Head of Process Safety engineering profile Prakash Thapa

-

Upload

prakash-thapa-ta-1 -

Category

Documents

-

view

203 -

download

1

Transcript of Head of Process Safety engineering profile Prakash Thapa

To,

Human Resources manager,

Dear Sir/Madam,

I am very interested in discussing possible opportunities within your organization. I think my

background and experience will enable you to decide about the suitability against the

available/reading positions. Particular note for you as consider my extensive experience and

skills are my strong accomplishments mainly on process safety, loss prevention and

technical safety, and HSE management system background in line with the improved

operating efficiency of plant /facilities process as a whole. Additionally this has been

enhanced by extended services,effective follow ups and improved coordination between the

stack holders of a range of MNC’s of international repute.

I am eager to consider new challenges to supporting my technical excellence demonstrated

total commitment to values including safety, quality, ethics, and controls. As an open

communicator ability to build sound working relationships has allowed me to work effectively

with a strong team based culture.

If you are looking for skilled and dynamic personnel combine practical skills with high-end

analytical engineering expertise to deliver reliable, innovative solutions to complex problems.

I believe I can match my passion for safety; integrity and technical excellence for the

available role then please consider what I have to offer. I would be happy to have a

preliminary discussion with you to see if we can establish a mutual interest.

Thank you for your attention to my details. I certainly look forward to exploring this further. I

am available to start work immediately and am flexible to the rotational assignment.

Sincerely yours’

Yours Sincerely,

Prakash Bahadur Thapa

75 Bold Street Hamilton Ontario Canada

Mobile No (1) 709 330 8666

Email: [email protected]

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

Prakash Thapa (Head of Process Safety Engineer)Chevron Canada Ltd, Kitimat LNG project, 500 - 5th Avenue S.W. Calgary, AB T2P 0L7

Canada Tel: (C) + 1 709 330 8666, Email: [email protected]

Career Objectives

Technical Specialties: Certify TA (I) over 23 years’ experience in industry as a HSE Management and

Technical Safety Engineering, process and instrumentation system design engineering, lose

prevention engineering, Reliability and Maintenance engineering in the major Oil and Gas

Petrochemical Industry. I have a wide range of Research and Development Projects experience in

aerospace and nuclear power plant industries.

Lead Technical Safety, Head of process safety role with technical Design Safety experience covering

a wide range of projects both Offshore (Platforms and FPSO) and Onshore to includes Safety and

Risk assessment studies work associated with all phases of projects including Conceptual Design,

Front-End Engineering, Detail Design, Construction, Commissioning and Operations.

Corporate HSE experience includes coordination and development a numerous of Company Health,

Safety and Environmental Plans, Procedures, safety concept, HSE case, Work Methods, Strategy

documents, Safety Critical Performance Standards, Toolbox Talk Presentations and development and

updating of Corporate HSE Philosophies. Corporate activities involved undertaking Internal and

External Corporate HSE and Technical Audits both of as a lead or part of an integrated team where

required. External Audits typically covered Contractor’s HSE Management System Compliance. Other

Corporate roles included undertaking Incident Investigation as lead and team Member.

Particular areas of expertise include process engineer, project engineer, Safety and Risk

Study/Assessment, formal safety study, function safety study, Safety Case Development, Safety

Audits and Reviews, Reliability, Availability and Maintenance (RAM) studies, safety critical element

and equipment identification, and fire protection system design.

Higher Academy Qualifications : -

a) PHD Degree in safety & Risk and Oil and Gas Engineering (Estimate complete date on 2016)

b) Master Degree in Chemical engineering

c) Bachelor's Degree in Chemical Engineering

a) Memorial University St. johns Newfoundland Canada Estimate compete date end of 2016

b) Tribhuvan University Kathmandu Nepal 1991

c) TU at. Tree Chandra collage Katmandu Nepal 1993

Overall Employments Summary :

From Date Position Hold in project Employer company and Project location

1) 25 January 2015 till date Head of Process Safety Engineer

2) June 2013 to January 2015 Technical Safety

1) Chevron Canada Ltd , Kitimat LNG project Calgary AB Canada.

2) Total E&P Myanmar YSP and Badamyar Basis

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

Engineer Lead

3) October 2012 to June 2013 Lead Safety Risk Engineer

4) October 2011 to September 2012 Lead Technical Safety, Loss Prevention Engineer

5) May 2009 to September 2011 Led Technical Safety Representative

6) January 2007 to May 2009 Senior Lead technical safety and Risk Engineer

7) March 2005 to January 2007 Senior Risk Safety Coordinator

8) February 2003 to April 2005 Lead Technical Safety Engineer

9) January 2000 to February 2003 Sr. Technical & Process Safety engineer

10) February 1998 to June 2000 Senior Process Safety Engineer

11)March 1995 to February 1998 Project Technical Safety Engineer

12)April 1993 to March 1995 Technical Safety & Loss Prevention engineer

and details Engineering Project Bangkok Thailand.

3) Husky Energy Ltd, White Rose extension Basis Engineering Project St. Johns NL Canada.

4) Ras Gas Company Ltd, Barzan onshore Gas project detail engineering Yokohama Japan

5) Sabah Shell Petroleum Company Ltd, Gumusut Kakap Detail Engineering project Malaysia

6) Qatar Shell GTL Ltd, Pearl GTL Project detail Engineering Doha Qatar

7) Dolphin Energy Ltd, Dolphin Gas project details engineering and construction Doha Qatar

8) Total LNG Nigeria Ltd, LNG Six upgrading details engineering project Bonny Island Nigeria

9) Exxon Mobil Force Ins, QIT PH-II Infrastructure Project Tripoli Libya

10)Shell Petroleum Development Company (SPDC) Ltd AG Gas Gathering Project Nigeria

11)Saudi Arabian oil Company (ARAMCO) Riyadh refinery Fire and safety upgrade project KSA

12)Ras Gas Company Ltd, at CTJV Project basis and details engineering Doha Qatar

Technical Specialist skill Safety and Risk Engineering : -

Technical Safety Skill Process Safety skill

• Hazard Identification (HAZID) Study

• Effective Behaviors assessment (EBA) survey and Hazard and operability HAZOP study.

• Fire water pumps Displacement study.

• Quantitative and qualitative risk (QRA) assessment

• Fire Explosion Risk (FERA) Analysis,

• Faller mode effective critical (FMECA) analysis

• Bow Tie and Temporary Refuge (TRA) Analyses

• Helicopter Crash & Ship Collision Studies.

• Accident Reporting and (ARCA)Investigation

• Health safety and environment (PHSER) review

• Drops object (DOS) Study

• Hazard Identification of Escape, Evacuation and Rescue (HAZEER) analysis

• Safety Critical Elements model study analysis.

• Non-Hydrocarboné Hazard Analyses (NHHA)

• Escape Evacuation Rescue (EERA) Assessment

• Emergency Systems Survivability (ESSA) Assessment

• Simultaneous and operations (SIMOPS),

• Safety Integrity Level (SIL) and Wave Protection Study

• LOPA Layer of Protection Analysis

• Hazard Identification Risk Assessment (HIRA)

• Ship collision Study (SCS)

• Non-flammable Major Hazard Accident investigation.

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

• Computational fluid dynamics (CFD) simulation

• Vent Radiation and Dispersion Study

• Safety Review and Process Hazard (PHA) Analysis

• Environment which have potential for harm to the environment (ENVID), Task Risk Analysis (TRA)

• Control of major accident hazards (COMAH)

• Health Safety Environmental Impact (HSEIA) study and Layers of Protection (LOPA) Analysis

• Environment baseline survey (EBS), Safety Critical Element Impact Analysis

• Plant fire gas Relief and blow-down Studies,

• HAZARD effective management system (HIMS) and Process safety distance Assessments

• Developing the technical safety and fire protection system related general specification, policy, plane and project procedure

• Waste Management, Chemicals handling and Spill Contingency plane development to implementation based on the OSHAS 18001 and ISO 14001, Facilitator of Behavioral Safety

• Human factors engineering (HFE) study

• Noise and Vibrations (NAVS) Study

• Reliability, Availability, Maintainability (RAM) study.

• Fire Risk assessment and toxics gas dispersion modeling and safety case study.

• Safety Critical Element Identification/ Assessment.

• Gas dispersion & Flare Radiations study.

• High pressure liquid hydrocarbon pumps to minimize leaks study, Seismic Hazard Analyses

• Fire Escape Evacuation Rescue Analysis

• Project Design (ALARAP) demonstration

• Structural integrity under fire load calculations

• Spill Protection and Mitigation plane/design study.

• Process safety barrier calculation

• Developing the design, construction, commissioning and operations safety case and safety concept.

• Developing the technical safety risk registers and Project Life Cycle Management

Technical Specialist Skill Loss Prevention system engineering : -

Design developing Fire protection systemHazard and Active and Passive Fire protection

system

• Hazardous area Classification and Fire zone layout

• Fire & Gas Detection System layout, emergency escape and evacuation route layout

• Fire protection system equipment design layout

• Electrical Hazardous area Classified and area area determination overall safety Signage layout

• Fire protection and lifesaving equipment layout

• Fire zone layout, Fire Water system network layout

• Fire water Spray System layout, emergency evacuation system Survival Craft layout

• Fire water pipe Hydraulic calculations,

• Fire water demand calculation

• Fire water ring main system pressure calculation

• Fire water pump Pump and deluge system calculation

• Project fire suppression system calculation

• Fire zones definitions and gap analysis/calculation

• Fire water system and Foam Systems calculation

• Fire explosion radius and Fire sprinkler system design calculation

• Fire gas detector cover area, Deluge valve pressure and Fire water supply pipe sizing calculations

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

• Fire water network layout

• Fire water deluge system layout, Fire proofing system design layout

• Fire gas detection system layouts and fire water pump design layout.

• Ship impact system design layout.

• Emergency boat landing area design layout

• Safety alarm system design and Shout down bolo down valve design layout

• Safety chart design layout and Safety system cause and effect and logic diagram design

• Fire and Gas Interface with Emergency Shutdowns Blow down system calculation, CO2 total flooding systems design calculation

• FM 200 systems calculation

• Fire water pump capacity preference calculation

• Fireproofing (PFP) system and dry chemical Fire Protection system calculation.

• Fire hydrant cover area and design calculation

• Hazardous Materials Evaluations

• Frequency analysis and consequence modeling

At April, 1993 to till date now Employments History (employments summary) : -

25 January 2015 till date Head of Process Safety Engineer Chevron Canada Ltd, Kitimat LNG project Calgary AB Canada

Duty and Responsibility: -

• Facilitated and leading the process safety study such as Fire Relief & Blow-down Studies, Flare Studies, Fire Hazard Analysis, ALARP demonstration, Safety Critical Element Impact Assessments, Failure mode effective critical analysis, Fault Tree analysis and project safety design.

• Facilitated HAZID / HAZOP/ HAZAN studies workshop and review/approve these study documents. Participated as Facilitated and developing of project SIL classification study, health and safety assessments, compliance EHS audits, formulating emergency response plans, , fire protection system layout study, SIMOPS studies, and PHSER studies

• Review/approve Equipment sizing, Package handling, Process Control, Startup, shutdown and stabilization of various Refinery units, Plant performance, yield & energy monitoring, catalyst activity monitoring and de-bottlenecking, trouble-shooting.

• Reviews/approve Fire and gas dispersion study, Fire and explosion modeling, Safety critical element impact assessments, Safety integrity level studies SIL study, Fire & Explosion modeling, Quantitative/Qualitative Risk Assessments, frequency and consequence analysis, evacuation rescue Analysis, smoke gas dispersion analysis and Dropped objects study.

• Facilitated/design process safety study, fire protection system such as flare radiation study, failure modes and effects Analysis (FMEA), Active Fire Protection system design, Hazardous Area classification studies, Passive Fire Protection system design, Human Factors Engineering design.

June 2013 to January 2015 Technical Safety Engineer Lead Total E&P Myanmar YSP and Badamyar Basis and details Engineering Project Bangkok Thailand.

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

Duty and Responsibility: -

• Facilitated/ leading technical safety study such as Fire and Gas dispersion modeling ,Simultaneous and operations SIMOPS, Safety Integrity Level SIL, Fire water pump Displacement study, Noise and vibration study, BOW TIE Assessing, Ship collision and Helicopter Crash study and Drop object study, Safety instrumented functions (SIFA), Health, Safety and Environmental Impact (HSEIA), Environmental base line survey and design safety review.

• Facilitated/ leading technical safety study such as Hazards Scenario evaluation, consequence frequency modeling, lifesaving & safety critical elements and equipment identification, temporary refuge (TRA) analyses, flare radiation study, formal safety assessments (FSA) Studies, HAZID, risk assessment, Risk Control and Cost Benefit Analysis. Safety Study QRA, LOPA, FRA, HAZOP, FMEA, FMECA, TRA, Reliability Availability and Maintainability (RAM) study.

• Design/Review project design drawing Hazardous Areas Classification Non-Hazardous Areas and Offshore Drainage Systems, Hazardous Area Classification, design and layout Active Fire Protection and passive fire protection system, Fire and Gas Detection system, Emergency escape evacuation rescue facilities layout, safety equipment, lifesaving equipment Survival Craft and Lifesaving Appliances layout drawing, emergency access, egress route Layouts drawing, telephone and Alarm systems Block Diagrams, fire and gas cause and effects diagram.

October 2012 to June 2013 Lead Safety Risk Engineer Husky Energy Ltd, White Rose extension Basis Engineering Project St. Johns NL Canada

Duty and Responsibility: -

• Facilitated/ leading technical safety study such as HAZOP, SIL, QRA, LOPA, EERA, FERA, RAM, TRA, Dropped Objects Releases Frequencies Analysis, Deluge valve pressure calculation, Explosion Overpressure, Consequence modeling, and Noise vibration study.

• Facilitated/ leading technical safety study such as Loss of Containment Gas Detection, Inventory Isolation, Impact on the Environment, Iceberg Collision, Ship Collision impact, Helicopter Transport Risk, Helicopter Crash Frequency analysis, Seismic Activity and Structural Failure Analysis.

• Review layout drawing such as fire water system, active and passive fire protection system and total flooding systems. Approve safety elated drawing such as Facility Layout, Classification of Hazardous Areas, Ventilation of Hazardous Areas, Ventilation of Non-Hazardous Areas and Offshore Drainage Systems and Fire and Gas Detection system.

• Review layout drawing such as Emergency Shutdown and Blow down System, Emergency Power supply system, Active Fire Protection system, Fire Alarm Systems, Escape Routes layout, Firewater Distribution System, Passive Fire protection system and fire protection dry chemical system, Telecommunication, fire suppression systems (deluge, pre-action, water mist, CO2).

October 2011 to September 2012 Lead Technical Safety, Loss Prevention Engineer Ras Gas Company Ltd, Barzan onshore Gas project detail engineering Yokohama Japan

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

Duty and Responsibility: -

• Facilitated/ leading technical safety study such as HIRA, SIMOPS, High Integrity pressure protection system (HIPPS), EER, TRA study, Quantified Risk Assessment QRA, Hazard & Operability HAZOP, FERA, EERA, Hazard Analysis HAZAN’s, Hazard Identification HAZID’s, Safety integrated Level SIL’s, Emergency shutdown (ESD) system, 3-D model review, Hazard and Consequence modeling, gas vapors cloud dispersion modeling, blast pressure modeling, safety risk consequence modeling.

• Generate and updates the fire protection system, lose prevention, shutdown, blow down philosophies, technical safety specifications and updating the design safety case and Review/approve firewater network system system P&ID, PFD.

• Design and review project design layout drawing such as Safety Signs & Fire Fighting Equipment’s Layout, Plant/Equipment and Spacing layout, fire and hazards area classification layout, cause and effect matrix, fire and gas logic diagram, fire water demand calculations, Fire protection and fire gas detection systems equipment layout, firefighting equipment layout, Pressure relief/flare/vent system design layout drawing related with fire protection system and technical safety layout.

May 2009 to September 2011 Led Technical Safety Representative Sabah Shell Petroleum Company Ltd, Gumusut Kakap Detail Engineering project Malaysia

Duty and Responsibility: -

• Facilitated/leading technical safety study such as QRA, HAZOP, BOW Tie, Safety Integrity SIL, Safety Critical equipment and, HAZAN, SIL, LOPA, RAM, ship collection study, FMEA, HEMS, COMAH Safety Instrumented Systems (SIS), drop object study, HAZID, study, safety Critical Element, Hazards and Effects Management Process HEMP, Fire and Explosion Assessment, Non-flammable Major Accident Assessment, Emergency System Survivability and Availability Assessment

• Facilitated/leading fire protection system study such as ALARP demonstration, ship collision and helicopter crash study Safety Critical Element identification, Emergency System Survivability & Availability analysis, high pressure pipelines risk assessment, fire and Explosion Risk Analysis, Non-flammable Major Accident Assessment, and Escape Evacuation and Rescue Assessment (EER), Hazard identification techniques FTA, ETA, PHA, FMECA.

• Developing/Updating the project HSE Case, fire protection and technical safety general specification/ philosophy and firefighting and safety equipment specifications.

• Design/review and approve technical safety drawing such as Fire and gas detectors system design layout, firewater system deluge system, foam system, Fire Hydrant layout, fire gas detector layout and fire extinguisher layout, design, fire-fighting equipment layout, Escape evacuation route layout, fire-water ring main and Safety & Life Saving Equipment Layout.

January 2007 to May 2009 Senior Lead technical safety and Risk Engineer Qatar Shell GTL Ltd, Pearl GTL Project detail Engineering Doha Qatar

Duty and Responsibility: -

During this job I was in charge of different safety and risk assessment and fire protection system designing following Report:

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

• HAZID, HAZOP study, SAFE Chart accords API RP 14C , SIL assessment using Risk Graphs, Layer protection analysis, Fault tree/Event trees methods according IEC-61511 part 3, Quantitative SIL assessment using combination of fault tree and event tree analysis according bow tie method, SIL verification, spill collection, firewater system/firewater pumps hydraulic calculations; dispersion and radiation study, and flare network study.

• Design study ESD/EDP philosophy including HIPPS system, generate and conducting the Fire and gas detection philosophy, Cause & effect matrix, Fire & Explosion study and Quantitative Risk Analysis (QRA), blow down analysis of of fire and provision of fire case relief valve or/and passive fire protection on the jet fire receiver, Dynamic simulation, Alarm handling and ALARP demonstration.

• Design/review Hazards area, active passive fire protection system layout and other safety related drawings such as Hazardous Area Classification and Fire zone layout, Fire & Gas Detection System layout, emergency escape and evacuation route layout, Fire protection system equipment layout, Electrical Hazardous area Classified and area Determination and overall safety Signage layout.

• Fire protection and lifesaving equipment layout, fire zone layout, Fire Water system network layout, fire water Spray System layout, emergency evacuation system Survival Craft layout, Fire water network layout, fire water deluge system layout, Fire proofing system design layout, fire gas detection system layouts and fire water pump design layout.

March 2005 to January 2007 Senior Risk Safety Coordinator Dolphin Energy Ltd, Dolphin

Gas project details engineering and construction Doha Qatar

Duty and Responsibility: -

• Key responsible for developing and delivery of Technical Safety aspects such as HAZID, HAZOP SIL/LOPA, Emergency System Survivability & Availability, Escape Evacuation rescue analyses, (EER), Human Factors and Ergonomics Assessment, Fire Hazard Analysis, Reliability Availability and Maintainability (RAM) study, Non-Hydrocarbon Hazards Analysis NHHA, Emergency Systems Survivability Assessment Dropped Object Study, platform gap analysis, Flare Radiation study, As low as reasonably practicable (ALARP) and Quantitative risk assessment (QRA) study.

• Review and approve the Fire and gas desperation modeling and Cost benefit analysis and prepare the fire protection system equipment data sheets, technical bid evaluation and development the project Hazard and Risk Registers.

• Review and approve the Safety layout drawings such as Fire Area layouts, Fire Plot Plans layout, Hazard Area Classification layouts, Safety Equipment and Escape Route Layouts, Fire and Hazard Area Zones definitions, fire water system design, fire gas detection system, Water Mist system design, CO2 fire protection design, Life-saving appliances system design, foam system design and radio alarms system design.

• Alarm systems: Block Diagrams, Cause & Effects diagram, Fire water demand calculation, fire gas system logic diagram, fire segregation calculation, Safety Critical

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

Element and equipment indication and review the specify SIL requirements for instrumented safety functions system.

February 2003 to April 2005 Lead Technical Safety Engineer Total LNG Nigeria Ltd, LNG Six upgrading details engineering project Bonny Island Nigeria

Duty and Responsibility: -

• Conducting and reviewing the safety study such as RAM, Failure Mode Effect Analysis (FMEA), Root Cause Failure Analysis (RCFA), QRA study, HAZID, ENVID, HAZOP, SIL, QRA, FERA, RAM, EERA, heavy lifting study, Fire explosion and gas dispersion study, Explosion overpressure study, Heat radiation study, Vent gas dispersion analysis, flare radiation & dispersion analysis, Fire water demand estimation calculation,

• Chair and reviewing the design 3D model review, consequence analysis, firefighting systems and lifesaving system design analysis, hydraulic calculations, firefighting systems design to develop the cause & effect matrix, fireproofing studies, hazardous area classification, Escape routes layout active and passive fire protection system equipment layout, safety equipment data sheets and technical bid evaluation. To develop the project technical safety and fire protection general specification, technical plane and technical philosophy.

• Developing and reviewing the Fire Water Network & Spray System design Lifesaving equipment design study, firefighting equipment and safety route layouts, preparing the firefighting equipment and lifesaving equipment datasheets and project safety specifications.

January 2000 to February 2003 Sr. Technical & Process Safety engineer Exxon Mobil Force Ins, QIT PH-II Infrastructure project Tripoli Libya

Duty and Responsibility: -

• Generating, facilitating, performing the (quality assurance) Hazard and Operability Studies (HAZOPs), Layer of Protection Analyses (LOPAs) and Process Hazard Analyses (PHAs)) and/or other studies, Bowtie Studies, Facility Siting Studies, Major Accident Risk (MAR) modeling), As low as reasonably practicable demonstration (ALARP), Major Hazard Register Report, Safety Critical Elements, Flare Radiation and Dispersion Assessment Report, Active and Passive Fire Protection Philosophy.

• Generation/review update the technical safety specifications for freighting and safety equipment such as Fire and Gas system Philosophy, updating the Design HSE case, Noise Model, Fire Hazard Analysis and Fire Water Design Criteria.

• Generating review and approve the project Layout Drawings such as Fire Area Layout drawing, Fixed and mobile firefighting Layout Drawings, Fire water P&IDs and PFD, Safety Equipment Specifications, Fire Water Network & Spray System design Lifesaving equipment design study, firefighting equipment and safety route layouts, firefighting equipment and lifesaving equipment datasheets and project safety specifications and Hazardous Area Classification.

• Involve in the and process safety management study such as PSM system, Management of Change (MOC), Process Hazard Analysis (PHA), Safety Integrity Level (SIL), Prestart-up Safety Review (PSSR), Quantified risk assessment (QRA), Facility siting (occupied buildings and trailers) and Auditing.

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

February 1998 to June 2000 Senior Process Safety Engineer Shell Petroleum Development Company (SPDC) Ltd AG Gas Gathering Project Nigeria

Duty and Responsibility: -

• Reviewing/ approve and facilitating in house hazard workshops for Process Safety hazards study include HAZID, HAZOP, SIL, FERA, FERA, LOPA, FMEA, FMECA, COMA, COMAHA, HEMP/HEMS and Bow-Ties, ALARP, SIMOPs, safety case modeling. COMAH, HEMP, BOW Tie’s Fire and gas Explosion Studies, EERA, TRA, As low as reasonably practicable (ALARP) demonstration, Qualitative and Quantitative Risk Assessment, gas dispersion and fire and explosion models, safety cases, FMECA techniques analysis, risk ranking, EERA, ESSA and TRIA study.

• Review/approve project explosion toxic gas hazard modeling consequence analysis, dispersion and flammable, toxic & pollutant emissions Study. Consequence Dispersion, Jet Fire and Explosion analysis) risk matrix Likelihood Modeling.

• Design safety drawing such as Escape Evacuation, Rescue Muster point layout and Analysis, emergency Systems Survivability Assessments, project Safety Case Development, Fire zones definitions, Identification of Safety Critical Elements and equipment performance standard.

March 1995 to February 1998 Project Technical Safety Engineer Saudi Arabian oil Company (ARAMCO) Riyadh refinery Fire and safety upgrade project KSA

Duty and Responsibility: -

• Review approve the technical design document such as Fire water demand estimation calculation, fire Water pump and fire water tank datasheets, updating the Fire Water Network and Spray System design (P&ID, PFD Layout drawing) updating the drawing. Lifesaving Firefighting equipment, and safety route layouts, safety and Firefighting equipment layout, Vendor bid evaluation, fire water supply pipe Hydraulic calculation.

• Design and approve the project document such as Fire water network and deluge system design. Update the telecommunication, Firewater Systems and hydraulic calculations and alarms system. Design review technical document such as Fire protection layouts, safety equipment layouts, area classification layouts, fire proofing design, F&G cause & effect diagrams, F&G detection layouts, firefighting and safety equipment specifications, Fire Protection Design Basis, Fire & Gas Philosophies.

April 1993 to March 1995 Technical Safety & Loss Prevention engineer Ras Gas Company Ltd, at CTJV Project basis and details engineering Doha Qatar

Duty and Responsibility: -

• Review project document such as HAZOP, SIL FERA and Implementation of recommended measures to carry out the project site audits and inspection to assist the accident investigation team. Update the technical safety and fire protection system general specification.

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

• Design review the project document such as Electrical Hazardous (Classified) Area Determination, Hydraulic Calculation, Fire and Life Safety Systems Evaluation, Fire Cause Investigation, Fire System Performance/Failure Analysis, Emergency Shutdowns, Blow-down and other executive actions, Fireproofing Fire Zone Layout Lifesaving Appliances layout, escape and Egress route Layouts and Pre-Start-Up Safety.

Specialist in Technical Software : -

Very Good Knowledge in operating and Very good experience in Industry Use

Very Good operating Knowledge and Very good experience in Industry Use

• Safety and Rick analysis software such as SHELL FRED 5.0, PHAST, BP CIRRUS, FLARENET, FLARESIM, HAZOPPRO and SILCORE.

• PHAST, FRED, BOWTIE and @RISK. Hydraulic Calculation Software PIPESYS, PROFES, OLGA 2000, PIPE PHASE and TLNET.

• Autodesk software such as AutoCAD, Autodesk Simulation, P&ID, piping design and computational fluid dynamics simulation.

• Hydraulic analysis software such as PIPESIM, PRO-II, HYSYS, PROSIM, HTRI, HTFS, FLARENET, PHA Works, PHAPRO, PIPENET, RISK Track, and transient

Training and Associates membership with International Organization

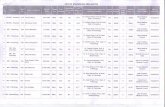

Certification Training Program Training provider CompanyCompete

YearsLevel 2 Foundation Certificate in Food Hygiene Course

Chartered Institute of Environmental Health

2003

Level 1 Food safety and Hygiene Course Virtual Collage 2011Safe Food Handler Course Level 2 California Food Handler Training 2012HACCP For Warehousing Distributing Operation Guelph Food Technology Center 2012Food Risk Assessment Course British window cleaning Academy 2006Diploma Fire Prevention and Fire Fighting Maritime Training Academy 2008Diploma in Fire safety Management National Institute of Labor Education and

Management2005

Diploma in Industry Safety National Institute of Labor Education and Management

2005

Behavioral Based Safety (BBS)Training Course TUV NORD 2008Business Continuity Management system Awareness (BCMSA) Course (BS 25999) Course

BSI Management System UK 2011

Quality Management system (QMS) Auditor/Lead Auditor Training (ISO 9001:2008 Course

BSI Management System UK 2010

IEMA Approved Advanced (EMS) Auditor Course (UK) (ISO 14001:2004 Course

BSI Management System UK 2011

Environmental Management System (EMS) Lead Auditor (ISO 14001:2001) Course

DET NORSKE VERITAS (DNV) 2012

Practical Marine Risk Assessment (MRA) Training

DET NORSKE VERITAS (DNV) 2011

OHSAS 18001:2007 Occupational Safety and Health Auditor/Lead Auditor Program Course

DET NORSKE VERITAS (DNV) 2010

Environmental Management System (EMS) Lead Auditor (ISO 14001:2004) Course

DET NORSKE VERITAS (DNV) 2012

Professional Accident Investigation Course DET NORSKE VERITAS (DNV) 2008Train The Trainer Course DET NORSKE VERITAS (DNV) 2008Managing of Safety Course Institution of Occupational Safety and 2002

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)

HealthLevel 3 First AID Work (QCF) Course NUCO Training 2014International General Certificate in Occupational Safety and Health (IGC) Course

National Examination Board in Occupational Safety and Health

2000

International Diploma Certificate in Occupational Safety and Health (IDC) Course

National Examination Board in Occupational Safety and Health

2005

NEBOSH Level 3 Certificate in Occupational Safety and Health Course

National Examination Board in Occupational Safety and Health

2006

TapRooT@ Advance Investigation Team Leader Course

System Improvements Ins 2008

Occupational Safety and Health Specialist Training

OSH Academy USA 2014

Effective Accident Investigation Training OSH Academy USA 2010Hazard Communication Program Training OSH Academy USA 2011

NRA Range Safety Officer CourseThe National Rifle Association of America

2004

Canadian National Certify Lead Process Safety Engineer Grate “A” Course

Alberta Construction association 2012

Hazard Management Course Alberta Construction association 2014Prime Contractor Course Alberta Construction association 2014Leadership for safety Excellence Examination and Certification Course

Alberta Construction association 2014

Basic Instruction Techniques Course Alberta Construction association 2014Construction Safety Administration Course Alberta Construction association 2014Auditor Training Program Course Alberta Construction association 2014Alberta OHS Legislation Awareness Course Alberta Construction association 2013Effective Health and safety Management system Alberta Construction association 2013“TDG” Train the Trainer Course Alberta Construction association 2014ESQ Basic Training ESQ Leadership Training 2008Personal safety and Social Responsibilities (STCW 95) STCW Code A

SCMS Maritime Training Institute 2008

Helicopter Underwater Escape Training GSMS Maritime Training Institute 2008Offshore Competence Certificate Training RAY/MCA Yachtmaster Offshore 2011Basic Offshore Safety Induction and Emergency Training

GTSC Training Center 2012

Elementary First AID SSMS Maritime Training Institute 2008Scaffolding Safety Inspection Training Borneo Safety Training Services 2009NEPA recognizer Certificate Course NFPA International 2002

Head of Process Safety Prakash Bahadur Thapa Profile (Page # 11)