Hino Torque Summer 2010

-

Upload

the-project-group -

Category

Documents

-

view

220 -

download

1

description

Transcript of Hino Torque Summer 2010

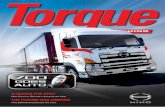

ISSUE No.10 SUMMER 2010

Critical ResponseWhat journalists look for when reviewing trucks

All Aboard!Hino buses in demand

IN THE LONG RUN.VALUE

A TOYOTA GROUP COMPANY

BETTERPARTS & SERVICE AREGENUINE HINOREASON WHYANOTHER

Your Hino truck is a key part of your business. Our

business is to help you make as much money with it

as possible. So in order to help you do so, we offer an

industry leading warranty. Buy any Genuine Hino Part

or Accessory fitted by an authorised Hino dealer and

we’ll give you a three year warranty with unlimited

kilometres during this period. And since it applies both

to the parts and labour it makes brilliant business

sense no matter what

model Hino you drive.hino.com.au

The 3 year / unlimited kilometre warranty applies to defects in workmanship and materials only, and does not cover fair wear or tear of the part / accessory. The 1 year / 100,000 kilometre warranty applies to defects in materials only, and does not cover defects in workmanship or fair wear or tear of the part / accessory. If the genuine Hino part or accessory is modified in any way, any Hino warranty that may have been applicable to that genuine Hino part or accessory, including but not limited to the 3 year / unlimited kilometre warranty and the 1 year / 100,000 kilometre warranty is voided. HMS07232

Torque | 3Torque | 3

From all of us at Hino, Happy New Year.Welcome to 2010 and to a significant anniversary,

celebrated in the lead story of this edition of Hino Torque.It was 60 years ago that American statistician W. Edward

Deming held a quality improvement conference at Mt Hakone, outside Tokyo.

The topic was Process Control Methods, and virtually nobody came… except Eiji Toyoda – boss of the Toyota Motor Corporation.

Deming was in Japan as part of its post-WWII recovery and his role was to assist industry to get back on its feet.

Deming's proposal was a very logical formula, but at the time it was highly radical.

Quality, he said, could best be achieved by improving productivity and that would naturally lead to cost reduction. Simple.

Eiji Toyoda was so entranced that he followed Deming back to America and became a disciple. The Toyota Manufacturing System (TMS) was born from Toyoda’s experience, giving life to something which today is regarded as the world benchmark: not just for motor vehicles but for any production process.

TMS is the mortar that binds the Toyota Group of Companies. It is employed by Hino, Lexus and, of course, Toyota. Every day it is reviewed and improved.

Simply, TMS builds vehicles better.It’s at the very heart of the shared knowledge which continues

to make the companies and their supplier networks so strong.

These days its principles also apply to all facets of the business – distribution, parts as well as sales and marketing.

While the systems have become complex, the basic guidelines of Plan Do Check Act remain constant.

In Japan and other global plants, TMS makes manufacturing processes interchangeable. Hino-made components are fitted to Toyotas and vice versa.

Amazingly, TMS has never been locked up in copyright. Members of the Toyota Group make it freely available and many of our competitors – as well as our customers – have availed themselves of it.

For Australians synergies also apply, to the benefit of our network and our customers.

Under one roof we offer a full transport solution, a full finance solution and a universal ability to understand the needs of our customers and the issues that affect the market.

At Hino we're looking on 2010 as a time of growth.There's no doubt the economic environment is going to

be tough. We believe, under the banner of the Toyota Group of Companies, we are in the best possible position to provide real help to critical decisions.

I look forward to working with you all throughout the year.

Steve LotterPresidentHino Motor Sales Australia

Torque | 3

4 | Torque

Hino Australia recently accompanied 10 sales staff from its dealer network to Thailand on a study tour after they successfully won the opportunity to visit Hino operations in Bangkok.

The unique opportunity for the sales staff came in mid-November last year after a four-month retail sales campaign across Hino’s nationwide dealer network, which ran from July to October 2009.

Dubbed “Hino Heavy Hitters”, the retail campaign doubled as an internal sales incentive that focussed on a range of Hino’s heavy duty trucks and included a cash bonus to sales staff for each eligible truck sold during the campaign period.

Hino Australia’s national marketing manager Paul Tuffy was pleased the incentive proved so successful.

“The sales incentive certainly worked,” Mr Tuffy said. “We saw a noticeable increase in sales of the heavy duty campaign models during the promotional period and we received some very positive feedback from those people who took part in the study tour.”

The highlight of the study tour was a visit to Hino’s Bangkok head office and an inspection of the manufacturing facility, where the group witnessed the entire truck assembly operation.

Andrew Agius from Newcastle Hino was one of the lucky 10 to travel

to Thailand and was impressed with the efficiency of the truck assembly operation.

“The attention to detail of the Thai staff in the manufacturing process has

to be seen to be believed,” Mr Agius said. “They displayed a great deal of pride in their job and the result is obvious when you see the quality of the Hino trucks made in Thailand.”

A Hino 300 Series prototype fire truck proved a popular talking point during the 2009 Australian Trucking Association (ATA)/Australian Road Transport Suppliers’ Association (ARTSA) Technical and Maintenance Conference.

The three-day conference – held in mid-November at Phillip Island in Victoria – was attended by more than 250 fleet managers, workshop mangers and industry suppliers to discuss the latest technical and maintenance developments.

Topics covered the latest developments in truck and trailer design, improvements in on-road safety, ways to reduce the

environmental impact of trucks, as well as a hybrid truck maintenance session.

Hino was well-represented on the hybrid maintenance panel, putting its experience as the industry’s hybrid leader to good use.

Hino has supported the conference for a number of years and again sponsored the day-two lunch, where it displayed its prototype fire truck.

The truck was jointly developed between Hino and the CFA, and underwent a burn over that provided invaluable data regarding the effectiveness of new safety systems.

Hino national government sales manager Tom Ayrton attended the conference and praised the

efforts of ATA/ARTSA for providing the industry with an invaluable

opportunity to meet and discuss the latest industry trends.

Emerging Darwin landscaping business, Prestige Garden Care has chosen a Hino 300 Series dump from Vanderfield Hino to tackle the Top End's tough conditions.

Business owner and mother-of-two Shannon Fordham started Prestige Garden Care mid-last-year, but has already received a strong response from her rapidly expanding customer base.

“In my field of work there are a lot of men and only a handful of women out there doing it, so mine is a position you don't see too often,” Ms Fordham said.

“I chose the Hino dump because all the gardening stuff can go in the back. The tipper makes it easy to mulch and move rocks and soil.

“We have no dramas with it at all and, importantly, up here the air conditioner just about blows you away in the cab – it's really good.”

Vanderfield Hino sales manager, Guy Hassall praised Ms Fordham for her approach and said the 300 Series dump is a popular choice among private buyers in the Northern Territory.

HEAVY HITTERS VISIT BANGKOK

CONFERENCE SHOWCASES HINO TECH

TOP END PRESTIGE

Prestige Garden Care puts its 300 Series to work in Darwin’s harsh conditions

The Hino Heavy Hitters delegation visited Hino’s Thai manufacturing facility

The CFA’s Hino 300 Series prototype fire truck formed a central part of Hino’s presence at the 2009 ATA/ARTSA Technical and Maintenance Conference

Torque | 5

Hino Australia recently released its first dedicated parts catalogue that showcases its aftermarket range of products including parts, accessories and merchandise.

Titled Parts Torque, the eight-page catalogue will be released every quarter and aims to inform customers of the wide range of Hino genuine parts and accessories available for purchase.

The first edition was launched in Spring 2009, while the Summer edition was released in December and included Christmas gift ideas such as a toy model of the Hino 500 Series truck that competed in the Dakar rally.

Parts Torque is mailed to thousands of Hino’s customers around the country and the first two editions have been welcomed enthusiastically by small and large business operators, as well as

corporate fleet customers. “The introduction of Parts Torque

has definitely helped our business,” said Hino Australia parts manager, Peter Michetti.

“From the moment we began to mail the catalogue to Hino customers, our dealers started receiving phone calls and orders. The new catalogue helped us achieve our sales targets in October, November and December.”

Parts Torque includes a diverse range of parts and accessories including, air filters, engine kits, clutch and lube kits, windscreen wiper refills, canvas seat covers and bullbars, as well as a range of merchandise items such as polo shirts, golf umbrellas, caps and pens.

Hino completed a major upgrade of its parts distribution centre about

12 months ago. The centre provides a 24-hour turnaround of orders to the Hino dealer network with a service level

objective in excess of 95 per cent. Visit www.hino.com.au to view the

latest edition of Parts Torque.

Hino trucks are playing an integral role in a special project on the popular Thai tourist island of Phuket, where a 45-metre-high image of Buddha is being constructed.

Known as the “Big Buddha”, the structure is situated on top of a hill between Chalong Bay and Kata in the island’s south, near the large temple of Wat Chalong.

Hino trucks are being used to shuttle visitors up the steep mountain road to view the near-complete Buddha, while Hino cement mixers work daily to pour the large amount of concrete needed at the site.

The Big Buddha is fast becoming a popular destination for prayer for the island’s majority Buddhist population.

Though the Buddha is not complete, the thousands of tourists who flock to the holiday island each year have also made the site one of the most visited new tourist destinations on Phuket.

The Phra Puttamingmongkol Akenakkiri Buddha (its official name) is 25 metres wide at the base and will eventually be covered in 135 tonnes of Burmese white marble.

On completion it will be dedicated to Thailand’s king, HM King Bhumibol, while a smaller Buddha made of 22 tonnes of brass that sits alongside the main image will be dedicated to HM Queen Sirikit.

Thailand was the home to Hino’s first manufacturing facility outside of Japan and Phuket is serviced by the Sangroong Phuket Co dealership.

HINO LAUNCHES PARTS CATALOGUE

HINO HELPS BUILD BIG BUDDHA

TIPPERS HIT PLANT CO. FOR SIXProgressive Queensland plant hire company P&E Francis Plant Hire logged its sixth anniversary with Hino FG tippers late in 2009.

P&E Francis has 27 Hino tippers at its base in Wacol, Brisbane and Hino’s represent one-third of its plant hire fleet of more that 90 machines.

Maintenance manager Tim Ledez has tended the Hino tippers since the first unit was purchased in 2003.

“We've had a good run from the Hinos and we have a good rapport with our dealer, Sci-Fleet Hino,” Mr Ledez said. “From the salesman Brad Elliot to the service and parts people; they're always ready to help.

“The trucks are also good for our operators. The latest model is like a car to drive, with a CD-player, electric windows and the easy-to-use transmission.”

Mr Ledez said the P&E Francis Hinos work all over Brisbane, as well as the north and south coast areas.

“There are some working on the Airport Link project and we just had six working on the Boggo Road bus tunnel, as well as other major building projects throughout Brisbane. But, they also do general hire - like if someone wants to build a swimming pool, for example.”

The 45m-tall Big Buddha is under construction on the Thai island of Phuket Hino cement mixers pour the masses of concrete required at the site

Parts Torque provides customers with the latest offers from Hino’s range of genuine parts and accessories

6 | Torque

The astronomical figures were accrued on daily runs between Sydney and Brisbane, via the business’ Taree headquarters.

Bourkes Transport’s trucks travel an average 400,000 kilometres per year and stop only for a few hours between driver shifts and for servicing.

Brothers and directors in the family business, Wayne and Kerry Bourke, say one of Bourkes Transport’s oldest trucks – an FD Ranger 6 Turbo purchased in 2003 – is estimated to have travelled over 2.5 million kilometres and is still in service.

“Even with the high mileage the truck is too good to get rid of. There’s no need to move it on at the moment,” says Wayne Bourke. “We’ll keep it working for another six to 12 months and then look at retiring it.”

The fleet also includes four FD Ranger Pro 6 Long Air 260 horsepower models, three of which have reached

the mammoth two million kilometre milestone. “One of them has an odometer stuck on 1,999,999km and another won’t go over 2,300,000km,” says Kerry Bourke. “The third Ranger Pro has just gone two million and the fourth is close behind on 1.8 million.”

In clear testimony to Hino’s reputation for durability, the biggest repair conducted on any of the two- million-kilometre trucks was a front brake lining replacement, says the company.

Multiple factors contributed to the trucks’ remarkable longevity, especially a meticulous transport authority-accredited servicing regime.

“As soon as a truck comes off a run, it goes over the pits for inspection. If we find a problem it is fixed on the spot,” Kerry Bourke says.

Two full-time mechanics are employed to service the business’ 20-strong truck fleet. On average the

trucks are serviced every second or third day, or weekly as a minimum.

“Our mechanics have a very close relationship with Hino and are very experienced with the trucks,” he says. “The mechanics love them. Our head mechanic reckons you can count on one hand the things that go wrong with them over their life, which could include a little plastic bush in a gearbox. None of the issues we’ve had with our Hinos have included major components.”

Wayne Bourke also attributed the trucks’ durability to regular usage. “Trucks don’t like sitting around. The best thing you can do for a diesel engine is use it,” he says.

His final acknowledgement was of the truck itself. “It’s a quality product, isn’t it? We do all the right things by using genuine Hino parts and the best oils, but the truck does the rest.

“It’s damn good design that has proven itself,” says Wayne.

Bourkes Transport Industries has four original-condition Hino trucks that have each reached the remarkable 2,000,000 km milestone.

A HIT FOR BOURKES TRANSPORTHINOS

A collection of Bourkes Transport Industries trucks, including (L to R) a 300 Series, 500 Series 1027 Long Air and 2003 Ranger Pro 6 260 Air

Kerry (L) and Wayne Bourke of Bourkes Transport Industries with an original-condition Hino FD Ranger Pro truck that has travelled over two million kilometres and is still in service

2 0 0 k0 00 m

Torque | 7

Ready Towing will service its RACQ contract using 14 Hino 500 Series in crew and single cab configurations

RACQ READY WITH HINO

Ready Towing, Brisbane's largest tow-truck operator, purchased a fleet of 14 single and crew cab 500 Series trucks late last year to manage the city’s metro towing services as part of its RACQ contract.

The FD1024 model trucks were supplied by Sci-Fleet Hino, Queensland’s largest Hino dealer, and all take to the road in the auto club’s distinctive yellow hue.

Sci-Fleet Hino has been supplying Ready Towing with trucks for more than 20 years, and Hinos now represent more than 70 per cent of the company’s 140 vehicle flat-bed towing fleet.

Ready Towing general manager Matthew Ready named Hino's dependability and Sci-Fleet's 24-hour service centre as two reasons central

to his company's ongoing relationship with the dealership.

“We have been dealing with Sci-Fleet for a long time and they have always been easy to deal with and very reliable,” Mr Ready said.

“Their 24-hour service centre is a necessity for us and is almost more important than the trucks, as without it we would be nowhere.

“Having said that, Hino makes a very reliable truck. We have tried a few other brands and Hino is the most reliable of them all and has considerably fewer breakdowns.”

Sci-Fleet Hino dealer principal Craig Andersson knows the strong working relationship established across the last two decades is a key factor why Ready chose Hino to service its RACQ contract.

“When Ready secured the RACQ contract we worked very closely with them to rush through four service-ready trucks fitted with slide trays – supplied by ATB Engineering – and radio equipment from Northfield Car Sound,” Mr Andersson said.

“The majority of their fleet is Hino because they find them to be good on brakes and fuel consumption, and most importantly for Ready, they simply get the job done without a problem.”

Mr Andersson acknowledged the proximity of their headquarters to Sci-Fleet's Kedron dealership, and the ability to have their fleet serviced at night was also central to why they select Hino to supply their trucks.

“Our service arrangement includes a free loan ute that allows their

drivers to drop the truck off on the way home, take home a ute for the night and return in the morning to collect their serviced truck,” Mr Andersson said.

“Importantly, this eliminates the need to have two drivers involved and keeps more trucks and drivers on the road.”

Ready Towing began operating in 1961 and is now Australia's largest towing transport company with a fleet of more than 200 vehicles.

Apart from being Hino’s largest Queensland dealer, Sci-Fleet is also Australia's number one seller of Toyota Group commercial vehicles and has showrooms and service centres at Kitchener Rd, Kedron and Beaudesert Rd, Coopers Plains.

Queensland motorists will be extra happy to see a Hino, following Ready Towing’s decision to use a fleet of 500 Series to service its recently awarded RACQ towing contract.

8 | Torque

A TOYOTA GROUPHINO

The year 1966 heralded the introduction of decimal currency in Australia, was the final time the Beatles would perform in concert and saw the first man-made object orbit the moon.

It was also the year that Hino entered into partnership with Toyota Motor Company and Toyota Motor Sales Co. – the precursor to what is the present day Toyota Motor Corporation (TMC).

Hino benefited greatly from the alliance with Toyota, and by 2001

Toyota’s parent company was the majority shareholder in the company, making Hino an official part of the Toyota Group.

The Toyota Group encompasses all brands under TMC’s ownership including Toyota, Lexus, Toyota Materials Handling, Toyota Financial Services and, of course, Hino.

Although all automotive-based, these companies are unique in their own right and produce a broad range

Hino is one of many companies within the Toyota

Group and although these companies cover different areas of business, they all

share a common ethos.

COMPANY

Torque | 9

A TOYOTA GROUP1867 – Sakichi Toyoda born

1890 – Sakichi Toyoda invents wooden handloom

1918 – Early incarnation of Hino produces first truck

1929 – Sakichi Toyoda’s son, Kiichiro, visits US and Europe to investigate automobiles

1935 – First Toyota models completed

1937 – Toyota Motor Corporation established

1949 – Eiji Toyoda implements Toyota Production System

1956 – Toyota Industrial Equipment production begins

in Japan

1959 – First Toyota sold in Australia

1962 – One millionth Toyota vehicle produced domestically

1966 – Hino enters alliance with Toyota

1968 – First Toyota forklift imported into Australia

1972 – Ten millionth Toyota vehicle produced

1982 – Toyota Motor Co. Ltd. and Toyota Motor Sales Co. Ltd. merged into Toyota Motor Corporation

1982 – Hino cumulative production reaches one million vehicles

1982 – Toyota Financial Services established in Australia

1989 – Lexus brand launched

1991 – Hino launches world’s first diesel-electric hybrid bus

1994 – Hino Motor Sales Australia established

1995 – One millionth Toyota forklift produced

1997 – Toyota Prius launched

1999 – One hundred millionth Toyota vehicle produced domestically

1999 – Lexus reaches one million sales in America

2000 – Toyota Financial Services Corporation established

2000 – Toyota Materials Handling acquires BT and

Raymond brands

2001 – Toyota’s stake in Hino surpasses 50 per cent

2003 – Hino launches world’s first two-tonne hybrid truck

2005 – First Lexus hybrid launched

2009 – TICO launches world’s first engine-powered hybrid forklift

2009 – Hino cumulative production exceeds three million vehicles

of products and services. However, they all benefit from the Toyota Way – the binding principles that have seen TMC grow into one of the world’s leading and most respected companies.

When it entered into its partnership with Hino in 1966, Toyota immediately began implementing the Toyota Way principles, including the Toyota Production System (TPS) – the industry-leading production methods that sets Toyota apart from its competitors.

Hino’s already high production standards were further increased as it began implementing the TPS across its domestic and overseas plants. Adopting the TPS has allowed Hino to achieve continuing gains in productivity and quality in order to offer customers the best-possible products.

Hino’s successful implementation of the TPS meant Toyota increased its relationship with Hino, to the point where the company now manufactures

Toyota vehicles and parts, including the recently released all-new Prado and popular FJ Cruiser SUV in America.

Aside from manufacturing benefits, Hino and Toyota also collaborate on technical projects. Last year they developed a breathalyser that locks a vehicle’s ignition if the driver blows a positive reading – a product that is being tested on Hino trucks being used by Japanese transport companies.

Both companies have grown

into global leaders since they began collaborating more than four decades ago. With this rise in demand it became apparent that a financial services arm needed to be added to meet the growing demand from fleet and private buyers.

Toyota Financial Services (TFS) was first established in Australia in 1982. The business model proved successful and was followed by similar Toyota finance companies in leading Toyota markets, including Japan and America.

A lot has happened in the world of Toyota since Sakichi Toyoda invented the wooden Toyoda handloom at the end of the 19th Century. Torque has produced an abridged timeline of keys dates in the rise of the Toyota Group.

TOYOTA GROUP TIME LINE

10 | Torque

In the year 2000, TMC established Toyota Financial Services Corporation to oversee Toyota’s finance companies worldwide, which are now present in almost every market where Toyota does business.

In Australia – as a benefit of being part of the Toyota Group – Hino Financial Services works on the same model as TFS, providing private buyers and fleet customers with a range of finance options.

Likewise, Toyota Group’s luxury brand – Lexus – also takes advantage of being part of the group, offering financial services to its customers around the world.

Lexus, launched by Toyota in 1989 to rival the world’s leading luxury car brands, has been at the forefront of automotive technology since its introduction.

Its place in the market ensured its models took full advantage of the TPS to provide the utmost quality to customers. Alongside its world-leading quality, Lexus has also been the Toyota Group flagship for implementing hybrid technology.

Although Prius is the Toyota

model best known for Toyota’s hybrid technology, Lexus has embraced the technology across its range to the benefit of the brand and the wider Toyota Group.

Thanks to the brand’s premium position in the marketplace, Lexus has introduced environmentally sustainable motoring to the top-end of the automotive industry – a move that has not only won many customers, but forced other manufacturers to adopt green technology.

The Lexus business model has shown that hybrid technology can work across a range of vehicle platforms, including SUVs, sedans and saloons – dismissing early myths surrounding the viability of hybrids.

Hino has, like Lexus, made the most of its Toyota Group link to prove the viability of Toyota’s hybrid technology. Hino has taken hybrid technology beyond the realms of what many people thought possible by adapting it to be beneficial in the commercial environment for both trucks and buses.

The 300 Series Hino Hybrid light-duty truck was launched in Australia

in early 2007 after years of testing and development in both Japan’s urban environment and the harsh climate of Australia’s outback.

The company released its first hybrid bus in 1991 and started developing the technology as early as 1973. However, in more recent times it has been able to call on the resources of the Toyota Group to bring the technology to the global truck market.

Hino is now working on bringing the green power source to its 500 Series range of medium duty trucks and – like Toyota and Lexus passenger vehicles before it – proving that the adoption of hybrid technology is possible in all areas of motoring.

Another company within the Toyota Group that has embraced the shared knowledge of hybrid is Toyota Material Handling (TMH), the arm within Toyota responsible for producing forklifts, skid steers, lift trucks and other materials handling products.

Under the banner of parent company Toyota Industries Corporation (TICO), TMH products are produced under three brands – Toyota Industrial

Equipment, BT and Raymond. Like Hino, Toyota and Lexus, TICO

is a hybrid pioneer and launched the world’s first engine-powered hybrid forklift in December last year. The GENEO-HYBRID forklift is a 3.5-tonne payload diesel-electric hybrid that utilises the Toyota Group’s hybrid technology to combine a diesel engine, electric motor and battery power.

TICO is the present day incarnation of the company started by Toyota founder Sakichi Toyoda, who developed and begun selling automatic looms in 1926.

Loom production soon turned to automobiles and industrial equipment and by the 1950s the guiding principles developed by Sakichi’s cousin, Eiji Toyoda (see Inside Line) began filtering through the various organs of the company.

In the ensuing decades the company expanded and eventually evolved into the Toyota Group we know today.

Hino, like Toyota, Lexus, TMH and Toyota Financial Services, has grown to be a global leader and under the Toyota Group it has shown the world the way – the Hino Way.

Torque | 11

The Major Training Group uses Hinos to put the truck drivers of tomorrow through their paces

Major has added three more Hino 700 Series trucks to its rapidly-expanding fleet because they have proven to be the best trucks for training both new and experienced drivers.

The new additions were supplied by Sci-Fleet Hino in Brisbane, with Hinos now representing 85 per cent of Major’s fleet.

Major’s general manager, Glen Taylor, said his company selected Hino for three key reasons – quality, ease of use and Sci-Fleet’s high level of service.

“We chose Hino, firstly as they have very good trucks,” Mr Taylor said. “Trainees find them easy to drive and, like us, Hino pride themselves on quality and service.

“Hinos also look great on the road and it is important for us to keep up with technology and appearance, so no Major truck is more than five years old.”

According to Mr Taylor, Major is one of Queensland's fastest growing Registered Training Organisations in its field and has recently invested $5.5 million to cater for increased demand and to expand the training it offers.

“We now have three sites that service south-east Queensland after we opened a facility at Morayfield/Caboolture in January (2008), and then one in Dinmore/Ipswich in February last year,” Mr Taylor said.

“The training we do is representative of what goes on in the industry. We are keen to see governments take a more active role in what we do, as we are future-focussed on improving the competency of all truck drivers on the road.”

Sci-Fleet Hino dealer principal Craig Andersson praised Major for its efforts in improving driving standards across

all facets of the truck industry. “Major certify drivers of B-double

trucks, but they have taken a wider approach, which goes much further than sitting in the truck and teaching someone how to change gears,” Mr Andersson said.

“Major has a very good group of specialist teachers and they fill a void in the marketplace by going that step further – teaching skills trainees can take into the field and pass onto other drivers as best-practice.

“Importantly they take on established drivers with licences and make them competent users of that specific licence.”

Major Training Group opened in 1998, but a previous incarnation of the business has been running for more than 20 years.

Major also offers a number of industry-related short courses, including a leading driver fatigue management program and civil construction courses.

HAS HINO HELPING DRIVER TRAININGMAJOR DEAL The Major Training Group in Queensland is a leader in heavy vehicle training – and the company recently selected Hino as its truck of choice for training the truck drivers of tomorrow.

“ WE CHOSE HINO, FIRSTLY AS THEY HAVE VERY GOOD TRUCKS… TRAINEES FIND THEM EASY TO DRIVE AND, LIKE US, HINO PRIDE THEMSELVES ON QUALITY AND SERVICE.”

The Major Training Group uses Hinos to put the truck drivers of tomorrow through their paces

HAS HINO HELPING DRIVER TRAININGMAJOR DEAL

12 | Torque

Hino Genuine Accessories continue to add value and versatility to Hino trucks, with the added benefit of the best warranty in the business.

Introduced just over a year ago, the Hino warranty covers parts and accessories for three years, regardless of the kilometres travelled, when fitted by an authorised Hino dealer.*

Hino Australia product support and business development divisional manager, Greg Bleasel, says new Hino truck owners choose Hino Genuine Accessories to protect, enhance and customise their rigs.

“The quality and reliability of Hino accessories, teamed with the factory backed three year, unlimited-kilometre warranty, means customers can be sure

they are getting value for money,” said Mr Bleasel.

Among the most popular accessories are bull bars, foot well- liners and seat covers.

The high-quality and strength of Hino genuine bull bars toughen and protect the front end of Hino trucks.

Hino bull bars are available across the range, and are factory-cut for a perfect fit on both standard and wide body cabs. All have towing pins and antenna-mount options.

Hino foot well-liners are a practical accessory for truck drivers. Made from a rubber composite, they are designed to fit each vehicle and are easily removed for cleaning.

Seat covers have also proven to be popular and are available in hard-wearing cloth, sheepskin and canvas.

“Hino genuine seat covers are UV-resistant, easy to clean and some feature a flame-retardant foam backing,” said Mr Bleasel.

Hino Genuine Accessories are designed, tested and manufactured to meet Hino’s own high standards as well as Australian Design Rules.

Hino genuine parts and accessories fitted by anyone other than an authorised Hino dealer still qualify for a one year/100,000km warranty, whichever comes first.

Visit www.hino.com.au to view the full range of Hino Genuine Accessories.

* The three year/unlimited kilometre warranty and one year/100,000 kilometre warranty apply to defects in workmanship and materials only, and do not cover fair wear or tear of the part/accessory. If the genuine Hino part or accessory is modified in any way, any Hino warranty that may have been applicable to that genuine Hino part or accessory, including but not limited to the three year/unlimited kilometre warranty and the one year/100,000 kilometre warranty is voided.

Hino has released a new UHF CB to help drivers communicate with ease and clarity while on the roads and highways around Australia.

The unit features a large display, easy-to-use, backlit, soft-touch keys, and a big speaker built directly into the speaker-microphone for clear audio.

The scan function finds available “hill top” repeater stations for greater operating range, and out on the highway, Open/Group and Priority Scan functions keep drivers in touch with the people they want to hear from.

The Silent Standby feature allows users to listen only to their own desired group.

A handy push-to-talk hold feature allows one-touch transitions of up to 60 seconds.

The CB unit kit includes a hand-held microphone, a microphone extension cable, a DC power cable, spare fuses, mounting bracket kit and microphone hanger kit.

Hino is offering a free Hino-

branded UHF CB antenna with each IC-440 UHF CB unit sold until 28 February 2010 at participating Hino Dealers.

GENUINE BENEFIT

NEW CB MAKES COMMUNICATIONS EASY

Torque | 13

TRAINING FOR THE FUTUREHino Australia has begun hosting The Mathematics of Selling Trucks training course so sales staff in its nationwide dealer network can provide customers with exactly the right Hino rig.

The two-day program is based on a ‘back to basics’ approach to selling trucks and focuses on the fundamental elements of specifying and building Hino trucks.

Hino sales and marketing divisional manager Bram van der Schaar says sales training benefits both employees and customers.

“With the knowledge learned on these two-day courses, every sales member at every Hino dealership can put together workable rig combinations for a customer’s particular usage requirements,” said Mr van der Schaar.

“They learn how to correctly specify a truck with the appropriate body and

accessories, and how to apply the knowledge on the showroom floor.

“This means they have to take in a lot of technical information, including load limits, performance, product densities and weight distribution, and understand how they can affect each other.”

The training also focused on different applications and building specific customer requirements into the rig.

As such, Hino body-building instructions and details, including chassis properties and attachments, electrical and air supply, power take off, crane and tail lift, were addressed.

Sales staff were also taken through their duty-of-care responsibilities as retailers.

Mr van der Schaar says the training courses are the initial stage in the development of a Hino sales training guide, and will continue through 2010.

The most recent upgrade to Hino Australia’s training facility in Sydney has resulted in a more realistic training environment and delivered OH&S improvements.

An $80,000 Fumex exhaust extraction system has been installed allowing training vehicles to run at rated engine RPM without filling the centre with exhaust emissions.

A flexible boom-mounted

extraction point attaches directly to the vehicle’s exhaust and is coupled to two high-powered vacuum fans, which suction all exhaust emissions from the training centre.

The Fumex system can extract emissions from six 16-litre engines running at 2500rpm.

Technical and service support manager for Hino’s product support and business development division,

Scott Brown, explains the system helps to create a more authentic training environment, because the vehicles are running at full power.

“The air quality during training is improved for the safety and health of employees and instructors attending training,” says Mr Brown.

“We’ve also accounted for future models with this system, ensuring the extraction hoses

will withstand the high exhaust temperatures of future models.”

The Hino training facility runs courses on new models, hybrid technology, diagnostics, electrical training and engine and driveline for up to 200 technicians per year.

Future plans for the training centre include increasing the floor space to allow more vehicles to be accommodated during practical training.

Hino Australia recently hosted the Oceania Region 2009 Parts and Service Managers Conference at which high-level discussions were held regarding service procedures.

The 21 delegates in attendance from Australia, New Zealand, Fiji, Papua New Guinea and Japan explored new ways of improving their relationships with Hino customers.

Attendees took part in presentations, demonstrations and a dealer visit to see how internal processes can be continually enhanced,

resulting in time reductions for vehicle servicing.

A demonstration conducted by HML Japan technical instructor Mr Kenzo Moriyama utilised a specially built trolley that contained all the components and tooling required to complete a service job.

Mr Moriyama was able to show that if a technician can minimise their movement around the workshop during a service, the customer benefits by having their truck back on the road sooner.

MATHS MULTIPLIES HINO SALES SKILLS

A BREATH OF FRESH AIR FOR HINO TRAINING FACILITY

CUSTOMER SATISFACTION KEY AT PARTS AND SERVICE CONFERENCE

14 | Torque

As part of its marketing strategy, Hino provides trucks to the media for testing and evaluation. Torque asked three of Australia’s leading truck journalists for the inside story on what they do behind the wheel, so you too can be testing like a pro. The following are edited excerpts from our interviews.

TRUCK TESTINGWITH THE PROS

Truck testing is much different to car testing. Cars are about driver experience, whereas trucks are all about making money. Driving experience is still important because happy drivers make more money, but most important is whether or not the truck is going to do the job the business bought it to do, and whether it will keep doing it.

When I’m testing a truck, I get into the truck and think: ‘as an employee, if I was working with this truck, what would I do?’

Businesses often buy trucks because of perceived useful features – it could be an automatic gearbox or some kind of monitoring device – but if those features aren’t useful for a driver or if they’re difficult to use, the driver will just go back to doing things they way they’ve always done it. A lot of business owners have been through that. They try ideas out and those ideas fail because they didn’t suit their operation or the drivers didn’t like it,

so it’s important that a business’ drivers test the truck, as well.

The other thing you need to consider is how the truck is actually used, what its operations are. If it’s a delivery truck, I put it in the actual situations it would be used. For example, there’s a shopping centre I use that has a particularly nasty loading bay. Because it’s so dodgy, when you back a delivery truck in there you’ll soon find problems without really good visibility and manoeuvrability. You’ve got to get trucks into really tight spots before you know how they really work: that’s where you find a truck’s limitations.

If I can, I try to test trucks on routes I’ve done before and keep a log so I can compare how they compare with other trucks I’ve had there in the past. Another thing I like to do is fully loading a truck and taking it up a hill climb that you’re familiar with, so you can test it at its limits. If they’re fully loaded you can compare how different

trucks work. A truck will not always be treated kindly in its life – it will be badly driven and worked hard – so, to replicate real-world conditions when testing a truck, you’ve got to push it to it limits.

You can’t rely just on figures on paper that say it has this much power and this much torque. Maximum torque may be specified, but in reality there’s a variation in the quality of torque – you could have two engines that specify 2400Nm at 1500 revs, but when push comes to shove and you’re hauling up over that last bit of hill, one truck might sail over the top and the other might die away. There’s only one way to find out which one it’s going to be and that is to push the truck to that point.

Also, a truck has to be specified to meet the needs of the Australian market. Sometimes it’s just pure luck and you can slot an overseas-designed truck straight in and it does the business. But, most often trucks that are built for, say, the European market are more problematic to use here.

So, you need to understand how a truck got to be here, in its particular specification – what goes on behind the scenes to tailor the design to suit it to local conditions. If you look at the most successful truck brands here in Australia you’ll find they are the ones whose product is most tailored to the Australian market.

I do break a truck down into different areas for testing. Yes, I have a pecking order. I think about the driveline individually – the engine, gearbox and rear diffs. Then I consider

the combination of those and how they work together.

Then you go through the rest. From the driver’s point-of-view, you ask if it is ergonomic and sensible. Is everything there and easy to use? Then I take a tape measure and examine the space. How high is everything?

If it’s a prime mover, I look at the bunk. Can you stand up to take your trousers off? If you can’t then you’ll be laying on the bunk. If it’s a bread delivery truck then you’re obviously looking for different things. Has it got somewhere handy to put the load sheets? Does it have a good light for delivering at night? Does it have good air-con, a good radio? Where’s the cup-holder?

Then I look at steering and ride. They tend to go together. You consider the feedback. Are you getting the right kind of feedback?

As for testing duration, it varies. Bigger trucks, I like to drive for a day or so. With little trucks, you can get away with less time because you can pretty much simulate a delivery run in a shorter period.

Also, safety. Owners now have a duty of care to think about safety and so do drivers. There’s driving experience and owning experience. They’re different, but you have to think about both of them.

Some of the trends mark the way trucks have changed. Since I stopped driving for a living, trucks have become a lot more powerful and a lot more comfortable – that includes Hino's trucks. There’s been a series of improvements, they’re really noticeable.”

“ I’ve been in the transport industry all my life. I’ve owned trucks and driven trucks. Foremost, I’m a driver. Then, I’m a writer.

TIM GILES

Torque | 15

Senior Technical Writer, Prime Mover Magazine

16 | Torque

I follow a very specific program. First thing: walk around it looking for obvious things, like a stone jammed in the duals. Do a safety check. Look for broken lights, and damage or scarring.

Turn on the hazards and parking lights/headlights. Then walk, again. That will tell you if all your blinkers and lights are working, so you can at least be seen.

Then, the daily pre-trip check. Tyre pressures are absolutely critical and you should trust no-one when it comes to tyre pressures. The inners of duals are almost always wrong because they’re difficult to check.

Then visual checks for water, coolant, power steering fluid and oil. It’s nice if you can dip-stick. I also assess

how easy it is to do a full check rather than just looking at the gauges. If you have to tilt the cab to get to the oil, it’s a black mark from me because no one will check it.

Cleaning the windscreen. How easy is it to do? Is there a grab handle? Does the bumper bar have usable foot grips?

Check the ergonomics. Can you get comfortable? Will the seats support your shoulders? Hino’s cab ergonomics and wand controls are excellent. Then it’s just a question of how the driver fits in the cab. It can’t be just about you as the tester, it’s got to be about all drivers.

I start the engine and let it warm for a minute or so. If it’s an airbraked truck you have to wait for the air to build up

in the brake circuit, anyway. I check the gauge and make sure the air builds up quickly. Some have air-assisted clutches, too, so you can’t depress the clutch until the air is built up.

Then the side mirrors. You can get away with a manual mirror on the driver’s side but not the passenger side. Also if it doesn’t have heated mirrors, that’s another black mark from me. In a car, it’s not a problem. Nearly every truck is parked outside.

I usually drive very slowly for the first 20 kilometres – nowhere near the speed limit. That’s because you don’t know yet how everything operates. Give the steering a bit of a tug and see what the response is. If it’s a semi or a B-Double, you need to judge it in corners to determine how much cut-in you’ve got.

Clutch weight: how heavy is it? Sitting at traffic lights, the best way to drive is to be in-gear with your foot on the clutch. That’s not such a big issue these days with the advent of assisted clutches.

Also, we are getting more automatic gearboxes and automated manual gearboxes. If it has an automated manual, I’ll ask before the test if they can send me the pages of the truck manual so I know how it works, because they’re all different.

When I’m under way, I judge the feel and the cornering. Has the steering got too much kick? Does it feel so isolated you don’t know what’s going on?

After about an hour, I start to judge engine performance. Give it an hour. Then you’ll know what gear is right for certain situations and you can

judge if the engine has enough torque. Also, there’s no point judging noise too early, because you’re probably using too many revs.

It’s about making sure that the truck is fit for purpose, but you don’t know that unless you have it on the road for an appropriate amount of time. I’d say you need at least six hours in a truck to start to get used to it.

The emphasis on safety is a priority. I like to evaluate a truck on its primary safety: the handling and brakes. But, there should be more active safety in trucks such as ABS and ESP. Included in primary safety are ease-of-driving and vision, and a good comfortable seat so you don’t get fatigued.

I was in a Hino FC Hybrid recently that was nice to drive. It was the most pleasant Japanese truck I’ve ever driven. It’s a good thing that Hino incorporates these items in their trucks.

After I have an overall impression forming in my head about the truck along the lines of, ‘this thing’s not bad’, or, ‘it’s a bit of a dog’, I think about what the truck is intended to do.

I’ve read scathing appraisals of trucks that I disagree with completely because the truck in question should not have been tested on that road.

A ‘doughy’ truck can be perfect in a lot of applications, if that’s what the customer wants. Perth, Adelaide, East Melbourne and South-West Brisbane are flat – whereas virtually all of Sydney is hilly.

Many owners don’t mind if a truck is down on performance compared with some of its competitors. It’s road transport, not a race.”

“ When you’re road testing a truck, you should be putting yourself in the buyer’s position. It’s very different from buying a car because most guys who buy trucks don’t drive them – you need to consider what’s going to be done with the truck.

ALLAN WHITINGFreelancerTransport Today Magazine

Torque | 17

We mainly focus on engine and driveline technology. Obviously the truck’s ergonomics and comfort come into the equation, but our prime consideration is whether the truck actually fits the function for which it was designed.

With the move to Euro IV and Euro V emission standards, our fuel economy testing is now particularly important.

It used to be a more cursory drive. Now we are running longer distances – something like 2500 kilometres over two or three days. We do that to get data that will help an operator evaluate whether a vehicle will perform well in his particular circumstances and whether there are cost advantages for accepting new technologies. It’s our business to find ways of keeping the reader informed so they can make the right decisions to achieve greater profitability.

So, the key areas of evaluation are performance, fuel economy and emissions, and driver fatigue. We look out for ease of access, comfort levels, and interior noise suppression – anything that combats fatigue. Drivers who are relaxed and less fatigued perform better and the vehicle is less subject to stress in the engine driveline, therefore the operator gains through less maintenance.

As far as trends are concerned, engines are becoming more efficient and producing more horsepower and torque than before. Cooling packages are improving, too. And the environment is a big winner in that we’re reducing emissions. All those aspects are hugely important.

ABS and EBS are a huge change from five years ago and I think roll stability and electronic stability programs will be soon introduced universally on all operations. I think we’re not too far away from government offering operators incentives to use Euro V and VI Emission Standards earlier than legislated. Hino is moving quite quickly towards those positions.

If I had a suggestion for owners who are evaluating trucks it would be: Remain open to new technology and evaluate what is best for your particular needs.”

“ We’re always looking at whether the vehicle fits the function for which it has been designed. Also, to see how well the vehicle performs on the road within the parameters of the vehicle’s design structure. We’re not looking to push it to limits beyond its design, but we are of course trying to evaluate how it performs within those areas in the hands of an operator.

CHRIS MULLETTManaging Editor, Power Torque Magazine

18 | Torque

Two Hino buses and a new RN8J chassis were among 60 buses and bus components on show at the inaugural BusNSW Bus and Coach Show on 7-8 October last year at Rosehill Racecourse, NSW.

Hino Australia threw its support behind the show, which was hosted by BusNSW and attracted hundreds of industry and bus enthusiasts.

Hino displayed an RN8J auto bus

with a P&D Coachworks body, on loan from Forster Coaches, and a Chiron Mark 3 body – the first to be shown in Australia.

The Hino stand was well attended and generated solid sales leads.

Over $30 million worth of vehicles from leading manufacturers were on display with 100 indoor exhibition booths for products, services and tourism information.

CUSTOMERS HAIL HINO BUSES AT NATIONAL SHOW

Big issues facing the bus transport system were presented and discussed at the 2009 Bus Industry Confederation (BIC) conference held across three days in Hobart in late-October last year.

The conference ran under the theme ‘Moving Australians – Sustainable Transport’ and included representatives from Hino among the 540 delegates in attendance.

The conference focused on the BIC’s efforts to see a National Moving People Strategy developed

and implemented for Australia as part of the solution to address issues such as climate change, urban congestion, social exclusion and peak oil.

Session topics included the future of public transport, setting a new training agenda, the future of the bus market in relation to alternative fuels, hybrid and all-electric vehicles, and how to deliver a best practice school bus system.

Hino Australia is a member of BIC and sponsored the conference lanyards.

HINO SUPPORTS SUSTAINABLE TRANSPORT

HINO BUSES ON THE SCHOOL RUNThe Department of Education and Children Services (DECS) has six new Hino RB 8 Mark 2 buses doing the school runs in regional South Australia.

Delivered by CMI Hino of Adelaide, the buses seat 34 children with seat belts, and come with air conditioning as standard.

Hino buses are renowned for their reliability, economy and serviceability and were preferred by DECS over other bus brands.

To prepare the buses for their role as school transport, DECS requested modifications to the rear boot.

An internal luggage rack was fitted so school children can safely store their school bags, rather than have them on the floor.

The buses will pick up and drop off school children throughout South Australia, including Kangaroo Island and as far afield as Ceduna, on the edge of the Nullabor.

DECS now has 10 RB 8 buses, all supplied by CMI Hino of Adelaide, in addition to many more Hino buses of varying ages on the fleet.

The Hino RB 8 Mark 2 bus is a 27-34 seat bus which is built as a standard production model, but can be diversified for many usage requirements.

CMI Hino of Adelaide service and maintain the majority of the DECS Hino bus fleet as part of an ongoing and long-established relationship.

On the Buses

Torque | 19Torque | 15

NEW SOUTH WALESAlbion Park Rail Illawarra Hino ���������������(02) 4256 7111

Beresfield Newcastle Hino ����������������������(02) 4974 7800

Camden Adtrans Hino ������������������������������� (02) 4655 5755

Grafton Black Hino ����������������������������������� (02) 6642 2644

Guildford City Hino ����������������������������������� (02) 9681 8111

Kempsey Mavin and McNamara �������������� (02) 6562 6211

Mascot Adtrans Hino �������������������������������� (02) 9598 9444

Muswellbrook Muswellbrook City Hino ��� (02) 6543 3066

Orange West Orange Motors ��������������������� (02) 6361 1000

Queanbeyan Southern Truck Centre ��������� (02) 6299 6433

Tamworth Tamworth City Hino ����������������� (02) 6765 5552

Wagga Trucks Hino����������������������������������� (02) 6925 5779

West Gosford Adtrans Hino ���������������������� (02) 4320 4932

VICTORIABendigo Bendigo Truck Centre ����������������� (03) 5440 9111

Dandenong Prestige Hino ������������������������ (03) 9212 5555

Laverton North CMI Hino ������������������������� (03) 9931 6500

Mildura Sunraysia Auto Group (Mildura) ��� (03) 5021 2999

North Geelong ISR Hino ��������������������������� (03) 5278 9844

Wodonga Jacob Hino ������������������������������� (02) 6055 9800

TASMANIAHobart FRM Hino (Derwent Park) �������������� (03) 6272 3822

Devonport FRM Hino �������������������������������� (03) 6424 9855

Launceston FRM Hino (Invermay) ������������ (03) 6334 5877

QUEENSLANDAyr Don West Toyota ��������������������������������� (07) 4783 1600

Cairns Pacific Hino ����������������������������������� (07) 4052 4777

Coopers Plains Sci Fleet (Brisbane) ��������� (07) 3722 2888

Goondiwindi Tait Motors �������������������������� (07) 4671 7300

Gympie Hi-Way 1 Truck & Tractor ������������� (07) 5480 5000

Kedron Sci-Fleet (Brisbane) ���������������������� (07) 3361 0024

Kunda Park Hi-Way 1 (Maroochydore) ���� (07) 5453 5000

Mackay Carlisle Hino�������������������������������� (07) 4952 1088

Maryborough Hi-Way 1 Truck & Tractor ��� (07) 4190 4190

Mt Isa Bell & Moir Corporation ������������������ (07) 4743 3066

Nerang Gold Coast Hino ��������������������������� (07) 5596 3599

Rockhampton Ian Weigh Motors�������������� (07) 4924 5200

Toowoomba Vanderfield Hino������������������� (07) 4633 4822

Townsville Primemovers �������������������������� (07) 4779 0077

NORTHERN TERRITORYAlice Springs Peter Kittle Motor Co ��������� (08) 8952 5500

Darwin Vanderfield Hino (Pinelands) ��������� (08) 8932 4200

WESTERN AUSTRALIAPerth WA Hino (Welshpool)������������������������ (08) 9351 2000

SOUTH AUSTRALIAMt Gambier Barry Maney Sales ��������������� (08) 8721 3400

Port Augusta Northpoint Hino ������������������ (08) 8642 3433

Adelaide CMI Hino (Regency Park) ����������� (08) 8243 8100

hino.com.auHMS07611

A TOYOTA GROUP COMPANY

UP TO 480HP.PACKEDIT’S POWERHINO HEAVY DUTY RANGE.THE BEEFED UP

HMS07159/PT Overseas model shown

When we say beefed up, we mean beefed up. Our enhanced heavy-duty models offer more power, improved fuel economy, reduced emissions, and allow for more applications from tippers to interstate transport. So if you’re looking for power and heaps of it, head

to your local Hino dealer today.hino.com.au

MODElS

FM Auto

FM

FS

SS

POWER

300hp

320hp

440hp/450hp

450hp/480hp

![Hino Torque Spring2007[1]](https://static.fdocuments.net/doc/165x107/5517c5e049795947228b4b3e/hino-torque-spring20071.jpg)