GUIDE ON GARI PROCESSING - orr.naerls.gov.ng

Transcript of GUIDE ON GARI PROCESSING - orr.naerls.gov.ng

GUIDE ON GARI PROCESSING

Introduction Cassava tuber, also known as moanioc, is one of

the most important food in the tropics and it is avail· able in the whole of West Africa. It is a popular crop because it is a cheap source of cabohydrate.

In Nigeria, there is the sweet low Cyanide and bitter high cyanide cassava varieties. The sweet vari· ety has very low hydrogen cyanide content and can be eaten raw without processing. However, the bitter vari · ety contains toxic substance called hydrogen cyanide (HCN) and can be processed into flour, starch, chips, flakes and gari to reduce its toxicity and increase its economic value.

Processing cassava aims at removing toxic sub· stances, improving texture, flavour, colour and prolong· ing the shelf life of the foods. This guide describes the traditional method of gari processing and introduces the various modern equipment that can be used for large scale processing of gari with minimum cost in time and energy. The introduction of these equipment enhances earning in gari processing business and stimulates increased cultivation of cassava in the coun· try.

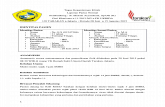

Gari Processing Gari processing comprises of the following op·

erations: peeling, washing, grating, fermentation, pressing, frying, sieving and drying.

FLOW CHART OF GARI PROCESS

~1-f.stl 1 "~~J

p~,~~--..1

F~'i~-~~- r

L s~~:~~ 1 ~ . ··- --r . - ------

~ll~·~~- J ~~---- 1 E~ t~c,, ~"~(~

2

METHOD OF' PROCESSING GARI

Cassava is processed within 24 hours of harvest. The traditional method of processing gari is discussed along with the mechanised system.

Fig. 1 Fresh Cassava Tubers

1. Removing soil from the harvested tubers tradi · tionally is done by hand operation or rinsing tu · bers in water.

· 2. Peel the tubers to remove skin and wood layers by use of knife.

3

Fig. 2A.

The source of power for the peeler may be electricity, petrol or diesel powered machines.

The washed cassava tubers are fed into the hop· pers of the machine and the outer skin of the tubers is removed in a limited time as compared with the tedi · ous hand peel ing. ·

4

Fig 2b MOTORIZED CASSAVA PE.ELER

3. Washing the peeled tubers. This involves wash· ing the peeled tubers clean in a basin or con· tainer of water to remove any dirt.

4. Manual grating of the tubers into a paste is by use of abrasive metal board

5

Fig3'A' GRATING CASSAVA TUBERS BY MANUAL CASSAVA GRATER

5, The use of mechanical graters save women the cumbersome tasks of grating on metal abrasives and running the risk of having their fingers peeled off by the grater.

6

The mechanical grater has a hopper for feeding in the peeled tubers and an outlet for grated pulp. Graters are of varying sizes and designs. In cassava growing areas, the graters can be individually owned either for their own use or for commercial purposes. An electricity · powered or dieselpowered grater takes 4 hours to grate 0.5 tonne peeled cassava roots.

Fig 3'8' GRATING CASSAVA TUBERS BY A MOTORIZED CASSAVA GRATER.

7

6. The grated paste is then tied in hessian bags and allowed to ferment for three to four days. They are usually stacked and heavy objects are put on top of the bag to squeeze out the water.

Fig. 4 'B' Dewatering grated Cassava by Manual Cassava Pressers.

8

Traditional method of dewatering cassava provide a low output. . The new hydraulic jack operated presser can dewater 4 ·6(50kg) bags of grated cassava in two days. The combne use of motorized cater mechanised prosser and hydnulec Jack for denatering accelerates gari processing and emjamces local income genera· tion.

Groups or individuals can have their cassava pulp dewatered in a small unit pressors and be charged for their services.

Fig.4'8' Dewatering by use of Hydraulic Jack

9

7. The cassava paste is screened on home·made sieve to remove fibres and ungrated ends. Re·sieving with finer sieve for uniformity of grains is encouraged.

Fig. 5'A' Manual Sifting of Gari.

Mechanical device has sifting machines which are very efficient and they are varied in mesh sizes, shapes and screen sizes. The motorized sifter saves a lot of time compared with the traditional manual method of sifting which is time consuming.

Motori zed sifter is more hygienic since there is

10

less handling of the product by hand as is the case with the traditional sifting process.

Fig. 5'8' Motorized Cassava Sifter.

8. Traditionally the sieved gari is then fried on hot clay or iron pots with continous stirring until gelatinization and drying are achieved. Palm-oil may

.. be added to the gari during frying to give it colour.

Fig. 6'A' Manual Gari Fryer.

11

Firewood or gas gari fryer fries large quantities of gari. The frylng blades are usually semi-circular in

~ shape and swirm stir the wet gari for uniform heat dis· tribution. The paddles or blades that stir the gari are turned by electric motor and sometimes can be manu· ally operated.

Fig. 68: Gas Fired Gari Fryer

Traditional method of processing gari has the fol· lowing disadvantages. It is labour . intensive time con· suming and the quantity of gari produced is usually small. Also the method is unhygienic (due to overhand ling) and hazardous (due to inhalation of hy· drogen cyanide by the processor).

The improved method of processing gari is Ia· bour saving because it is mechanized. It is more pro· ductive, hygienic, and minimizes the risk of cyanide poisoning. The mechanical devices in use for gari processing are peelers, graters, pressers, sifters and fryers.

12

Processors (co-operatives and individuals) who embark on producing gari for income generation can now make considerable progress by using these devices.

13

SUMMARY AND CONCLUSION

Cassava is one of the crops of immense economic importance in Nigeria. Since gari is widely consumed, there is need to intensify its production.

The traditional methods of gari production can· not satisfy gari demand in Nigeria. The mechanical gari processing units, although capital intensive, are cost effective in large scale gari producing areas and can be purchased by cooperatives groups or govern· ment where individuals cannot afford one. State gov· ernments and cooperatives should set up gari process· ing industries. In addition, with the ?etting up of com· munity (and peoples) banks all over the country. rural communities and income handicapped citizens can avail themselves of the opportunity of investing in this area of the economy, since these banks are out to en· hance such ventures and at minimal interest rates.

Finally improved gari processing devices should be used for higher income, reduction of item and en· ergy involved in processing and the risk of cyan ide poisoning.

14