HIGH MOBILITY ENGINEER EXCAVATOR HMEE - MASZYNY JCB … · HIGH MOBILITY ENGINEER EXCAVATOR HMEE 7...

Transcript of HIGH MOBILITY ENGINEER EXCAVATOR HMEE - MASZYNY JCB … · HIGH MOBILITY ENGINEER EXCAVATOR HMEE 7...

GOVERNMENT & DEFENCE

HIGH MOBILITY ENGINEER EXCAVATOR | HMEEOperating weight: 14125 – 16180kg Gross rated power: 149kW Maximum speed: 88.5kph Maximum dig depth: 3.94m Maximum loader capacity: 1.0m³

1 The JCB HMEE is a specialised machine originally designed to a US Army TACOM specification for a high mobility engineering vehicle to support its Stryker Brigades. In 2005 JCB was selected to supply 800 machines to the US Army.

2 Varying levels of armour and equipment can be added to the HMEE depending on the role it needs to play, from our unarmoured A-Kit to the highly protected Theatre Entry Standard (TES) specification machines.

3 As a high mobility machine, the HMEE is capable of 88km/h and is able to keep up with military convoys both on and off-road. A low loader is therefore not needed, while the size and vulnerability of deployed forces is reduced.

4 Without bar armour the HMEE is transportable in a C-130 aircraft with preparation. Two HMEEs with bar armour can be transported in a C-17 and six (with bar armour) will fit in an Antonov AN-124. The B-Kit HMEE has been certified for airdrop operations from a C-17.

5 The HMEE has been used successfully on operations by several countries in a variety of roles, including earthmoving, fortification construction, route proving and clearance. 542

A PROVEN SOLUTION.

THE JCB HMEE IS A HIGHLY CAPABLE, PROVEN MILITARY ENGINEERING VEHICLE THAT HAS BEEN USED IN OPERATIONS BY ARMED FORCES AROUND THE WORLD.

31

2 HIGH MOBILITY ENGINEER EXCAVATOR HMEE

3HIGH MOBILITY ENGINEER EXCAVATOR HMEE

THE HIGHEST PERFORMANCE.

THE JCB HMEE IS DESIGNED TO PERFORM A HUGE RANGE OF TOUGH TASKS IN EVEN THE HARSHEST CONDITIONS.

4321

1 Four suspension modes mean that the HMEE can be optimised for loading, roading, excavating or maintenance.

2 Four-wheel drive and locking differentials allow the HMEE to cope with demanding terrain; because the differentials are soft-engage units, they can be locked on the move.

3 A wading depth of 1m increases the cross-country mobility of the HMEE.

4 All-round dry disc air brakes with twin callipers and ABS provide safe and reliable stopping power, both on and off-road.

The HMEE has three selectable steering modes for impressive manoeuvrability – two-wheel steer, four-wheel steer and crab steer.

A-Kit.1 The “base” model of the HMEE range, the A-Kit has a fully ROPS/FOPS-certified glass cab with excellent all-round visibility. There’s also seating for a passenger, making this machine ideal for non-deployed units.

2 As a tough and versatile machine that can self-deploy quickly on and off-road, the A-kit HMEE is perfect for disaster relief operations.

3 For optimum versatility, this model has a hose reel fitted as standard, along with a 4-in-1 shovel mounted onto a quickhitch carriage.

B-Kit.4 The B-Kit HMEE adds applique armour to the A-Kit machine without impacting on performance; top speed and excavating/loading power are unchanged.

5 Blast and ballistic protection on the B-Kit HMEE is tried and proven on operations in recent conflicts around the world.

6 Useful standard features of the A-Kit model are carried over onto the B-Kit, including the hose reel, 4-in-1 bucket, quickhitch and passenger seat.

6

5

HMEE MODELS.

4 HIGH MOBILITY ENGINEER EXCAVATOR HMEE

THE JCB HMEE IS DESIGNED FOR MAXIMUM OPERATOR SAFETY AND OPERATIONAL VERSATILITY.

43

2

1

5HIGH MOBILITY ENGINEER EXCAVATOR HMEE

10987

HMEE MODELS

C-Kit.7 Originally designed as part of a route proving and clearance system for the UK Army, the C-Kit HMEE has also successfully performed this hazardous role for other countries.

8 Using the B-Kit HMEE as its foundation, the C-Kit adds a blast mitigating belly plate, a blast attenuating seat, an internal spall liner and a footplate for additional protection. There’s also the option to add bar armour for RPG protection.

9 We can prepare this machine for aftermarket additions like a combat net radio, electronic countermeasures, night cameras and thermal imaging technology.

10 In C-Kit trim, the HMEE passenger seat is removed and – if the optional bar armour is fitted – its ability to be transported on a C-130 plane. However, excavating performance, loader performance and roading speeds (unless limited) remain unchanged.

The C-Kit HMEE or TES (theatre entry standard) is a B-kit HMEE with many specialised modifications to allow it to operate in high-threat environments.

1 JCB provides a unique global parts support system via its 2000 Dealerships in 157 countries. The system provides year-round 24-hour-a-day support with rigorous targets to ensure machine downtime is reduced to a minimum.

2 We can provide training for all maintenance levels from operator to maintainer level, with bespoke courses held in either the customer’s country or the UK.

3 JCB supplies technical publications with all machines – both in hard and soft copy, and to commercial or specific military formats. These can be provided in any language as required.

32

ARMED FOR ANYTHING.

JCB’S INTEGRATED LOGISTICS SUPPORT (ILS) PROVIDES FIRST CLASS CUSTOMER BACKUP, HELPING TO INCREASE MACHINE AVAILABILITY AND DECREASE DOWNTIME.

6 HIGH MOBILITY ENGINEER EXCAVATOR HMEE

1

7HIGH MOBILITY ENGINEER EXCAVATOR HMEE

1 JCB’s first military machines were articulated steer loaders capable of 30mph and fitted with forks instead of shovels. In total nearly 1,000 JCB 410M models were supplied to the UK MoD beginning in 1984. 30 years on, JCB has supplied over 3,500 military machines to over 56 countries.

2 We can supply military vehicles that are lightly modified from our standard production models. And, with a range of over 300 machines, we can fulfil nearly any military requirement.

3 In addition to largely standard machines, JCB also offers dedicated military solutions with extensive modifications like 24V electrics, wading and cold climate capabilities, lift and tie-down points for air transportation, and armouring options.

4 JCB is one of the few construction companies willing to design and develop specialised machines for military applications. Alongside the HMEE, we’ve also developed the High Mobility Rough Terrain Forklift (HMRTF) – a high speed telescopic handler designed to support military logistics operations. 4

MILITARY FOCUS.

3

22

1 3

SPECIFICATION HIGH MOBILITY ENGINEER EXCAVATOR HMEE

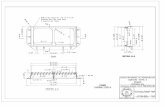

Model A/B-KIT TES

A Overall length (with full ancillaries) m 10.10 10.10

B Overall height m 3.89 3.89

C Height to top of cab (prepared for air transport) m 2.67 2.67

D Wheelbase m 3.06 3.06

E Ground clearance – kingpost m 0.85 0.85

F Width – shovel m 2.44 2.44

G Overall height m 3.07 3.07

H Length m 9.45 9.45

I Width – bar armour m N/A 2.95

STATIC DIMENSIONS - A-KIT, B-KIT, TES

H

A

D

H

A

D

C

E

F

B

G

C

E

F

B

G

C

E

F

I

B

G

H

A

D

ENGINE

Make Cummins

Model QSB

Displacement lt 6.7

No. cylinders 6

Bore size/mm mm 102

Stroke/mm mm 120

Aspiration Turbocharged with charge air cooling

Air filter Dual element, dry filter

Cold start Inlet grid heater

Power rating to: ISO/TR 14396 & SAE J1995

Gross power @ 2300 rpm 149kW

Gross torque @ 1600 rpm 705Nm

TRAVEL SPEEDS

1st forward km/h 12.2

2nd forward km/h 18.8

3rd forward km/h 29.0

4th forward km/h 44.9

5th forward km/h 62.3

6th forward km/h 88.5

1st reverse km/h 12.8

2nd reverse km/h 30.6

*In TES configuration forward travel speed is limited to 65kph.

ELECTRICS 24 VOLT

Starting circuit 24 Volt

Standard alternator 240 Amp 28V brushless

No. front work lights 2 adjustable

No. rear work lights 4 adjustable

*In TES configuration No. front work lights is 4.

AXLES

Dedicated JCB heavy duty steer-drive axles front and rear. Both axles incorporate JCB soft-engage differentials enabling on-the-move engagement of differential locks.

WHEELS AND TYRES

Bridgestone 445/80 R25 tyres on steel 2 piece rims. Hutchinson VFI runflat inserts can be fitted to preserve mobility in the event of tyre burst or deflation.

BRAKES

• Outboard dry discs with twin callipers front and rear provide outstanding retardation and endurance.• ABS for controlled stopping in difficult conditions.• Air over oil operation for low pedal efforts.• Service brake disc diameter 460mm (18.1in).• Parking brake provided by two spring applied hydraulically released callipers operating on discs mounted on the transmission output

shafts. Capable of holding vehicle on 1:2.5 (21.8 degrees) slope. Park brake disc diameter 380mm (14.9in).

SPECIFICATIONHIGH MOBILITY ENGINEER EXCAVATOR HMEE

Model 4WS 2WS

A Min. Kerb-kerb m 10.38 18.40

B Min. Wall-wall m 13.10 20.10

(Depending on tyre size, ground condition, front ancillaries and cab type etc.)

MULTI MODE SUSPENSION SYSTEM

Full suspension with optimised spring rates and damping gives increased mobility and operator comfort and predictable handling on highway. The suspension system allows the operator to select one of four suspension modes –

• Travel mode – full suspension for travel on and off highway. • Transport / Maintenance mode – lowers suspension for tie-down, storage or workshop. • Loader mode – front axle locked for maximum stability, rear axle oscillates. • Backhoe mode – rear axle locked, front axle oscillates.

TRANSMISSION

The ZF Ergopower transmission allows full power gear shifts without loss of speed or momentum. Gear shifts can be under operator control or fully automatic. Electrically operated reversing shuttle enables fast loading cycle times. Torque converter and low first and second gear ratios give excellent tractive effort for loading and sitestripping. Transmission controlled torque convertor lock-up gives improved fuel economy and on-highway performance.

• Easy to use column mounted electric switch controls both machine direction and gear selection.• Direction changes are modulated from forward to reverse with detented lever gates for safety. The light electric twist grip provides

effortless shifting between gears.• Torque converter (13.4”) stall ratio: 1.79:1.• Electrical selection of 4WD.

STEERING

Three operator selectable steering modes available.

• 2WS for on-highway travel. Power assisted mechanical front steering and locked rear steering.• 4WS for loading duties and confined sites. Power assisted mechanical front steering and

synchronised hydrostatic rear steering.• Crab steer for parallel drive when digging close to walls and other obstacles. Power assisted

mechanical front steering and synchronised hydrostatic rear steering.

A B

CAB – A-KIT

The A-Kit cab is designed to seat two people in comfort and to fit in a C130 for air transport with a minimum of modification. The cab frame is ROPS and FOPS approved to ISO 3471 and 3449 (SAE J1040 and J231) for maximum operator protection.

• Adjustable operator’s seat with ergonomically positioned controls to minimise operator fatigue. Fixed passenger seat. 3 point inertia reel seat belts for both seats meeting SAE J386 and FMVSS 210 and 207.

• A-Kit cab provides two door access and sliding rear glass. Standard features include 3 speed heating and air conditioning blowers, front and rear screen wash/wipers, front and rear horn, exterior mirrors.• The main instrument panel is positioned to the right-hand side for ease of viewing from either the loading or excavating position. The main panel carries full instrumentation for vehicle systems and audio/visual warning of system failure. Warning lights for key systems are repeated on a panel in front of the steering wheel.• SAE J1939 CANBUS enables diagnostic access to main vehicle systems.• The A-Kit cab is prepared to accept applique armo.

Pump flows

Open Centre System

Main pump 1: 100 l/min at 2300 rpm rated engine speed

Auxiliary pump 2: 70 l/min at 2300 rpm rated engine speed

Auxiliary pump 3: 12 l/min

CAB – B-KIT

As A-Kit configuration with the addition of applique armour and balistic glazing and removal of 2nd door.

CAB – TES

As B-Kit configuration with the addition of blast mitigating belly plates, internal spall liner, blast attenuating seat, bar armour, roof hatch, foot plate, removal of passenger seat, provision for electronic communications and counter measures as well as night & thermal imaging systems.

HYDRAULICS

The hydraulic system is comprised of 2 fixed displacement gear pump sets and one electrically operated emergency pump feeding the open centre loader and backhoe control valves. Hydraulic integrated circuit manifold blocks control suspension, steering, parking brake, transmission services. The system incorporates:–

• Gear pumps for high reliability, low noise operation of main hydraulics.• Electrically driven emergency pump allowing limited operation of main hydraulic functions in the event of engine failure.• Integrated hydraulic handtool circuit to HTMA type 2 with 50 foot hose reel.• Full flow 10 micron filter to ensure that oil stays free of contaminants.• Auxiliary hydraulic connections on loader and backhoe for optional attachments.

CAPACITIES

Hydraulic system (inc. tank) ltrs 140

Fuel tank ltrs 265

Engine coolant ltrs 37.1

Engine oil (inc. filter) ltrs 15.0

Axle differential casing (each axle) ltrs 18

Axle hubs (each axle) ltrs 3.0

Transmission (inc. filter) ltrs 30.0

WEIGHT

Operational weight with one operator, 4-in-1 GP shovel, 610mm excavator bucket, full fuel load, runflat inserts, no stowage A-Kit – 14125kg, B-Kit – 15959kg, TES – 16180kg.

STANDARD EQUIPMENT

Clear glass, Front sunvisors, Front and rear wipers and washers, Cab heater with demist, Air conditioning, Operator and passenger seat, 3 point inertia reel seat belts, Reverse alarm, External mirrors, Fire extinguisher, Road lights, Front and rear work lights with light guards, Battery isolator, Inter-vehicle starting socket, Support and maintenance struts for loader and backhoe, Hydraulic self levelling for loader end, Loader quickhitch with 0.93m3 4-in-1 shovel with teeth, 600mm excavator bucket with teeth, Tyre inflation air supply, HTMA Type 2 Hydraulic handtool supply and 50ft hose reel, Lighting blackout system.

OPTIONAL EQUIPMENT

Loader end – General purpose 1.0m3 shovel, spare wheel and extra tool stowage, sandbagger, sweeper, snowplough, 4500lb forklift frame with sideshift and rotate.Excavator end – Lifting shackle or hook, wide range of excavator buckets including ditching, grading and ripping buckets, JCB Hammermaster breaker, auger up to 36” capacity, compactor, Extradig extending dipper.Hydraulic handtools HTMA type 2 – impact wrench, rock drill, post driver, pavement breaker, chainsaw. Winterisation kit.

SPECIFICATION HIGH MOBILITY ENGINEER EXCAVATOR HMEE

A

B

C

D

F

G

J

Q

UT

M

N O

P

S

R

V

E

A

B

C

D

F

G

J

Q

UT

M

N O

P

S

R

V

E

B

C

A

LOADER AND EXCAVATOR REACH GROUND LINE ANGLES

A Approach angle degree 36.5o

B Interface angle, travel mode degree 148o

C Departure angle degree 31.5o

EXCAVATOR REACH

SPECIFICATIONHIGH MOBILITY ENGINEER EXCAVATOR HMEE

BACKHOE DIMENSIONS

Std Dipper

A SAE max dig depth m 3.94

SAE 2ft flat bottom m 3.89

Maximum dig depth m 3.94

B Reach – ground level to rear wheel centre m 6.54

C Reach – ground level to slew centre m 5.25

D Reach – at full height to slew centre m 2.10

E Side reach – to centre line of machine m 5.25

F SAE maximum operating height m 5.63

G Maximum loadover height m 3.86

J Bucket rotation degree 187.5o

LOADER DIMENSIONS

Shovel type – 0.93m3 4-in-1 on quickhitch

M Dump height m 300

N Loadover height m 3.79

O Pin height m 4.03

P Pin forward reach m 0.68

Q Reach at ground (toe plate horizontal) m 2.50

R Max. reach at full height m 2.02

S Reach at full height fully dumped m 1.46

T Dig depth m 0.16

U Rollback at ground degree 40.1o

V Dump angle degree 45o

BACKHOE PERFORMANCE

Std Dipper

Bucket tearout SAE J1179 speed 4378kg

power 5131kgf

Dipper tearout SAE J1179 3164kgf

Lift capacity over end SAE J31 1300kgf

LOADER PERFORMANCE

Shovel type – 0.93m3 4-in-1 on quickhitch

Shovel breakout kgf 3568

Loader arm breakout kgf 2300

Lift capacity to full height kg 2041

Shovel type – 1.0m3 General Purpose on quickhitch

Shovel breakout kgf 4082

Loader arm breakout kgf 2300

Lift capacity to full height kg 2300

BACKHOE ATTACHMENTS

Standard Profile Buckets – Capacity SAE – Weight

Width* mm Rated m3 Struck m3 +Teeth kg Teeth

305 0.06 0.05 102 3

400 0.09 0.07 109 3

457 0.12 0.09 116 3

610 0.17 0.13 140 4

800 0.24 0.17 162 5

950 0.30 0.21 198 5

Standard Profile Buckets – Capacity SAE – Weight

Width* mm Rated m3 Struck m3 +Teeth kg Teeth

305 0.09 0.07 102 3

457 0.16 0.13 122 3

610 0.23 0.18 142 4

800 0.30 0.24 163 5

950 0.38 0.30 183 5

1100 0.48 0.34 203 6

*Including sidecutters. Width less sidecutters deduct 25mm (1in). †Capacity in cu yd

LOADER ATTACHMENTS

Standard 4-in-1 shovel – Capacity SAE

Width* mm Rated m3 Struck m3

2438 0.71 0.61

Optional G.P. shovel – Capacity SAE

Width* mm Rated m3 Struck m3

2438 1.00 0.81

www.carbonbalancedpaper.comunique print number

J C Bamford Excavators Ltd., Defence Products, Rocester, Staffordshire, ST14 5JP England Tel +44 (0)1889 590312

©2009 JCB Sales. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB Sales.

All references in this publication to operating weights, sizes, capacities and other performance measurements are provided for guidance only and may vary dependant upon the exact specification of machine. They should not therefore be relied upon in relation

to suitability for a particular application. Guidance and advice should always be sought from your JCB Dealer. JCB reserves the right to change specifications without notice. Illustrations and specifications shown may include optional equipment and accessories.

The JCB logo is a registered trademark of J C Bamford Excavators Ltd.

HIGH MOBILITY ENGINEER EXCAVATOR | HMEEOperating weight: 14125 – 16180kg Gross rated power: 149kW Maximum Speed: 88.5kph Maximum Dig Depth: 3.94m Maximum loader capacity: 1.0m³

GOVERNMENT & DEFENCE

9999/5581 05/14 en-GB Issue 1