Hammer & Dolly August 2014

-

Upload

thomas-greco-publishing-inc -

Category

Documents

-

view

229 -

download

0

description

Transcript of Hammer & Dolly August 2014

-

www.grecopublishing.com

Youre Invited! Revamped WMABA Labor Rate Survey to Provide Broadened Industry Insight - page 34

www.wmaba.com

August 2014Volume 8, No. 8$5.95

Inside this Issue:EMBRACING ALUMINUM DIVERSIFYING IN TOUGH TIMES THE DANGERS OF DIGITAL ESTIMATING

-

3August 2014

-

Cover Photo by Norman Morano

THIS PAGE, CLOCKWISE FROM TOP:

Photo by Norman Morano

thinkstockphoto.com/monkeybusinessimages

thinkstockphoto.com/Iaroslav Neliubov

thinkstockphoto.com/Devonyu

Photo courtesy of Spring Mall Auto Body

thinkstockphoto.com/Darko Novakovic

DEPARTMENTS6 Calendar of Events

10 Editors MessageJOEL GAUSTEN

12 Presidents MessageDON BEAVER

20 Technician of the MonthTony Escobar

22 Legal Perspective

47 WMABA Board ofDirectors

48 Executive DirectorsMessage JORDAN HENDLER

50 Advertisers Index

28

PHOTOS BY NORMAN MORANO

CONTENTS August 2014

44Our tech writers warn against a new industry trend. BY LARRY MONTANEZ III, CDA & JEFF LANGE, PE

TECHNICAL FEATUREDIGITAL ESTIMATES?

5August 2014

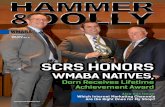

COVER STORY

2014 WMABAGOLF OUTINGHIGHLIGHTS

12NEWS

PARTSTRADER HITS A BUMPY ROAD The procurement program's rollout faces unexpected issues.

Hammer & Dolly Tech Writer Testifies in RILarry Montanez takes on recycled airbags at a controversialSenate hearing.

SEMA 2014: MORE DETAILS REVEALED SCRS' Repairer Driven Education schedule continues to take shape.

14

34

WMABA is revolutionizing the way the industry gathersinformation on shop rates and procedures.

YOU'RE INVITED!REVAMPED WMABA LABOR RATE SURVEY TO PROVIDE BROADENED INDUSTRY INSIGHT

CONTENTS August 2014

Members, vendors and industry supporters gather for the biggest associationevent of the year.

14

16One member's ingenuity leads to a dramatic increasein business.

FEATURESWMABA SHOP DIVERSIFIES TOGREAT SUCCESS

38WMABA members weigh in on the costs andbenefits of high-end work.

DOES ALUMINUM REPAIR MAKE SENSEFOR YOUR SHOP?

-

August 13, 20142015 Ford F-150 Structural repair training courSe Sharrett Collision Center, Hagerstown, MD

August 14, 2014HazardouS materialS, perSonal SaFety & reFiniSHSaFetyCoxtons Gold Team Collision Center, Yorktown, VA Steel unitized StructureS, tecHnologieS & repairKunkels, Baltimore, MD

August 19, 2014meaSuringCoxtons Gold Team Collision Center, Yorktown, VA rack & pinion & parallelogram Steering SyStemSKeystone Linthicum, Linthicum, MD 2015 Ford F-150 Structural repair training courSe Courtyard Marriott-Silver Spring, Silver Spring, MD

August 20, 20142015 Ford F-150 Structural repair training courSe Courtyard Marriott-Silver Spring, Silver Spring, MD

August 21, 2014 overview oF cycle time improvementS For tHecolliSion repair proceSSCoxtons Gold Team Collision Center, Yorktown, VA 2015 Ford F-150 Structural repair training courSe Courtyard Marriott-Silver Spring, Silver Spring, MD

August 26, 2014Steering & SuSpenSion damage analySiSCoxtons Gold Team Collision Center, Yorktown, VA www.i-car.com or

(800) 422-7872 for info

September 2, 20142015 Ford F-150 Structural training courSe Coxtons Gold Team, Yorktown, VA

September 4, 20142015 Ford F-150 Structural training courSeTimbrook Kia, Cumberland, MD

September 11, 2014SuSpenSion SyStemSFrederick Co. Career Tech, Frederick, MD

September 18, 2014documentation & digital pHotograpHyFrederick Co. Career & Tech, Frederick, MD

September 23, 2014wHeel alignment & diagnoStic angleSKeystone Linthicum, Linthicum, MD

September 24, 2014color tHeory, mixing tonerS & tintingRefinish Solutions, Springfield, VA

September 25, 2014Blueprinting proceSS & damage diScoveryFrederick Co. Career & Tech, Frederick, MD

CALENDAR OFEVENTS

August 2, 20142015 Ford F-150 Structural repair training courSe State Farm Insurance-Midlothian, Midlothian, VA

August 4, 2014 BeSt practiceS For HigH-StrengtH Steel repairS First Team Toyota, Chesapeake, VA

August 5, 2014Blueprinting proceSS & damage diScoveryCriswell Collision Center, Annapolis, MD color tHeory, application, tinting & BlendingCoxtons Gold Team Collision Center, Yorktown, VA

August 6, 20142015 Ford F-150 Structural repair training courSe Hampton Inn, Glen Burnie, MD

August 7, 2014 overview oF cycle time improvementS For tHe colliSion repair proceSSAutomotive Collision Technologies, Randallstown, MD plaStic & compoSite repairCriswell Collision Center, Annapolis, MD Structural StraigHtening SteelCoxtons Gold Team Collision Center, Yorktown, VA

August 12, 2014Squeeze-type reSiStance Spot weldingCriswell Collision Center, Annapolis, MD 2015 Ford F-150 Structural repair training courSe Hilton Wilmington/Christiana, Newark, DE wHeel alignment & diagnoStic angleSCoxtons Gold Team Collision Center, Yorktown, VA

6 August 2014

Industry training opportunitiesand don't-miss events.

Top-Notch Educational Opportunities

Over 150 industry-leading exhibitors

Fun for the Whole Family, And More!

Save the Dates forNORTHEAST 2015!

March 20, 21, 22

www.aaspnjnortheast.com

-

7August 2014

-

8 August 2014

-

9August 2014

-

Rodney Bolton ([email protected]) 410-969-3100 ext. 250Mark Boudreau ([email protected]) 703-671-2402

Kevin Burt ([email protected]) 301-336-1140Bobby Wright ([email protected]) 434-767-4128

adminiStrationexecutive directorJordan Hendler ([email protected]) 804-789-9649wmaBa corporate oFFiceP.O. Box 3157 Mechanicsville, VA 23116

StaFFpuBliSHer thomas greco

managing editor alicia [email protected]

editor Joel [email protected]

art director lea [email protected]

oFFice manager Sofia [email protected]

advertiSing director norman [email protected] 800-991-1995 Fax 732-280-6601

PUBLISHED BY TGP, Inc.244 Chestnut St., Suite 202Nutley, NJ 07110973-667-6922 FAX 973-235-1963

Reproduction of any portions of this publication is specifically prohibited without written permission from the publisher. The opinions and ideas appearing in this magazine are not necessarily rep re sen ta tions of TGP Inc. orof the Washington Metropolitan Auto BodyAssociation (WMABA). Copyright 2014Thomas Greco Publishing, Inc.

repair program and offer your time, insights and expertise, add it to your to-do list this fall.A few weeks ago, I was among a small group of journalists credentialed by the White

House to attend a special commencement speech given by President Barack Obama forthe graduating class at the Worcester Technical High School in Worcester, MA. In 2006,Worcester Tech was one of the lowest-performing institutions in Massachusetts. Thanks toa strong commitment by faculty, students and the community, the school stands today asone of the most successful educational facilities in the state. As President Obama told theaudience at the graduation ceremony, Together, youre an example of whats possiblewhen we stop just talking about giving young people opportunity, when we dont just give lipservice to helping you compete in the global economy and we actually start doing it.

As the summer comes to a close, I urge you to consider ways that you can personallyassist your area vocational school auto body department in building a better future fortomorrows repair technicians. Offer to do tours of your facility, stop by the school to tellstudents what to expect in the real world and build relationships with the future industrynow. You will not regret the experience. H&D

HEAD OFTHE CLASS

I think its about time many of you stepaway from your businesses and go back tohigh school.

Now, before I get a bunch of angry letters,let me explain. In my work at Greco Publishing,I have the pleasure of covering a variety ofautomotive education-focused events on theeast coast. These special gatherings includeeverything from SkillsUSA competitions tostudent-industry networking events hosted byarea vocational schools. In every setting, twothings are instantly obvious: 1. These eventsare extremely positive for the students involved,and 2. The members of the auto body fieldteaching these programs can sure use yourhelp.

As we all know, this industry suffers from aserious lack of new blood. In many vocationalschools Ive encountered, the instructors battleagainst budgetary constraints, equipment woesand a lack of support for their communities. It isnot uncommon to see a program survive basedalmost entirely on the time, commitment anddonations of area industry members. Yourfuture employees (and perhaps even the techswho will one day take over your shops) aredeveloped in vocational schools. If youve nevertaken the time to visit with your area collision

Joel gausten(973) 600-9288

MESSAGEEDITORS

10 August 2014

2014 wmaBa oFFicerSpreSident don Beaver

[email protected] 443-539-4200 ext. 17061vice preSident torchy chandler

[email protected] 410-309-2242treaSurer mark Schaech Jr.

[email protected] 410-358-5155Secretary John krauss

[email protected] 703-534-1818immediate paSt preSident Barry dorn

[email protected] 804-746-3928

Board oF directorS

president obama delivers the commencement speech for the worcester technicalHigh School class of 2014 in worcester, ma on June 11. (Photo by Joel Gausten)

-

11August 2014

-

Information and updatesfrom WMABA and beyond.

For most of the day, I rode around in a cart with my wife, talking with people and watching thegame. In doing so, I realized we had golfers from every facet of the auto repair game. We certainlyhad players who hit the ball a few more times than others, but I know everyone had fun. By nostretch of the imagination would I ever consider myself to be a golfer; I would even go as far as tosay I am a terrible golfer. All I heard all day is, Just pick up the ball, Beaver, but I wouldnt missthis event for the world. The food was great, we gave away a lot of nice door prizes and the bever-ages were cold. Thats a good day in my book, and all for a great cause. Again, a big thank you toeveryone who sponsored, helped, played or volunteered. We hope to see everyone again nextyear and then some. H&D

A GOOD DAYFOR A GREATCAUSE

On June 26, WMABA held its an-nual Golf Outing at Virginia Oaks inGainesville, VA. We could not haveasked for better weather or playing con-ditions. Once again, this fundraiser wasa huge success. Events like these helpthe WMABA membership fund efforts toaddress the daily woes our industryfaces. We owe so many thanks to oursponsors, members, players and volun-teers. Everyone had a great time!

Sometimes, it helps to recharge ourinternal batteries just to get out of theshop, enjoy the weather and have a littlefun with our colleagues, friends and fam-ilies. I saw many familiar faces as wellas some new ones. It was refreshing toknow that more and more people arejoining our ranks.

MESSAGEPRESIDENTS don Beaver(443) 539-4200 ext. [email protected]

12 August 2014

With State Farms parts procurementprogram with PartsTrader now operatingacross the country, Hammer & Dolly contin-ues to receive feedback from Select Serviceshops on their direct experiences with thesystem. According to reports from readersin the southwestern part of the country,

PartsTraders presence has led to overbur-dened LKQ providers and an upswing inOEM parts usage.

I use more OEM parts with State Farmthan Ive ever used; 95 percent of every partI use now with them is OEM, offers onelarge Select Service shop owner. The LKQvendors dont have time to respond becausetheyre too busy. I dont get responses backfrom them. Some vendors have had to hiresomeone to do nothing but monitor all the re-quests that are coming in because they cantget to them fast enough. State Farm nowsays, Were going to give you an hour. If no-body responds in an hour, you can just optOEM. And thats what we do.

Despite this apparent increase in OEM

parts in his market, one industry membercautions readers not to get too excited.

In a twisted way, its turned out good,he says. But I promise you thats not goingto last. State Farm is getting and calculatingnumbers, putting two and two together anddoing a lot of research behind the scenes...Ican assure you that their goal when they putout PartsTrader wasnt to purchase all OEMparts.

In related news, PartsTrader is sched-uled to begin charging participating dealersin Maryland and Virginia this month in orderto use the program. Suppliers participating ineach market had an opportunity to use thesystem at no cost for six months before a feewas charged. H&D

PARTSTRADERHITS A BUMPYROAD

NEWS

Photo by Norman Morano

-

13August 2014

-

Information and updatesfrom WMABA and beyond.NEWS

14 August 2014

On June 5, Hammer & Dolly technicalwriter Larry Montanez (P&L Consultants,pictured far right above) appeared before theRhode Island Senate Committee on theJudiciary as an expert witness on behalf ofthe Auto Body Association of Rhode Island(ABARI) to offer professional comments andopinions on a variety of industry-specific bills.One piece of legislation in particular, SenateBill 2833, aims to prohibit insurance compa-nies from requiring the use of used or reman-ufactured airbags and/or suspension parts inthe repair of a vehicle.

Opposing the bill, LKQ Government Af-fairs Manager Andreas Heiss stated thatshops that perform airbag removal are sub-ject to very strict federal safety standards,adding that technicians who perform this pro-cedure are trained to remove these airbagsin a certain way to ensure consumer safety.

Theres no rational basis for the restric-tion of a non-deployed airbag; its a safe, ef-fective alternative, he argued. Anyrestriction on their use would just further ex-tend the monopoly for car companies andharm the Rhode Island consumers by givingthem [only one] option - to put in a brand-newairbag.

Unconvinced by this testimony, Senator

Stephen R. Archambault (D- District 22) laterasked Montanez (who he called the only ex-pert Ive heard tonight come before us) ifsuch standards actually existed.

Theres no federal standard on remov-ing an airbag out of a vehicle; Id like to seeone if one exists, replied Montanez, whoadded that although there is a federal stan-dard on what EDRs [event data recorders]have to record, there is no existing standardon taking an airbag in or out.

The only standard on taking it in or outis what the manufacturer says is the torquerating on the bolts, and if you can re-use thebolts or not, he reiterated.

Senate Deputy Minority Leader DawsonHodgson (R-District 35) praised Montanezstechnical knowledge and insight into the is-sues addressed at the hearing.

The technical expertise that ABARIbrings to the table every year at these hear-ings, and the professionalism that you arerepresenting your industry with, is impres-sive, he said.

Complete video of the hearing (includingMontanezs extensive testimony) is availablefor free streaming at http://ricaptv.discovervideo.com/embedviews/vod?c=all&w=640&h=480&s=1#.H&D

HAMMER & DOLLY TECH WRITER TESTIFIES IN RI

MORE DETAILSREVEALEDThe Society of Collision Repair

Specialists (SCRS) is working hard todeliver a stellar slate of Repairer DrivenEducation (RDE) courses at this yearsSEMA Show (November 4-7 at the LasVegas Convention Center in Las Vegas,NV). A closer look at this years extensiveRDE schedule (available at www.semashow.com/scrs) reveals participation fromtwo of WMABAs most popular guest speak-ers: Mike Anderson (www.CollisionAdvice.com) and Tim Ronak (AkzoNobelAutomotive and Aerospace Coatings).

On November 4, Anderson will presentUsing Industry Statistics to Your Advan-tage, a two-hour course that will look atindustry trends, OEM trends and statisticsfrom the latest sources from across thecountry. The seminar will also explorelegislation, laws and pending courtcases that could impact collision repairbusinesses. On November 6, Ronak willpreside over Surviving the Push forRefinish Reductions - Spot within PanelSurvival Kit, a 120-minute presentation thatwill offer a 2014 update on the industry-acclaimed Spot within Panel Survival Kitdesigned to utilize the databases to deflectrequests to alter or reduce refinish times.The session is slated to explore the historyof the labor operation (and where it camefrom), the differences between a BlendPanel, Spot within Panel or Refinishwithin Panel Boundaries, the specificcriteria that qualifies a repair as a Spotwithin Panel and more. Ronak will alsopresent a second November 6 seminar,Getting Paid for Investing in Facility,Equipment and Training, which will explorethe mechanisms at a shops disposal tooffset rising business costs in equipment,facility and training.

Registration information and a com-plete listing of RDE events is available atwww.semashow.com/scrs. More SEMAnews will be featured in next monthsHammer & Dolly. H&D

-

15August 2014Clockwise from top: thinkstockphoto.com/zimmytws/PaulPaladin/eccolo74

-

FEATURE

If we can paint it, we can dip it.For thrilled customers throughout the WMABA region, the above words have

come to symbolize an unforgettable visual experience. Whether its a gun, a motorcy-cle, a switch plate, a skateboard or a even a mason jar, the team of industry profes-sionals that comprise Hydrodipper can turn just about anything into an amazing workof art. Boasting hundreds of unique designs and an environmentally sound process,Hydrodipper has revolutionized the custom graphics industry and provided a uniquenew revenue source for WMABA member shop Spring Mall Auto Body (Springfield,VA).

The Hydrodipper story began in July 2013, when Spring Mall Auto Body GeneralManager John Procacina first incorporated the process into the business as a way toupsell and perform non-insurance work.

It was a way for us to try to increase revenue without getting the insurancecompanies involved, and try to reach out to our customers and say, You can person-alize anything, he says.

Hydrodippers OSHA-compliant process is based on ink designs on film. Thefilm is placed in water, then an activator is sprayed to melt it away. The ink designstays on top of the water, allowing a technician to dip a variety of products to stun-ning effect. Best of all, the end result is as durable as a car finish. According to theHydrodipper website (www.hydrodipper.com), the process goes like this:

an item that is paintable is prepared with a basecoat.

a tank of water is used and a film design is laid on top of the water.

a chemical is sprayed over the film design, which will dissolve the film but leaves the ink design floating on top of the water.

the item then enters the water at an angle to allow the filmdesign to cover the item with as little distortion as possible. (How-ever, a little distortion or stretching of the design is what makesthis process unique and very cool-looking.)

once the item is fully dipped, it is then rinsed off and allowedto dry.

an automotive clearcoat (either a matte or gloss finish) isthen applied several times to protect it from peeling or fading.(this is the same step that body shops use to repair vehicles.)

Environmentally, its super safe, offers Procacina. Basically, everything you dois paintwork. You prep it, prime it and base it, and then the dipping is probably the

16 August 2014

WMABA SHOP DIVERSIFIESTO GREAT SUCCESS

fastest part of it. You lay your film in the water, and thefilm is biodegradable.

Hydrodipper has been so successful for SpringMall Auto Body that the shop moved the operation intoits own building and showroom last April. In fact, thecurrent demand is so strong that Hydrodippers four-person crew is putting in 12 hours a day, seven days aweek to keep up with orders. Not surprisingly, the serv-ice has received an incredibly strong response fromthe biker communities in DC, Maryland and Virginia. Allwork performed by Hydrodipper comes with a lifetimeguarantee.

While every design created by Hydrodipper issure to amaze, items that receive the companys dou-ble dipping process are particularly impressive. One ofthe best examples of this procedure is Money toBurn (pictured above), which brilliantly combines dol-lar bill and fire designs into one piece.

One of seven body shops that comprise theCherner family of repair facilities, Spring Mall AutoBody has been in business since 1978. Currently, theroughly 28,000-square-foot facility boasts 15 bays(each with the ability to accommodate four cars) andfour downdraft booths.

For more information on Hydrodipper, pleasevisit www.facebook.com/dipperhydro or www.hydrodipper.com. H&D

The capacity to diversify is something this industryshould be taking hold of. No different than marketingyourself to your customer, or differentiating your busi-ness in a way that captures more of the market, this is away one shop has stepped outside of the box to securetheir future. - Jordan Hendler

Executive Directors Thoughts

-

17August 2014

Shops think of new waysto thrive and survive.

Hydrodipper offers amazing art for customers and a new way togenerate non-insurance work for a longtime wmaBa shop.

-

Conquest your Mitsubishi parts needs!

Mitsubishi now offers Genuine OEM parts through our new Opt-OE parts program at discounted prices. See Mitsubishis Ultra-Conquest parts and prices in the Optional OEM Suppliers category of popular collision estimating systems.

Ultra-Conquest Collision Parts Program Highlights:

Discounted prices on quality new and unblemished OEM parts Automated price and part selection in collision estimating systems High parts availability Delivery to most major U.S. cities within 24 hours Available through all participating Northeastern area Mitsubishi dealers Includes the majority of key collision components for select popular models We can meet or beat aftermarket prices!

To find out more about Ultra-Conquest pricing contact your local Mitsubishi dealer.

For Genuine Mitsubishi parts, contact these authorized Mitsubishi Dealers.

Buy Genuine Mitsubishi Parts and get the perfect fit at the perfect price. 10% off on all parts orders when you mention this ad.

Jerrys Mitsubishi1906 East Joppa Road

Baltimore, MD 21234

Toll Free: 800-255-0691

Direct: 410-668-2119

Fax: 410-513-0236

www.jerrysmitsubishi.com

Fitzgerald Mitsubishi1930 West Street

Annapolis, MD 21401

Direct: 410-224-4636

Fax: 410-224-4264

E-mail: [email protected]

Younger Mitsubishi1945 Dual Highway

Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465

www.youngermitsubishi.com

Malloy Mitsubishi14655 Jefferson Davis Hwy

Woodbridge, VA 22191

Direct: 703-490-8263

Toll Free: 888-533-3400

Fax: 703-490-3864

18 August 2014

-

19August 2014

-

As anyone who oversees a high-end collision facility will tellyou, it takes a rare breed of technician to successfully repair todaysever-complex vehicles. In the last handful of years, Mercedes-Benzhas begun introducing new models that require exceptional repairskills far exceeding the technical demands of yesteryear. Thesedays, something as simple as replacing a windshield is not what itused to be. Thankfully, Mercedes-Benz of Arlington has a fantasticasset in longtime technician Tony Escobar.

A graduate of Yorktown High School, Escobar has been a partof the Mercedes-Benz of Arlington team since 1998. Throughout histime with the operation, he has displayed an eagerness to learnabout the latest innovations in the industry, specifically with the Mer-cedes-Benz line. As Mercedes-Benz of Arlington Collision CenterManager John Alcorta sees it, Escobar is a shop leader among hisfellow technicians.

He has been trained and passed every course on every modelline that Mercedes offers, which is pretty amazing, Alcorta says.Because of his training, he is approached by the rest of the shopwhen it comes to some of the repair methods, and sometimes justfor advice. He has very quietly earned the respect of everyone. Theysay timing is everything; he knows when to offer help and when to sitback and wait to be asked.

Additionally, Escobar is a firm believer in repairing a vehicle theway the manufacturer says it should be done.

We all know that there are things that are not recognized [byinsurers] as necessary procedures, offers Alcorta. Even though wedont get compensated, he will still do the job the right way.

For Escobar, being an integral part of Mercedes-Benz of Arling-tons success is the fulfillment of a childhood love for automobiles.

Its something that Ive had a passion for since I was a littlekid, he says. I like to challenge myself on every car I work on.

With the latest crop of vocational school graduates now hittingthe industry, Escobar encourages anyone new to working on vehi-cles in the real world to understand and appreciate the importance ofwhat they do on the shop floor especially if they are expected tokeep high-end customers happy.

Were not back in the 80s and 90s, he says. With some ofthese cars now, the technology is amazing. You have to take this jobseriously. Ill tell any kid who goes through high school that if youwant to get into it, its not something you can play around with.

When not showcasing his advanced talents at Mercedes-Benzof Arlington, Escobar enjoys spending time with his wife (and highschool sweetheart) Amanda and children Nathan (13) and Khloe (5).As far as his future in the industry is concerned, Escobar is excitedby the opportunity to receive more training and continually sharpenhis craft.

It gets me pumped up because I learn more and more everyday, he says. Its good that the company has provided me with a lotof training. It makes things a lot easier for me to work on the carswhen I come back to the shop. H&D

If you would like to nominate someone as Technician of the Month, please contact Hammer & Dolly Editor Joel Gausten at [email protected].

Hammer & Dolly chats with the WMABAcommunitys best and brightest.TECHNICIAN OF

TONY ESCOBARTHE MONTH

ongoing training and a commitment to professional repairs have made tony escobar an invaluable part

of mercedes-Benz of arlington.

20 August 2014

-

21August 2014

-

Whats happening at the State House, inyour industry and everywhere in between.

PERSPECTIVELEGAL

is your workplace in compliance with allemployment posting regulations? they differ to somedegree depending on if you are in maryland, dc orvirginia, so make sure that you are complying withall applicable State laws.

MarylandIn Maryland, the Department of Labor, Licensing and Regulations

governs employment posting regulations. Employers are required toput up posters that advise their employees about certain federal regu-lations including job safety, governed by the Occupational Safety andHealth Administration (OSHA); their rights with respect to the Ameri-cans with Disabilities Act; minimum wage requires; equal employmentopportunity requires, governed by the Equal Employment OpportunityCommission (EEOC); Family and Medical Leave Act rights; and addi-tional federal regulations that govern individual types of employment.

In addition, there are State-level regulations that must be refer-enced. These include unlawfulness of employment discrimination,which, depending on the jurisdiction, could be covered by both Mary-land law and local County or City law; workers compensation laws;minimum wage laws; regulations affecting minors who may be work-ing for you; equal pay for equal work laws; unemployment insurancerights; and health insurance rights. If you are not posting all necessaryposters for your employees review, you could be in violation of fed-eral, State or local laws.

District of ColumbiaAlthough not a state, DC has its own local regulations that must

be met and communicated to employees. This includes all federal

employment requirements, plus a summary of minimum wage law inDC; unemployment compensation rights; workers compensationrights; OSHA requirements; and child labor laws.

VirginiaAs in Maryland and DC, there are certain posters that should be

posted in the workplace that explain employee rights under federallaw. In addition, the Virginia Department of Labor and Industry statesthere are Virginia regulations that should be communicated to employ-ees related to a State-level OSHA, which pertain to job safety; unem-ployment insurance rights for employees; workers compensationnotices; tax credit information; and benefits for low-income individuals.

If you are concerned that you are not in compliance in one ormore jurisdictions, call Alexander & Cleaver to go over your currentemployment plan. H&D

EMPLOYMENT POSTINGREQUIREMENTS

thi

nks

tock

pho

to.co

m/P

opa

rtic

By JameS a. cleaver,Senior Partner, The Law Offices

of Alexander & Cleaver

Jim Cleaver is the senior partner of Alexander & Cleaver. Jim co-founded the firm in 1984 with Gary R. Alexander. He works primarily in the field of civil liti-gation, heading up the firms personal injury practice. In that role, Jim is the firms primary negotiator and litigator in personal injury cases, using his vast ex-perience and knowledge acquired over parts of the past five decades to achieve results for clients. It is no surprise to colleagues and clients that Jim hasbeen designated a Super Lawyer in personal injury cases, was named one of Marylands top trial lawyers and was selected by the prestigious Million DollarAdvocacy Forum. Jim can be contacted at (800) 292-LAWS.

22 August 2014

-

23August 2014

-

24 August 2014

-

25August 2014

-

BMW of Annapolis25 Old Mill Bottom RoadAnnapolis, MD 21409410-349-2565Fax:410-349-2586www.mybmwannapolis.com

Apple BMW of York1370 Roosevelt Ave.York, PA 17404800-839-1755Fax: 717-843-2948www.applebmwofyork.com

BMW of Fairfax2805 Old Lee HighwayFairfax, VA 22031800-879-2269Fax: 703-641-8562www.bmwoffairfax.com

BMW of Sterling21826 Pacific Blvd.Sterling, VA 20166888-954-8222Fax: 571-434-7727www.bmwofsterling.com

BMW of Alexandria499 South Pickett StreetAlexandria,VA 22304Direct: 703-684-5255Fax: 703-647-1853www.bmwofalexandria.com

BMW of Silver Spring3211 Automobile BlvdSilver Spring, MD 20904866-737-8937Fax: 301-890-3748www.bmwofsilverspring.com

Passport BMW5000 Auth WayMarlow Heights, MD 20746301-423-0733Fax: 301-423-2717www.passportbmw.com

Northwest BMW9702 Reisterstown RdOwings Mills, MD 21117410-363-1461Fax: 410-363-7749www.northwestbmw.com

For Original BMW Parts, contact one of these authorized BMW centers:

AS A COLLISION REPAIR SPECIALIST, YOU MUST ALWAYS FOC HOWEVER, INSURANCE ESTIMATES ARE OFTEN FOCUSED ON

BMW centers stock Original Equipment Parts that never sacrifice quality or s

26 August 2014

-

BMW of Catonsville6700 Baltimore National PikeBaltimore,MD 21228800-828-6529410-744-2000Fax: 410-818-2600www.bmwofcatonsville.com

Checkered Flag BMW5225 Virginia Beach BlvdVirginia Beach, VA 23462757-687-3494Fax:757-687-3495bmw.checkeredflag.com

BMW of Bel Air1705 Conowingo Road(US 1 in Hickory)Bel Air, MD 21014443.640.1230Fax: 443.640.1234www.bmwbelair.com

BMW of Towson700 Kenilworth DriveTowson, MD 21204410.296.7908Fax: 410.296.4852www.bmwtowson.com

Richmond BMW8710 West Broad StreetRichmond, VA 23294800-237-0130Direct: 804-527-6860Fax: 804-965-6254www.richmondbmw.com

Valley BMW2824 Franklin Road SWRoanoke, VA 24014PH: 540-342-3733Fax: 540-345-9060www.valleybmw.com

Richmond BMW12100 Midlothian TpkeMidlothian, VA 23113Phone: 804-897-2211Fax: 804-897-2202www.richmondbmw.com

BMW of Rockville1396 Rockville PikeRockville, MD 20852301-984-8989Fax: 301-984-1710www.bmwrockville.com

FOCUS ON SAFETY, QUALITY AND COST. ON JUST COST.

r safety for cost.

Every detail is exactly matched to the vehicles safety systems for optimum occupant protection.

Original BMW Panels and Components are built from premium materials using ultra-precise processes.

To maximize the safety of all passengers, replacement panels undergo strict and extensive quality control tests.

To ensure optimal paint adhesion, electrophoretically primer coats are applied during the manufacturing process.

27August 2014

-

Finishmaster team: doug, marina & James

axalta team: Steve, chris, Harry & Bob

axalta team (2): Bill, glen, Jerry & michael

national coatings and Supplies team: Jacob, rick, tom & John

ppg team: Jim, chris, randy & andrew

ppg team (2): tom, matt, Jason & Shawn

marks Body Shop team: nick, Sarah, chris & mark

akzonobel team: robert, alex, Brett & Henry

Fort washington auto Body team: alan, laura & Bruce

1

2

3

4

5

6

7

8

9

1

STORYCOVER

28 August 2014

2014 WMABA Golf Outing

June 26, 2014 Virginia Oaks Golf Club, Gainesville, VA

Benefiting the Jerry Dalton Memorial Education FundAlways, in Memory of John A. Mattos

Photos by Norman Morano

2 3

4 5 6

7 8 9

-

lkq team: Billy, Steve, Harold & arnold

enterprise team: nick, matt, matt & aaron

Sherwin-williams team: chris, chris, Bucky & rich

Sherwin-williams team (2): Brandon, Jake, charlie

mid-atlantic paint and Supply team: ralph, Howard, cory & mark

Single Source team: walt, chris, wayne & ed

ted Britt Ford team: mark, matt, greg & Blaine

wheelsonSite team: ryan, ken, mark & austin

lkq team (2): andrew, tom, tim & curt

12

13

14

15

16

17

18

10

11

Looking back on a fun-filled day.

29August 2014

Team Entrants

10 11 12

13 14 15

16 17 18

-

30 August 2014

STORYCOVER

2014 WMABA Golf Outing

Mark Muldoon (Ted BrittFord team) Beat the Pro!

The Sherwin-Williams team (pictured with WMABA President Don Beaver - far left, and Executive Director Jordan Hendler - far right) was the winner of this years tournament.

Jeff Hendler, event organizer with volunteer Hannah Hughes, gives away thebig prize of the day.

-

31August 2014

Major Sponsor ppg industries Major Prize Sponsor mid-atlantic paint

Major Prize Sponsor national coatings

Box Lunch Sponsor enterprise rent-a-car

Beverage Cart Sponsor all Foreign auto parts

Hole-In-One Sponsor refinish Solutions

Supporting Sponsor axalta coating Systems

Supporting Sponsor akzonobel coatings

Supporting Sponsor Finishmaster

Pro Assist Sponsor craftsman auto Body

Tee Prize Sponsor Brandywine auto parts

Tee Prize Sponsor Sherwin-williams

Beverage Cart Sponsorall Foreign used auto parts

Hole-In-One Sponsor refinish Solutions

Closest-To-The-Pin Sponsor mitchell international

Closest-To-The-Pin Sponsor Burkeville Body Shop

Closest-To-The-Pin Sponsor chesapeake automotive equipment

2014 Hole Sponsors alexander & cleaver - legal and lobbying Firm

chandlers collision center

Fort washington auto Body

Hammer & Dolly/thomas greco publishing

insurance auto auctions

karen radley acura/volkswagen

marks Body Shop

precision collision

Safety regulation Strategies

Sullivans auto Body

walker mill auto collision

wheelsonsite

WMABA would like to thank these sponsors for making this years Golf Outing such a success:

Closest to thePin winner:Blaine Keyser,Ted Britt Fordteam - 26inches

H&D

Several luckygolfers tookhome somegreat doorprizes.

-

32 August 2014

-

33August 2014

-

FEATURE

Its time for the collision repair industry to look at itself in amore comprehensive way.

In recent years, the Washington Metropolitan Auto Body Associ-ation (WMABA) has asked regional collision repairers to participate ina special Labor Rate Survey to help the group and the industry itserves better understand the financial landscape in Maryland, Vir-ginia and DC. But for this years installment of the Survey, WMABAhas decided to dig deeper than ever before into a multitude of otherareas that impact and influence the daily lives of collision repair facil-ity owners and their employees.

Executive Director Jordan Hendler offers historical feedback,saying, Many repairers were asking about particular operations orbilling practices, and whether or not there was a way to find out cur-rent industry responses to them. With other associations [for exam-ple, ASA of Arizona] going down the same road, we thought that wecould use the opportunity to gain insight in our region as well. Thisinformation is useful to repairers and those who represent them, to

bring further dialogue into rectifying areas of the industry that causeconcern. Some of the questions may be considered obvious, butthere just isnt data to back it up that we can use. Thats why wereasking all the questions.

In addition to asking shops to provide rate information, the asso-ciation is hoping to use this years Survey to gain data on a variety ofindustry practices. For example, the Survey asks participants if theybelieve certain operations are required, and if they currently performand charge for these practices. Some of these items include:

Bagging vehicle to prime and for final refinish;

Bag opening to prime and for final refinish;

Bonding materials in the repair process;

undercoating, installation and removal;

YOU'RE INVITED!Revamped WMABA Labor Rate Surveyto Provide Broadened Industry Insight

34 August 2014

-

WMABA gears up for the most comprehensive member survey yet.

35August 2014

Structural foam, installation and/or removal;

check and test seat belts being used in the accident;

pressure test cooling systems after front end damage;

prep raw plastic when recommend by paint supplier;

Feather, Fill, Block and prime on repaired panels; and

Feather, Fill, Block and prime on welded panels.

WMABA President Don Beaver believes that restructuring the Surveyin this manner will offer the Board more insight into its membershipsneeds, concerns and regular repair habits.

Expanding our Labor Rate Survey to ask questions about proce-dures, processes and insurer-repairer activity is to further understand anddocument where there are issues, and know these things with certainty,he says. We may think we know that a problem exists, but having re-spondents of a larger scale give their input is what makes this such an im-portant tool for the association.

Industry members who take the Labor Rate Survey will also beasked to answer yes or no to a number of questions, including:

continued on page 40

do you find imitation sheet metal parts generally inferior inquality to new oem parts?;

is it your experience that blending a panel takes as long, orlonger, than refinishing a new undamaged panel?;

does it take more skill and materials to "blend" a panel versusrefinish a full panel?;

can you blend or melt clearcoat within a panel and give a life-time warranty?;

is "clean up" time necessary on most "lkq" or used parts?

Have you been able to provide across-the-board increases inthe pay and benefits of your employees in the past five (5)years?;

do you believe insurers rate you on the use of alternativeparts to oem, such as used or aftermarket?;

do you feel many insurers try to control or insert themselvesinto the repair process, including selection of parts and repairmethods used?;

do you have an insurer who requires you to order parts from aparticular vendor or through a particular online procurement system?; and

do you believe insurer reimbursement rates are fair to supportadequate profit for continuing education, certifications and newequipment?

thi

nks

tock

pho

to.co

m/b

izo

o_

n

-

36 August 2014

BOB BELL FORD 7125 RITCHIE HWY, GLEN BURNIE, MD 20161Phone: 410-689-3038Fax: 410-766-1275www.bobbell.com

WALDORF FORD2440 CRAIN HWY, WALDORF, MD 20601Phone: 301-843-3028Fax: 301-843-0334e-mail: [email protected]

TED BRITT FORD11165 FAIRFAX BLVD, FAIRFAX, VA 22030Phone: 703-673-2420Fax: 703-870-7982www.tedbrittparts.com

PLAZA FORD1701 BEL AIR RD, BEL AIR, MD 21014Phone: 410-879-3367Fax: 410-877-7248www.plazaford.com

APPLE FORD8800 STANFORD BLVD, COLUMBIA, MD 21045Phone: 800-492-7999Fax: 410-312-0928www.appleford.com

ACADEMY FORD13401 BALTIMORE AVE, LAUREL, MD 20707Phone: 301-419-2700Fax: [email protected]

SHEEHY FORD5000 AUTH RD, MARLOW HEIGHTS, MD 20746Phone: 301-899-6300Fax: 301-702-3650www.sheehyford.com

HAGERSTOWN FORD1714 MASSEY BLVD,HAGERSTOWN, MD 21740Phone: 800-200-0276Fax: 301-733-0603www.hagerstownford.com

RICHMOND FORD4600 WEST BROAD STRICHMOND, VA 23230Phone: 804-355-4517Fax: 804-254-9240www.richmondford.com

Contact these Ford or Lincoln Mercury dealers for all your parts needs:

2014, Ford Motor Company

-

37August 2014

-

FEATUREDOES ALUMINUMREPAIR MAKESENSE FORYOUR SHOP?

38 August 2014

As some WMABA members have al-ready learned, getting a facility up to speedwith aluminum repair can be a costly experi-ence. In addition to sending their aluminumtech out for quarterly training, one dealer tellsHammer & Dolly that they committed around$350,000 in initial expenses to get the equip-ment and training necessary to be part of theMercedes and Audi programs. This fact isnothing new to Criswell Collision in Annapo-lis, who committed a similar amount ofmoney over the last 18 months to becomecertified to repair Audi, Porsche and Tesla.

That's for everything from equipment andtraining to food, travel and hotel expenses fortechs.

It's a huge investment out of pocketthat you won't see a return on for years, of-fers Criswell Collision Center Body ShopManager Kevin Marvin. You have to chooseyour technicians carefully. If you're going toinvest time and money in training them, youwant to make sure they're individuals whocan do the work and are going to stay withyou.

Fortunately, a number of Criswell's tech-nicians have embraced aluminum trainingwith open arms.

The best aluminum classes to take arethe ones from the manufacturer, offers tech-nician Ed Clark, who recently returned from aweek's worth of Porsche training in Atlanta.When you go there, you get trained on ex-actly how they want it.You get to practice howthey want it done, so when the car comesinto the shop, there's no misunderstanding.

Other area shops are feeling the eco-nomic pinch when taking on aluminum, withsome WMABA shops reporting to us thatthey are already investing upwards of$50,000 to get ready for the 2015 F-150 laterthis year. This is in line with Ford's estimatethat it will cost $30,000 to $50,000 for adealer or body shop to purchase new equip-ment needed to repair damage to aluminum.

No stranger to being aluminum-ready,Mark Schaech, Jr. of Mark's Body Shop(Baltimore) began the journey of training histechs and equipping his shop all the wayback in 2004 in order to work on BMW alu-minum vehicles. Since then, he has spentmore than $100,000 to stay up to speed on

with aluminum repair all the rage in today'sindustry, body shops across the country are taking a serious look at how to add this specialized service and if their markets will generate enough ofthis work to justify a very high price tag.

WMABA members work to add new technologiesto their businesses.

the aluminum repair area at criswellcollision center in annapolis, md.

thi

nks

tock

pho

to.co

m/Ia

rosl

av

Ne

liubo

v

-

the aluminum repairs he currently offers at hisshop and get ready for the arrival of the 2015Ford F-150.

There's a lot of talk about aluminumthese days, but still the majority of vehicles wesee today are mainly steel vehicles, he says.We are doing a lot of rivet bonding in ourBMW work, and every manufacturer has theirnuances whether it be MIG brazing or rivetsand glue. Still, aluminum is not on the majorityof vehicles that we're repairing today, but we'llbe ready when it comes.

Kenny Jennelle, president of WMABAmember facility Collision Plus (Blacksburg,VA), expects to spend around $50,000 by thetime his shop gets the equipment and trainingneeded to work on the new F-150s later thisyear. In addition to receiving referral work froman area Ford dealer, he hopes to get jobs fromother shops that will sublet their structural re-pairs.

Twenty-five years ago, I'd say 80 percentof shops subletted out the frame work or uni-body work; they didn't do it in-house, he of-fers. That may be what happens with thesealuminum bodies.

Criswell team member and recentHammer & Dolly Technician of the Month RoyZamostny, who joined Clark for the Porschetraining in Atlanta, is quick to urge his industrypeers to consider the cost necessary to repairaluminum vehicles before diving into offeringthese services.

You'd have to make sure you can getenough work to cover your tools, material andoverhead, he explains. Some of the glue weuse is $400 or $500 a tube!

Naturally, aluminum vehicle manufactur-ers often recommend procedures that mightseem foreign to technicians who are used tomore traditional cars.

There's a lot less welding [on aluminum];it's a lot of bonding and riveting, explains tech-nician Preston Hudson, a 24-year industry vet-eran who began taking aluminum classes in2013 and recently completed Tesla training inFremont, CA. The material is so much differ-ent; it's just softer. You really have to changeyour mindset.

Of course, all of this expense needs to bepaid for by the actual repairs being performed and that requires the insurance industry. For-tunately, Schaech's facility has been success-ful in receiving proper payment for aluminumstructure rates.

Any time an insurer doesn't want to pay ahigher rate, we usually just put that in front ofour customer and explain to them what kind ofequipment we needed and what it took to be

able to repair their car, he says. For the mostpart, most of the insurers have paid a higherrate in our market, anyway for those typesof repairs.

While some shops are working to incorpo-rate aluminum repair, other businesses havedecided to hold off on making the leap for thetime being. Although he is an instructor for I-

CAR's F-150 classes in the area, AntwerpenNissan Collision Center Manager and WMABAPresident Don Beaver is taking a wait-and-seeapproach at his Clarksville, MD-based facility.

The biggest problem that I find is that it'sgoing to cost a lot of money to equip a shopproperly to do aluminum repairs, he offers.I'm just not seeing enough of it out here at this

39August 2014

continued on page 42

-

40 August 2014

Away from sharing information on theirdaily practices and procedures, shop ownersare also being asked to tell the association ifthey fully, partially or dont pay for health in-surance, dental insurance, vision insurance,long-term disability, life insurance, paid sickleave (after a set period), paid vacation (aftera set period), personal leave (after a setperiod), 401(k) or retirement program,performance bonuses or yearly cost of livingincreases for full-time employees. They arealso being provided with an opportunity todescribe the general economic state of thecollision repair industry on a scale beginningat very poor/depressed and ending withvery strong/thriving.

No participating shop names will be pub-lished when the results are released, whileusers from multi-location businesses arebeing asked to fill out a Survey for each indi-vidual location. Anonymity will remain a prior-ity throughout the information-gatheringprocess; names are only needed to track de-mographics and ensure that only one surveyis cast per repair facility location. The ratesthat are requested for this Survey are a partic-ipants retail/cash/posted rates, not an agree-ment rate for an insurer or wholesale account.The rates explored in the Survey include BodyLabor, Frame/Structural, Paint/Refinish, PaintMaterials, Mechanical, Aluminum StructuralRate (if applicable), Inside Storage (Daily) andOutside Storage (Daily). Shops are alsoasked to identify themselves as DRP or non-DRP and provide their total number of techni-cians (body, paint and mechanical), totalnumber of estimators, total number of officepersonnel and the total square footage of thecollision facility.

WMABA Treasurer Mark Schaech, Jr. ishopeful that the information generated by theSurvey will greatly assist the association in itsongoing efforts in the political arena.

As weve seen in the past, whenWMABA is going after legislation or regulationin Maryland and Virginia, having Survey feed-back for repairers across the region is impor-tant for factual discussion, he says. When alegislator asks us about operations or prac-tices within our industry, we can give them thereal number. The difference between us andsome of the counter-argument is that we giveopinion based on professional experience inaddition to hard data.

FEATURE continued from page 35

-

41August 2014

It is important to understand that this Sur-vey function is to give WMABA feedback aboutactual marketplace activity across our area,adds WMABA Immediate Past President BarryDorn. Then, the association can utilize thatfeedback to have conversations with prominentrepresentatives, both in government and repaircommunities, about things that are going rightand wrong and have the data to back it up.Having the numbers is what makes those con-versations effective and factual.

For those repairers who may feel uncer-tain about answering all the additional ques-tions in this years Survey, WMABA asserts thatfilling out the basic Labor Rate data from yearspast is still an effective means of participation.

More data leads to more insight, notesHendler, so any and all submissions arehelpful.

The 2014 WMABA Labor Rate Survey canbe taken online at www.wmaba.com nowthrough September 1. The results of the Surveywill be featured in an upcoming issue of Ham-mer & Dolly. If you have questions or requireadditional information, please contact Execu-tive Director Jordan Hendler at (804) 789-9649or [email protected]. H&D

-

42 August 2014

point to justify the investment. We will beseeing it, and we will be making that invest-ment. But right at this point, what I would makeoff of it doesn't offset the investment.

With the arrival of the 2015 F-150 rightaround the corner and shops embracingaluminum like never before, time will tell ifthe investments being made throughout theindustry will truly pay off. In the meantime,Beaver urges his I-CAR students as well asanyone else in the field to acknowledge theserious changes going on around them.

I won't say it's going to be an easyrepair, he says. I just think it's going to be adifferent repair.

Shop owners need to do their homework,adds Schaech. You can't just assume becauseyou make an investment that cars are going toflood into your shop. Due diligence needs to bedone before making an investment like thisone.

More information on the equipment andtraining needed to be a Ford-recognized repairfacility is available at www.certifymyshop.com/ford. H&D

For more information on vehicle-specificrepair certification programs, please visitthe links below:

audi:http://www.audiusa.com/help/collision-repair

Jaguar:http://www.jaguar.com/content/market/us/en/65385/e-brochure-Jlr_Site2.pdf

land rover:http://www.landrover.com/za/en/rr/owners/service-and-maintenance/approved-body-shops

mercedes Benz: www.mbcollisioncenters.com

nissan:http://collision.nissanusa.com/certified-repair-network

porsche:https://www.porschecollisioncenter.com/pa/porsche/index.html

tesla:http://www.teslamotors.com/service

volkswagen:www.vwccrf.com

FEATURE continued from page 39

-

43August 2014

-

44 August 2014

Nuts and bolts, tips and tricksfrom our resident industry experts.

FEATURETECHNICAL

By larry montanez iii, cda & JeFF lange, pe

In this digital, social and advanced media age, a time wheneveryone owns a mobile device that can take photos similar to thosetaken by expensive DSLR cameras, it is no surprise that somebodywould try to use this technology to save money and time. Maybe youhave heard about insurance companies attempting to have insureds(and/or claimants) take photos of their vehicle damage using a mobileapp? These photographs are submitted to the insurance company sothey can then write an estimate and send out a check immediately. Itsounds so good, I almost cant wait to get into an accident just to try itout!

Unfortunately, this could be problematic and also quite danger-ous. Most collision-damaged vehicles are not safe to drive, thoughthey may be drivable. In this article, we will look into the issues withdigital estimates and why this concept is flawed.

A few years ago, we saw multiple online bidding sites forestimating damage repair. That process was eventually proven to bea disaster. Vehicles were severely underwritten, mostly due to hiddendamage. Lets look at the issues of using a digital estimating app.

Pictures do not always represent damage accurately.Depending on who is taking the photos, their skill level and even

the type of camera he or she is using can affect the quality of the pho-tos and what is being depicted in those photos. Photos often do notaccurately reflect the extent of damage; they can underrepresent theseverity of dents and scratches, while some dents cannot be clearlyseen. Based on the photos, an insurance company desk reviewermay interpret that a deformity can be removed using paintless dentrepair techniques, or under/overestimate the amount of time to usedent-removal techniques - when, in fact, the panel may not be re-pairable due to the type of substrate. A scratch that appears like itcould be buffed out may actually be too deep and require refinishingor may not even be seen in the photos at all. Additionally, withoutdisassembly (which no consumer is going to attempt), no photographwill show hidden damage unless someone has an X-ray app.

Another issue is that photos cannot accurately determine if avehicle is safe to drive. As many of us know, there is often structuralmisalignment, suspension damage and deformed structural compo-nents that cannot be seen without disassembly and/or measuring.Operating the vehicle in this condition could put the vehicle operator,passenger and other vehicle on the roadway in a dangerous situation.We should also mention that many times, a bumper fascia (cover),bumper reinforcement and front uni-rail can become damaged, but

the fascia could show little to no damage, as the ductile part mayhave returned to its original shape. Another issue would be operatingthe vehicle with an airbag lamp on, indicating a problem with thesystem.

Many vehicles will set a Malfunction Indicator Lamp (MIL) for theSupplement Restraint System (SRS) just because the vehicle wasinvolved in a collision event and now the passenger Occupant WeightSystem/Occupant Presence System requires reweighing and sensitiv-ity testing. Otherwise, the passenger airbag may not deploy when in-tended or may deploy when not intended.

Delays in repair timeIf the initial repair estimate from the insurance company is in-

complete, a second estimate or supplemental estimate will have to bewritten once the additional damage is discovered. In some cases, thiswill require an adjuster from the insurance company to come out andreview the supplement (as they cannot approve anything). This willadd considerable time to the collision repair and extend the originalrental. Conversely, if the vehicle went to a professional, well-trainedrepair facility with an educated, trained damage assessor, the vehiclecan be inspected, triaged, blueprinted and pre-measured. After this, athorough and complete final invoice could be generated. This will re-sult in lower overall repair time and rental times and ultimately elimi-nate expensive supplements. This in turn would also reduce the cycletime and return the vehicle to the consumer faster.

So who is gaining an advantage in this process by saving timeand money? The consumer, you...or the insurance company?

Well, consumers sometimes believe whatever they hear. Doregulations support complete truth in advertising? Unfortunately, no.Until a claim is issued, they can say whatever sounds good ontelevision and in print advertisement. Once in the hands of claimspersonnel, however, things can change. By using a photo estimatingapp, the insurance companies are relying on many people to just

thi

nks

tock

pho

to.co

m/m

on

keyb

usi

ne

ssim

age

s

DIGITALESTIMATES?thinkstoc

kpho

to.co

m/m

on

keyb

usi

ne

ssim

age

s

-

45August 2014

keep the money and never repair their vehicle, on some shops that willdo the repairs for whatever price they pay and/or counting on the con-sumer not believing the repair facility when the shop says it needs asupplement.

Look at it this way: The insurance company saves time and moneyusing a repair estimate app because they dont have to pay an adjusterto come out and look at your vehicle. If you (or the consumer) accepttheir estimate and choose not to repair the vehicle, they will avoid havingto pay for any hidden or additional damage. If you do choose to repairyour vehicle and there is hidden or forgotten damage, then there will bea supplement, which will cause a delay in the repair process. So whereis your advantage? Your best interests are served by getting your carproperly restored to its pre-loss condition by a professional repair facility.

Now, Im not saying that these collision repair estimate apps haveno value. If you are involved in a collision event, they could be used totake on-scene photos of the vehicle(s) involved. We would recommendthe following steps for using such an app:

1. if you are involved in a collision event, ensure everyone isuninjured and you are safe.

2. if anyone is injured, call 911 for an ambulance; if not, call the police department.

3. use your app to take photos of the involved vehicle(s). 4. after your vehicle is taken to a repair facility and you are

calling in to report the claim, tell the claims handler that youhave scene photos.

We hope this article has helped the industry to better understandthe changes in and, in some cases, the dangers of collision estimat-ing photo apps. Feel free to contact us if you have any questions. H&D

Larry Montanez, CDA is co-owner of P&L Consultants with Peter Pratti Jr. P&LConsultants works with collision repair shops on estimating, production andproper repair procedures. P&L conducts repair workshops on MIG & resistancewelding, measuring for estimating and advanced estimating skills. P&L also con-ducts investigations for insurers and repair shops for improper repairs, collisionrepairability and estimating issues. P&L can be reached by contacting Larry at(718) 891-4018 (office), (917) 8603588 (cell), (718) 6462733 (fax) or via emailat [email protected]. The P&L website is www.PnLEstimology.com.

Jeff Lange, PE is president of Lange Technical Services, Ltd. of Deer Park, NY(www.LangeTech.net). Jeff is a Licensed New York State Professional Engineerwho specializes in investigating vehicle and component failures. Lange TechnicalServices, Ltd. is an investigative engineering firm performing forensic vehicleexaminations and analysis for accident reconstruction, products liability andinsurance issues. Jeff can be reached at (631) 667-6128 or by email [email protected].

Consumer education on this type of claims process is key. An informedconsumer, or someone without complete trust of the insurance claimprocess, will get a second opinion. That second opinion is the collision re-pair professional who would know exactly what it takes to repair the vehi-cle properly and safely. Settling a claim without another opinion is whatthe insurance company banks on. - Jordan Hendler

Executive Directors Thoughts

-

46 August 2014

-

PRESIDENT: Don [email protected]

443-539-4200 ext. 17061

VICE PRESIDENT: Torchy [email protected]

410-309-2242

SECRETARY: John [email protected]

703-534-1818

OFFICERS

BOARD OF DIRECTORS

Rodney [email protected]

410-969-3100 ext. 250

EXECUTIVE DIRECTOR: Jordan Hendler

PAST PRESIDENT: Barry [email protected]

804-746-3928

Mark [email protected]

703-671-2402

Kevin [email protected]

301-336-1140

Bobby [email protected]

434-767-4128

Just like equipment and training, WMABA membership is notonly a commitment to excellence, but also a valuable investment.

WMABA is recognized both regionally and nationally as the keyforum for the exchange of ideas concerning the D.C., MD, and VAcollision repair industry. It is the venue to discuss, learn about andimpact evolving standards and policies in the technical, administra-tive and legislative fronts of our industry. Shops and industrysupporters can best develop themselves and their employees byactively engaging in the association and its activities.

Automotive collision repair facilities in Maryland, Virginia andWashington, D.C. who are willing to adopt WMABAs Standards ofMembership and offer a guarantee to their consumers areencouraged to engage their business as an active member of theassociation. For over 40 years, the WMABA membership of profes-sional collision repair businesses and affiliates have committed tooperating at a higher standard on behalf of their industry and theirconsumers. Over the years, WMABA has proudly represented the col-lision repair industry at hearings on Capitol Hill, in Annapolis, MD,and Richmond, VA as well as almost every national collision repairevent. While WMABA has a rich history of dedicated men and womenserving the local collision repair community, WMABA also boasts nu-merous past and current accomplished Board members who repre-sent our membership at the national level.

WMABA offers current and dynamic discussion forums on top-ics facing collision repairers, technical information and educationalseminars, opportunities to network and discuss pressing topics withleaders of the collision repair industry, an arbitration program thatworks with consumers to help resolve issues they might have, ap-prenticeship programs, legislative representation and the ability toreceive and contribute to one of the nations leading collision repairmagazines, Hammer and Dolly.

Contact Executive Director Jordan Hendlerto find out how WMABA can amplify YOUR

voice in the collision repair industry.

Position YourBusiness as a Leader!

An association fostering the exchange of ideas, and providing a voice and support for the collision repair professional.

TREASURER: Mark Schaech [email protected]

410-358-5155

47August 2014

-

48 August 2014

MESSAGEEXECUTIVE DIRECTORS Jordan Hendler(804) [email protected]

THE IMPORTANCEOF GIVING INPUT

Our industry is the most unforgiving,cutthroat business to be in. People who go theextra distance to involve themselves withWMABA all seem to have the same ingrained,fundamental belief in trying to effect some kindof change.

I grew up hearing the phrase, You cannotcomplain about something without offering asolution. Mostly, though, I didnt heed thatadvice until I was older, and until then, the worldalways seemed unfair. It took me time to figureout that the world is what you make it; if youwant to see change, then you need to have theinitiative to do it yourself.

we cannot know where we are goingunless we know first where we are. TheWMABA Labor Rate Survey (discussed onpage 34) is something in which all people in ourindustry can give input to help with the prospectof change. Not by changing prices by virtue oftheir input, but by giving a face to the reality thatour industry is in.

All things considered, we are in a commu-nity that spans many miles but is in actualityvery small. You can go anywhere in anymodern country and find a repairer who dealswith the exact same circumstances as you.You are not alone. In that premise, you cannotpossibly be the only one who questions what isbeing asked of them, told to them or expectedof them as usual and customary.

Operating an association comes with therealization that no one is ever the only one. Ifyou were to monitor my phone or email, youwould quickly see the fact in that statement.Sometimes, its as if there are ripples where Ill

have three or four repairers call me about the very same thing within a two-day window.Some issues I get relate to government oversight, finding good technicians, how topurchase the right equipment or get the right educational need met and even getting aninsurance question answered from the higher ups. There are so many resources sharedby our membership that (sorry to sound so clich) it never hurts to ask about your ownissue. What would you lose by calling in and asking the question that nags you? What ifsomeone else who had been in bed staring at the ceiling each night cracked the code andwe already have the answer - and sound sleep - for you? Wouldnt it serve your interest toat least find out? Last question: What are you waiting for?

Participation of any kind in the efforts pushed by WMABA is a way of keeping yourvoice, even anonymously, included with those who want to see positive change in ourindustry. That could be by any means in your imagination.

We often put the call out that if you believe passionately about just one thing, whateverits significance, and see it through to resolution, youve effectively moved a mountain. Findout if there is already someone working on a door lock that just needs your key to get to theother side. Some things really are just a basic connection for simple conclusion. H&D

thi

nks

tock

pho

to.co

m/A

nci

ka

-

49August 2014

-

50 August 2014

ADVERTISERSINDEX

Alexander & Cleaver............................23

Alexandria Toyota ................................41

All Foreign Used Auto..........................40

Audi Group ..........................................21

Axalta Coating Systems ......................4

BMW Group ........................................26-27

BMWof Bel Air ....................................IBC

BMW of Fairfax....................................3

BMWof Rockville ................................IBC

BMWof Towson ..................................IBC

CAPA ..................................................15

Chesapeake Automotive Equipment ..50

Empire Auto Parts................................42

Ford Group ..........................................36

Future Cure ........................................39

GM Parts Group ..................................43

Hendrick Honda ..................................41

Honda Group ......................................24

Hyundai Group ....................................32

Koons Ford ..........................................23

Mazda Group ......................................37

MINI Group ..........................................33

MINI of Baltimore County ....................IBC

Mitsubishi Group..................................18

Mopar Group ........................................9

Nissan Group ......................................7

NORTHEAST 2015 ..........................6

ODonnell Honda ................................42

Packer Norris Parts ............................11

Porsche Group ....................................13

PPG ....................................................IFC

P&L Consultants..................................45

Russel Toyota ......................................25

Safety Regulations ..............................40

Sherwin-Williams ................................8

Steck Manufacturing............................50

Subaru Group......................................46

Tire World ............................................25

Toyota Group ......................................49

Valspar Automotive..............................OBC

VWGroup............................................19

-

51August 2014