Prediction of sulfur content in propane and butane after ...

HANDBOOK BUTANE-PROPANE GASES_VOLUME 2.pdf

Transcript of HANDBOOK BUTANE-PROPANE GASES_VOLUME 2.pdf

-

HANDBOOK/BUTANE-PROPANEGASES/ VOLUME ltd]

-

Preface

HandbookButane-Propane

Gases

In this publication, Volume I I of theHandbook Series, the emphasis changesfrom basic and general to specific andtechnical. Whereas Volume I dealt withthe more elementary aspects of thefuels, traced the history of LP-gasproduction and marketing, and

! described the makeup of the industry inthe U.S . and around the world, VolumeII is aimed primarily at engineers,

I chemists, and technicians.Subsequent volumes, to be published

in sequence, will deal with production ,transportation , and storage of butaneand propane; distribution; andutilization of the products.

William W. ClarkEditor and Publisher

April 9 , 1973

1

-

Table of Contents: Vol. II

5 PROPERTIES OF THE HYDROCARBONS IN LP-GAS

Physical and chemical properties . . .Thermodynam icproperties...Use of Mollier char ts Combustioncharacteristics of the hydrocarbons Gases car-bureted with air . . .Mean spec ificheats Viscosity. ..Properties of olefin hyd rocar-bons .

25 PROPERTIES OF BUTANE-PROPANE MIXTURES

Nomenclature. . .Vapor pressure Hea t of com-bustion . . .Weight per gallon Latent heat o fvaporizat ion per pound. . .Cubic fee t o f gas pergallon. ..Spec ific gravity of liquid. ..Cubic feet of gasper pound. ..Specific heat o f l iqu id...Gallons ofliqu id per Mcf of 550 Btu gas. . .Vapor izat ion o f LP-gas. . .Dew poin t. . .

37 VOLUME CORRECTION FACTORSUse of volume correction fac tor table and spe c if icgravity conversion tables . . .

43 ANALYTICAL DETERMINATION AND TESTING

Compos i tion o f LP-gases . .. Anal yt ic al De ter -mination . . .Specificat io ns for comme rc ial gr ades andrela ted tes t pro ced ures.. .NGPA an d ASTMspec if icat ions and test methods.. .

3

-

Chapter 1

PROPERTIES OF THEHYDROCARBONS IN LP-GAS

T he com pi latio n of dat a on th e ph ysical andche mica l co ns tants of the hyd ro carbons involves these lection of the best measurem en ts mo st likel y to beof pract ical use. T he princ ipal p roperties of thehyd roca rbons used fo r de term in ing the charac-teristi cs of LP-gas include th e va por pr essure , thehea t of co mb us ti o n, the weight of a ga llo n of liq uid ,the lat ent hea t of va po riza tio n, the vo lu me of thevapor o r gas , a nd the specific gravity of th e liqu id.For th e pu rp o ses of this d iscussi on , th e term va po r isapp lied to the co nd itions exist ing in the pressu recy linde r or sto ra ge tank a nd th e ter m gas is appliedto the co nditio ns a fte r th e ex pa ns io n to low pressureas thro ugh a regul ator o r va lve.

The so u rce of supp ly fo r th is info rmati on is thescient ific work rep o rted by che mists an d ph ys ic istswho ge ne ra lly perform th e ir d e term ina tio ns us ing ahighl y puri fied fo rm of the che mical co mpo undbe ing inves ti ga te d . These propert ies a re re ported byman y aut ho ri t ies in va rio us uni ts an d at vario us tem-peratures a nd pressures whic h have been convertedto the E nglish system of measurem ent in this pr esen-tat ion . The E ngl ish sys tem is a lso know n as the foo t-p oun d -se c ond sys te m in w h ich the linea rmeas u re me nt is th e foot, the mea sure of wei ght is thepound a nd the measu re o f tim e is the seco nd . Bo ththe cub ic foot and the gallon a re measures ofvo lume . Ho wever , in the case of the gall o n, there is a

5

devia ti on fro m th e E ng lish system. The U .S. gall on isdefin ed as 231 cu . in ., whereas the Im pe r ial ga llon is20 per ce nt la rge r. The ga lio n referred to in thisHandbo ok Seri es is the U.S. gall on .

Wh en incons istencies are no ted in com pa ring themat eri al in th is cha pter wit h propert ies g iven for theco mmercially used p ro pan es and butanes , it shou ldbe rem embered that the co mme rc ia l co m po u nds a reno t as highl y puri fied as th ose used by the chemistso r ph ysic ist s in mak ing their d eterm ina tions.

In mak ing co mpa riso ns of d ata o n the propert iesof hyd roca rbo ns as ob tai ned fro m va ri ou s so urces,th e fo llowing factors sho u ld be ta ke n into con-sidera tio n:

I . The degree of pur ity of th e hydrocarbo ns usedfo r testing purposes .

2. The ex perime nta l met ho d used .3. T he type of appa rat us e mployed .4 . The author's defi nitio n of the p ropert y: fo r

ex a mp le, ther e is a d ist inct ion between bo iling poi nt ,b ubble po int and d ew poin t, a ltho ug h these proper-ties a re c lose ly related .

5 . The tem pe ra ture an d pr essu re at whic h theme as u re me nt was mad e.

6 . T he bas ic co nve rs io n fac tor used whe n ameas u reme nt is mad e in o ne system of u n its (e .g., themetric sys te m) an d then re po rte d in anot her sys tem(e.g., the En glish syste m) should be indicated .

-

TABLE 1 - PHYSICAL CONSTANTS OF HYDROCARBONSCOMPOUNDS FOUND IN LPGA S

ISO ISO 150 -NAME METHANE ETHEN E ETH AN E PROPENE PROPANE BUTANE BI JTENEl BUTENE N-BUTANE PENTANE PENTE NE-l N-PENTAN E AIR WA TER

FORM ULA CH' C 2H 1 C, H" C1HI ' C1He C-lH1 Q C -lH8 C4HB C4H 1O C sHl ' C sH10 C sH12 H2O

Vapor Pressure at 100'F.Lbs. per sq. in. gauge .. . .. . . . . . .. . . . . . . . .. 212 .5 175 .8 57 .5 47 .6 48.9 36.9 . 5.7 . . . .9 . . . . . .Lbs . per sq. in. absolute . .. .. . . . . . . . . . . . 780 227 .2 190 .0 72.2 62 .3 63 .6 51 .6 20.4 19.4 15.6 . . . .949

Normal State at Atmos phericPressure and 60 'F.. . . . .. .. ...... . .. . Gas Gas Gas Gas Gas Gas Gas Ga s Gas Liqu id Liquid Liquid Gas Liquid

Boiling Point 01 LiquidAt Atmospheric Pressure

OF. . .. . . .. ... .. . ............. . .. .. - 258.7 - 154 .7 - 127. 5 - 53 .9 - 43 .7 10.9 20 .7 19.6 31 .1 82 .1 85.9 96.9 -317.7 212DC.. . .. ... . .. . . . . ........... . .. .... - 161.5 - 103.7 - 88 .6 - 47 .7 - 42 .1 - 11.7 - 6.3 -6.9 - 0.5 27 .9 30.0 36 .1 - 194.3 100

Weight of Liquid at 60F.Pounds Per Gallon ... . ... . ... .. .. . 2.5 3.3 3 .11 4.35 4.23 4 .69 5.011 5.004 4.86 5.20 5.387 5.387 7.136 8.328Specific Gravity . . . . . . . . . . . . . . . . . .. .3 .. . .374 .5218 .508 .56 3 .6011 .6002 .584 .625 .6461 .631 .856 1.000

API Gravity . . .. . . . .. . .. . . . . .. . . . . . 340 .0 ... 247 139 .7 147 .2 119.8 103 .9 04 .3 110.6 95 .0 87 .5 92 .7 165 .3 10.0

Cubic Feet 01 Va por atAtmospheric Pressure and60 F. Formed Iro m

1 Gallon 01 Liquid a t 60' F. .. . ..... 59 .0 44.6 39 .25 37 .9 36.35 30.59 33 .81 33.94 . 31.75 27 .40 29.18 27 .68 . .. . . .1 Pound of Liquid . . . .. . . .. . .. .... . 23 .6 13 .51 12.65 8.71 8 .62 6.53 6.75 6.78 6.54 5.27 5.42 5.27 . .. . . .

Weight of Vapor at Atmo s ph e ricPressure and 60'F.

Pounds Per Hund red Cubic Feet .. 4 .227 7.393 7.923 11.09 11.62 15.31 14.79 14.79 15.31 19.01 . . . 19.01 7.64 . . .Specilic Gravity (Air-1) . . . . . . . . . . . .554 .9684 1.038 1.4527 1.522 2.006 1.9370 1.9370 2.006 2.491 .. . 2.491 1.000 . . .

Gross Heat 01 C ombustionBtu Per Pound .. .. .. ............ . . 23 .891 21.650 22 .329 21 .060 21 .670 21 .265 20.860 20.740 21.315 21 .046 20.720 21.094 . . . . . .Btu Per Cubic Foot at 60F. . .. ... . 1.012 1.601 1.783 2.335 2 .558 3 .354 3.084 3.066 3.368 4.003 3.829 4,015 . .. . . .Btu Per Gallon at 60F.. . . .. . ... . . .. . 70 .910 69.433 87 .740 91 .044 99 .097 103.4 80 104.060 103 ,047 108,820 110 ,850 110,125 .. . . . .

Cubic Feet 01 Air to Burn 1Cubic Foot 0 1 Gas At AtmosphericPressu re and 60 'F . . . . .. . . . . . . . . . . . . . 9.53 14.29 16.67 21.44 23.82 30 .97 28 .58 28.58 30 .97 38 .11 35 .73 38.11 .. . . ..Pounds 01 Air to Burn1 Pound 01 Gas .. . .. .. . .. .. . .. .. .. .. 17 .24 14 .76 16.13 14.76 15.71 15.49 14.76 14.76 15.49 15.35 14.76 15.35 . . . .. .

Flammability Lim itsLower % in Air ... ... . .. . . ... . . . . . 5.3 3.1 3.0 2.4 2.2 1.8 1.6 . . . 1.9 1.4 1.5 1.5 . . . .. .Upper % in Air . . . . . . . . . . .. . . . . . . . 14.0 32.0 12.5 10.3 9.5 8.4 9.3 . . . 8.5 7.6 8.7 7.8 .. . .. .

-

TABLE 1 - PHYSICAL CONSTANTS OF HYDROCARBONSCO MPOUNDS FOUND IN LP GAS

ISO ISO ISONAME METHANE ETHEN E ETHANE PROPENE PROP ANE BUTANE BUTENE 1 BUTENE N BUTANE PENT ANE PENTENEl NPEN1ANE AIR WATFR

FORMULA CH, C2H' C2H6 C3H6 C3Ha C,H IO C'Ha C'Ha C 4H l0 C5H12 C 5Hlo CSH 12 H 2O

Heat Required to VaporizeLiquid at the Boiling Pointand Atmospheric Pressure

Btu Per Pound . . .... .. . . .. .. .. . . . . 245 208 211 189 183 158 174 167 166 146 148 153 92 970 .3Btu Per Gallon . . . .. . . . . .. . . .... . . . 712 686 696 822 774 741 872 836 797 759 797 803 656 .5 8089.4

Ratio 01 Liquid Volume at 60'F.to Gas Volume at AtmosphericPressure and 60'F... ... , ... .... .. . .. 443 333 .7 294.3 283 .5 272 .7 229.3 252.9 254 .0 237.8 205.0 218.3 207 . .. . ..

Freezing Point of Liquidat Atmospheric Pressure

' F. .. . . . .. . .. . . . .. . ... ... . . .. . .. .. . -296.5 - 272.6 - 297 .8 - 301.4 - 305.9 - 255.3 -301 .6 1-220 .6 -216.9 - 257 .1 -265.5 - 201.5 . . . 32' C. . . . .. . . . . . . ... .. . ... .. .. . . . .. . . . -182.5 - 169.2 - 183.2 - 185.2 -187 .7 -159.4

- 185.3 1-140.3 -138.3 -160.6 -165.3 - 129.7 ... 0

Molecular Weight 16.042 28.052 30.068 42.079 44 .094 58.12 56.105 56.105 58.12 72.146 70.131 72.146 28 .966 18.016

Gallons Per Pound Mol at 60'F . . . . . 6.4 8.5 9.64 9.7 10 .41 12 .38 11.2 11.2 11.94 13.84 13.0 13.71 4.06 2.16

Specific Heat at AtmosphericPressure at 60'F.

Cp Liquid-Btu Per Pound Per ' F . 0.54 0.555 .55a t32F. 0.533 . . . 0.536 . . . 1.000Cp Vapor-Btu P"r Pound Per ' F. . 0.5271 0.362 0.410 0.352 0.389 0.387 0.347 . . . 0.397 0.388 . .. 0.397 0.171 0.455Cv Vapor-Btu Per Pound Per ' F. . 0.402 0.288 0.343 0.298 0.342 0.352 0.303 . . . 0.363 0.361 . . . 0.370 . . . 0.333Cp Vapor-Btu Per Pound Per ' F.. 1.308 1.258 1.193 1.180 1.133 1.097 1.145 ... 1.094 1.076 . . . 1.074 1.410 1.335Cv

Critical ConditionsTemperature ' F.. . .. . .... . . .. ... ... -116.5 49.8 90 .1 196 .5 206 .2 273.2Temperature ' C. . .. . . . .... . . . .. . . . . - 82.5 9.9 32 .3 91 .4 96.8 134.0 297 292.5 305.6 370 .0 394 387.0 -221 .3 705Pressure-Pounds Per 147.2 144 .7 152.0 187.6 201 197.2 -140.7 374.1

Square Inch Absolute . . . . . . . . . . . 673 742 708 667 617 529Pressure-Atmospheres .... .. ..... . 45 .8 50.5 48 .2 45.4 42.0 36.0 588 580 551 .0 483 40.4 33.3 37.2 218 .2Density-Pounds P.or Gallon . . . . . . . 1.351 .. . 1.695 ... 1.888 1.946 . . . . . . 1.891 1.955 . .. 1.935 . . . .. .Volume Cubic Feet Per Pound Mol . 1.586 .. . 2.371 . .. 3.123 3.990 .. . . . . 4.130 4.930 . . . 4.98 . . . . . .

-

Uses of Tabulated Data

Tabulated properties of hydrocarbons are valuablefor comparison purposes . They indicate the relativeproperties of the materials and serve the engineer orplant operator as a valuable means of making ap-proximate identifications of mixtures. For example,if the vapor pressure at a given temperature of a mix-ture of hydrocarbons is known, it is possible to makea preliminary judgment as to which hydrocarbonsare likely to be present in the mixture. Thisprocedure is also of use to the analyst who may savehimself preliminary analysis by an approximate iden-tification through one or more simple physicalpro pert ies.

Tabulated data on these properties are often usedto calculate the corresponding properties of mixturesas explained in Chapter 2 which covers properties ofbutane-propane mixtures and relation of propertiesto temperatures. The procedure developed is usefulin the absence of direct experimental data on themixture and also for the purpose of determining theproportion of each constituent to obtain a desiredphysical property.

Physical and Chemical Properties

The liquefied petroleum gases are readily con-densable to liquids at normal atmospheric tem-peratures by the application of pressure. It is thisproperty which renders the gases or mixtures ofthese gases valuable as fuels. They may be tran-sported, stored, and handled with the convenience ofa liquid . On the other hand, it is possible todistribute them locally and to burn them with all theconvenience characteristic of the fuel gases .

In this connection it should be realized that heattransfer plays an important part in the production ofthe gaseous fuel from the liquid existing in the tank.Conversion from the liquid to the gaseous state isalways accompanied by an absorption of heat. In acontainer, a saturated vapor exists above the liquid.As soon as the gas valve is opened, this vapor ab-sorbs heat from its surroundings. As it passesthrough the heat exchanger, regulator or pipingsystem, it absorbs additional heat. This process ofheat absorption produces gaseous characteristicswhich are very different from those of the originalsaturated vapor.

For the convenience of the user, hydrocarbons

8

below and above the range of LP-gas have been in-cluded in the composite Table 1. The first twohydrocarbons mentioned in Table 1, methane andethane, are the principal constituents of natural gas .Propane and the butanes are the principal con-stituents of LP-gases.

The various items listed in the composite Table 1indicate the physical or chemical properties of thehydrocarbons.

The molecular formula is useful in showing therelative proportion of carbon and hydrogen con-tained in these gases and reference to a table of in-ternational atomic weights as given in any standardchemistry text book will indicate the relative weightof carbon and hydrogen contained in each.

The molecular weight indicates the relative weightof material represented by the chemical symbolwhich would enter into a chemical reaction. .

A number placed ahead of each symbol in a balan-ced chemical equation represents the number ofmolecules entering a chemical reaction. This may beillustrated by a chemical equation representing theperfect combustion of propane, forming carbondioxide and water as the products of combustion:

Balanced equation:C3H8 + 502 = 3 C02 + 4 H2O

Molecular Weights:44 .094 + 5 (32) = 3 (44 .01) + 4 (18 .016)

Relative Combining Weights:I lb. + 3.629 lb. = 2.995 lb. + l. 634 lb .

The boiling point of each hydrocarbon is given atatmospheric pressure. These hydrocarbon liquidshave this property in common with all liquids,namely, there is a liquid temperature at whichevaporation is rapid enough to produce noticeableformation of vapor bubbles.

Taking normal butane as a typical example, it isfound that the boiling point is given as 31.1 deg. F.This means that if an open vessel containing normalliquid butane were held in an atmosphere severaldegrees below the freezing point of water it wouldnot boil although butane vapor would slowlyevaporate. If the temperature of the liquid were thenraised to 31 .1 deg. F., it would begin to boilnoticeably.

The specific gravity of the liquids expresses therelative weight of these hydrocarbon liquids as com-pared to water at 60 deg.F. The data in Table 1 in-

-

TABLE 2. THERMODYNAMIC PROPERTIES OF SATURATED PROPANEEnthalpies and Entropies are referr ed to saturated liquid at -200F. where the values are zero. Refer to Fig. 1 for Enthalpies

and Entropies of super heated propane vapor.

Pressure Specific Volume I Density Enthalpy" " Entropy""Lb. per Sq. In. Cu. Ft. per Lb. Lb. per Cu. Ft. Btu per Lb. Latent" " Btu per Lb. Deg. F.

Temp. Heat Temp.Deg. I Btu Deg.F. Absolute Gauge Liquid Vapor Liquid Vapor Liquid Vapor per Lh. Liquid Vapor F.

t P g.p. 0 V ' 10 ' IV hI hg L sf .g t- - - - - -

-75 6.37 "17.0 0.02660 14.5 37.59 0.0690 65.5 255.5 190.0 0.142 0.624 -75-70 7.37 "14.9 0.02674 12.9 37.40 0.0775 68.0 257.0 189.0 0.148 0.623 - 70-65 8.48 "12.7 0.02688 11.3 37.20 0.0885 71.5 258.0 186.5 0.154 0.621 -65-60 9.72 "10.1 0.02703 9.93 37.00 0.111 74.0 259.5 185.5 0.160 0.620 -60- 55 11.1 " 7.3 0.02717 8.70 36.80 0.115 77.0 261.0 184.0 0.167 0.618 -55-50 12.6 " 4.3 0.02732 7.74 36.60 0.129 79.5 262.7 183.2 0.173 0.617 -50-45 14.4 " 0.6 0.02748 6.89 36.39 0.145 82.3 264.2 181.9 0.179 0.615 -45-40 16.2 1.5 0.02763 6.13 36.19 0.163 85.0 265.8 180.8 0.185 0.614 - 40-35 18.1 3.4 0.02779 5.51 35.99 0.181 87.5 267.2 179.7 0.190 0.613 -35-30 20.3 5.6 0.02795 4.93 35.78 0.203 90.2 268.9 178.7 0.196 0.612 -30-25 22.7 8.0 0.02811 4.46 35.58 0.224 92.8 270.3 177.5 0.202 0.610 -25-20 25.4 10.7 0.02827 4.00 35.37 0.250 95.6 271.8 176.2 0.208 0.608 -20-15 28.3 13.6 0.02844 3.60 35.16 0.278 98.3 273.2 174.9 0.214 0.607 - 15-10 31.4 16.7 0.02860 3.26 34.96 0.307 101.0 274.9 173.9 0.220 0.607 -10- 5 34.7 20.0 0.02878 2.97 34.75 0.337 103.8 276 .2 172.4 0.226 0.606 - 5

0 38.2 23.5 0.02895 2.71 34.54 0.369 106.2 277.7 171.5 0.231 0.605 0+5 41.9 27.2 0.02913 2.48 34.33 0.403 108.8 279.0 170.2 0.236 0.604 + 510 46.0 31.3 0.02931 2.27 34.12 0.441 111 .3 280.5 167.2 0.246 0.603 1015 50.6 35.9 0.02950 2.07 33.90 0.483 114.0 281.8 167.8 0.248 0.602 1520 55.5 40.8 0.02970 1.90 33.67 0.526 116.8 283.1 166.3 0.254 0.601 20

25 60.9 46.2 0.02991 1.74 33.43 0.575 119.7 284.4 164.7 0.260 0.600 2530 66.3 51.6 0.03012 1.60 33.20 0.625 122.3 285.7 163.4 0.266 0.599 3035 72.0 57.3 0.03033 1.48 32.97 0.676 125.0 287.0 162.0 0.272 0.598 3540 78.0 63.3 0.03055 1.37 32.73 0.730 128.0 288.3 160.3 0.278 0.597 4045 84.6 69.9 0.03078 1.27 32.49 0.787 131.1 289.5 158.4 0.285 0.596 45

50 91.8 77.1 0.03102 1.18 32.24 0.847 134.2 290.7 156.5 0.292 0.596 5055 99.3 84.6 0.03125 1.10 32.00 0.909 137.2 292.0 154.8 0.298 0.596 5560 107.1 92.4 0.03150 1.01 31.75 0.990 140.6 293.2 152.6 0.306 0.595 6065 115.4 100.7 0.03174 0.945 31.50 1.06 143.8 294.5 150.7 0.313 0.594 6570 124.0 109.3 0.03201 0.883 31.24 1.13 147.5 295.8 148.3 0.321 0.594 70

75 133.2 118.5 0.03229 0.825 30.97 1.21 150.3 296.9 146.6 0.327 0.594 7580 142.8 128.1 0.03257 0.770 30.70 1.30 154.0 299.1 145.1 0.335 0.593 8085 153.1 138.4 0.03287 0.722 30.42 1.39 157.0 299.2 142.2 0.342 0.593 8590 164. 0 149.0 0.03317 0.673 30.15 1.49 160.3 300.3 140.0 0.349 0.593 9095 175.0 160.0 0.03348 0.632 29.87 1.58 163.4 301.3 137.9 0.356 0.592 95

100 187.0 172.0 0.03381 0.591 29.58 1. 69 166.8 302.4 135.6 0.363 0.592 100105 200.0 185.0 0.03416 0.553 29.27 1.81 169.8 303.2 133.4 0.370 0.592 105110 212.0 197.0 0.03453 0.520 28.96 1.92 172.8 304.0 131 .2 0.376 0.591 110115 226.0 211.0 0.03493 0.488 28.63 2.05 176.2 304.7 128.5 0.383 0.590 115120 240.0 225.0 0.03534 0.459 28.30 2.18 179.8 305.2 125.4 0.391 0.589 120

125 254.0 239.0 0.03575 0.432 27.97 2.31 183.5 305.8 122.3 0.399 0.588 125130 272.0 257.3 0.03618 0.404 27.64 2.48 186.8 306.1 119.3 0.406 0.587 130135 288.0 273.3 0.03662 0.382 27.32 2.62 190.0 306.3 116.3 0.413 0.586 135140 305.0 290.3 0.03707 0.360 27.00 2.78 194.0 306.5 112.5 0.422 0.585 140

I

Inches of mercury below one standard atmosphere (29.92 in.) From Mollier Diagrams for Propane. W. C. Edmister. Standard Oil Co. (Indiana).

9

-

st itute, It will be noted th at the heavier liquids havethe lower API numbers .

The liquid density in pounds per gall on is given at60 deg. F. but the density at other temperatures maybe obta ined from data given in Fig. 7, Chapter 2. Thedensity of the olefin hydrocarbons may be calculatedo n the basis of the coefficient of the expansi on of theliquid given in Table 10. When changes in pressureare small, its effect on the liquid density may be con-sidered negligible. (See p.24)

Thermodynamic Properties

The principles o f thermodynamics form theframework upon which the measurements of thephysical and chemical properties of the hydrocar-bons are correlated and presented for practical use.For this reason, some of the less obvio us propertiesmust be described with reference to conceptionsdeveloped from considerations of thermodynamic

principles . The values given in literature for ther-modynamic properties will vary depending on thesource of the physical or chemical measurements aridthe method used to compute them , when equationsof state are employed.

The density of liquid methane and ethene given inTable 1 should be considered in connection with thetherm odynamics o f gases , vapors , and liquids . Thevalues given may be considered as apparent liquiddensities because the liquid state as generally un-derstood does not exist at a temperature of 60 deg .F. Referring to the " cr it ica l temperatures" in thetable, it may be seen that the temperature of 60 deg .F . is ab ove the critica l temperature for these twogases; hence the mass of methane or ethene wouldremain homogeneous throughout the entire range ofpressure. In fact , closest obse rvatio n would fail tosh ow where the gaseous state ceased and the liquidstate began, even if pressures in excess of the' criticalpressures were applied .

2 4 5 ~ 78 10PIGESSt./I2E L BS'/SQ, IN. A 850L U TEI~ 7 20 30 40.50 60 :v 100

"l50

225

4++1:1. t+ :~ !">;. ~~;SE:

/75

/j(}

~ /25

,t mm~~ uH2E I 1m LCD~ ...,--~

'-'.:.... ,++ ..,,- " H"- - - ~

20e

/.0 e 3 4 5.. 7 8 10 14 7 ! O 30 40 so 60 70 1M .a:v.w 4a?.w 7ev

Fig . 1. Vapo r pre ssur e o f etha ne , p ro pane , i so b ut ene . norm al butane , iso- p ent ane and normal pentane.

12

-

25'

20

70

90

/50

250

.360340

,, I

I

I I I II I

II

", I v r

, i

I I I j

~rn:tf~-ri /I~ :t-'*'--" :~ , ; ~ VX \11, ,

~- i;~ T. Vii~ .. :.r-= :-:"':'F r. _ - f:..-- ~, ~: I "'C; i t{

.__. f-i~il 7_.....!1:':=_:.t . 4

-~ i'~ .r '_ . -iB i'F

~ /i ttI.t1 ;I :/- I.- .l.

260 280 .100 .J2O,..,.-,

+T+-Ir

..

.

y- , l ilIltr

C

MOLLIER DIAGRAM ~FOR j

PROPANE, , I

I I,

, I I ,

I ,

"

I , ,,

20

so

25

ISO

15I

, II

T,

I i

I -.

I I !

"~

280 J()O .320

, I

I I I.J30 340 ),0

15

Fig. 2. Mollier chart for propane. Enthalpy:-Btu/lb/deg. F. (above saturated vapor at-200 deg . F.). Refer to Table 2 for properties of saturated propane liquid and vapor.

13

-

260 280 300 3H .15112Q() 2IJQ

MOLL IER DIAGRAMISO FOR 15IJ

U~ NEIP() IIJI

90 gO

60 80

7(J 70

ill ~

~ SO 54~~

-

T he speci fic gravity of th e vapo r o r th e gas in -d ica tes th e rel a tive weight as co mpared to air. Fo rth e va lues gi ven in T a ble 1, both th e hydro ca rbonand a ir a re at a te mpera ture o f 60 deg. F., bo th gasesbe ing in a dry sta te .

T he d en si ty of the vapo r or gas is a lso ex pressedin pounds per hundred cub ic feet. T he cubic footre presents a defin ite mass o r we ight of hyd ro carbo nssi nce the standa rds ado pted fo r the mea suremen t a re60 deg . F. a nd 760 m illimet er s of mer cu ry o n th e d rybasis .

T he cubic feet per gallo n o f liquid is no t a densitybut re prese nts a chan ge fro m the liq uid to the vapo ror ga seou s state. T he eva po ra tio n of a gallon ofliq uid at 60 deg. F. wo uld produce the num ber ofcubic feet of va po r o r gas indi ca ted in Tabl e 1, thecubic foo t being measu red a t 60 deg. F . and 760 mm .of mercury. Fo r th e purposes of vis ua lizing pressu recond iti ons , 760 mm. of mercury may be co nsideredto be normal atmos phe ric pressure. This pressu remeasurem ent is eq uiva lent to an abso lute p ress ure of14. 7 lb . pe r sq. in .

The critical co nd it ions of temp e ra ture andpressu re given in Table 1 re p res ent conditio ns a twhich liq u id and gas eous sta tes cease to bed ist ingu ishabl e. At th is temperatu re and pressure thede nsities of th e liq ui d and the gas are identical. F ur-the rmo re, th e top lim it of the va po r pressu re as su chis obtained a t th e cri tica l temp er ature an d is ex-pressed in po unds per squa re inc h abso lute under"c rit ical pressu re" in the tab le.

T he gauge pressure is an obse rve d measur ement. Itreprese nts the abso lute pressure in pounds persq ua re inch less the normal at mospheric pr essu re atsea ' level, which is ge nera lly ta ke n to be ap-pro ximately 14 .7 psi. In scientific literature, pressurewi ll often be ex pressed in terms of atmo sphe res . T hepressu re in pou nd s per sq uare inch absolu te may bedivided by the p redete rmined pressure in pou nd s persquare inch fo r o ne a tmosphere to give th eeq u iva lent at mo spheres .

The va po r pressure has been given in pounds persq ua re inc h abso lute at 100 d eg. F., a ltho ugh valuesat o the r temperatures may be obta ined from Tables

f\."'\....,........,, "~ ,-ETHYLEN~,PROPYLENE)BUTYLENE-, "', ~'''' r-,

-

TABLE 5. COMBUSTION DATA OF HYDROCARBONS

ICubic Feet Required Products of Combustion Pounds Required for Products of Combustionper Cu. Ft. of Gas or in Cu. Ft. Formed by Burning Combustion One Lb. in Pounds from Burning UltimateVapor for Combustion One Cubic Foot of Gas or Vapor One Pound Gas or Vapor Carbon

Dioxidein Flue

Chemical Carbon Waler Carbon Water ProductsFormula Air Oxygen Dioxide Vapor Nilrogen Air Oxygen Dioxide Vapor Nitrogen Per Cent

- ---

Methane . .. . . . . . . . CH, 9.55 2.0 1.0 2.0 7.55 17.24 3.98 2.74 2.24 13.26 11.7

Ethane. .. .. . C,H, 16.70 3.5 2.0 3.0 13.20 16.13 3.73 2.92 1.79 12.40 13.1

Propane.. . . . .... - C3Hs 23.86 5.0 3.0 4.0 18. 86 15. 71 3.63 2.99 1.63 12.08 13.7

Butane. .... . . . . C.H1o 31.02 6.5 4.0 5.0 24.52 15.49 3.58 3.03 1.55 11.91 14.0

Pentane. . .. .. CSHI2 38.19 8.0 5.0 6.0 30.19 15.35 3.54 3.05 1.50 11.80 14.2

Ethylene.... . .. . . C,H, 14.32 3.0 2.0 2.0 11.31 14.80 3.42 3.13 1.28 11.38 15.0Propylene. . . . C3H 6 21.48 4.5 3.0 3.0 16.98 14.80 3.42 3.13 1.28 11.38 15.0

Butylene. .. .. . ... C,H. 28.58 6.0 4.0 4.0 22.58 14.80 3.4 2 3.13 1.28 11.38 15.0

2, 3, and 4, and F ig. 1. These liquids have a vap orpressure wh ich bec om es grea ter with an increase intemperature. T he numerical value o f this vapo rpressure is a distinctive property of th at part icularhydrocarbon and may be defined as the pressureexisting in a clos ed space abo ve the pure liquid whenno o ther gases or vap ors are present in th is closedsystem.

T he latent heat o r the quant ity o f heat absorbed

TABLE 6. MEAN SPECIFIC HEATS OF GASES ATCONSTANT PRESSURE IN BTU PER CUBIC FOOT

AT 60 F. AND 30 IN. OF MERCURYCALCULATED FOR THE INTERVAL 600 F.-T

Nitrogen, OxygenTemperature Carbon Water and Other

of. Dioxide Vapor Diatomic Gases- - - ---

200 0.0237 0.0220 0.0174400 0.0246 0.0220 0.0175600 0.0253 0. 0221 0.0177800 0.0260 0.0222 0.0178

1000 0.0268 0. 0224 0.01801200 0.0275 0.0226 0.01811400 0.0282 0.0229 0.01831600 0.0287 0. 0232 0.01841800 0.0292 0.0236 0.01862000 0.0298 0.0240 0. 01872200 0.0302 0.0245 0.01892400 0.0306 0.0250 0. 01902600 0.0309 0.0256 0.01922800 0.0312 0.0263 0.01943000 0. 0314 0.0270 0.01963500 0.0317 0.0288 0.02014000 0.0319 0.0312 0.0206

16

o n vap ori zat ion o f the liquid is given at the normalboiling po int of the hydrocarbon as indicated inTable 1. When vaporizati on occurs at temperaturesother tha n the normal boiling point , refer to F ig. 2 o rTables 2, 3, and 4, which indicate the lat ent heat ofvap ori zati on at vari ous temperatures . This late ntheat decreases in value with inc reasing temperatureand is zero at the critical temperature.

The latent heat given in Btu per pound is theamo unt of heat that would be absorbed by I lb . ofthe liquid if it were to be converted to a saturatedvap or in a closed container at the temperature andpressure given in the end column. The latent hea tvaries with temperature and is zero at the criticaltemperature and pressure.

The gross heat of combustion, often called thehe ating value , is obtained b y lab oratorymeasurement in the calorimeter , suitable correctionbeing made to report a definite heating value understanda rd conditions of 60 deg. F ., 29 .92 in . mercurypressure t o n a dry basis (i.e. , without water vapor) .T he gross heat of combustion may be defined as theam ount of heat rel eased when the gas is completelyburned at normal atmospheric pressure, the init ia lai r-gas mixture being at the normal ro om tem -pe rature and the products of combustion beingcooled down to practically room temperature withall the latent heat of water vap or recovered by theca lo rimeter. The gross heating value is the standardused universally in the United States for the co m-putation of th e rmal efficiency of fuel burning ap -pl ian ces.

t Norm a l pressure is specified as 29.92 in Hg. for meas urements of gas vol ume It iseq uiva lent to a n a bso lut e pr essure of 14 .73 lb s. pe r sq. in .

-

The thermodynamic properties of the constituentsof the liquefied petroleum gases may best bediscussed by referring to Table 2, which tabulatesthe properties of propane. The properties listed inTable 2 are the properties of a saturated vapor as itwould exist in a closed container at the temperatureand pressure specified in the table and in thepresence of liquid material. As a result , the valuesgiven may only be applied to conditions existing inthe typical closed container and not to the propertiesas they exist after pressure reduction, or in thepipelines to appliances .

The first column expresses the vapor pressure ofpropane in pounds per square inch absolute (psia),which is not the numerical value indicated on apressure gauge attached to the container. Thecorresponding gauge pressure in the adjacent columnis obtained by deducting 14.7 pounds from the ab-solute pressure.

The next item, the specific volume in cubic feet perpound, expresses the volume of either the liquid orthe saturated vapor at any desired temperaturewithin the range of the table. As can be seen, theliquid expands as the temperature increases, and itwould be possible to determine the coefficient of ex-pansion * from the tabulated data given. The liquidand vapor densities given in pounds per cubic footare merely the reciprocals of the values given in theprevious columns .

Table 1 lists the properties of the chemically purehydrocarbons. Commercial propane and butane arenot pure products, but contain small quantities of theother hydrocarbons neighboring them in theirchemical series. Even though not chemically "pure"products, both are sold as specification products .Commercial propane and commercial butane aredefined according to standards established by theNatural Gas Processors Association, Society forTesting Materials and other organizations .

In addition to the specifications for commercialpropane, other specifications have been establishedfor motor fuel-grade propane. HD-5, set up byNGPA, specifies a maximum of 5% propylene con-tent and a minimum of 90 % propane. Its purpose isto assure a product that will perform like a"premium" high-octane fuel in critical engines.

Specifications for commercial butane, commercialpropane, commercial b-p mixes, and HD-5 are setforth in NGPA 2140-70. These are also dealt with in

"Coeffici en t o f ex pa nsio n is de fined as the facto r o r numb er express ing the a mo unt ofexpans io n brought a bo ut in a substance by a cha nge in temper atur e.

17

a later chapter in this volume of the HandbookSeries.

Enthalpy or total heat content of a saturatedliquid is the heat content of the liquid at a given tem-perature, expressed in Btu per pound, or the heatrequired to raise the temperature of I lb. of liquidfrom absolute zero (--460 deg. F.) to the given tem-perature.

Enthalpy o r total heat content of saturated vaporis the heat content of the vapor at a given tem -perature expressed in Btu per pound, or the amountof heat required to raise the temperature of I lb. ofvapor from absolute zero (--460 deg . F.) to the giventemperature. It is the sum of the enthalpy of theliquid plus the latent heat of vaporization .

As most engineering calculations using enthalpyand entropy (see below) require the use of dif-ferences in the values at commercial operating tem -peratures, these tables and charts are expressed asthe values above arbitrary base values used by theauthors , and in using them this should be taken intoconsideration. The values expressed are not absolutevalues but values above or below a definite referencepoint.

Entropy, expressed as Btu per pound per degreeF., is the property of the material that remains con-stant if no heat enters or leaves while it alters itsvolume or does work, but which increases ordecreases should a small amount of heat enter orleave. Its value is determined by dividing the in-trinsic energy of the material by its absolute tem -perature. The intrinsic energy is the product ofspecific heat at constant volume multiplied by achange in temperature. The numerical value of theabsolute temperature is obtained by adding 460 deg .to the Fahrenheit thermometer temperature.

Use of Mollier Chart

Problems in the flow of butane-propane gasesthrough regulator valves may be solved by the use ofthe Mollier chart. Suppose that propane liquid froma storage tank is vaporized and then passes to aregulator for pressure reduction and control.Assume the conditions at the regulator are asfollows:

Inlet Pressure-200 lb. per sq . in. absolute .Inlet Temperature-lOS deg . F.

Outlet Pressure-IS .I lb. absolute (12 in. watercolumn).

-

The problem in this case is to find the temperatureof the gas on the low pressure side of the regulator.Reference to the Mollier chart , Fig. 2, will indicatethat the propane vapor exists in the saturated stateunder its initial pressure and temperature con-ditions. The passage of a gas or vapor through anyreducing valve may be considered a throttlingprocess in which the heat content or enthalpy is con-stant from the initial conditions to the final con-ditions existing at the outlet of the pressureregulator . Reference to Fig. 2 will indicate that theheat content of the vapor is 303 Btu per lb . under theinitial conditions of temperature and pressure. Thethrottling process is along the vertical line represen-ting a constant heat content of 303 Btu per lb. Thisline is followed downward until it intersects thehorizontal line representing a pressure of 15 lb . ab-solute. At this point a reading between the lines ofconstant temperature indicates that the final tem-perature of the gas will be 55 deg. F .

The actual temperature of the gas may be lowerthan 55 deg. if there is a long run of uninsulatedpiping between the vaporizer and regulator. The heatcontent on partial vaporization may be calculatedfrom the following equation:

h = hg - (l-x ) Lh = Heat content of mixture of vap or and liquid .hg = heat content of dry, saturated vap or.x =portion of liquid vaporized, quality .(l-x ) = portion of liquid not vaporized .L = latent heat of vaporization at constant pressure.

The quality of the vapor from a heat exchanger isgenerally about 98 per cent. The result of cooling ofsaturated vapor in a pipeline is, first, a liquid fog willbe produced, which is carried along the pipe, andsecond, upon further cooling, condensation will takeplace on the walls of the piping. Under these cir-cumstances the temperature at the outlet of theregulator will decrease further because the throttlingprocess must supply the latent heat of vaporizationof liquid particles .

Similar problems may be solved for butane by theuse of the Mollier chart, which appears as Fig. 3.

Combustion Characteristics of the Hydrocarbons

Comparative combustion characteristics of thevarious hydrocarbons are best presented in terms ofperfect combustion conditions in which the amount

18

of air as given by a balanced chemical equation isassumed to be used . In actual practice it is necessaryto use a certain amount of air in excess of thesetheoretical requirements, depending on the type anddesign of the appliance and its gas burner. With thislimitation understood it is possible to use the basicdata contained in Table 5 as a guide in making airsupply provisions for gas appliances, or for burnersused to convert coal or oil-fired furnaces to use gas .The ultimate percentage of carbon dioxide given inthe table represents an upper limit, to be approachedbut never reached in actual practice, and its valuevaries for different types of fuels.

Fig. 4 shows the relation between the percentagesof carbon dioxide and various amounts of excess airused to complete the combustion of the hydrocarbongases . In compiling the data for this chart it wasfound that the lines representing the butane andpropane gases are quite close together indicating thata specified carbon dioxide content of the flueproducts would hold for either gas , or for mixturesof the two, within close limits. It is also true that theusual small proportions of other hydrocarbon gasesin liquefied petroleum gas mixtures would not ap-preciably affect the general relation between the per-centage carbon dioxide and the air used in excess oftheoretical requirements .

An example is given in Fig. 4 for the propane-butane gases, indicating that 8 per cent carbondioxide in the flue gases corresponds to the use ofapproximately 66 per cent excess air in terms of thetheoretical requirements. A determination of thecomposition of the flue products may be obtained byreferring to the data of Table 5 and the compositionof air by volume, namely 20 .95 per cent oxygen. Atypical computation for propane gas is as follows:

Cubic Feet Carbon Dioxide per Cu. Ft. of PropaneBurned (from Table 6) 3.00 cu. ft.Total Dry volume, Perfect C ombustion (fromTable 6) :Carbon Dioxide 3 .00Nitrogen ' " 18.86

Total Cu. Ft. 21 .86

Total Dry Volume, Including Excess Air ,Cu.Ft. Carbon Dioxide (100)

'70 Carbon Dioxide in Flue Gas

3.00 (100) . . . .37.50 Cu . Ft.8.0

-

Excess Air , 37 .50-21 .86 15.64 Cu. Ft.Volume Oxygen , 15.64 ( .2095) 3.28 Cu. Ft.Volume Nitrogen in Excess Air

15.64-3.28 12.36 Cu. Ft.

The usual flue gas analysis , using absorptionchambers , reports results on a dry basis . Hence thevarious constituents o f the flue gas may be assembledto determine the complete flue gas analysis :

The application of the specific heats of gases asgiven in Table 6 to the constituents will indicate theheat content of the flue products per cubic foot ofhydrocarbon gas burned .

Fig. 5 shows the heat contained in the flueproducts for propane for stack temperatures up to1200 deg. F. and for various percentages of carbondioxide in the flue gases. For example, we find fromthis chart that with 8.0 per cent carbon di oxide inthe flue products and a flue temperature of 500 deg.F., the quantity of heat in the flue gases is 550 Btuper cu . ft. of gas burned . It will also be noted that theper cent excess air corresponding to 8.0 per centC02 is 65.2 per cent of that theoretically required forcombustion .

Combustion Characteristics of Propane: The ap-pliance utilization of propane involves a study of itsproperties from the standpoint of their effect o n thecombustion characteristics of the gas as well as onthe capacity of pipes and burner orifices. The moreimportant properties of any gas from this standpointare its heating value, specific gravity , and com-position.

The composition , of course , determines both theheating value and specific gravity and also revealsother important characteristics such as the airrequirements for perfect combustion , ignitionvelocity, and limits of inflammability, all of whichhave an influence on the utilizat ion of the gas .

Table 5 lists various items of informat ion con-cerning several commercially distributed petroleumgases . It will be noted from this table that pr opanerequires a relatively large amount of air (23 .86 cu .ft .) for perfect combustion of I cu. ft . of gas , com-

Constituent

C arbon D iox ide .Ox ygen .Nitrogen (18 .86 + 12.36) .

T otal .

Cu.ft,

3.003.28

31 .22

37 .50

Analysis

8 .07c8.77c

83 .3%

100.0%

19

pared to 9.55 cu . ft. of a ir per cubic foot of methane .The theoretical air requirement for gases issignificant in burner and appliance design. However,it is nece ssary in actual pr actice to use air in exce ssof the theoretical requirements in order to obta insatisfactor y performance of the appliance .

Fig. 6 shows the heat contained in flue pr oductsfrom the combustion o f a commercial butane whosecomposition is 93 % butane and 7% propane. Th eheat contained in the flue products is expressed asthe gross heat in Btu per cubic foo t of gas burned forstack temperatures up to 1200 deg. F. and forvari ous percentages of carbon dioxide in the fluegases . For example, we find from this chart that with8 per cent carbon dioxide in the flue products and aflue temperature of 500 deg ., the quantity of heat inthe flue gases is 710 Btu per cu. ft. of butane burned.It will also be noted that the per cent of excess aircorresponding to 8 per cent C02 is 68 .7 per cent ofthat the oretically required for perfect combustion .

Gases Carburetted with Air

The flammable limits for butane-air mixtures arefro m 1.9 to 8.5 per cent of gas in the mixture, whichcorresponds to a range o f 61 to 240 Btu per cu . ft. ofgas. Since the leanest butane-air mixture distributedcommercially is usually 525 to 550 Btu per cu. ft.,representing a mixture of 16.5 to 17.2 per cent gas, itis apparent that such mixtures are well outside theexplosive limits.

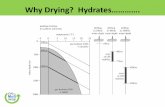

The dew point, o r the temperature at which con-densation begins , depends on the partial pressureexisting in a mixture of gases. Fig. 7 shows the dewpoints of pure hydrocarbons diluted with air invarious proportions. Taking as an example a butane-air mixture commercially distributed and having aheating value of 550 Btu per cu . ft., we find thatthere is approximately 20 per cent of gas in the mix-ture . On referring to the chart for normal butane wefind that the dew point of such a mixture in a lowpressure distribution main would be minus 35 deg.F. This temperature is well below either normal at-mospheric temperatures o r ground temperaturesexisting in most sections of this country.

Mean Specific Heats

The mean specific heat of a gas may be defined asthe average amount of heat required in British ther-mal units to raise o ne standard cu. ft. through a tern-

-

"11cP'!" 8:J: II)CI)

.g~ lPn '10 ~:!.Dl fis'CI) II)Do

S'0Ml

C ~

~CI) ....

0'tl

J::

0II)

Do ogc '1n 0iii Po2-

p0

n

-

~- r H-H-J-'!-f-;-~~'

~ t-t-t-t- . -- ; ~~ ttt+ ~-- t- '- ~ -H - ,

_-+4 j..-;--,--'

~h- :

:-;...l + ..;..

,~4 .::itt '-!-r ;J:j:-

-e-r-r-

-.-+---! :t-.;- i::j: ,~~::;:;: --t:;.4

,-- tEl +

-

PROPANE N - BUTANE I ISOBUTANE

80

-60

-70

-so

1101 I I I I I I I I I I

1001 I I I I I I I I I I

1// '7 / /1/ /V /1II 01 I I ~ fi,+/ 1/ / / II 0 / / v1001 I I _,~J!} J / ~ 100 I_~ / /

I h'/~v V V /7 ~PI J /V 1/ L901 , I I t I I e,,~ 90 L~ /A~/ V/ ./' 90 ~lV V 1/ V ~

I I I I I ~,e:,'l 80--f--

-

perature of o ne degree F . Table 6 presents the meansp ecific heats of th ose gases commonly found in thecombustion products of hydrocarbon gases. Table 7presents the me an sp ecific heats on unit weight ba sis ,ex pressed as Btu per lb .

The range of temper ature over which the meanspe ci fic heat is given extends from 60 deg. F . to thetemperature indicated in the first co lumn of thetabl e. For example, suppose that combusti onproducts ar e at a temperature of 400 deg. F . and it isdesired to determine the heat content of the carbondi oxide constituent ab ove the base temperature of 60deg. F. The mean specific heat oppo si te 400 deg . F.(0.0246) is multiplied by the temper ature rise (34 0deg. F.) to give .the heat co ntent of each cu. ft . o f ca r-bon di oxide. The heat contents of o ther component sof the flu e gases are determined in a similar manner.T hese tabulated data are used in the pr eparati on o fcombust io n charts and heat co ntent ch arts simila r toth at of Fig. 5.

Viscosity

The viscosity of liquid hyd rocarbons enters int opipeline flow determinati ons and in heat tr ans ferequat ions used for de sign ing vaporizers . Withrel at ion to the flow of liqu ids there is fricti on bet -wee n the liquid part icles and th e side walls of thepipe and there is als o internal fricti on between liquidmolecules . As a general rule , the heavier liquids havehigher visc osities and hence higher internal fri ct ionwhen pumped through a piping syste m.

Table 8 pr esents th e viscosi ties of propane, butan eand pentane in the saturated liquid st at e. It will benoted that the lightest liquid , propane, ha s th e lowestnumerical va lue of the visco sity. Absolute viscosityis measured in centipo ises in the Metric system ,although the micropoi se, whi ch is o ne mill ionth of apoi se, is sometimes used for the lighter hydroc arbonliqu ids. Kin em atic viscosity is th e abso lu te viscosi tydi vided by th e den sit y in consist ent un its.

Flame Temperatures of Hydrocarbon Gases:Maximum flame temper atures are the h ighest tem -peratures whi ch th eoretically may be obtai ned fromthe combusti on of a fuel. T hey a re useful in ex-pl aining man y of th e results of gas burning, but donot nec essar i ly indicat e the effec t iveness of a gas, o ro the r fue l, to do a part icul ar work .

T he results of di rect tes ts of fla me tempe rature a regiven in T able 9. During these test s th e ex-perimenters noted th at maximum flam e temperaturesd id not al ways occur when the theoretical gas-a ir

23

TABLE 7. MEAN SPECIFIC HEATS OF GASES ATCONSTANT PRESSURE IN BTU PER POUND

CALCULATED FOR THE INTERVAL 60 F._T

Temperature Carbon I Waterof . Dioxide Vapor Nitrogen200 0.2067 0.4653 0.2365400 0.2143 0.4657 0.2386600 0.2216 0.4673 0.2407800 0.2285 0.4698 0.2428

1000 0.2348 0.4735 0.24491200 0.2406 0.4782 0.24701400 0.2462 0.4841 0.24911600 0.2512 0.4910 0.2512

1800 0.2559 0.4990 0.25342000 0.2601 0.5081 0.25552200 0.2638 0.5182 0.25762400 0.2670 0.5294 0.2597

2600 0.2698 0.5420 0.26182800 0.2722 0.5557 0.26393000 0.2742 0.5702 0.26603500 0.2770 0.6093 0.27074000 0.2790 0.6599 0.2755

TABLE 8. VISCOSITY OF HYDROCARBONLIQUIDS IN SATURATED STATE

PoiseAbsolute Viscosity in Centipoises (--)

100

40F. 60F. 80F. 100F. 120F. 140F.

Propane. . . 0.117 0.106 0.097 0.086 0.077 0.067Isobutane. . 0.182 0.163 0.146 0.130 0.114 0.100N-Butane .. . 0.200 0.180 0.162 0.147 0.131 0.116Pentane. . . 0.270 0;242 0.219 0.200 0.181 0.165

TABLE 9. MAXIMUM FLAME TEMPERATURESOF HYDROCARBON GASES MIXED W ITH AIR

Flame Speed inl-in . tube.

Gas Temperature - of . in. per secondMethane 3416 26Ethane 3443 34Propane 3497 32N-Butane 3443 33Isobutane 3452 33Ethylene 3587 65Propylene 3515 39Butylene 3506 38

Taken from American Gas Assn. "Gaseous Fuels."

-

TABLE NO. 10. LIQUID SPECIFIC GRAVITY OF LOWER OLEFINS(Interpolated Values, Water at 39 F. C. Having a Density of 8.347 Lbs. per Gallon)

Temperature of . Ethene Propene I-Butene 2-Butene Ieobutene

-40 0 .461 0 .599 0 .674 0 .663-30 0 .450 0 .593 0 .668 0 .657-20 0.437 0 .585 0 .650 0 .663 0 .651-10 0 .423 0.578 0 .644 0 .657 0 .645

0 0 .408 0 .571 0.638 0 .651 0 .639+10 0 .392 0 .563 0 .632 0 .645 0 .633

20 0 .372 0.556 0 .626 0 .639 0 .62730 0 .348 0 .548 0 .620 0.632 0.62140 0 .309 0 .540 0 .613 0 .626 0.61450 Critical 0.531 0 .606 0 .620 0 .60860 Temperature 0 .522 0 .599 0 .613 0 .60170 49 of . 0 .51480 0 .50490 0 .493

100 0 .482Reference (1) (1) (2) (2) (3)

mixture was burn ed , nor when th e mixtureproduc ing th e highe st flam e was burned . How ever,there is gen eral agreement between th e highest flam espeed and the highest flam e temperature.

Many facto rs encountered in both test work andpractical work affect the flame conditions so that th e

24

flame temperatures do not reach the th eoreticalultimat e. Some of these fac to rs are : ( I) rad iation , (2)di ssoc iati on of di atomic mol ecul es at elevated tem -peratures, (3 ) excess a ir, (4) conduction losses , (5)convecti on losses , (6) time o f co mbust ion, and (7 )objects in the flam e.

-

Chapter 2

PROPERTIES OFBUTANE-PROPANE MIXTURES

Since in actual practice pure hydrocarbonsare almost never used, the chief value of the proper-ties of the pure hydrocarbons is for their use incalculating the properties of their mixtures.

Most mixtures known as LP-gas are largely com-posed of propane, isobutane and normal butanetogether with small amounts of ethane, pentanes andheavier hydrocarbons. The percentages of eachdepend on the gas from which they are obtained , theequipment used for their recovery, and the purposesfor which the gas is to be used.

In order to facilitate the determination of theproperties of propane, isobutane and normal butanemixtures at the standard conditions used in the LP-gas industry, i.e. , 60 deg. F. and 14.73 lb . per sq . in .,Figs. 1,2 and 3 have been ~p l o tted . The charts can beused for determining the properties of all three orany two constituents at this temperature and underpressure, when the percent by liquid volume of eachis known.

For propane-isobutane mixtures read off therequired result at percentage of propane on line P-I.For isobutane-normal butane mixtures , read off therequired result at percentage of normal butane online I-N . For propane-normal butane mixtures , readoff the required result at percentage of propane ornormal butane on line P-N .

These charts will give results that are accurateen ough for most engineering purposes , and more ac-curate than can be obtained by slide rule com -putation, even when there are small quantities ofethane or pentane present in the liquid, exceptpossibly in the case of the vap or pressures given inFig. 1. The presence of ethane o r pentane in theliquid , o r in non-condensable gases ab ove the liquid,

25

wi II have a marked effect on the vapor pressure .

Calculating the Properties

Nomenclat ure . Formulae for calculating theproperties of mixtures at any ordinary pressure andtemperature when their composition is known aregiven in the following discussi on . The nomenclatureused in these formulae appears below:

x, y, z fraction of a gallon of propane,isobutane and normal butane, respec-tively, per gallon of mixture.

Qp, Q i, Q n = heats of combustion per gallon at deg.F. of propane, isobutane and normalbutane, respectively, Btu. Obtain fromtable, Fig. 1.

W p, W i, W n = weight per gallon of propane,isobutane and normal butane, resp ec-t ively , pounds. Obtain from Fig. 7 atdesired temperature.

H p, H i, H n = latent heat of vaporization per pound,etc., Btu. Obtain from Fig. 4 atdesired temperature.

V p, V i, V n = cubic feet of gas at 14 .7 3 lb . per sq.in. absolute and 60 deg. F., per gallonat 60 deg . F., etc. Obtain from Fig. 2.

O p, D r, O n = specific gravity, etc. obtain by use ofTable I , Chapter 3, as directed in text.

1r= total pressure, pounds per sq . in. ab-solute.temperature, deg . F.

k volume corr ec tio n fa ctor, i.e. , volumeat 60 deg. F . occupied by unit volumeat indicated temperature, from Table I,Chapter 3.

-

P100

~ 80~oJo>o 70

~QoJ

60>-III

t-Z 50wua:::wn, 40I

WZ~ 30oa:::c,

2 0

10

0;9 ~550 B.T{/. ttl.

- B '000 .92, 85 /11

260 0 8. TU.

FIG. 1. Approximate vap or pre ssure and heat ofcombustion of butane-propane mixtures . Plottedfrom the following values:

NormelPropane Isobutene Butane

Vapor Pressure at 60 F.Pounds per Square InchGage 92.4 24.0 11.6

Gross Heat of Combustionper Ga llon at 60 F.,B.t.u 91,001 98,550 101,888

Gross Heat of CombustionCubic Foot of Gas, at14.73 Pounds per SquareInch Absolute and 60 F .,and Dry, B.t.u................... 2518 3260 3273

oI 0 10 20 30 40 50 60 70

NORM AL BU TAN E - PER CEN T BY LIQUID80

VOLUME90

N100

Vapor Pressure. When the rate of vap orization o fa liquid is exactly equal to the rate of condensationof its vapor , the va por is saturated . The pressu reexerted by the sa turated vap or o n the walls of thecontaine r is called the vap or pressure o f the liquid atthe exist ing temp er ature.

The vap or pressu re lin es shown in Fig. 1 arecalculated for an arbitrary temperature of 60 deg. F .,but this ch art together with Fig. 4 can be used for ob-

26

taining the vap o r pressure of any mixture at any or-dinary temperature . For example, suppose it isdesir ed to kn ow the va por pressu res of a mixtu re of12% propane, 38 % isobutane and 50 % normalbutane at temperatures of 30 deg. F. and I 10 deg. F .On F ig. 1 the pressure is fou nd to lie between 25 and30 lb. pe r sq . in. ga uge . Interpo lating between theseline s, the pressure is found to be 27 .3 lb . per sq . in .gauge (psig) , and add ing 14.7 , th e pressure is 42 .0 lb .

-

per sq . in. abso lute (ps ia). O n F ig. 4 at 60 deg . F . and42.0 lb . per sq . in . absol ute move parall el to th enear est dotted line to 30 deg. F. , and read 24 .5 lb .per sq. in . absolute. Moving in th e o ther directi on to110 deg . F., g ives 93 lb . per sq . in. abso lute .

T he ca lcu la t io n o f the vap or pr essu re of a mixtureat any giv en temperature is explained as follows:

Acco rd ing to Dalto n's law, th e tot al p res sure e xe r-ted by a mixture of gases o r vapors is the sum of theparti al pressures o f the con stituent ga ses o r vapors.

Accord ing to Raoult ' s law , the partial pressureexerted by each component is the product o f th evapo r pressure of each component at the existingtemper ature and th e mol fract io n o f th e co mpo ne ntpresent in th e liquid . Since liquid and va po r ab o ve itare in equilibrium, the sum of th e partial pressures inth e liquid eq ua ls the sum of th e partial pressures ofth e va po r abo ve it.

This is best illustrated by th e following examp le:F ind the vapor pressure a t 70 deg. F. of a mi xture

whose cornpo sition is:0.57 per cent eth ane, by vo lume.

30.94 per ce nt propan e, by vo lume .6 2.69 per cent isobutane, by volume.

5 .80 per cent normal butane, by volume.The calculation s sho wn in Table 1, vapor

pressures fo r pure co nst itue nts a t 70 deg . F ., aretak en from Fig. 4 .

The total o f th e partial pressures in column j is th evap or pressure o f the mixture, whi ch , in the examplegiv en , is 75.73 lb. per sq . in. absolute, o r 61 .1 lb . persq . in . gauge.

Heat of Combustion. T he heat o f combustion o f afuel may be defined as the amount o f heat that is ab-

so rbe d by coo ling th e product s o f co mbust io n ba ckto the origi na l te mpe rature of th e fuel mixture . Wh enthis defini tion is app lied to d iffe re nt cases , however ,it becomes apparent th at a fu el may have variousheat s of co mb ust io n, th e va lue d ep ending up on theco mposi t ion of th e products o f combustion , th eo rigina l temperature of the mixture , and whether theheat has been rem o ved at constant pressure o r atco nstant volume. These fa ctors will not be discussedhere , but the he ats o f co mbust io n most commonlyused will be defined .

The high o r gross he ating value (H .H .V.) of a fuelis defined as the am ount of heat ab sorbed from theproduct s o f co mp le te combustion of a unit weight ofthe fu el when they are cooled to the in itial tem -pera ture o f the fuel mixture under such conditi onsthat a ll of the water vapo r formed from the com-bust ion o f hyd rogen in the fu el is condensed . If th epressure is kept constant , the amo unt of heat ab-st rac ted is called the high heating value at con stantvolume.

The low o r net heating value (L. H. V.) of a fuel isobta ined wh en the products o f complete combustionare cooled to the init ial temperature of the fuel mix -ture without condensing any of the vapor formed bythe burning of the hydrogen in the fuel. Just as in thepreviou s ca se, the low value may be obta ined at con-stant pressure o r a t constant volume.

The difference between the heats of combusti onobta ined at constant volume and at co nstant pressureusu ally is so sm a ll as to be negligible in most pr ac-tical applications.

The units used to e xpress the heats of combusti onof fuels vary, and depend on the unit o f energy and

TABLE I. CALCULATION OF VAPOR PRESSURE OF LP-SAS MIXTURE

VaporVol. % or Pressure Partial CompositionGals. per Lb. per Lb. Mols. at 70 F. pressure. of vapor in100 gal. Lb. per 100 gal. Molec- per 100 Mol. lb. per lb. per equilibriumof mixt. gal. at of mixt, ular gal. of Frac- sq. in. sq. in. with liquid,

Component Formula at 70" F. 70 F. at 70 F. weight mixtu re tion absolute absolute % by Vol.a b c d cxd = e f e -7- f = g g -7- total i hxi = j j -;- total

g = h jx100 = kEthane C,H. 0.57 3.200 1.82 30.068 .061 .007 570 3 .99 5.27Propane C.H , 30.94 4.175 129.17 44 .094 2.929 .345 124 42.78 56.19Isobutane C.H ,o 62.69 4.646 291.26 58.120 5.011 .5!!1 46 27 .19 35.90N-Butane C.H " 5.80 4. l!17 27.94 58.120 .481 .057 31 1.77 2.34

--- ---- - - - ----

Totals 100.00 8.482 1 .000 75.73 100.00

27

-

~/.P21;250

225

W

/7;

'AIlS

~ lOt?~!it'~~9.:6tJ~!OR4()

!KJ'}(J10o

-If)-aJ-J()4()

/.0

FIG . 4.

,P~!15URE L 8 .5/SQ. IN. A8S0LV TEI~" 20 ~O 4O.so eo l!1 100

21S

11.1

/JIO

/2J

10

a

-~

-za

-30ill! I' .. ..

~ + ' ,.; .:. ' . I ;: : ':1 . I I I : ; : : . .: . :j : i , ,;::' ' I I; ': oS{)Z :f 4 5 ;; 7 6 10 14.., to JO 40 SO 60 70 1M av.w -I

-

FIG. 6. Latent heat of vapo rizat ion of propa ne. isob uta ne and normal butane.

FIG. 7. Weight pe r gallon of propane, isobutane and norma l butane.

-

dinary temperature o r pressure is eq ua l to

(x Qp + yQi + zQ n) 1r 520( x V + yV i + zV ) 14.7 3 X t + 46 0

W he re th e ex pressio ns

tr14.73

have been used to change Btu per cubic fo ot at 14 .73lb. per sq. in . absolute a nd 60 deg. F . to Btu percubi c foot at desired pressure , 1r , and desired tem-perature, t, accord ing to Boyle 's and Charles ' Laws ,respectively.

Heat of Combustion per Pound: The gross heat o fcombustion per pound of mixture may be o bta inedfrom Fig. 3. The heat o f combusti on per pound iseq ua l to

xQ p + yQ i + zQnxW p + yWi + zWn

Weight per Gallon . The wei ght pe r ga llo n o f mi x-ture a t 60 deg. F . ma y be obtai ne d from Fig. 2. Thewe igh t per gall on of mix ture at any desired tem-pera tu re is equal to

xW p + yW i + zW n

The weight per gall on of th e individual con-st itue nts o f mixtures is ob tai ne d fro m Fig. 7.

Latent Heat of Vaporization per Pound. Thelat ent heat o f va po r iza tio n of a liquid is th e a mo u ntof heat required to vap orize a unit weight o f th atsu bs ta nce a t th e temper ature a nd pressure underwh ich th e vapori za ti on is carr ied o ut.

T he lat ent heat of vaporizati on a t 60 d eg. F . per lb .of mixture may be obtained from Fig. 2. The vaporsa re ne ces sarily supe rhea ted fro m th eir respec t iveboi ling points at at mos phe ric pr essure up to 60 d eg .F . To d et ermine th e la te nt heat of va po r izat io n of amixture at any o the r o rd inary te mpe ra tu re, ta ke th elat ent heat of each co ns t itue n t at th e re q u ire d tem -perature fro m Fig. 6, ta ke the weig ht per ga llo n atthe sa me tempera ture from Fig. 7 , and subst itutethese va lues in th e eq ua tio n be lo w.

Latent hea t of va poriza tion per pound of liqu idmixt u re is eq ua l to :

xH pWp + yH iW i + zH nWnxW p + yW i + zW n

32

Cubic Feet of Gas per Gallon. The cubic fee t ofgas a t 14 .7 3 psi a and 60 d eg . F . pe r gall on of mixturea t 60 deg. F. ma y be o btained from Fig. 2. The cu b icfee t of gas at any o rdi na ry pr essure o r temperaturepe r gallon of liquid a t 60 deg . F. is eq ua l to

(x V + yV i + zV ) 14.73 X t + 460 X k.tr 520

Specific Gravity of Liquid. The spec ific gravit y o fa liquid in th e ratio o f the mass of a volume of th eliquid to the mass o f an equ al vo lume of water at 60deg. F . o r o therepec ified temperature .

The specific gravity of a mixture at 60 d eg. F .referred to water a t 60 d eg . F . may be o bta ined fromFig. 3~ The specific gravit y at a ny temperaturereferred to water a t 60 deg. F . is eq ua l to

xOp + yO i + zD,

Cubic Feet of Gas per Pound. The cubic feet ofgas at 14 .7 3 lb . per sq . in . a bso lute, and 60 d eg. F .per pound of liqu id mixture may be obta ined fromFig. 3. T he c ub ic feet o f gas at any pressure a nd tem -perature per pound is eq ua l to

(xVp + yV i + zV n) !.!11 X I + 460(x W p + yW i + zWn) 1r 520

Specific Heat of Liquid. T he spec ific he at isdefined as th e quantit y o f heat nec essar y to ra ise un itmass of a subs ta nce th rough a unit temperature in -te rva l. T he spec ific hea ts of th e sa tu ra ted hydro car-bon s usu ally found in LP-gas mixtures a re giv en inFig. 5 as Btu per pound per degree F . temperatureint erval.

Gallons of Liquid per Mcf of 550 Btu Gas. Th egall ons of an y propan e , iso butan e, normal butanemi xture required to p roduce 1000 c u. ft. o f 55 0 Btugas may be d et erm in ed fro m Fig. 8.

Vaporization of LP-Ga s. L P- gas ma y beva po rize d in th e line to th e b urner by d rawing offliqu id th rough a dip tube from the bo ttom of th eliquid sto ra ge co ntainer, o r by d ra wing off va porfrom th e space ab ove the liq u id . Th e former isso meti mes refe rr ed to as flas h va po rization and thelatt e r as ba tc h va po rization . In either case the heatreq uired for va porizati on comes from the su rr o u n-dings , su pp lemented o n o ccasio n by some typ e o fart ificial hea t exchanger.

F la sh Vapor iza t ion . When gas is drawn from an

-

P100

FIG. 8. Approximate gallons of liquid butane-propane mixtures per Mef of 550 Btu gas. Plotted-from following values:

wao~::J-.J

~ 70o::JCY 60-oJ

~.... 50z;wu

ffi40a..1

UJ~30Q.o0::a.. 20

fO

Prppane

Heat of Combustionper Gallon ofLiquid B.t.u 91.000

Isobutane

98,550

NormalButane

101,888

oI 0 to 20 30 40 50 60 70 80 90

NORMAL BUTANE - PER CENT BY LIQUID VOLUME .

LP-gas sys te m, th e tan k press u re forces liquid fro mthe co n tai ner in to a liqu id regu lato r in the lin e . A tthis po int , a pressure reduction occ urs and part ofth e liquid is va po r ize d. A ny liqu id leaving the liqu idregul ato r is va porized in th e l ine d own st ream fr omth e regul at o r. As a resu lt the te mpe rat ure of theliqu id d rops to a va lue which d ep ends on the rat e ofva por iza tio n (w hic h, in turn , de pe nds o n the load ,co mpos it io n of th e LP -gas , am b ie n t temperatu re , ef-fecti ve heat tran sfer su rface, a nd o ve r-a ll coeffi ci entof heat tr an sfer ).

33

If su bsta ntia lly adiabatic va po r izat io n ( i.e., p rac-t ically no hea t excha nge between th e liqu id and itssu rro u nd ings) o cc ur re d in the lin e , th e heat requ iredfor va po riza tio n co u ld co me o n ly from the se nsi b leheat o f th e liquid . As a result , the tempe ra tu re of theliqu id would tend to drop un til th e co rres po ndi ngva por pressure becam e subs ta nt ia lly eq ua l to thepressure d o wn stream fro m th e liqu id regulat o r. Atth is point , practi call y no further vapori zati on wouldtak e pl ace.

It is o bv io us fr om the fore goi ng th at heat tra ns fer

-

Isobutane

.....

bu,

bN

,I , - '"f

.\ .7 '

inN

..,,

" ~

,' , , ~I , , ,

1.- ' \/ ",.

N-Butane Propane

Fig. 9. Approximate dew points of mixtures of propane, isobutane and n-butane at atmospheric pressure, 14.73 lb. per sq in. (Curveby B. H. Shepley Jr.)

must take place into the line downstream from theliquid regulator. For example, if the peak load on asystem consisting of an underground tank containinga 20 % propane-80% butane mixture is equivalentto 40,000 Btu per hr. and the heat of combustion is21,000 Btu per lb. of mixture , then 1.9 lb . of theliquid must be vap orized per hour. If the latent heatof vaporization is 160 Btu per lb. , then the amount of

heat required for the vaporization of 1.9 lb. per hr.will be 304 .5 Btu per hr.

Assuming that the minimum ambient temperatureat the regulator will be 47 deg. F ., the temperaturedifference between the surroundings and the liquidin the regulator must be less than 15 deg. F. in orderto pre vent freezing. If the over-a ll coefficient of heattr ansfer between the surrounding air and the liquid is

34

-

2 Btu per hr. per sq . ft. per deg. F. , and if the ef-fecti ve he at transfer area of the regulator is 0 .5 sq.ft. , and if the delivery pressure is set for II lb. persq . in. , then 15 Btu per hr. will be absorbed by theliquid in the regulat or from the surroundings , and0.09 lb. will be vap orized in the regulator. Thisleaves 1.81 lb . o f liquid per hr. to be vaporizeddownstream from the regulator requiring 289 .6 Btuper hr.

This heat must be provided by some type ofvaporizer such as an air vaporizer using either plaino r finned tubes , a hot water vaporizer , o r a steamvapo rizer. Over-all coefficients of heat transfer , tem-perature difference, and effective heat transfer areafor each of the above types of vaporizers as appliedto thi s example are presented in Table 2.

The ab ove over-a ll coefficients are only ap-pr o ximations for the example given and sh ould notbe used in the design of an actu al system. The rec om-mendation of a competent LP-gas equipmentmanufacturer sh ould be followed in each actual case.

When liquid mixtures are drawn from the bottomof the container a nd flashed in the line to the burner,the composition of the vapor will remain the sameuntil the entire tank of liquid is used.

Balch Vaporizalion. When saturated vap or isdrawn off from the spa ce ab ove the liquid, the with-drawal disturbs the state o f equilibrium that existsbetween the liquid and vapor. As a result thepressure drops and the liquid begins to boil and con-t inues boiling so long as vapor is wi thd ra wn. Thepressure and temperature will fall and if vapor iswithdrawn at a constant rate, a state o f thermalequilibrium will be reached . At this equilibrium tem-per ature , the di fference in temperature between theliquid and the surroundings is such that heat will beabs orbed by the liquid at the same rate at which it issupplied by the liquid to fo rm the vapor. At thispoint no furthe r change in the temperature of theliquid will take place until there is a ch ange in rate ofvap or withdrawal.

For example, if the withdrawal of 40 ,000 Btu perhr. is needed fro m a I SO-lb . cylinder of LP -gas a ndif th e heat of combusti on is 21 ,000 Btu per lb. ofmixture , then 1.9 lb . of liquid must be vap orized perhour. If th e latent heat of vap orization is 155 Btu perlb. , th e amo u nt of heat required for the vaporizati onof 1.9 lb . per h r. will be 295 Btu per hr. If the over-all coefficien t of heat transfer is 2 Btu per hr. per sq .ft. of effective heat tr ansfer surface per degree F .tempe rature difference , and if the heat tr ansfer sur-

35

face of the ISO-lb. cylinder is 19 .6 sq. ft. , then a tem -perature difference of 7.5 deg. F. will supply the heatnecess ary for vap orization.

When saturated vapor is drawn off from the spaceabo ve an LP-gas mixture , distillati on takes placeand the percentage of constituents changes con-tinuously from the full to the empty tank . Thisprocess o f evaporation is als o known a s"weathering." As evaporation progresses, the com-position of the liquid continuously changes , per-centages of the most volatile constituents decreaserapidly and the per cent of the least volatile in-creases .

When a mixture of kn own composition evaporatesin the above manner, it is sometimes necessary tokn ow its composition after a certain amount o fevaporation has taken place. For example, assume amixture of 100 lb . of propane and normal butaneconsists of 75 lb. of propane and 25 lb. of normalbutane. If evaporation takes place at 80 deg. F ., whatamo unt of propane will be left when the mixture hasevap orated down until 10 lb. of normal butane isleft ?

rat io of vol atiles o f the two con st ituents ,

o r the vapor pressure of pure propane at 80 deg. F .di vided by the vapor pressure of pure normal butaneat 80 deg. F. These pressures, taken from Fig. 4, are143 lb. and 37 .5 lb . absolute, so

Pp 143--p;;- 1i3 = 3.8 1

Lei AD, Bs, A n, B, equal o riginal and final weights

TABLE 2. COEFFICIENT OF HEAT TRANSFER ANDHEAT TRANSFER AREA TO VAPORIZE 1.8 LB. OF

LP-GASOverall

CoeffiCIentof Heat Temp. of Heat

Transfer, Heating Temp. TransferType of Btu Hr. Medium, Diff.* Area.

Vaporizer sq. ft. 0 F. o f . o f . sq. ft.

Air-Plain Tubes . .. 2 65 32 4.88Air-Finned Tubes . 9 65 32 1.08Hot Water . . . . . ... 20 140 107 .15Exhaust Steam. .. . 50 212 179 .035

Ass uming t he temperature of the li qu id to be vaporizedt o be 33 ' F .

-

TABLE 1Redu crion of Volume t o 60F-Agoinst Specific Gra v it y 60/ 60 F-For lique f ied Pe tr o leum Ga ses

(Abridge ment of A.S.T.M. Tobie 24-LPG)

SPECIFIC GRAVITY 6 0j60 oF.Observed

0 .495 0 .505 0 .515 0 .525 0 .535 0 .540 0 .555 0 .565 0 .575 0 .585 0 .595 0 .605 0 .615 0 .625 0 .635 0 .1145Temper- TO TO TO TO TO TO TO TO TO TO TO TO TO TO TO TOarure, 0 .504 0.514 0 .524 0 .534 0.544 0 .554 0 .564 0 .574 0 .584 0.594 0 .604 0.614 0 .624 0 .634 0 .644 0.654of .

FACTOR FOR REDUCING VOLUM E TO 6 0 cF.

- 20 1.120 1.114 LIM 1.104 1.099 1.095 1.090 1.086 1.082 1.079 1.076 -

I-

- - -

- 19 1.118 I.IU 1.108 1.103 1.098 1.094 1.089 1.085 1.081 1.078 1.075 - - - - -- 18 1.117 1.111 J.llIfi 1.101 1.097 1.093 1.088 1.084 1.080 1.077 1.074 - - - - -- 17 1.115 1.110 I. If I;) 1.100 1.09.; 1.091 1.086 1.082 1.079 1.076 1.073 - - - - - -- 1& 1.114 1.108 1. 103 1.098 1.094 1.090 1.085 1.081 1.078 1.075 1.072 - - - - -

-15 1.112 1.107 1.102 1.097 1.093 1.089 1.084 1.080 1.077 1.074 1.071 - - - - -- 14 1.111 1.106 1.10 1 1.0!10 1.092 1.088 1.083 1.079 1.076 1.073 1.070 - - - - --13 1.109 1.104 1.0\19 1.011,1 1.091 1.087 1.082 1.078 1.075 1.072 1.069 - - - - -- 12 1.108 1.103 J.(~18 1.0113 1.089 1.085 1.081 1.077 1.074 1.071 1.068 - - - - --II 1.106 1.101 1.0!I6 1.092 1.088 1.084 1.080 1.076 1.073 1.070 1.067 - - - - -

-10 1.10;; 1.100 1.119;; LOlli 1.087 1.083 1.079 1.075 1.072 1.069 1.066 - - - - -9 1.104 1.099 1.094 1.090 1.086 1.082 1.078 1.074 1.071 1.068 1.065 - - - - -- 1.081 1.077 1.073 1.070 1.067 1.064 - - - - -

-8 1.102 1.098 1.093 1.089 1.08;;7 1.101 1.096 1.091 1.087 1.083 1.080 1.076 1.072 1.069 1.067 1.063 - - - - -

-

& 1.099 1.095 1.090 1.086 I. C82 1.079 1.075 1.071 1.068 1.066 1.062 - - - - --

5 1.098 1.094 1.089 1.685 1.081 1.078 1.074 1.070 1.067 1.065 1.061 - - - - --

4 1.097 1.093 I.IIS8 1.084 1.080 1.077 1.073 1.069 1.066 1.064 1.060 - - - - --

3 1.09G 1.092 1.087 1.083 1.079 1.076 1.072 1.068 1.065 1.063 1.059 - - - - --2 1.09 4 1.090 1.086 1.082 1.078 1.075 1.07l 1.068 1.065 1.063 1.059 - - - - -

-

I 1.093 1.089 1.085 1.081 1.077 1.074 1.070 1.067 1.064 1.062 1.058 - - - - --

0 1.092 1.088 1.084 1.080 1.076 1.073 1.069 1.066 1.063 1.061 1.057 1.055 1.053 1.05 1 1.049 1.048I 1.090 1.086 1.083 1.079 1.075 1.072 1.068 1.065 1.062 1.060 1.056 1.054 1.052 1.050 1.049 1.04 72 1.089 1.0H5 1.081 1.077 1.074 1.070 1.067 1.064 1.061 1.059 1.055 1.053 1.051 1.050 1.048 1.0463 1.088 1.084 1.080 1.076 1.073 1.009 1.000 1.063 1.060 1.058 1.054 1.052 1.050 1.049 1.047 1.04 54 1.086 1.082 1.079 1.075 1.07l 1.068 1.065 1.062 1..Q59 1.057 1.054 1.052 1.050 1.048 1.046 1.0455 1.085 1.081 1.077 1.074 1.070 1.067 1.063 1.061 1.058 1.055 1.053 1.051 1.049 1.047 1.045 1.04 4& 1.084 1.080 1.076 1.072 1.069 1.065 1.062 1.059 1.057 1.054 1.052 1.050 1.048 1.0 46 1.045 1.04 37 1.082 1.078 1.075 1.07 1 1.068 1.064 1.061 1.058 1.056 1.053 1.051 1.049 1.047 1.045 1.044 1.0428 1.08 1 1.077 1.074 1.070 1.066 1.063 1.060 1.0i,7 1.055 1.052 1.050 1.048 1.046 1.044 1.043 1.04 29 1.079 1.076 1.072 1.069 1.065 1.062 1.059 1.056 1.054 1.051 1.049 1.047 1.045 1.044 1.042 1.04 1

10 1.078 1.074 1.071 1.067 1.064 1.061 1.058 1.055 1.053 1.050 1.048 1.046 1.044 1.043 1.041 1.040II 1.077 1.073 1.0 70 1.066 1.063 1.060 ] .057 1.0i>4 1.052 1.049 1.047 1.04.; 1.043 1.042 1.040 1.03912 1.075 1.071 1.06 8 1.064 1.06 1 1.059 1.056 1.053 1.051 1.048 1.046 1.044 1.043 1.04 1 1.040 1.03813 1.074 1.070 1.067 1.063 1.060 1.057 1.054 1.052 1.050 1.047 1.045 1.043 1.042 1.040 1.039 1.03814 1.072 1.069 1.066 1.062 1.059 1.056 1.053 1.051 1.049 1.046 1.044 1.042 1.04 1 1.039 1.038 1.037

15 1.071 1.068 1.064 1.06 1 1.058 1.055 1.052 1.050 1.047 ) .045 1.043 1.042 1.040 1.039 1.037 1.0361& 1.070 1.066 1.063 1.060 1.056 1.054 1.051 1.048 1.046 1.044 1.042 1.041 1.039 1.038 1.036 1.03517 1.0H9 1.065 1.06 2 1.058 1.055 1.052 1.050 1.047 1.045 1.043 1.041 1.040 1.038 1.037 1.036 1.03418 1.067 1.064 1.061 1.057 1.054 1.051 1.049 1.046 1.044 1.042 1.040 1.039 1.0:17 1.036 1.035 1.03419 1.006 1.062 1.059 1.056 1M3 1.050 1.047 1.045 1.043 1.041 1.039 1.038 1.036 1.035 1.034 1.033

20 1.064 1.001 1.058 1.054 1.051 1.049 1.046 1.044 1.042 1.040 1.038 1.037 1.036 1.034 1.033 1.03221 1.063 LOGO 1.056 1.053 1.050 1.048 1.045 1.043 1.041 1.039 1.037 1.0:16 1.03.5 1.033 1.032 1.03122 1.061 I.U58 1.055 1.052 1.049 1.046 1.044 1.042 1.040 1.038 1.037 1.035 1.034 1.03:1 1.031 1.03023 1.060 I.U57 1.053 1.051 1.048 1.045 1.043 1.041 1.039 1.037 1.036 1.034 1.03:1 1.0:12 1.031 1.03024 1.058 1.055 1.052 1.()49 1.046 1.044 1.042 1.040 1.038 1.036 1.035 I.U33 1.032 1.031 I.U30 1.02925 1.057 1.054 1.050 1.048 1.045 1.043 1.04 1 1.039 1.037 1.035 1.034 1.032 1.031 1.030 1.029 1.0282& J.055 1.052 1.04 9 1.047 1.044 1.042 1.039 1.037 1.036 1.034 1.033 1.031 1.030 1.029 1.028 1.02727 1.054 r.os. 1.048 1.045 1.043 1.041 1.038 1.036 1.035 1.033 1.0 32 1.031 1.029 1.028 1.027 1.0272 8 1.0:.2 1.049 1.047 1.044 1.041 1.039 1.037 1.035 1.034 1.032 1.031 1.030 1.029 1.027 1.027 1.02629 1.05 1 1.048 1.045 1.043 1.040 1.038 1.036 1.034 1.033 1.031 1.030 1.029 1.028 1.027 1.026 1.02530 1.049 1.046 1.044 1.041 1.039 1.037 1.03" 1.033 1.03 2 1.030 1.029 1.028 1.027 1.026 1.025 1.02431 1.tl47 1.04;; 1.04 2 1.040 1.038 1.036 1.034 1.032 1.031 1.029 1.028 1.027 1.026 1.025 1.024 1.02332 1.046 1.043 1.041 1.038 1.036 1.035 1.033 1.031 1.030 1.028 1.02 7 1.020 1.025 1.02~ 1.023 1.0233 3 1.044 1.042 1.040 1.037 1.035 1.034 1.032 1.030 1.029 1.027 1.026 1.025 1.0l4 1.023 1.022 1.0223 4 1.043 1.040 1.038 1.036 1.034 1.032 1.031 1.029 1.028 1.026 1.025 1.024 1.0l3 1.0l2 1.022 1.021

3 5 1.04 1 1.039 1.037 1.035 1.033 1.031 1.029 1.028 1.027 1.025 1.024 1.023 1.022 1.022 1.021 1.0203 & 1.0:19 1.037 1.035 1.033 1.031 1.0:!0 1.028 1.027 1.025 1.02 4 1.023 1.022 1.02 1 LOll 1.020 1.0 1937 1.038 1.036 1.033 1.032 1.030 1.029 1.027 1.026 1.024 1.023 1.022 1.021 1.021 1.020 1.019 1.01938 1.0:16 1.034 1.03 2 1.031 1.029 1.027 1.026 1.02!i 1.023 1.022 1.021 1.020 1.020 1.019 1.018 1.01839 1.035 1.033 1.031 1.029 1.028 1.026 1.025 1.024 1.022 1.02 1 1.020 1.020 1.019 1.018 1.017 r.oiz40 1.033 1.031 1.0 29 1.028 1.026 1.025 1.024 1.023 1.021 1.020 1.019 1.019 1.018 1.017 1.017 1.0164 1 1.03 1 1.030 1.028 1.027 1.025 1.024 1.023 1.022 1.020 1.019 1.018 1.018 1.017 1.016 1.016 LOI S42 1.030 1.028 1.027 1.025 1.024 1.023 1.022 1.021 1.0 19 1.018 I.on I.on 1.016 1.016 1.015 1.0 154 3 1.028 1.027 1.025 1.024 1.022 1.021 1.020 1.019 1.018 1.017 1.016 LOW 1.015 LOIS 1.014 1.01444 1.027 1.025 1.023 1.022 1.021 1.020 1.019 1.018 1.017 1.016 1.015 1.015 1.014 1.011 1.0 13 1.01 3

45 1.025 1.024 1.022 1.021 . 1.020 1.019 1.018 1.0 17 1.016 1.01S 1.0 15 1.014 1.013 1.0 13 1.013 1.01 24& 1.02:1 1.022 1.021 1.020 1.0 18 1.0 18 1.017 1.016 1.0 15 1.014 1.014 1.0 13 1.013 1.012 1.0 12 1.01147 1.022 1.021 1.019 1.018 1.017 1.016 1.015 1.0 15 1.014 1.01:1 1.013 1.012

I1.0 12 i.ou LOl l 1.0 11

48 1.020 1.019 1.018 1.0 17 1.016 1.015 1.014 1.013 1.01:1 1.012 1.0 12 1.011 1.011 1.010 1.010 1.01049 1.0 19 1.0 18 1.017 1.015 1.015 1.014 1.013 1.012 1.0 12

I1.011 LOll 1.010 1.010 1.0 10 1.009

I1.00 9

50 1.017 1.016 1.0 15 1.014 1.0 13 1.0 13 1.012 1.01 1 LOll 1.0 10 LOW 1.009 1.909 1.009 1.008 1.008

38

-,

-

TABLE 1 (CONTINUED)SPECIFIC GRAVITY 60 /60F.

ObservedTem per 0. 4 9 5 10 .505T0 .5 15 0 .525 0 .5 3 5 1 0 .545 1 0 .555 1 0 .565 1 0 .575 0 .585 0 .595 0 .60!! 0 .61!! 0 .62!! I0 .63!! I0 .64!!TO TO TO TO TO TO TO TO TO TO TO TO TO TO TO TOa ture , 0 .504 0 .514 0.5 2 4 0 .534 0 .544 0 .554 0 .564 0 .574 0 .584 0 .594 0 .604 0 .614 0 .624 0 .634 0 .644 0 .6!!4

of .FACTOR FOR REDUCING VOLUM E TO 60 F.

50 1.017 1.016 1.015 1.014 i1.013 1.0 13 I 1.012 1.011 1.011 1.0 10 1.0 10 1.009 1.009 1.009 1.008 1.0085 1 1.0 15 1.0 14 1.013 1.0 13 1.012 1.011 1.011 1.010 1.0 10 1.00!l 1.009 1.008 1.00S 1.008 1.007 1.008

52 1.1l14 1.()12 1.0 12 1.01 1 1.010 1.0 10 i.oos 1.009 1.009 I.00S 1.00S 1.007 1.0117 1.00 7 1.006 1.00753 1.012 1.0 11 1.011 1.010

IU)oJ'J 1.')019 1.008 1.008 1.008 1.007 1.!107 1.007 1.006 1.006 1.006 1.006

54 1.010 1.009 1.009 1.008 I.Ull8 1.007 1.007 1.007 1.007 1.006 1.006 1.006 1.005 1.005 1.005 1.005

55 1.009 1.008 1.008 1.007 1.00~ 1.006 1.006 1.006 1.006 1.00:; 1.005 1.005 1.005 1.004 1.004 1.00456 1.007 1.006 1.006 1.005

I1.0m 1.005 1.005 1.005 1.004 1.004 1.1>04 1.004 1.004 1.004 1.003 1.003

57 1.005 1.005 1.005 1.004 1.004 1.004 1.004 1.003 1.00:1 1.00:1 UK):I 1.003 1.003 1.003 1.002 1.00358 1.003 J .003 1.003 I.(JO:l I. IM ):1 1.002 1.002 1.002 1.002 1.002 1.002 1.002 1.002 1.002 1.002 1.00259 1.002 1.002 1.002 l.ooJ 1.l.HJI 1.001 1.001 1.001 1.001 1.001 LOlli 1.001 1.001 1.00 1 1.00 1 1.001

I 1.000 1.000 1.00060 1.000 1.000 1.000 1.000 1.01H) 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.00061 0.998 0 .998 0.999 0.999 O.!lHH 0 .999 0.999 0 .999 0 .Hn9 O.H!)!") 0.n1l9 0.999 0.9 99 0.999 0.999 0.99962 o.nn 0.99 7 0.9n 0.n97 o.!l~n 0.99~ 0.998 0.998 O.!J!J~ O.H!IS 0.9!18 0.998 0.998 0.998 0.998 0.99863 o.ml!> 0 .995 0.995 O.!I!I6 0.\'96 0.996 0.990 0.997 O.H~n O.mli 0 .Hn7 0.997 0.997 0.997 0.998 0 .99864 0.993 0 .994 0.994 0.994 0.994 0.995 0.995 0.995 O.UUt.i O.!l!JU 0 .996 0.996 0.996 0.99 7 0.997 0.997