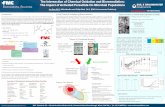

Hardness Spec (Fmc) Rev 5

description

Transcript of Hardness Spec (Fmc) Rev 5

-

Date : 06/06/13 Rev:5

HARDNESS SPEC for FMC Prepared by : Zulhiskandar

DOCUMENT GRADE DIAMETER HARDNESS CONTROL3rd PARTY

TESTINGREMARKS

M10007 Aisi 1018/1020

Rev:C

M10300 AISI 1040-1042 All size 7 22 HRC / 174237 HBw Medium carbon steelRev:H (ASTM A370) (8999 HRB)

M10401 Stress proof steel All size 26 42 HRC High strength shear pin

Rev:D (ASTM A370) (258-390 HB) Min 26 HRC or 258 HB

M11400 AISI A516 Grade 60 All size 0 4 HRC / 120-165 HBwRev:D (ASTM A370)

M11600 ASTM A194 2H All size 24 35 HRC Frequency check follow Table 1Rev:G (ASTM A370) (101108 HRB or 247327 HB)

M11700 ASTM A194 2HM All size 3 22 HRC 100% hardness testedRev:F (API 6A) (84.5-99 HRB or 159237 HB)

M11800 ASTM A36 All size N.A. Low carbon steelRev: T (shapes, plates, bars)

M12100 SAC 50 & 350, DIN 1629-ST52, All size N.A. Low carbon steel

Rev: Q COS AR 50, 350 & 500, etc.

M12201 ASTM A307 Grade A & B All size 0 16 HRC Rev:E (ASTM A370) (69-95.5 HRB or 121212 HB)

M12202 ASTM A574 1/2" & below 39 45 HRC 100% hardness testedRev:E (ASTM A370) > 1/2" 37 45 HRC Non H2S Cap Screw

M12203 ASTM A574 All size 16 - 22 HRC / 212237 HBw 100% hardness testedRev:E (ASTM A370) (95.5-99 HRB) H2S Socket head cap screw

M12204 ASTM F912 All size 45 53 HRC Alloy steel socket set screwRev:E (ASTM A370) Frequency check follow Table 1

M12205 ASTM A354 Gr BD 1/4" 2 1/2" 33 39 HRC

Rev:C (ASTM A370) > 2 1/2" 31 39 HRC

M12206 ISO 898-1 Class 8.8 All size 23 - 32 HRC / 243-300 HBw Max 32 HRC (301 HB)

Rev:H (100-107 HRB) Metric Fasteners

M12207 ISO 898-2 Class 8 All size 23 - 32 HRC Max 32 HRC (300 HB)Rev:G (100-107 HRB or 243-301 HB) Metric Nut

M20118 ASTM A193 B7 All size 25 34 HRC Max 35 HRC (321 HBw)Rev:C (ASTM A370) (101.5-108 HRB or 253-321 HB) Frequency check follow Table 1

M20121 ASTM A193 B7 or L7 All size 25 34 HRC Max 35 HRC (321 HB)Rev:C (ASTM A370) (101.5-108 HRB or 253-321 HB) Frequency check follow Table 1

M20200 ASTM A193 B7 All size 25-34 HRC / 253-321 HBw Frequency check follow Table 1Rev:J (ASTM A370) (101.5-108 HRB)

M20303 AISI 4140 (110/90) All size Before Mach: 235-302HbwRev:E After Mach: 229-302Hbw

M20305 AISI 4140 (130/110) All size 29 34 HRC / 277-321 HBwRev:E (104.5-108 HRB)

M20313 AISI 4140 All size 13 22 HRC / 197-239 HBwRev:D (ASTM A370 or API 6A) (93-99 HRB)

M21000 ASTM A193 B7M All size 16 21 HRC / 212-235 HBw 100% hardness testedRev:H (ASTM A370) (95.5-98.5 HRB)

M21200 AISI A194 G7 All size 24 34 HRC / 248-321 HBw Frequency check follow Table 1Rev:F (ASTM A962) (101-108 HRB)

M21501 AISI 4130 All size Before Mach: 184-237HbwRev:M (ASTM A370 or API 6A) After Mach: 174-237Hbw

M21509 AISI 4130 All size 1322 HRC / 197-237 HBwRev:N (ASTM A370 or API 6A) (93-99 HRB)

M21901 ASTM A320 L7 All size 25 34 HRC Frequency check follow Table 1Rev:K (ASTM A370 or API 6A) (101.5-107 HRB or 253-321 HB)

M21902 ASTM A320 L7M All size 1622 HRC / 212-237 HBw 100% hardness testedRev:K (ASTM A370 or API 6A) (95.5-99 HRB)

M21903 ASTM A320 L7S All size 25 32 HRC 100% hardness tested

Rev:M (ASTM A370) (101.5-107 HRB or 253-300 HB) Max 32 HRC (300 HB)

M21904 AISI A194/A194M G7L All size 24 32 HRC / 248-300 HBw 100% hardness testedt.

Rev:E (101-107 HRB) Marking according Q00346

M21905 ASTM A194/A194M 7M All size 1422 HRC / 200-235 HBw 100% hardness tested

Rev:D (93-99 HRB) Marking according Q00346

M21906 ASTM A320 L7M All size 1422 HRC / 200-235 HBw 100% hardness tested

Rev:D (ASTM A370-11 or API 6A) (93-99 HRB) Marking according Q00346

Grade A (Max 22 HRC/241HBw) acceptable

Mpi

Decaburization

Mpi

finished product

21-31 HRC

finished product

8-22 HRC

Mpi

Decaburization

Mpi

Decaburization

Mpi

Decaburization

-

M21907 ASTM A320 L7S All size 2432 HRC / 248-300 HBw 100% hardness tested.Rev:D (ASTM A370) (101.5-107 HRB) Max 32 HRC (300 HB)

M30113 AISI 316 All size 15 22 HRC 10% hardness testedRev:B ASTM A484 (UNS S31600) (94.7-99 HRB or 207-237 HB) Max 22 HRC (235 HB)

M30200 AISI 316 (75/30) All size 0 22 HRC / 152-237 HBw Max 22 HRC (237 HB)Rev:H (81.7-99 HRB) Ring gasket max 83HRB

M30201 AISI 316 (100/60) All size 15 34 HRC / 207-321 HBwRev:E (94.7-108 HRB)

M30207 ISO 3506-1 A4-80 / B8M2 All size 15 35 HRC Max 35 HRC (325 HB)Rev:G (94.7-108.5 HRB or 207-325 HB) >> for fastener

M30208 ISO 3506-2 A4-80 All size 15 35 HRC Max 35 HRC (325 HB)Rev:D (94.7-108.5 HRB or 207-325 HB) >> for nut

M30601 a) ASTM F593/F594 Grade 2 All size >> 0 15 HRC (65-95 HRB) Frequency check follow Table 1Rev:F b) ISO 3506-1/-2 A4-80 All size >> 0 22 HRC (65-99 HRB)

M33005 AISI 410 All size 197 - 237 HBw 100% hardness tested

Rev:P

M36100 ASTM A453 660 (130/85) All size 27 35 HRC 100% hardness testedRev:F (API 6A) (103-108.5 HRB or 264-327 HB)

M36101 ASTM A453 660 (130/105) All size 2435 HRC / 248-321 HBw 100% hardness testedRev:M (104.5-108.5 HRB)

M36201 ASTM A453 630 (17-4PH) All size 29 33 HRC 100% hardness testedRev:N (ASTM A370) (104.5-107.5 HRB or 279-311 HB)

M40100 Naval Brass All size N.A. ASTM B21 Alloy 464 or

Rev:F (ASTM A370) equivalent

M40102 Brass All size N.A. normally for set screw

Rev:C (no require marking)

M40902 Inconel 718 All size 35 39 HRC Max 39 HRC (362 HB)

Rev:L (UNS N07718) (327-362 HB)

Table 1 : Test Frequency for Individual Fasteners B7 & L7

Lot size (pcs) Sample Size (pcs)

50 and less 2

51 - 500 3

501 - 35000 5

> 35000 8

* Pad stud if don't have specify drawing, will use standard calculation table drawing as document P60133 Rev:E

Mpi

Decaburization

LPi

LPi