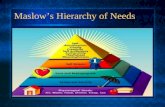

Hierarchy of Decisions

description

Transcript of Hierarchy of Decisions

Hierarchy of Decisions

1. Batch versus continuous

2. Input-output structure of the flowsheet

3. Recycle structure of the flowsheet

4. General structure of the separation system Ch.5

a. Vapor recovery system

b. Liquid recovery system

5. Heat-exchanger network Ch.6, Ch.7, Ch.16

Ch. 4

LEVEL 3 :

reactor separator products

purge

feeds

Liquid ?Liquid / Vapor ?

Vapor ?

LEVEL 4 :

1 ) Liquid

reactorliquid

separationsystem

Liquid recycle

productsliquidfeeds

LEVEL 3

LEVEL 4 :

2 ) Liquid / Vapor

reactorliquid

separationsystem

Liq. recycle

productsliquid

feeds

LEVEL 3

PhaseSplit

VaporRecovery

system35Cgas recycle

vapor liq.liq.

vapor

purge

LEVEL 4 :

3 ) Vapor

reactorliquid

separationsystem

Liquid recycle

productsfeeds

LEVEL 3

PhaseSplit

VaporRecovery

system35Cgas recycle

liquidliquid

vapor

purge

vapor

LOCATIONS OF VAPOR RECOVERY SYSTEM

2 1

3

Gas

Recycle

Purge

vapor from phase split

1 ) The purge stream

2 ) The gas-recycle stream

3) The flash vapor stream

4 ) None

RULES FOR PLACING THE VAPOR RECOVERY SYSTEM

1 ) Place the vapor recovery system on the purge stream if significant amounts

of valuable materials are being lost in the purge.

2 ) Place the vapor recovery system on the gas-recycle stream if materials that

are deleterious to the reactor operation (catalyst poisoning, etc.) are present

in this stream or if recycling of some components degrades the product

distribution.

3 ) Place the vapor recovery system on the flash vapor stream if both 1 ) and 2 )

are valid.

4 ) Do not use a vapor recovery system if neither 1 ) nor 2 ) are important.

TYPE OF VAPOR RECOVERY SYSTEM

1 ) Condensation - low. T and/or high P

2 ) Absorption

3 ) Adsorption

4 ) Membrane separation

5 ) Reaction

ADJUST MATERIAL BALANCE ?

DECISION IN SYNTHESIZING LIQUID SEPARATION SYSTEM

1. How should light ends be removed, if they might contaminate the product ?

2. What should be the destination of light end ?

3. Do we recycle components that from azeotropes with reactants, or do we split the azeotropes ?

4. What separations can be made by distillation ?

5. What sequence of columns do we use ?

6. How should we accomplish separations if distillation is not feasible ?

1 ) ALTERNATIVES FOR LIGHT-ENDS REMOVAL

Phase Splitter — T and/or P

Partial Condenser on Product Column

Pasteurization Section on Product Column

a Stabilizer Column before the Product Column

Lowercost

Higher cost

lights

product

lights

product

lights

product

2 ) DESTINATION OF LIGHT ENDS

a ) vent or flare stacks - if light ends have very little value.

b ) fuel - if light ends are flammable.

c ) vapor recovery system - if light ends are valuable.

3 ) AZEOTROPES WITH REACTANTS

4 ) APPLICABILITY OF DISTILLATION

5 ) SEQUENCING OF SIMPLE COLUMNS

6 ) COMPLEX COLUMNS

Reactor Flash

Recycle

Product

Stablizer

Diphenyl

Toluene

H2, CH4

Compressor

Benzene H2, CH4

Purge

Process Simulation

Run ChemCAD to obtain M&E balance data !

ECONOMIC POTENTIAL AT LEVEL 4

EP4 = EP3 - annual purge loss - annualized distillation costs - annualized vapor recovery costs

2106

1106

$/yr 0

-1106

-2106

-3106

0.1 0.3 0.5 0.7

0.20.40.6

PHy

x

2 ) DESTINATION OF LIGHT ENDS

a ) vent or flare stacks - if light ends have very little value.

b ) fuel - if light ends are flammable.

c ) vapor recovery system - if light ends are valuable.

3 ) AZEOTROPES WITH REACTANTS

4 ) APPLICABILITY OF DISTILLATION

5 ) SEQUENCING OF SIMPLE COLUMNS

6 ) COMPLEX COLUMNS

A B

C

Design 1 : Direct Sequence

A

B

Design 2 : Indirect Sequence

C

B

Design 3 : Side-stream rectifier

C

A

Design 4 : Side-stream Stripper

C

A

B

Design 5

Prefractionator arrangement

C

A

B

A , B

B , C

A A

C

Design 6 Design 7

side stream

B

C

B