High Performance Anchor FH II-I09022014 155103

description

Transcript of High Performance Anchor FH II-I09022014 155103

-

http://www.fischer.de/en/ - 02/09/2014

High performance anchor FH II-I

Hig

h-p

erf

orm

ance

ste

el a

nch

ors

1

The intelligent internally threaded anchor with easy mounting

for fixings in cracked concrete

VERSIONS

zinc-plated steelstainless steel

BUILDING MATERIALS

Approved for:Concrete C20/25 to C50/60,cracked

Concrete C20/25 to C50/60, non-cracked

Also suitable for:Concrete C12/15Natural stone with dense structure

APPROVALS

ADVANTAGES

The functional principle of the FH II-Ienables fast, deformation-controlledexpansion with a hexagon wrench,thus ensuring top installationcomfort.

The visual setting control with apredefined gap U between theanchor and the concrete surfaceallows a compliant approved settingprocess without a torque wrench.

The metric internal thread allows forthe use of standard screws andthreaded rods for perfect adaptationin line with the attachment.

The FH II-I enables surface-flushremoval and the reuse of theundamaged fixing point, thusoffering optimum flexibility.

Furthermore, the FH II-I offers all ofthe benefits of the FH II.

APPLICATIONS

Steel constructionsGuard railsBracketsLaddersCable traysMachinesStaircasesPipeline routesVentilation systemsSprinkler systems

FUNCTIONING

The FH II-I is suitable for pre-positioned installation.

When a hexagon wrench is used forinstallation, the internal thread boltstarts to rotate. This pulls the coneinto the expansion sleeve andexpands it against the drill-hole wall.At the same time, the anchor istightened through compression ofthe black plastic ring. A gap U to theconcrete surface is created (seeimage 4).

The anchor is set according to theapproval when the gap U is 3-5 mm.Alternatively, an installation torqueof Tinst can also be applied.

-

http://www.fischer.de/en/ - 02/09/2014

High performance anchor FH II-I

Hig

h-p

erf

orm

ance

ste

el a

nch

ors

2

galvanized

A4

TECHNICAL DATA

High performance anchor FH II-I

ETA-

appr

oval Drill diameter Min. drill hole depth for

pre-positionedinstallation

Anchor length

d0 h1 l

Article name Art.-No. [mm] [mm] [mm]FH II 12/M6 I 520358 12 85 77,5FH II 12/M8 I 520359 12 85 77,5FH II 15/M10 I 519014 15 95 90FH II 15/M12 I 519015 15 95 90

ETA-

appr

oval Drill diameter Min. drill hole depth for

pre-positionedinstallation

Anchor length

d0 h1 l

Article name Art.-No. [mm] [mm] [mm]FH II 12/M6 I A4 520360 12 85 77,5FH II 12/M8 I A4 520361 12 85 77,5FH II 15/M10 I A4 519018 15 95 90FH II 15/M12 I A4 519019 15 95 90

-

TECHNICAL DATA

High performance anchor FH II-I

zinc plated, steel grade

8.8

stainless steel

Approval

Drill hole diameter

Min. drill-hole depth for pre-positioned installation

Anchor length

Thread Min. bolt penetration

Max. bolt penetration Sales unit

do h1 l M lE,min lE,max

Art.-No. Art.-No. ETA [mm] [mm] [mm] [mm] [mm] [pcs]Item gvz A4

FH II 12/M6 I 519012 519016 12 85 77,5 M 6 11 + U 20 + U 100FH II 12/M8 I 519013 519017 12 85 77,5 M 8 13 + U 20 + U 50FH II 15/M10 I 519014 519018 15 95 90 M 10 10 + U 20 + U 25FH II 15/M12 I 519015 519019 15 95 90 M 12 12 + U 20 + U 20

Cracked concrete Non-cracked concreteType Effective

anchorage depth

Min.member thickness

Torque moment

Permissible tensile load

Permissible shear load

Min.spacing

Min.edge

distance

Permissible tensile load

Permissible shear load

Min.spacing

Min.edge

distancehef hmin Tinst Nperm

3) Vperm3) smin

2) cmin2) Nperm

3) Vperm3) smin

2) cmin2)

[mm] [mm] [Nm] [kN] [kN] [mm] [mm] [kN] [kN] [mm] [mm]

FH II 12/M6 I 60 125 15,0 4,3 4,6 50 50 7,6 4,6 60 60FH II 12/M8 I 60 125 15,0 4,3 8,0 50 50 9,5 8,0 60 60FH II 15/M10 I 70 150 25,0 5,7 13,1 60 60 14,1 13,1 70 70FH II 15/M12 I 70 150 25,0 5,7 13,7 60 60 14,1 13,7 70 70

High performance anchor FH II-I (screw property class 8.85))Highest permissible loads for a single anchor1) in concrete C20/254)

For the design the complete approval ETA - 07/0025 has to be considered.

1) The partial safety factors for material resistance as regulated in the approval as well as a partial safety factor for load actions of L = 1,4 are considered. As an single anchor counts e.g. an anchor with a spacing s 3 x hef and an edge distance c 1,5 x hef.

2) Minimum possible axial spacings resp. edge distance while reducing the permissible load. The combination of the given min. spacing and min. edge distance is not possible. One of them has to be increased according approval.

3) For combinations of tensile loads, shear loads, bending moments as well as reduced edge distances or spacings (anchor groups) see approval.

4) For higher concrete strength classes up to C50/60 higher permissible loads may be possible.5) Values for further screw property classes acc. approval.

LOADS

Cracked concrete Non-cracked concreteType Effective

anchorage depth

Min.member thickness

Torque moment

Permissible tensile load

Permissible shear load

Min.spacing

Min.edge

distance

Permissible tensile load

Permissible shear load

Min.spacing

Min.edge

distancehef hmin Tinst Nperm

3) Vperm3) smin

2) cmin2) Nperm

3) Vperm3) smin

2) cmin2)

[mm] [mm] [Nm] [kN] [kN] [mm] [mm] [kN] [kN] [mm] [mm]

FH II 12/M6 I A4 60 125 15,0 4,3 3,2 50 50 5,3 3,2 60 60FH II 12/M8 I A4 60 125 15,0 4,3 6,0 50 50 9,5 6,0 60 60FH II 15/M10 I A4 70 150 25,0 5,7 9,2 60 60 14,1 9,2 70 70FH II 15/M12 I A4 70 150 25,0 5,7 13,7 60 60 14,1 13,7 70 70

High performance anchor FH II - I A4 (screw property class A4-705))Highest permissible loads for a single anchor1) in concrete C20/254)

For the design the complete approval ETA - 07/0025 has to be considered.

1) The partial safety factors for material resistance as regulated in the approval as well as a partial safety factor for load actions of L = 1,4 are considered. As an single anchor counts e.g. an anchor with a spacing s 3 x hef and an edge distance c 1,5 x hef.

2) Minimum possible axial spacings resp. edge distance while reducing the permissible load. The combination of the given min. spacing and min. edge distance is not possible. One of them has to be increased according approval.

3) For combinations of tensile loads, shear loads, bending moments as well as reduced edge distances or spacings (anchor groups) see approval.

4) For higher concrete strength classes up to C50/60 higher permissible loads may be possible.5) Values for further screw property classes acc. approval.

LOADS

http://www.fischer.de/en/ - 02/09/2014

High performance anchor FH II-I

Hig

h-p

erf

orm

ance

ste

el a

nch

ors

3

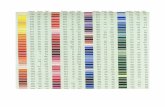

High-performance steel anchorsHigh performance anchor FH II-ITechnical DatagalvanizedA4

Loads