HdX^Va :ck^gdcbZciVa GZedgi · 2018-08-28 · Mr. Tetsuo Yamazumi May 1917 11,600 million yen as of...

Transcript of HdX^Va :ck^gdcbZciVa GZedgi · 2018-08-28 · Mr. Tetsuo Yamazumi May 1917 11,600 million yen as of...

Planning Department, Administration HeadquarterEnvironment Control Department, Production HeadquarterTokyo Club Building, 2-6, Kasumigaseki 3-chome, Chiyoda-ku, Tokyo, 100-0013 JapanPhone:81-(3)3506-3951 Fax:81-(3)5511-8541http://www.cmp.co.jp

Dear Stakeholders,

We are pleased to provide to you our “Social and Environmental Report 2009”. As a key supplier to shipping, shipbuilding, electric power, steel, construction, and woodworking industries, we are aware that we have a role to play in contributing to the development of such industries by improving the performance of our paints, which support the development of a prosperous society. We are also aware that this can only be realised by acknowledging the importance of the environment and by integrating such awareness into our company activities.

In broadening the aspects of our policy to pursue better product performance for environmental protection, we have approached the safety of manufacturing and selling processes and focused upon the reduction of environmental burden from various perspectives. Our activities include supply of paints containing no tar, nor harmful substances, or solvent-free paints for the reduction of VOC (volatile organic content), the declaration of “Coatings Care”, which is a voluntary management program on production process for Environment, Safety and Health proposed by the Japan Paint Manufacturers Association. Our activities also include the acquisition of ISO14001 environmental management certification and the construction of broad-ranging chemical material control systems.

Meanwhile, as a member of society, we are aware that we have a responsibility to be socially reliable and contribute to social development. For this, we are engaged in corporate governance and internal control as a management priority hence ensuring corporate soundness and transparency. We maintain good relationship with local communities through our 26 overseas affiliated companies in 14 countries around the world.

We would take great pleasure if this report could be of help to you in having an insight into the activities of our company.

CMP, as a whole group of companies, globally operates its business to be reliable and needed in today’s world. We therefore kindly ask you, and would appreciate it if you would send us your opinion or suggestion regarding anything related our company to assist with this.

Greetings

Reports a wide range of our social and environmental activities from the perspective of CSR.(*) The reports have been issued annually since 2003, formerly called “Environmental Report” and renamed “Social and Environmental Report” in 2008 to expand its contents as its title suggests.

October, 2009 (previous report issued: October, 2008, scheduled date next issue : October, 2010)

Editorialpolicy

Terms

Scope of activitiesreported

Periodcovered

Date of Issue

What is VOC ?What is MSDS ?PRTR (Pollutant Release and Transfer Register)

102527

Greetings

Company Profile

Relationship with society and environment

Corporate Governance / Internal Control

Risk Management / Compliance

Marine Paint Field (Paints for vessels)

Marine Paint Field (Paints for fishing boats and fishing nets)

Container Paint Field

Industrial Paint Field (Heavy duty paints)

Industrial Paint Field

IBC Recycle System

Environmental Management

Plans to deal with Environmental, Safety and Health Issues

Green Purchasing and Procurement

Environmental Accounting

Chemical substance management

Commitment to the reduction of the environmental impact

Environmental Impact data by offices or factories

Environmental Management System

Prevention of Global Warming

Disaster and Accident Prevention

Together with Customers

Together with Local Communities

Together with Employees

2

3

5

6

7

9

11

12

13

15

17

19

21

23

24

25

27

30

31

33

34

35

37

41

CompanyOverview

Product development

Environmental Reporting

SocialPerformance

PresidentTetsuo Yamazumi

This report focuses on our domestic business activities (a part of the descriptions in this report includes data of our overseas affiliates).

October, 2009 (previous report issued: October, 2008, scheduled date next issue : October, 2010)

The following abbreviated names are used in the summary of collected environmental data.■ Kyushu Factory■ Shiga Factory■ Technical Center(Otake)■ Technical Center(Shiga)■ Ohtake-Meishin Chemical■ Kobe Paints

Kyushu FactoryShiga FactoryTechnical Head Quarter, OtakeTechnical Head Quarter, ShigaOhtake-Meishin Chemical Co., Ltd.Kobe Paints, Ltd.

Paints for building materials, High performance paints for plastics, Caulking material for railways( )

Dear Stakeholders,

We are pleased to provide to you our “Social and Environmental Report 2009”. As a key supplier to shipping, shipbuilding, electric power, steel, construction, and woodworking industries, we are aware that we have a role to play in contributing to the development of such industries by improving the performance of our paints, which support the development of a prosperous society. We are also aware that this can only be realised by acknowledging the importance of the environment and by integrating such awareness into our company activities.

In broadening the aspects of our policy to pursue better product performance for environmental protection, we have approached the safety of manufacturing and selling processes and focused upon the reduction of environmental burden from various perspectives. Our activities include supply of paints containing no tar, nor harmful substances, or solvent-free paints for the reduction of VOC (volatile organic content), the declaration of “Coatings Care”, which is a voluntary management program on production process for Environment, Safety and Health proposed by the Japan Paint Manufacturers Association. Our activities also include the acquisition of ISO14001 environmental management certification and the construction of broad-ranging chemical material control systems.

Meanwhile, as a member of society, we are aware that we have a responsibility to be socially reliable and contribute to social development. For this, we are engaged in corporate governance and internal control as a management priority hence ensuring corporate soundness and transparency. We maintain good relationship with local communities through our 26 overseas affiliated companies in 14 countries around the world.

We would take great pleasure if this report could be of help to you in having an insight into the activities of our company.

CMP, as a whole group of companies, globally operates its business to be reliable and needed in today’s world. We therefore kindly ask you, and would appreciate it if you would send us your opinion or suggestion regarding anything related our company to assist with this.

Greetings

Reports a wide range of our social and environmental activities from the perspective of CSR.(*) The reports have been issued annually since 2003, formerly called “Environmental Report” and renamed “Social and Environmental Report” in 2008 to expand its contents as its title suggests.

October, 2009 (previous report issued: October, 2008, scheduled date next issue : October, 2010)

Editorialpolicy

Terms

Scope of activitiesreported

Periodcovered

Date of Issue

What is VOC ?What is MSDS ?PRTR (Pollutant Release and Transfer Register)

102527

Greetings

Company Profile

Relationship with society and environment

Corporate Governance / Internal Control

Risk Management / Compliance

Marine Paint Field (Paints for vessels)

Marine Paint Field (Paints for fishing boats and fishing nets)

Container Paint Field

Industrial Paint Field (Heavy duty paints)

Industrial Paint Field

IBC Recycle System

Environmental Management

Plans to deal with Environmental, Safety and Health Issues

Green Purchasing and Procurement

Environmental Accounting

Chemical substance management

Commitment to the reduction of the environmental impact

Environmental Impact data by offices or factories

Environmental Management System

Prevention of Global Warming

Disaster and Accident Prevention

Together with Customers

Together with Local Communities

Together with Employees

2

3

5

6

7

9

11

12

13

15

17

19

21

23

24

25

27

30

31

33

34

35

37

41

CompanyOverview

Product development

Environmental Reporting

SocialPerformance

PresidentTetsuo Yamazumi

This report focuses on our domestic business activities (a part of the descriptions in this report includes data of our overseas affiliates).

October, 2009 (previous report issued: October, 2008, scheduled date next issue : October, 2010)

The following abbreviated names are used in the summary of collected environmental data.■ Kyushu Factory■ Shiga Factory■ Technical Center(Otake)■ Technical Center(Shiga)■ Ohtake-Meishin Chemical■ Kobe Paints

Kyushu FactoryShiga FactoryTechnical Head Quarter, OtakeTechnical Head Quarter, ShigaOhtake-Meishin Chemical Co., Ltd.Kobe Paints, Ltd.

Paints for building materials, High performance paints for plastics, Caulking material for railways( )

Company Profile

Company Overview

Corporate Data Global Network

Kyushu Factory

Kobe Paints, Ltd. Ohtake-Meishin Chemical Co., Ltd.

Factories

Main business locations in Japan

Hokkaido

Sendai

Akita

Tokyo

Shizuoka

Nagoya

ShigaOsaka

TsuchiyamaOkayamaOnomichi

KureHiroshima

MarugameImabari

UsukiFukuokaSagaSaseboNagasaki

Head OfficeFactorySales Office

Factories at domestic subsidiaries

Technical Center

Technical Center(Marine Paints),R&D Center/Otake

Technical Center(Industrial Paints)/Shiga

ISO 9001ISO 9001

ISO 9001ISO 9001

ISO 9001ISO 14001 Shiga Factory ISO 9001ISO 14001

Shanghai Guangdong Korea Malaysia

Singapore

Thailand

Netherlands U.S.A.Indonesia

China

Hong Kong

Indonesia

Korea

Malaysia

Singapore

U.A.E.

India

CHUGOKU MARINE PAINTS (SHANGHAI), LTD.

CHUGOKU MARINE PAINTS (GUANGDONG), LTD.

CHUGOKU MARINE PAINTS (HONG KONG), LTD.

P.T. CHUGOKU PAINTS INDONESIA

CHUGOKU SAMHWA PAINTS, LTD.

CHUGOKU PAINTS (MALAYSIA) SDN. BHD.

CHUGOKU MARINE PAINTS (SINGAPORE) PTE. LTD.

Dubai Branch

Mumbai Office

Overseas factories

Main Domestic & Overseas Subsidiaries and Affiliates

Taiwan

Thailand

Germany

Greece

Netherlands

U.K.

U.S.A.

CHUGOKU MARINE PAINTS (TAIWAN), LTD.

TOA-CHUGOKU PAINTS CO., LTD.

CHUGOKU PAINTS (GERMANY) G.m.b.H.

CHUGOKU MARINE PAINTS (HELLAS), S.A.

CHUGOKU PAINTS B.V.

CHUGOKU PAINTS (UK) LTD.

CMP COATINGS, INC.

ISO 9001 ISO 9001 ISO 9001 ISO 9001

ISO 9001

ISO 9001

ISO 9001ISO 9001

ISO 14001

Marine paints71%

Industrial paints13%

Container paints15%

Miscellaneous1%

(FY)

1000

800

600

400

200

005 06 07 08 09

Consolidated Sales Breakdown by Products in 2009

Since its foundation, Chugoku Marine Paints, Ltd. has been taking a unique approach in the industry to develop core products for marine paints and also paints for industrial applications. Our consistent and sincere attitude in areas of both software and hardware, towards developing better products has been highly appreciated and praised by customers not only locally but also internationally. With the help of strong customer confidence in our products and services and our never-ending quest to meet customers' expectations, we keep developing. As we are a supplier to key industries such as shipping, ship building, electric power, steel, construction and woodworking industries, our role and contribution can be vital to the growth of the industrial world in many aspects. Also, our efforts should be based in the ideal of maintaining harmony between man and nature. Chugoku Marine Paints, Ltd. is an industrial leader that seeks to promote industrial growth while protecting the global environment, and continues its efforts into the future with a creative and innovative approach towards meeting customers' needs.

Transition of Annual Net SalesConsolidated Non consolidated

Net

Sal

es (1

00 m

illio

n ye

n)

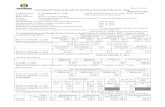

Company NameCHUGOKU MARINE PAINTS,LTD.

Head OfficesTokyo Office

Tokyo Club Building, 2-6, Kasumigaseki 3-chome, Chiyoda-ku, Tokyo, 100-0013 JapanPhone: +81-3-3506-3951 Fax: +81-3-5511-8541

Hiroshima Office1-7, Meiji-Shinkai, Otake-shi, Hiroshima-ken 739-0652, JapanPhone: +81-827-57-8555 Fax: +81-827-59-0017

Company President Date of EstablishmentCapitalNet Sales

Number of Employees2,356 as of the end of March 2009 (Consolidated) 386 as of the end of March 2009 (Non-consolidated)

Business to cover

Mr. Tetsuo YamazumiMay 191711,600 million yen as of the end of March 2009103,622 million yen in 2009 (Consolidated) 43,032 million yen in 2009 (Non-consolidated)

1. Manufacturing and sales of marine paints, industrial paints and container paints.

2. Sales of painting related equipments.3. Management and contract work for coating4. Others

U.S.A.Curacao

NetherlandsU.K.GermanyGreeceItalyNorwaySpainTurkey

Asia

Oceania

America

ChinaHong KongTaiwanJapanKoreaSingaporeMalaysiaThailandIndonesiaPhilippinesVietnamIndiaSri Lanka

AustraliaNew Zealand

Europe

Middle EastU.A.E.

AfricaSouth Africa Factory

Sales OfficeLicenseeAgentStock points

Company Profile

Company Overview

Corporate Data Global Network

Kyushu Factory

Kobe Paints, Ltd. Ohtake-Meishin Chemical Co., Ltd.

Factories

Main business locations in Japan

Hokkaido

Sendai

Akita

Tokyo

Shizuoka

Nagoya

ShigaOsaka

TsuchiyamaOkayamaOnomichi

KureHiroshima

MarugameImabari

UsukiFukuokaSagaSaseboNagasaki

Head OfficeFactorySales Office

Factories at domestic subsidiaries

Technical Center

Technical Center(Marine Paints),R&D Center/Otake

Technical Center(Industrial Paints)/Shiga

ISO 9001ISO 9001

ISO 9001ISO 9001

ISO 9001ISO 14001 Shiga Factory ISO 9001ISO 14001

Shanghai Guangdong Korea Malaysia

Singapore

Thailand

Netherlands U.S.A.Indonesia

China

Hong Kong

Indonesia

Korea

Malaysia

Singapore

U.A.E.

India

CHUGOKU MARINE PAINTS (SHANGHAI), LTD.

CHUGOKU MARINE PAINTS (GUANGDONG), LTD.

CHUGOKU MARINE PAINTS (HONG KONG), LTD.

P.T. CHUGOKU PAINTS INDONESIA

CHUGOKU SAMHWA PAINTS, LTD.

CHUGOKU PAINTS (MALAYSIA) SDN. BHD.

CHUGOKU MARINE PAINTS (SINGAPORE) PTE. LTD.

Dubai Branch

Mumbai Office

Overseas factories

Main Domestic & Overseas Subsidiaries and Affiliates

Taiwan

Thailand

Germany

Greece

Netherlands

U.K.

U.S.A.

CHUGOKU MARINE PAINTS (TAIWAN), LTD.

TOA-CHUGOKU PAINTS CO., LTD.

CHUGOKU PAINTS (GERMANY) G.m.b.H.

CHUGOKU MARINE PAINTS (HELLAS), S.A.

CHUGOKU PAINTS B.V.

CHUGOKU PAINTS (UK) LTD.

CMP COATINGS, INC.

ISO 9001 ISO 9001 ISO 9001 ISO 9001

ISO 9001

ISO 9001

ISO 9001ISO 9001

ISO 14001

Marine paints71%

Industrial paints13%

Container paints15%

Miscellaneous1%

(FY)

1000

800

600

400

200

005 06 07 08 09

Consolidated Sales Breakdown by Products in 2009

Since its foundation, Chugoku Marine Paints, Ltd. has been taking a unique approach in the industry to develop core products for marine paints and also paints for industrial applications. Our consistent and sincere attitude in areas of both software and hardware, towards developing better products has been highly appreciated and praised by customers not only locally but also internationally. With the help of strong customer confidence in our products and services and our never-ending quest to meet customers' expectations, we keep developing. As we are a supplier to key industries such as shipping, ship building, electric power, steel, construction and woodworking industries, our role and contribution can be vital to the growth of the industrial world in many aspects. Also, our efforts should be based in the ideal of maintaining harmony between man and nature. Chugoku Marine Paints, Ltd. is an industrial leader that seeks to promote industrial growth while protecting the global environment, and continues its efforts into the future with a creative and innovative approach towards meeting customers' needs.

Transition of Annual Net SalesConsolidated Non consolidated

Net

Sal

es (1

00 m

illio

n ye

n)

Company NameCHUGOKU MARINE PAINTS,LTD.

Head OfficesTokyo Office

Tokyo Club Building, 2-6, Kasumigaseki 3-chome, Chiyoda-ku, Tokyo, 100-0013 JapanPhone: +81-3-3506-3951 Fax: +81-3-5511-8541

Hiroshima Office1-7, Meiji-Shinkai, Otake-shi, Hiroshima-ken 739-0652, JapanPhone: +81-827-57-8555 Fax: +81-827-59-0017

Company President Date of EstablishmentCapitalNet Sales

Number of Employees2,356 as of the end of March 2009 (Consolidated) 386 as of the end of March 2009 (Non-consolidated)

Business to cover

Mr. Tetsuo YamazumiMay 191711,600 million yen as of the end of March 2009103,622 million yen in 2009 (Consolidated) 43,032 million yen in 2009 (Non-consolidated)

1. Manufacturing and sales of marine paints, industrial paints and container paints.

2. Sales of painting related equipments.3. Management and contract work for coating4. Others

U.S.A.Curacao

NetherlandsU.K.GermanyGreeceItalyNorwaySpainTurkey

Asia

Oceania

America

ChinaHong KongTaiwanJapanKoreaSingaporeMalaysiaThailandIndonesiaPhilippinesVietnamIndiaSri Lanka

AustraliaNew Zealand

Europe

Middle EastU.A.E.

AfricaSouth Africa Factory

Sales OfficeLicenseeAgentStock points

Relationship with society and environment Corporate Governance / Internal Control

Company Overview

Company’sbasic policy

Organization Chart for Corporate Governance

Shareholders Meeting

Board of DirectorsBoard of Auditors

Board of managingdirectors

Across-The-CompanyJoint Meeting

Risk ManagementCommittee

Compliance Committee

SalesHeadquarter

Subsidiariesand Affiliates

TechnicalHeadquarter

ProductionHeadquarter

AdministrationHeadquarter

Legal Department

Consulting lawyer

Auditor

Corporate Auditors’ Office

Audit Department

Chemical SubstanceAdministration Office

Management Meeting

President

Appointment/DismissalAppointment/Dismissal

Audit

Appointment/Dismissal

InternalAudit

Supervision

Audit

Appointment/Supervision

We are aware that it is our management priority to carry out our social responsibility for stakeholders, and globally operate our activities in the medium and long term, within the scope of the management policy as defined below.

Customers

Local communities

CMP continuously aims to fulfill its responsibility in society as a paint company, making best efforts to develop our products functionally and environmentally and improve the quality management system in order to be reliable and to provide customers with satisfaction.

Through developing environmentally conscious products, promoting environmental management, and participating in activities of environmental conservation, CMP intends to develop a relationship with all stakeholders with a strong focus on environmental protection.

Global Environment

As one of the members in local communities, CMP is trying to build a relationship of mutual trust with such communities through our 26 affiliated companies in 14 countries.

CMP is aware that increasing the corporate value is important for management policy, with the establishment of effective, healthy and transparent corporate governance. Forming the board of directors, the board of auditors, management meetings, and other committees, CMP reinforce its corporate system.

By aiming for the sustainable development of the company with efficient and effective internal control systems, CMP endorsed a resolution to establish the “Rules and Basic Policy for Establishing Internal Control System” at the board of directors in May 2006 (partially amended in March 2008), and are putting effort into forming and operating the appropriately related committees.

Corporate Governance

Internal Control

As a listed company, CMP recognize that to submit a highly reliable financial report to investors and shareholders is an important responsibility, thus “Basic policy of the Financial Reporting” was resolved at the board of directors in March 2008. Additionally, CMP maintain and improve the system through the “Self assessment concerning Internal Control over Financial Reporting”.

Reliable financial reporting

Post 999SuppliersCMP has a purchasing policy of open door, fair & law-abiding, of mutual trust and environment conservation, CMP endeavors to promote a relationship of trust with suppliers who are our business partners.

EmployeesCMP takes great concern over employee safety, and carries out fair human resource management processes which include recruitment, training and performance evaluations respecting the individuality of employees and promotion of a workplace environment which has a positive influence on morale and abilities of the employees.

Shareholders and InvestorsCMP str ives to increase the value of the corporation through efficient and highly transparent internal controls and corporate governance.

To win customer’s confidence and satisfaction with the highest quality products.

To develop technological innovation and create new products from a global point of view.

To introduce scientific methods to company’s management to let our company run continuously with proper profit and make a contribution to our society.

To be faithful, to cooperate each other and to be fair.

To cope with changes in business environment and move ahead on job standardization and implement systematic management.

Relationship with society and environment Corporate Governance / Internal Control

Company Overview

Company’sbasic policy

Organization Chart for Corporate Governance

Shareholders Meeting

Board of DirectorsBoard of Auditors

Board of managingdirectors

Across-The-CompanyJoint Meeting

Risk ManagementCommittee

Compliance Committee

SalesHeadquarter

Subsidiariesand Affiliates

TechnicalHeadquarter

ProductionHeadquarter

AdministrationHeadquarter

Legal Department

Consulting lawyer

Auditor

Corporate Auditors’ Office

Audit Department

Chemical SubstanceAdministration Office

Management Meeting

President

Appointment/DismissalAppointment/Dismissal

Audit

Appointment/Dismissal

InternalAudit

Supervision

Audit

Appointment/Supervision

We are aware that it is our management priority to carry out our social responsibility for stakeholders, and globally operate our activities in the medium and long term, within the scope of the management policy as defined below.

Customers

Local communities

CMP continuously aims to fulfill its responsibility in society as a paint company, making best efforts to develop our products functionally and environmentally and improve the quality management system in order to be reliable and to provide customers with satisfaction.

Through developing environmentally conscious products, promoting environmental management, and participating in activities of environmental conservation, CMP intends to develop a relationship with all stakeholders with a strong focus on environmental protection.

Global Environment

As one of the members in local communities, CMP is trying to build a relationship of mutual trust with such communities through our 26 affiliated companies in 14 countries.

CMP is aware that increasing the corporate value is important for management policy, with the establishment of effective, healthy and transparent corporate governance. Forming the board of directors, the board of auditors, management meetings, and other committees, CMP reinforce its corporate system.

By aiming for the sustainable development of the company with efficient and effective internal control systems, CMP endorsed a resolution to establish the “Rules and Basic Policy for Establishing Internal Control System” at the board of directors in May 2006 (partially amended in March 2008), and are putting effort into forming and operating the appropriately related committees.

Corporate Governance

Internal Control

As a listed company, CMP recognize that to submit a highly reliable financial report to investors and shareholders is an important responsibility, thus “Basic policy of the Financial Reporting” was resolved at the board of directors in March 2008. Additionally, CMP maintain and improve the system through the “Self assessment concerning Internal Control over Financial Reporting”.

Reliable financial reporting

Post 999SuppliersCMP has a purchasing policy of open door, fair & law-abiding, of mutual trust and environment conservation, CMP endeavors to promote a relationship of trust with suppliers who are our business partners.

EmployeesCMP takes great concern over employee safety, and carries out fair human resource management processes which include recruitment, training and performance evaluations respecting the individuality of employees and promotion of a workplace environment which has a positive influence on morale and abilities of the employees.

Shareholders and InvestorsCMP str ives to increase the value of the corporation through efficient and highly transparent internal controls and corporate governance.

To win customer’s confidence and satisfaction with the highest quality products.

To develop technological innovation and create new products from a global point of view.

To introduce scientific methods to company’s management to let our company run continuously with proper profit and make a contribution to our society.

To be faithful, to cooperate each other and to be fair.

To cope with changes in business environment and move ahead on job standardization and implement systematic management.

Risk Management/Compliance

Company Overview

Organizational Chart of the Risk Management System

Chief Compliance OfficerRisk Management

Committee

Audit Department

Chemical Substance Administration Office

To sustain the corporate activity in the society & conforming to the social norms and corporate ethics is imperative. CMP is aware that responding to compliance is one of the most important issues among a number of risks, and always remain committed to compliance, across the board checks by the Risk Management Committee and with the guidance of the Compliance Committee.

Providing compliance education

For a broad understanding of the applicable law for our activities, and highlighting the important points of law within them, directors and employees in Japan received education for compliance.

Risk Management system Compliance

The business environment surrounding CMP Group is always changing and requires CMP to respond quickly to various risks. Under the basic policy; “Establish the effective and efficient Risk Management System, to achieve Human Safety, Continuous Development of Corporate Value and Mutual Trust with Stakeholders”, CMP Group forms various committees and keeps improving the system. These committees include Compliance Committee, System Planning & Operating Committee and others in support of the Risk Management Committee. We consolidate the control system for prevention, detention, correction, recurrence prevention of such anticipated risks, and for response to crisis.

Chief Information Officer

Coatings Care Committee

Compliance Committee

System Planning & Operating Committee

Board of Directors Board of Auditors

President

Code of Conduct for CMP Group directors and staff members

In February 1998, we established the “Code of Conduct for CMP Group Directors and Employees” which states the compliance, management in the medium to long term viewpoint, and mutual understanding with stakeholders (May 2008, is the latest version).

Translated into English and Chinese, this code of conduct is displayed to all affiliated companies to raise awareness of CMP group directors and staff.

Preparation and distribution of “Antitrust Law Manual”

For the Antitrust Law related with CMP’s activity, CMP prepared the manual “Compliance of Antitrust Law and other regulations for the fair trade” and distributed it to all of the directors and staff members in Japan.

Setting up of anonymous consultation in and outside the company

In December 2002, CMP set up “Post 999”, which is an anonymous consultation network in and outside the company. Currently CMP Group has this system in 8 countries / regions.

Risk Management/Compliance

Company Overview

Organizational Chart of the Risk Management System

Chief Compliance OfficerRisk Management

Committee

Audit Department

Chemical Substance Administration Office

To sustain the corporate activity in the society & conforming to the social norms and corporate ethics is imperative. CMP is aware that responding to compliance is one of the most important issues among a number of risks, and always remain committed to compliance, across the board checks by the Risk Management Committee and with the guidance of the Compliance Committee.

Providing compliance education

For a broad understanding of the applicable law for our activities, and highlighting the important points of law within them, directors and employees in Japan received education for compliance.

Risk Management system Compliance

The business environment surrounding CMP Group is always changing and requires CMP to respond quickly to various risks. Under the basic policy; “Establish the effective and efficient Risk Management System, to achieve Human Safety, Continuous Development of Corporate Value and Mutual Trust with Stakeholders”, CMP Group forms various committees and keeps improving the system. These committees include Compliance Committee, System Planning & Operating Committee and others in support of the Risk Management Committee. We consolidate the control system for prevention, detention, correction, recurrence prevention of such anticipated risks, and for response to crisis.

Chief Information Officer

Coatings Care Committee

Compliance Committee

System Planning & Operating Committee

Board of Directors Board of Auditors

President

Code of Conduct for CMP Group directors and staff members

In February 1998, we established the “Code of Conduct for CMP Group Directors and Employees” which states the compliance, management in the medium to long term viewpoint, and mutual understanding with stakeholders (May 2008, is the latest version).

Translated into English and Chinese, this code of conduct is displayed to all affiliated companies to raise awareness of CMP group directors and staff.

Preparation and distribution of “Antitrust Law Manual”

For the Antitrust Law related with CMP’s activity, CMP prepared the manual “Compliance of Antitrust Law and other regulations for the fair trade” and distributed it to all of the directors and staff members in Japan.

Setting up of anonymous consultation in and outside the company

In December 2002, CMP set up “Post 999”, which is an anonymous consultation network in and outside the company. Currently CMP Group has this system in 8 countries / regions.

Marine Paint FieldPaints for vessels

Product development

Foul-release ship bottom paints

In seawaters, living organisms such as shells, weed and algae adhere and grow on ship’s bottoms in certain conditions. Their presence on the ship’s bottoms while sailing causes a lowering in the speed and the fuel efficiency, and even increase CO2. To prevent such living organisms from adhering to the ship bottoms, anti-fouling paints are largely applied. In order to have a lower negative impact on the environment from anti-fouling paints, CMP have introduced new anti-fouling agents with high decomposition rate in sea water and low environmental load, and consequently marketed a range of TBT-free antifouling paints.Two years ago, we were successful in introducing the third generation of biocide free ship’s bottom paint - ”CMP BIOCLEAN HB”, a dream product with effective five years anti-fouling performance, and actively promoted its applications to such as large container ships, vehicle carrier and other kinds of ships, eventually contributing to improve the marine environment.

Marine paints tend to contain many kinds of organic solvents (major component of VOC - volatile organic content) for workability. The organic solvents themselves do not contribute to the performance of the coated film, and in effect end up becoming the source of air pollution. Thus reduction of organic solvents has long been a major challenge to overcome for the marine coatings industry. CMP is successfully lining up low VOC products and will continue its effort to reduce VOC.

Complete transition to safer, specialized and high solid paints

Protection of Oceanic EnvironmentReduction of VOC

Ahead of the Paint Industry, CMP removed tar-containing products from its list, and manufactures and supplies epoxy-paints in their place which meet international regulations for ballast tanks.

Sea going vessels, which support worldwide trading and provide the most cost effective means in doing so, face a harsh and severe operating environment. CMP manufacture paints for every part of vessels, such as anticorrosive paints for all vessel areas, anti-fouling paints for ship bottoms and paints for cargo, drinking water and ballast tanks. CMP are also committed to product development for maritime environment protection, with anti-fouling agent free paints, lead and chromium free paints, water-based paints, high-solid paints, and so forth.

Switching to lead and chromium free productsCMP continues its effort to eliminate lead or chromium pigments from the entire range of anti-corrosives and finishing paints. Such elimination for anti-rusting paints was already completed and we continue our effort until the complete elimination from the colored finish ranges.

Tin-free paints

Copper compound-free paints

Anti-fouling agent free paints

Functions of ship bottom paints

Product development for maritime environment protection

Product development for VOC reduction

Prevention of shells and algae

Energy Saving

Reduction ofVOC

SEA GRANDPRIX CF-10(Copper free hydrolytic foul-release paint)Uninterrupted hydrolytic mechanism can extend foul-release effect to five years without using cuprous oxide.

CMP BIOCLEAN (Anti fouling agent free, long-lasting foul-release paint)By maintaining the painted surface at low free surface energy, foul-release effect can be extended for five years. Also owing to its superior smooth surface, fuel can be saved considerably.

Thermo Shadan is a special effect coating which prevents the coating film from

absorbing heat, hence improves cooling efficiency and contributes to energy saving (CO2 reduction).

NOVA 5000Solvent free type epoxy paint for ballast tanks. Its VOC content is almost nil.

SWANWater-based paint for interior areas.

Solvent free type odorless paint for drinking water, very popular in the market.

NOVA 2000Modified epoxy paint for ballast tanks to replace tar-epoxy paint. Lower VOC type of NOVA 1000. Switching from tar-epoxy paints

Lesssolventpaints

Lesssolventpaints

Water-basedpaints

Heatinsulation

Highsolid

paints

Dark color tar-epoxy Paints for tanks NOVA

What is VOC?VOC (Volatile Organic Compounds) is a generic name of volatile organic compounds. VOC, if released into the open sky, becomes to cause oxidant smog, known for its adverse effect to eco-systems. Inside buildings, it is often released from building materials such as plywood, wallpaper or from glues used during construction of new houses, and causes in many cases allergic reactions called "sick house syndrome".

Solvent-free

paints

Water-basedpaints

Highsolid

paints

Lesssolventpaints

THERMO-SHADAN

CLEAN KEEP 5000

Marine Paint FieldPaints for fishing boats and fishing nets

Container Paint Field

Product development

With product development paying attention to maritime environment protection and based on our high technology applied for large vessels, CMP have been able to supply high quality products for fishing boats and fishnet. Seajet series, paints for pleasure boats and yachts, are also reliable and highly evaluated products for marine adventurers and professional yacht racers.

Various seaweeds attach to fixed fishing and cultivation nets due to the long periods they spend under the sea, and it causes problem with fishing and working. CMP’s anti-fouling paints, “Bio series” contributes to the fixed-net fishing industry and fish culture industry by reducing the problems.

For at sea/sailing condition and environmental protection, CMP develops, manufactures and supplies the paints for the bottoms of FRP fish boats. These paints, which emanate from the original formula based on our long study and performance, protect such ships from seaweed due to the excellent self polishing function. The products are highly valued by customers engaged

Paints for fishing boats

Paints for fishnet

Paints for pleasure boats and yachts

Since it was introduced to the market, “Seajet”, the first paint for pleasure boats and yachts in Japan, has been used for various kinds of private leisure boats and sporting yachts worldwide. We continue to develop environment conscious products, containing no TBT and no copper for these markets.

CMP is a pioneer of the container paint market in China and succeeded in being one of the world leaders in this market with due to its vast knowledge and accumulated experience.Our container paints respond to the environment and thus lead the paint industry, by introducing odorless paints for inside of container in consideration of goods to be carried within, developing water-based paints for the reduction of VOC, and promoting paints containing neither lead nor chromium. CMP have made an effort to work for the global environment, which is indispensable for world trading development of the coatings industry.

Fetid Free Paint (FF Series)

The word ‘FF’ is an abbreviation of ‘Fetid Free’. FF paint has been developed as an eco-friendly product to achieve a non-irritating odor generated by thinner evaporation on the interior of the container, with unique methods of removing irritant solvents such as xylene and toluene from interior topcoat paint and floor board paint and neutralizing the complex odor.

Interior Topcoat Paint EPICON SC INTERIOR NP-FF (Various colors available) *Complies with FDA regulation

Wooden Floorboard Paint POLYULAC NO.200 F-HB (Clear or Chocolate Brown) *Complies with FDA regulation

Lead or chromium free paintsCMP continues its effort to eliminate lead or chromium from its finish coatings, and will also eliminate them from container paints, by gaining the understanding and support from customers.

Water-based paintsFor the protection of the global environment, CMP is aware that there is an urgent need to reduce organic solvent (main component of VOC) from container paints, which usually contain organic solvent. In developing products for the reduction of VOC, CMP has set a main goal of developing water-based paints.

Development of Eco and User-friendly products

Marine Paint FieldPaints for fishing boats and fishing nets

Container Paint Field

Product development

With product development paying attention to maritime environment protection and based on our high technology applied for large vessels, CMP have been able to supply high quality products for fishing boats and fishnet. Seajet series, paints for pleasure boats and yachts, are also reliable and highly evaluated products for marine adventurers and professional yacht racers.

Various seaweeds attach to fixed fishing and cultivation nets due to the long periods they spend under the sea, and it causes problem with fishing and working. CMP’s anti-fouling paints, “Bio series” contributes to the fixed-net fishing industry and fish culture industry by reducing the problems.

For at sea/sailing condition and environmental protection, CMP develops, manufactures and supplies the paints for the bottoms of FRP fish boats. These paints, which emanate from the original formula based on our long study and performance, protect such ships from seaweed due to the excellent self polishing function. The products are highly valued by customers engaged

Paints for fishing boats

Paints for fishnet

Paints for pleasure boats and yachts

Since it was introduced to the market, “Seajet”, the first paint for pleasure boats and yachts in Japan, has been used for various kinds of private leisure boats and sporting yachts worldwide. We continue to develop environment conscious products, containing no TBT and no copper for these markets.

CMP is a pioneer of the container paint market in China and succeeded in being one of the world leaders in this market with due to its vast knowledge and accumulated experience.Our container paints respond to the environment and thus lead the paint industry, by introducing odorless paints for inside of container in consideration of goods to be carried within, developing water-based paints for the reduction of VOC, and promoting paints containing neither lead nor chromium. CMP have made an effort to work for the global environment, which is indispensable for world trading development of the coatings industry.

Fetid Free Paint (FF Series)

The word ‘FF’ is an abbreviation of ‘Fetid Free’. FF paint has been developed as an eco-friendly product to achieve a non-irritating odor generated by thinner evaporation on the interior of the container, with unique methods of removing irritant solvents such as xylene and toluene from interior topcoat paint and floor board paint and neutralizing the complex odor.

Interior Topcoat Paint EPICON SC INTERIOR NP-FF (Various colors available) *Complies with FDA regulation

Wooden Floorboard Paint POLYULAC NO.200 F-HB (Clear or Chocolate Brown) *Complies with FDA regulation

Lead or chromium free paintsCMP continues its effort to eliminate lead or chromium from its finish coatings, and will also eliminate them from container paints, by gaining the understanding and support from customers.

Water-based paintsFor the protection of the global environment, CMP is aware that there is an urgent need to reduce organic solvent (main component of VOC) from container paints, which usually contain organic solvent. In developing products for the reduction of VOC, CMP has set a main goal of developing water-based paints.

Development of Eco and User-friendly products

Industrial Paint FieldHeavy duty paints

Product development

HIFLOOR100

KEYSOL 100 & 300

Pylons

By reducing the splatter of paint, these paints decrease the negative impact on the surrounding environment while working on tall structures such as iron towers.

UNIGUARD TOWERKEYSOL G

Top coatings of steel structures

Primer & top coating of steel structure

THERMOSHADAN(Heat reflection & conduction blocking paint)

THERMOSHADAN, lowering thermal conductivity out of the painted surface, contributes to the energy saving through better cooling efficiency.

According to the performance requirements of coatings for harsh environments; such as, salt water resistance, acid resistance and water resistance, various heavy duty paints are selected and applied as anti-corrosive paints. In further responding to environmental issues such as PRTR, soil and air pollution, CMP has developed heavy-metal free, low-VOC heavy duty coating products for chemical plants, steel structures and bridges. CMP continues to develop environmentally friendly products.

The production and sales of anti-corrosive paints containing lead and chrome was terminated at the end of 2004. CMP recommends customers to change to lead and chrome-free substitute paints.

Furthermore, CMP recommends customers to try lead and chrome-free type products for top and intermediate coatings in the field of heavy duty anti-corrosive paint.

BIOCLEAN ECOBIOCLEAN, free of heavy metals such as copper compounds or organotin compounds, is highly appreciated as an environmentally friendly anti-fouling paint and acquired many results with the application on power plants and the like, domestically as well as overseas. Furthermore, BIOCLEAN-ECO, free of toluene and xylene, joined the BIOCLEAN series. Also, ECOMAX Bi ECO, a heavy-duty paint with excellent compatibility with silicone type paint and free of toluene and xylene, shortens the application process and attains a higher environmental efficiency.

ECOMATE (JIS K 5674)LZI Primer

EPICON W seriesUNYMARINE W seriesHIFLOOR 500 group

For heavy duty painting, CMP lined up alkyd-, epoxy- and urethane-type paints.

Coated with BIOCLEAN

Antifouling effect(In circulating water pipe of power plants)

Coated with paints other than BIOCLEAN

Green Products

UNIVAN MSUNYMARINE MS seriesFLUOLEX MS

CMP replaced solvent of PRTR aromatic compounds such as Toluene and Xylene with hydrocarbons such as mineral spirits.

Designated Procurement Items - Heavy duty primer paints (lead & chromium free paints)

Development of tar free paints

Development of heavy metal free paints

For the area to apply heavy duty paintings, tar-epoxy resin paints were choice of products in the past. In response to the demand of tar free paints, however, CMP developed and sells the primer of heavy duty epoxy paints with equivalent quality and performance.

For the painting of heavy duty paint, CMP developed solvent free and water based paints to reduce VOC and mild solvent paints to reduce Toluene or Xylene.

VOC reduction

Product development for VOC reduction

Solvent-free

paints

Lesssolventpaints

Water-basedpaints

Lesssolventpaints

Water-basedpaints

ECOMAX, without tar, can be painted in bright colors. It is a multi-purpose primer applicable, under any kind of environmental conditions, to the manufacturing plants, power stations, underwater steel structures, oceanic platforms and concrete surfaces.

ECOMAX HB, S-HB

EPICON PRIMER NP

EPICON PRIMER CL

UNIVAN NT

ECOLOGUARD 100SL

UNIVAN HS PRIMER

UNIVAN HS fast-drying type

EPICON ZINC HB-2

EPICON F

ECOMAX HB

MULTIX PRIMER

ECOLOGUARD 100

ECOLOGUARD SL

UNIVAN HS

ECOLOGUARD NP

GALBON S-HB

ECOMATE 100

These top coatings have a delicate paint film structure with an excellent hydrophilic property to protect the aesthetic of painted steel structuressuch as plants for a long time.

FLUOLEX No. 500KEYSOL No. 100UNYMARINE No. 500

Fluoro resin paints

Inorganic resin paints

Polyurethane resin paints

Lesssolventpaints

Industrial Paint FieldHeavy duty paints

Product development

HIFLOOR100

KEYSOL 100 & 300

Pylons

By reducing the splatter of paint, these paints decrease the negative impact on the surrounding environment while working on tall structures such as iron towers.

UNIGUARD TOWERKEYSOL G

Top coatings of steel structures

Primer & top coating of steel structure

THERMOSHADAN(Heat reflection & conduction blocking paint)

THERMOSHADAN, lowering thermal conductivity out of the painted surface, contributes to the energy saving through better cooling efficiency.

According to the performance requirements of coatings for harsh environments; such as, salt water resistance, acid resistance and water resistance, various heavy duty paints are selected and applied as anti-corrosive paints. In further responding to environmental issues such as PRTR, soil and air pollution, CMP has developed heavy-metal free, low-VOC heavy duty coating products for chemical plants, steel structures and bridges. CMP continues to develop environmentally friendly products.

The production and sales of anti-corrosive paints containing lead and chrome was terminated at the end of 2004. CMP recommends customers to change to lead and chrome-free substitute paints.

Furthermore, CMP recommends customers to try lead and chrome-free type products for top and intermediate coatings in the field of heavy duty anti-corrosive paint.

BIOCLEAN ECOBIOCLEAN, free of heavy metals such as copper compounds or organotin compounds, is highly appreciated as an environmentally friendly anti-fouling paint and acquired many results with the application on power plants and the like, domestically as well as overseas. Furthermore, BIOCLEAN-ECO, free of toluene and xylene, joined the BIOCLEAN series. Also, ECOMAX Bi ECO, a heavy-duty paint with excellent compatibility with silicone type paint and free of toluene and xylene, shortens the application process and attains a higher environmental efficiency.

ECOMATE (JIS K 5674)LZI Primer

EPICON W seriesUNYMARINE W seriesHIFLOOR 500 group

For heavy duty painting, CMP lined up alkyd-, epoxy- and urethane-type paints.

Coated with BIOCLEAN

Antifouling effect(In circulating water pipe of power plants)

Coated with paints other than BIOCLEAN

Green Products

UNIVAN MSUNYMARINE MS seriesFLUOLEX MS

CMP replaced solvent of PRTR aromatic compounds such as Toluene and Xylene with hydrocarbons such as mineral spirits.

Designated Procurement Items - Heavy duty primer paints (lead & chromium free paints)

Development of tar free paints

Development of heavy metal free paints

For the area to apply heavy duty paintings, tar-epoxy resin paints were choice of products in the past. In response to the demand of tar free paints, however, CMP developed and sells the primer of heavy duty epoxy paints with equivalent quality and performance.

For the painting of heavy duty paint, CMP developed solvent free and water based paints to reduce VOC and mild solvent paints to reduce Toluene or Xylene.

VOC reduction

Product development for VOC reduction

Solvent-free

paints

Lesssolventpaints

Water-basedpaints

Lesssolventpaints

Water-basedpaints

ECOMAX, without tar, can be painted in bright colors. It is a multi-purpose primer applicable, under any kind of environmental conditions, to the manufacturing plants, power stations, underwater steel structures, oceanic platforms and concrete surfaces.

ECOMAX HB, S-HB

EPICON PRIMER NP

EPICON PRIMER CL

UNIVAN NT

ECOLOGUARD 100SL

UNIVAN HS PRIMER

UNIVAN HS fast-drying type

EPICON ZINC HB-2

EPICON F

ECOMAX HB

MULTIX PRIMER

ECOLOGUARD 100

ECOLOGUARD SL

UNIVAN HS

ECOLOGUARD NP

GALBON S-HB

ECOMATE 100

These top coatings have a delicate paint film structure with an excellent hydrophilic property to protect the aesthetic of painted steel structuressuch as plants for a long time.

FLUOLEX No. 500KEYSOL No. 100UNYMARINE No. 500

Fluoro resin paints

Inorganic resin paints

Polyurethane resin paints

Lesssolventpaints

Industrial Paint FieldPaints for building materials, High performance paints for plastics, Caulking material for railways

Product development

For the painting of building material, CMP developed Toluen & Xylene free paints to deal with sick house syndrome, solvent free or water-based paints to reduce VOC and acquired F in the ratings to certify lower Formaldehyde releasing.

VOC reduction

Product development for VOC reduction

Paints for building materials

CMP supplies UV (ultraviolet) curing paints and other products for the coating of wooden floors, interior materials and furniture to the building-products and interiors industries. CMP develops products taking into account health issues, such as formaldehyde emission, which is a serious problem to building materials surrounding us all.

CMP has a lot of experience with the UV curing paints applied to wooden materials (for the first time in Japan) which instantly become hardened by ultraviolet radiation. For the reduction of VOC or formaldehyde, we have further developed our products, such as solvent-free UV curing paints or water-based UV products for coloring agents, primer coatings and finishing coats.

Water-basedpaints

Solvent-free

paints

Water-based coloring agentsSTAIN W series

UV curing paintsAULEX series

Paints for the renovation of bath tubs

BATH REFRESHBathrooms can be renovated by painting to be as good as new. Also the base material can be used so that no wastes are generated in order to contribute to the protection of the environment.

Before After

Caulking material for railwaysCUS

UV curing paints for wooden floors (For on-site application)AULEX PRO

Caulking material for railwaysAs trains run faster, rails need to be stronger and safer. CUS, which provides a level of high-strength and durability to be proud of, softens the vehicle vibration and impact with appropriate elasticity for effective performance. Further, due to the ease of maintenance, CUS is adopted by a number of railroads - not only for the Shinkansen and local trains in Japan but for railroads overseas, where it supports safe and comfortable train travel.

CMP has product range for various types of rail tracks, such as slab track, bifurcated track, and directly connected rail track. CMP products are also used as caulking materials for linear motor trains and enjoy a reputation as a provider of high technology to this industry.

High performance paints for plasticsFor optical film or plastics, CMP supplies high-performance UV curing paints based on the UV curing technology established after the long study of paints for wooden floors. The paints also have other functions, such as scratch-resistance, hydrophilic effect, water repellence, and ultraviolet protection.

Through exposure to ultraviolet light, the UV curing type paints for house remodeling harden quickly. Similarly, wooden floors become beautiful and harmless.

Solvent-free

paints

Lesssolventpaints

Water-basedpaints

Industrial Paint FieldPaints for building materials, High performance paints for plastics, Caulking material for railways

Product development

For the painting of building material, CMP developed Toluen & Xylene free paints to deal with sick house syndrome, solvent free or water-based paints to reduce VOC and acquired F in the ratings to certify lower Formaldehyde releasing.

VOC reduction

Product development for VOC reduction

Paints for building materials

CMP supplies UV (ultraviolet) curing paints and other products for the coating of wooden floors, interior materials and furniture to the building-products and interiors industries. CMP develops products taking into account health issues, such as formaldehyde emission, which is a serious problem to building materials surrounding us all.

CMP has a lot of experience with the UV curing paints applied to wooden materials (for the first time in Japan) which instantly become hardened by ultraviolet radiation. For the reduction of VOC or formaldehyde, we have further developed our products, such as solvent-free UV curing paints or water-based UV products for coloring agents, primer coatings and finishing coats.

Water-basedpaints

Solvent-free

paints

Water-based coloring agentsSTAIN W series

UV curing paintsAULEX series

Paints for the renovation of bath tubs

BATH REFRESHBathrooms can be renovated by painting to be as good as new. Also the base material can be used so that no wastes are generated in order to contribute to the protection of the environment.

Before After

Caulking material for railwaysCUS

UV curing paints for wooden floors (For on-site application)AULEX PRO

Caulking material for railwaysAs trains run faster, rails need to be stronger and safer. CUS, which provides a level of high-strength and durability to be proud of, softens the vehicle vibration and impact with appropriate elasticity for effective performance. Further, due to the ease of maintenance, CUS is adopted by a number of railroads - not only for the Shinkansen and local trains in Japan but for railroads overseas, where it supports safe and comfortable train travel.

CMP has product range for various types of rail tracks, such as slab track, bifurcated track, and directly connected rail track. CMP products are also used as caulking materials for linear motor trains and enjoy a reputation as a provider of high technology to this industry.

High performance paints for plasticsFor optical film or plastics, CMP supplies high-performance UV curing paints based on the UV curing technology established after the long study of paints for wooden floors. The paints also have other functions, such as scratch-resistance, hydrophilic effect, water repellence, and ultraviolet protection.

Through exposure to ultraviolet light, the UV curing type paints for house remodeling harden quickly. Similarly, wooden floors become beautiful and harmless.

Solvent-free

paints

Lesssolventpaints

Water-basedpaints

IBC Recycle System

Product development

"By introducing IBC system, waste cans were reduced by 590 thousand in 2008, which is 150 thousand more than 2007 figure, 440 thousand, and which is also more than 2005 figure, 530 thousand when tar-contained epoxy resin paints were still used.Also, China introduced IBC system and paints are delivered under this system."

Automatic paint blending equipment

IBC(Intermediate Bulk Container)

By switching to IBC, premise of the shipyards were much better put in order

Approx. 3.2 million waste cans reduced in 8 years.Significant contribution to less industrial wastes.

Merits of IBC System

Transition of paints shipped in IBC and declining waste can disposals

To eliminate can opening operation

To mix paints at a time

To reduce paint loss

To improve quality of paints

It is a system to combine IBC (Intermediate Bulk Container) and automatic paint blending equipment. Traditionally 20 lit. cans were mainly used for the package of paints and partially 200 lit. drums are in use. Most of them, however, were one-way packages and disposed as industrial wastes. These days many corporations are paying more attentions to resource conservation and zero-emission (of industrial wastes). To contribute in anyway solving such problems and come close to the target of zero-emission, CMP has continued to offer customers IBC system since 1995. Paints are delivered to customers in 1,000 lit. container and recycled after use, washed and then used again for delivery of paints. Conversion to IBC System was, of course, driven by team works of CMP and its customers. Benefit of this IBC System can include not only reduction of waste cans but also reduction of waste paint, improved mechanical washing efficiency and better working environment. Thus CMP enjoys favorable reaction by customers.

RecyclingUsed IBC

Transportation

Transportation

Filling

CMP

01 02 03 04 05 06 07 080

7000

6000

5000

4000

3000

2000

1000

0

10

20

30

40

50

60

70

Annual paint shipment of IBC (ton)Estimated savings of wasted cans (10,000 cans)

(FY)

Washing

Blended paints

Agitator

BaseHardner

Thinner

Customer

Retractable wing

Ann

ual p

aint

shi

pmen

t (to

n)

Est

imat

ed s

avin

gs o

f was

ted

cans

( 10

,000

can

s)

Automatic Blending & Weighing Equipment

Blending &

Weighing

Airless Spray

Painting

IBC Recycle System

Product development

"By introducing IBC system, waste cans were reduced by 590 thousand in 2008, which is 150 thousand more than 2007 figure, 440 thousand, and which is also more than 2005 figure, 530 thousand when tar-contained epoxy resin paints were still used.Also, China introduced IBC system and paints are delivered under this system."

Automatic paint blending equipment

IBC(Intermediate Bulk Container)

By switching to IBC, premise of the shipyards were much better put in order

Approx. 3.2 million waste cans reduced in 8 years.Significant contribution to less industrial wastes.

Merits of IBC System

Transition of paints shipped in IBC and declining waste can disposals

To eliminate can opening operation

To mix paints at a time

To reduce paint loss

To improve quality of paints

It is a system to combine IBC (Intermediate Bulk Container) and automatic paint blending equipment. Traditionally 20 lit. cans were mainly used for the package of paints and partially 200 lit. drums are in use. Most of them, however, were one-way packages and disposed as industrial wastes. These days many corporations are paying more attentions to resource conservation and zero-emission (of industrial wastes). To contribute in anyway solving such problems and come close to the target of zero-emission, CMP has continued to offer customers IBC system since 1995. Paints are delivered to customers in 1,000 lit. container and recycled after use, washed and then used again for delivery of paints. Conversion to IBC System was, of course, driven by team works of CMP and its customers. Benefit of this IBC System can include not only reduction of waste cans but also reduction of waste paint, improved mechanical washing efficiency and better working environment. Thus CMP enjoys favorable reaction by customers.

RecyclingUsed IBC

Transportation

Transportation

Filling

CMP

01 02 03 04 05 06 07 080

7000

6000

5000

4000

3000

2000

1000

0

10

20

30

40

50

60

70

Annual paint shipment of IBC (ton)Estimated savings of wasted cans (10,000 cans)

(FY)

Washing

Blended paints

Agitator

BaseHardner

Thinner

Customer

Retractable wing

Ann

ual p

aint

shi

pmen

t (to

n)

Est

imat

ed s

avin

gs o

f was

ted

cans

( 10

,000

can

s)

Automatic Blending & Weighing Equipment

Blending &

Weighing

Airless Spray

Painting

Environmental Management

Environmental Reporting

In response to the current worldwide demand to harmonize with environment of earth, CMP has been proactively engaged in protecting environment, safety and health as prioritized management issue. On 18th July 2001, CMP declared promoting Coatings Care (program to protect environment, safety and health) proposed and advocated by the Paint Industry.

To promote Coatings Care, CMP setss up committees and associated organization to promote Coatings Care in Japan.

Organizational Chart to promote Coatings Care Announcing to promote Coatings Care

What is the Coatings Care?

Self-imposed control to protect environment, safety and health

Coatings Care is the self-imposed voluntary initiative proposed and advocated by the International Paint & Printing Ink Industry Council (IPPIC) and The Japan Paint Manufacturers Association to protect the environment, safety, and health at all stages of chemical processing, from their development right through to manufacturing, transportation usage and their disposal. Also its basic policy is expressed in the same way as the one described in "Responsible Care" advocated by The International Council of Chemical Associations and promoted internationally.

Basic Principle

Basic Policies

To comply with the law and regulations regarding the environment, safety and health.

To promote our business activities through all the steps from the development of our products to their disposal, not only keeping in mind the environment, safety and health, but also resource conservation.

To develop and improve the products and technologies that are eco-friendly and safe to the global environment.

To consider the environment, safety and health of our employees and local residents through our business process of production, operation and distribution, as well as to promote the reduction of the environmental loading and waste products, resource conservation

To shift to eco-friendly products and provide information and give advice to customers regarding the safe use and handling of our products in respect of the environment, safety and health in product markets.

To widely disclose information to the government and the local community regarding our products and operations.

To conduct business activities reducing the loading on the environment and maintaining harmony with it, as well as considering safety and health.

Coatings Care Committee

Market related Environmental Protection and Safety

(Sales & Marketing section)

Environmental, Safety and Health Protection (Production section)

To reduce environmental load (reducing energy consumption and industrial wastes, increasing recycling resources)

To secure safety and health

To comply with laws and regulations

Product related Environmental and Safety Protection (Technology section)

Technology Meeting Safety & HealthCommittee

EnvironmentalManagement

CommitteeAcross-The-Company

Joint Meeting

To promote the use of environmental products

To deal with MSDS

To deal with PRTR

To deal with PL Claims

Public Relations

Reduction of use of the harmful raw materialsTo reduce harmful air pollutants (volatile organic compounds)

To reduce use of designated harmful chemical substance

Committee Chair: Senior Managing Director

SecretariatTo promote actions to protect environment, safety and health

To coordinate summarizing and finalizing activity policies, action plans andaccomplishmentsTo assess activity accomplishments

Basic policies to secure environmental protection and ensure human safety and health

Environmental Management

Environmental Reporting

In response to the current worldwide demand to harmonize with environment of earth, CMP has been proactively engaged in protecting environment, safety and health as prioritized management issue. On 18th July 2001, CMP declared promoting Coatings Care (program to protect environment, safety and health) proposed and advocated by the Paint Industry.

To promote Coatings Care, CMP setss up committees and associated organization to promote Coatings Care in Japan.

Organizational Chart to promote Coatings Care Announcing to promote Coatings Care

What is the Coatings Care?

Self-imposed control to protect environment, safety and health

Coatings Care is the self-imposed voluntary initiative proposed and advocated by the International Paint & Printing Ink Industry Council (IPPIC) and The Japan Paint Manufacturers Association to protect the environment, safety, and health at all stages of chemical processing, from their development right through to manufacturing, transportation usage and their disposal. Also its basic policy is expressed in the same way as the one described in "Responsible Care" advocated by The International Council of Chemical Associations and promoted internationally.

Basic Principle

Basic Policies

To comply with the law and regulations regarding the environment, safety and health.

To promote our business activities through all the steps from the development of our products to their disposal, not only keeping in mind the environment, safety and health, but also resource conservation.

To develop and improve the products and technologies that are eco-friendly and safe to the global environment.

To consider the environment, safety and health of our employees and local residents through our business process of production, operation and distribution, as well as to promote the reduction of the environmental loading and waste products, resource conservation

To shift to eco-friendly products and provide information and give advice to customers regarding the safe use and handling of our products in respect of the environment, safety and health in product markets.

To widely disclose information to the government and the local community regarding our products and operations.

To conduct business activities reducing the loading on the environment and maintaining harmony with it, as well as considering safety and health.

Coatings Care Committee

Market related Environmental Protection and Safety

(Sales & Marketing section)

Environmental, Safety and Health Protection (Production section)

To reduce environmental load (reducing energy consumption and industrial wastes, increasing recycling resources)

To secure safety and health

To comply with laws and regulations

Product related Environmental and Safety Protection (Technology section)

Technology Meeting Safety & HealthCommittee

EnvironmentalManagement

CommitteeAcross-The-Company

Joint Meeting

To promote the use of environmental products

To deal with MSDS

To deal with PRTR

To deal with PL Claims

Public Relations

Reduction of use of the harmful raw materialsTo reduce harmful air pollutants (volatile organic compounds)

To reduce use of designated harmful chemical substance

Committee Chair: Senior Managing Director

SecretariatTo promote actions to protect environment, safety and health

To coordinate summarizing and finalizing activity policies, action plans andaccomplishmentsTo assess activity accomplishments

Basic policies to secure environmental protection and ensure human safety and health

Plans to deal with Environmental, Safety and Health Issues

Environmental Reporting

Basic Policy

In compliance with the Coatings Care Action Guideline proposed by the Japan Paint Manufacturers Association, CMP started systemizing wherever it is possible and promotes integrated management of reports, records and data generated in many places as much as possible. Each committee sets action targets, periodically checks progress status, announce and moves on to next actions. Important issues ought to be prioritized.

Major actions

Regional Social Responsibility

Lifecycle Management of Products

Areas for action Major actions - Target -

Employees' Safety & Health

Work Place Operational Procedure(Occupational Safety)

Environmental Management (Pollution Prevention & Wastes Management)

To manage storage and disposal of harmful substance and control through the final stage of wastes disposal followed by more frequent site inspections

Reduction of energy consumption (Basic Unit for Energy) 2% reduction compared to 2007 data

Reduction of industrial wastes disposal 3.5% reduction compared to 2007 dataBy promoting the utilization of IBC, tank-car and Flecon Pack

To prevent releasing harmful substance in the air over the surrounding communities (solvent vapor/odor)

To prevent releasing harmful raw materials to the surrounding communities (Storage tanks, etc.)

To manage rigorously to prevent occupational accident at work

To collect data about accidents at work and health problems, analysis, company-wide announcement and suggesting to improve equipment or operational manuals

To promote measuring workplace environment (organic solvent density, noise, lighting and ventilation)

To enhance awareness level and rigorous implementation to protect safety and health by contractors in the company premise

To conduct health management and education thoroughly

To reassess, prepare and implement operational manuals to ensure safe operation

To beef up educating operators MSDS to handle raw materials

To document and optimize documents to respond emergency situation

To enhance operational equipment inspection, complement, renew equipment operational manuals, and train operators to follow through

To render full consideration to regulatory compliance, resource and energy conservation, safety during manufacturing and of products (including coated film), and lessening environmental load from stages of product designing, development to improvement

To add additional check items to the check sheet

To exchange information about safety, health and environment between sales staff and customers

To check status of timely sending out MSDS to customers, its availability at customers, accumulation of products safety data and review product safety

To collect information about potential risk of products, and write in product application manual instruction and labels pre-announcement about circumventing or preempting potential risk or potential troubles in advance in large letter size

To switch to products with lower environmental load

To reduce use of harmful substance (ratio per total sales volume)

For example in Japan when compared to 2007 data

TX (Toluene, Xylene & Ethylbenzene) 7% reduction

Lead & Chromium 23% reduction

Endocrine disrupting chemicals 15% reduction

Tar [We discontinued it completely from April, 2006. (0%)]

To document and review emergency response plans prepared for factories and offices

To review emergency communication network and emergency evacuation plans

To train employees for emergency response, and review training record and training practice to find useful lessens

To announce all employees the company-wide promotion of Coatings Care, explain its contents and instruct its implementation

To clarify the role of and cooperative structure among the customer service section, the Communication Dept. and the Compliance office.

To document or review manuals and standards dealing with information and communication to the communities (fire fighting, governmental office and residents) in case of emergency

To distribute Environmental Report and have proper presentation (supervisory governmental office, neighboring residents)

Training

Risk Control

Management of Transportation SystemCarriers

Emergency Response

To understand laws and rules for transportation and distribution, instruct and train employees or contractors proper handling, packaging, storage, labeling, transportation and distribution

To document emergency manuals to handle accidents during transportation and set up emergency response teams

To secure safety on site of transportation

To check potential hazard and assess associated risks to the surrounding community & environment

To check availability of qualifying certificates and licenses, inspect maintenance of carriers, availability of insurance certificates and confirm its maximum coverage

To review availability of product information during transportation and emergency response team

To implement oversight and educate carriers

To document, review and refine emergency manuals and procedure to set up emergency response team

Areas for action Major actions - Target -

Areas for action Major actions - Target -

Areas for action Major actions - Target -

Management of Manufacturing Area

Management of Transportation & Distribution

New product development

Education & disclosure ofinformation about health, safety and environment

Product safety (safe use of products)

Emergency action plan

Training and education of employees

Communication with regional communities

Plans to deal with Environmental, Safety and Health Issues

Environmental Reporting

Basic Policy

In compliance with the Coatings Care Action Guideline proposed by the Japan Paint Manufacturers Association, CMP started systemizing wherever it is possible and promotes integrated management of reports, records and data generated in many places as much as possible. Each committee sets action targets, periodically checks progress status, announce and moves on to next actions. Important issues ought to be prioritized.

Major actions

Regional Social Responsibility

Lifecycle Management of Products

Areas for action Major actions - Target -

Employees' Safety & Health

Work Place Operational Procedure(Occupational Safety)

Environmental Management (Pollution Prevention & Wastes Management)