-

7/29/2019 HTS Rotating Machines 050303

30/63

3030

Other HTS Rotating Machine ProgramsOther HTS Rotating Machine Programs

5MW Navy Motor - AMSC

36.5MW Navy motor - AMSC

4MVA generator - Siemens

100 MVA generator - GE

5 MVA airborne generator - Lockheed-Martin2G motor - Rockwell/Reliance

8MVAR Condenser - AMSC

0.1MW marine motor - TUMST (J apan)

1000hp motor - KERI

-

7/29/2019 HTS Rotating Machines 050303

31/63

3131

HTS Electric MachinesHTS Electric Machines

Design FeaturesDesign Features

Electric Machine DesignElectric Machine Design

-

7/29/2019 HTS Rotating Machines 050303

32/63

3232

ggHTS Machine TopologyHTS Machine Topology

Output ShaftCryogenic Cooling Loop

Current Leads

Back Iron

Vacuumchamber

Rotor coils

EM Shield

Brushless Exciter

Stator coils

Support Structure

Multi-Layered Insulation

Stator Support Tube

Housing

Cooler Module

Multi phase synchronous air coremachine

HTS in DC rotor field only

Rotor is vacuum insulated Refrigeration in the stationary reference

frame

Copper Litz armature (>room temp)

Low reactance due to large air-gap

Removal of iron teeth plus ~zero rotorI2R yields high efficiency

High rotor and stator current densityyields high power density

Lack of iron teeth removes a majorsource of vibration yielding lowstructure borne noise

Uses any drive suitable for asynchronous machine

PM &

Conventional

Air

Core

HTS

-

7/29/2019 HTS Rotating Machines 050303

33/63

3333

Benefits of HTS MachinesBenefits of HTS Machines

Benefits of HTS MachinesBenefits of HTS Machines

-

7/29/2019 HTS Rotating Machines 050303

34/63

3434

Characteristics of an HTS GeneratorCharacteristics of an HTS Generator

For a 50 MW, 3600 RPM, 60 Hz Generator withFor a 50 MW, 3600 RPM, 60 Hz Generator withpower factor capability of 0.8 lag to 0.8 leadpower factor capability of 0.8 lag to 0.8 lead

Stator Copper

65%Stator Cooler

3%

Iron Core

24%

F&W

6%

HTS Ref.2%

High efficiency even at low loads with a very small refrigeration power

Benefits of HTS MachinesBenefits of HTS Machines

-

7/29/2019 HTS Rotating Machines 050303

35/63

3535

Rotor retrofitRotor retrofit

Replace rotors in existing

conventional machines to

achieve the following benefits:

0.4-0.5% efficiency gain

$2 M saving for life of a 100 MW

unit Higher power rating ~ 10-20%

Operation at lower power factor agood leading VARS supplier

Rotor replacement market is reachable now

-

7/29/2019 HTS Rotating Machines 050303

36/63

3636

HTS Machine ExperienceHTS Machine Experience

Industrial MotorsIndustrial Motors

5000 hp, 18005000 hp, 1800--RPM MotorRPM Motor

Industrial MotorsIndustrial Motors

-

7/29/2019 HTS Rotating Machines 050303

37/63

3737

AMSC 5000hp, 1800AMSC 5000hp, 1800--RPM Motor List of ParametersRPM Motor List of Parameters

List of parameters List of parametersMotor output Motor output 5000 hp

(nominal, tested to7,000 HP transient, and5900 HP maximumsteady state)

Speed 1800 rpm

Pole number 4

Line voltage 6.6 kV

Full load efficiency 97.7 %

Operating power factor - leading 0.99

Straight length of machine 23.2 inches

HTS field inductance 8.8 Henry

HTS field current 156 Amps

Stator resistance 0.10 Ohm

Stator current 333 Amps

Load angle at full load -17.069 deg

D-axis synchronous reactance 0.32 puQ-axis synchronous reactance 0.32 pu

D-axis transient reactance 0.27 pu

D-axis subtransient reactance 0.173 pu

Q-axis subtransient reactance 0.173 pu

Stator short circuit time constant 0.031 sec

The motor is 97.7%efficiency

1/3 reduction in volume

compared to the industrystandard

40% reduction in lossescompared to the industry

standard

Industrial MotorsIndustrial Motors

-

7/29/2019 HTS Rotating Machines 050303

38/63

3838

KERI 100 HP Motor SystemKERI 100 HP Motor System

Driving System

Motor

Cooling

System

Compressor

Photograph showing the 100hp HTS motor in the test bed. The cooling system with theG-M cryocooler is located in the right side.

KERI

Korea ElectrotechnologyResearch Institute

-

7/29/2019 HTS Rotating Machines 050303

39/63

3939

HTS MachineHTS Machine

ExperienceExperience

Ship Propulsion MotorsShip Propulsion Motors

5 MW, 2305 MW, 230--RPM MotorRPM Motor

Ship Propulsion MotorsShip Propulsion MotorsHTS M t Ad tHTS M t Ad t

-

7/29/2019 HTS Rotating Machines 050303

40/63

4040

HTS Motor AdvantagesHTS Motor Advantages

Inherently quieter

Higher net efficiency

Lower operating cost

Smaller volume Lighter

36 MW HTS36 MW Conventional *

* Scale derived fr om GEC ALSTOM FSAD 19 MW @150 RPM propulsi on motor

0

200

400

600

800

1000

1200

1400

1600

0 20 40 60 80 100

Power (MW)

Main

tenanceVolum

e(M3)

HTS

Source: MSCL

ActualConve

ntionalMotor

Envelope

HTS

Advant age

Volume Comparison: HTS versus Convent ional

0

100

200

300

400

500

600

0 10 20 30 40 50 60 70 80 90 100

Power (MW)

Weight(MetricTons)

HTS

QE2

GRANDEUR

CRYSTAL

Actua

lConv

ention

alMoto

rEnve

lope

Source: MSCL

HTS

Advantage

Weight Comparison: HTS versus Conventional

HTS motor volume advantages are impressive over a broad range of ratings

Ship Propulsion MotorsShip Propulsion MotorsRefrigeration S stemRefrigeration System

-

7/29/2019 HTS Rotating Machines 050303

41/63

4141

Refrigeration SystemRefrigeration System

Rotor

Rotor VacuumVessel

Cooler Module

GM-1A GM-1B

GM-2A GM-2B

Pumps

Compressors (4) 25KWHeliumMake-up

Helium TransferCoupling

25 MW Motor Cooling System ~ 1 kkg(ONR Program)

1280 mm

1150 mm

865 mm

Gas lines tocompressors(4)

Cold heads (4)

Transferline port tomotor

Reliabil ity with degraded mode capabil ity is achieved through redundant

components and design for maintenance

25MW Motor, 120 RPM

Off Optimum Cooler Operation

0

25

50

75

100

4 3 2 1Number of Active Coolers

%o

fFullM

otorSpeed

Ship Propulsion MotorsShip Propulsion Motors5 MW Motor Rotor Testing

-

7/29/2019 HTS Rotating Machines 050303

42/63

4242

5 MW Motor Rotor Testing

The rotor and associatedhardware was tested atAMSC including:

Excitation up to full current

Refrigeration operatingtemperature in full and

degraded modes Field winding up to full

design current

Rotor balanced in cold stateat ALSTOM

Successful rotor f ield winding testing validated HTS field windiSuccessful rotor field winding testing validated HTS field winding and its coolingng and its cooling

system prior to shipping to ALSTOMsystem prior to shipping to ALSTOM

Ship Propulsion MotorsShip Propulsion MotorsSt t M f tStator Manufacture

-

7/29/2019 HTS Rotating Machines 050303

43/63

4343

Stator ManufactureStator Manufacture

Stator assembly was designed, fabricated and tested byALSTOM

Completed StatorCoil Manufacture

Ship Propulsion MotorsShip Propulsion MotorsAssemblyAssembly

-

7/29/2019 HTS Rotating Machines 050303

44/63

4444

AssemblyAssembly

Motor assembly and testat ALSTOM ElectricalMachines, Rugby UK

Assembly completedJ anuary 2003

Ship Propulsion MotorsShip Propulsion MotorsFactory TestingFactory Testing 5 MW Motor Test Results5 MW Motor Test Results

-

7/29/2019 HTS Rotating Machines 050303

45/63

4545

Factory TestingFactory Testing 5 MW Motor Test Results5 MW Motor Test Results

No-Load IEEE 115- Motor Parameters

- Efficiency

Full torque at speed

Limited Structureborne Noise Data

Operation on a Drive

ONR Accepted motor shipped toCAPS on 22 J uly 2003

5 MW HTS Motor5 MW HTS Motor

2.5 MW Load Motor2.5 MW Load Motor

Ship Propulsion MotorsShip Propulsion MotorsCAPS TestingCAPS Testing 5 MW Motor Testing at CAPS Florida5 MW Motor Testing at CAPS Florida

-

7/29/2019 HTS Rotating Machines 050303

46/63

4646

CAPS TestingCAPS Testing -- 5 MW Motor Testing at CAPS, Florida5 MW Motor Testing at CAPS, Florida

InductionInduction

MotorMotorInductionInductionMotorMotor

5 MW5 MWHTSHTSMotorMotor

Motor is coupled with a pair of2.5 MW squirrel cage inductionmotor dynamometers

More PowerMore Powerin Small Sizein Small Size

Ship Propulsion MotorsShip Propulsion MotorsCAPS TestingCAPS Testing - Load TestingLoad Testing

-

7/29/2019 HTS Rotating Machines 050303

47/63

4747

CAPS TestingCAPS Testing -- Load TestingLoad Testing

0

10

20

30

40

50

60

70

80

90

100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5Time (hours)

T

emperature(Celsius)

Start of full

load heat runEnd of full

load heat run

Initial heat run conducted on September 19, 2004Initial heat run conducted on September 19, 2004 Motor delivered 5 MW at 230 RPMMotor delivered 5 MW at 230 RPM

Stator attained steadyStator attained steady

--state temperaturestate temperature

Ship Propulsion MotorsShip Propulsion Motors5 MW Navy Motor5 MW Navy Motor -- Future PlansFuture Plans

-

7/29/2019 HTS Rotating Machines 050303

48/63

4848

5 MW Navy Motor5 MW Navy Motor- Future PlansFuture Plans

After completing load and ship mission profilesimulation tests at CAPS, it will be moved toNSWCCD Philadelphia for further testing

The successful operation of the largest HTSpropulsion motor will provide the Navy with hands-on experience

Ship Propulsion MotorsShip Propulsion MotorsNow BuildingNow Building 36 5 MW Based on 5 MW ExperienceBased on 5 MW Experience

-

7/29/2019 HTS Rotating Machines 050303

49/63

4949

Now BuildingNow Building 36.5 MW Based on 5 MW ExperienceBased on 5 MW Experience

Being designed and built under anOffice of Naval Research (ONR)contract to power the next generation ofNavy warships

AMSC SuperMachines will deliver the36.5 MW, 120 RPM motor, integratedwith a commercial Variable FrequencyDrive

For the same torque, the HTS motorweighs 75 tonnes, as compared to 280tonnes1 for an advanced inductionmotors and 400 tonnes2 for a QE2synchronous motor

The 36.5 MW motor design based on5MW technology.

1 Scaled from ALSTOM IPS Induct ion Motor

2 http ://www.qe2.org.uk/engine.html

Detailed Design Reviewconducted on October 06, 2004

Motor delivery to ONR planned forthe spring of 2006

Ship Propulsion MotorsShip Propulsion Motors36 5 MW Motor Components36 5 MW Motor Components

-

7/29/2019 HTS Rotating Machines 050303

50/63

5050

36.5 MW Motor Components36.5 MW Motor Components

Rotor End RingRotor End Ring

HTS CoilsHTS Coils

36.5 MW motor is in construction phase with scheduled delivery at 75 ton

-

7/29/2019 HTS Rotating Machines 050303

51/63

5151

HTS MachineHTS Machine

ExperienceExperience

Utility ApplicationsUtility Applications

HoeganaesHoeganaes, TN, TN

Utility ApplicationsUtility ApplicationsSuperVARSuperVAR Prototype Project DescriptionPrototype Project Description

-

7/29/2019 HTS Rotating Machines 050303

52/63

5252

SuperVARSuperVAR Prototype Project DescriptionPrototype Project Description

Similar to a conventional synchronousmachine but with better performance

Developed an 8 MVA

prototype SuperVAR machinefor testing on TVA grid

TVA is partially supporting theprototype development

TVA has ordered 5 productionunits subject to successfultesting of the prototype

-rated 10 MVA at 13.8kV

Rating 8 MVAR

Voltage 13.8 kV line to line

Ambient Temp -30o to +40oC

Losses 1.5% rating at 8MVA

Including 30kW 480Vauxiliary power

AMSC is offering 10 MVA production units for delivery in 2005

Utility ApplicationsUtility ApplicationsMajor SuperVARTM Condenser Systems

-

7/29/2019 HTS Rotating Machines 050303

53/63

5353

Major SuperVAR Condenser Systems

Stator and HTS RotorStator and HTS Rotor

RefrigerationRefrigerationSystemsSystems

ExciterExciter

StartupStartup

MotorMotor480V Service480V Service

25 feet25 feet

Utility ApplicationsUtility ApplicationsMachine Performance on GridMachine Performance on Grid

-

7/29/2019 HTS Rotating Machines 050303

54/63

5454

Machine Performance on GridMachine Performance on Grid

Machine has been installed onTVA grid in Hoeganaes, TN

Was synchronized with thegrid on 10 October 2004

-Verified VARS capabilityfrom 8 MVARS to + 8MVARS

Machine has beenexperiencing transients due tothe arc furnace operations

It is supplying various levels ofMVARS to the systemdepending on the type of arc

furnace burn cycle

SuperVARTM machine is support ing the arc furnace by supplying variouslevels of MVARS

0.00E+00

1.00E+06

2.00E+06

3.00E+06

4.00E+06

5.00E+06

6.00E+06

7.00E+06

2:31:12

PM

2:38:24

PM

2:45:36

PM

2:52:48

PM

3:00:00

PM

3:07:12

PM

3:14:24

PM

3:21:36

PM

3:28:48

PM

3:36:00

PM

3:43:12

PM

Time of Day (cst)

Output(VArs)

Vars

VARS supplied during a typical melt cycleVARS supplied during a typical melt cycle

Motor Starting ProblemCorrected by SuperVARTM

-

7/29/2019 HTS Rotating Machines 050303

55/63

5555

SuperVAR Response to Motor Starting Events

Motor #1 Motor #2 Motor #3 Motor #4

Bus Voltage Without SuperVARTM

Condenser

Bus Voltage With SuperVARTM

Condenser

SuperVARTM MVAR Output

BusVoltageinkV

BusVolta

geinkV

O

utputinMVAR

Time (Seconds)

Time (Seconds)

Time (Seconds)

Voltage Collapse Problem3 SuperVARTM Machine Solution

-

7/29/2019 HTS Rotating Machines 050303

56/63

5656

3 SuperVAR Machine Solution

-

7/29/2019 HTS Rotating Machines 050303

57/63

5757

Issues Relating toIssues Relating to

Installation and Operation ofInstallation and Operation of

Superconducting RotatingSuperconducting Rotating Machines

Component Maintenance and Handling IssuesComponent Maintenance and Handling Issues

-

7/29/2019 HTS Rotating Machines 050303

58/63

5858

p g

No special equipment is requiredto maintain or handle the rotor Stator is the same as for a

Conventional machines

Cryogenic cooling system maintenance procedures are

well established in MRI and high vacuum industries

Installation ConsiderationsInstallation Considerations

-

7/29/2019 HTS Rotating Machines 050303

59/63

5959

Prime Mover

Generator

Stator

Cooler

Exciter

RotorCoolingModule

Cryocooler

Compressors

Most electrical and mechanical interfaces aresimilar to conventional synchronous machines

Installation is similar to conventional machines

for the following components:

- Prime mover

- Stator and stator cooling

- Exciter

The only difference is in the installation of the rotor cooling system

- Cooler module and its compressors

- Coolant transfer coupling

Cooling modules can be located remotely from the machine

Installation of HTS machines is similar to conventional machines

Mechanical OperationMechanical OperationSimilar to conventional machinesSimilar to conventional machines

-

7/29/2019 HTS Rotating Machines 050303

60/63

6060

Stator cooling is the same as conventional machines

Bearings are conventional roller or sleeve type

Cryocoolers employ cold heads and helium compressors

Cryocooler maintenance and service procedures are wellestablished in the industry

Each compressor has a charcoal filter that is replaced at 2-yearinterval

Cooler can be shutdown for short period of time without having tostop the machine

Compressors are water cooled and require 5 liter/min water flow

with inlet pressure of 2 bar at 5-25o

C.- Air-cooled compressors can also be specified

Maintenance procedures are similar to those for conventional machines

Control and CommunicationControl and CommunicationSimilar to conventional machinesSimilar to conventional machines

-

7/29/2019 HTS Rotating Machines 050303

61/63

6161

Typical monitored states are:

Brushless Exciter- Control field current in response to AVR or a command from

the operator Field Winding

- Coil voltages and currents- Coil temperature-

Current lead temperature Cryocoolers and Compressors

- Cryocooler temperature- Compressor helium pressure and flow rates-

Compressor temperature- Compressor cooling water temperature and flow rate

Cryogenic cooling system monitoring procedures are well established

-

7/29/2019 HTS Rotating Machines 050303

62/63

6262

Future

Future Technology DevelopmentFuture Technology Development

-

7/29/2019 HTS Rotating Machines 050303

63/63

6363

Wire volume production of HTS wire isresulting in improved cost/performance.

300,000 square foot HTS plant in Devens MA

Next generation wire

Refrigeration pulse tube developments offer: Improved efficiency approaching Stirling

cycle efficiencies

Lower noise - opposed pistons of Stirling styleGM compressors

Higher Reliability no cold moving parts

Coils winding development simplified construction for next generation

machine

High tip speed capability

Coated Conductor - potentialnext generation wire technology

SuperconductorCoating

BufferLayer

AlloySubstrate

Coated Conductor - potentialnext generation wire technology

SuperconductorCoating

BufferLayer

AlloySubstrate