Greases for Mining Equipments

-

Upload

juan-luis-rojas -

Category

Documents

-

view

53 -

download

1

description

Transcript of Greases for Mining Equipments

-

Copyright of Royal Dutch Shell plc 1

GREASES FOR MINING EQUIPMENTS

Augusto Fernandes Product Application Specialist

-

Copyright of Royal Dutch Shell plc 2

Introducing Shell Lubricants

18 grease manufacturing plants

Expert advice, practical tools and training

Grease specialists in the field worldwide

370 technical field staff and 30 product specialists

Customers in over 70 countries

Major global lubricants supplier

3,000+ employees across the global supply chain

R&D centres on four continents

-

Copyright of Royal Dutch Shell plc 3

SHELL GADUS S4 OG A HIGH-PERFORMANCE OPEN-GEAR GREASE

-

Copyright of Royal Dutch Shell plc 4

What Drives the Mining Equipments Market?

Energy Efficiency

Reduced Emissions

Increased Power Output

Extended Equipment

Life

Extended Service Intervals

Market Influence:

Legislation Market Influence:

Technology

-

Copyright of Royal Dutch Shell plc 5

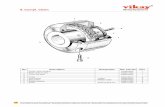

Evolution of Mining Equipments and Components

Euclid 10 ton

2020

Komatsu 50 ton 600 hp

70s Caterpillar

400 ton 4,000 hp

Nowadays

Komatsu 190 ton

2,000 hp

90s

Near Future

Belaz 450 ton

4,600 hp

Contamination Sensitivity

Vane Pum p

Piston Pum p

Gear Pum p

-

Copyright of Royal Dutch Shell plc 6

Shell Gadus S4 OG Designed to Improve Profitability

At Shell Lubricants we appreciate that, in tough conditions and in remote areas, you are constantly striving to:

Maximise machine availability Drive down production costs Cut maintenance costs

-

Copyright of Royal Dutch Shell plc 7

Working With the Mining Industry

Shell Lubricants is a leading supplier of oils, greases and fluids to the mining industry, providing:

Pioneering research centres and innovative technical partnerships to help our lubricants deliver excellent component protection.

On-the-ground experts to help analyse your needs and solve your lubrication problems, thereby unlocking your mining potential.

International resources offering security of supply and consistently high-quality products and services.

A comprehensive range of lubricants and services for mining operations.

Experience working with leading mining companies, including Anglo American, Barrick Gold, BHP Billiton, Rio Tinto, Thiess, Vale and Xstrata.

Over 4,000 equipment manufacturer approvals across the product range.

-

Copyright of Royal Dutch Shell plc 8

Shell Gadus S4 OG Outstanding Protection

Our newly extended open-gear grease range offers outstanding protection across all seasons and climates:

Shell Gadus S4 OGT for warm climates and extreme hot weather

Shell Gadus S4 OGXK for cold climates and sub-Arctic winters

Shell Gadus S4 OG Multi-Season our universal mid-range temperatures product.

These products are suitable for open gears on mobile mining equipment such as shovels, excavators and hoists. They meet equipment manufacturer specifications including CAT SD4713, P&H 520 and P&H 464.

-

Copyright of Royal Dutch Shell plc 9

Shell Gadus S4 OG Wide Temperature Range

Shell Gadus S4 OG is fully compatible with aluminium complex greases.

Shell Gadus S4 OGXK

Shell Gadus S4 OG MS

Shell Gadus S4 OGT

Temperature range, C -45C to +10C -20C to +40C -7C to +50C

NLGI 00/000 0/00 0

Base Fluid Viscosity, cSt* 4,000 4,000 5,500

45 30 20 7 0 +10 +20 +30 +40 +50

Temperature Range, C

Shell Gadus S4 OGXK

Shell Gadus S4 OG MS

Shell Gadus S4 OGT

*1cSt = 1mm2/sec

-

Copyright of Royal Dutch Shell plc 10

Shell Gadus S4 OG Meeting Tough Challenges

The Shell Gadus S4 OG product range offers protection during:

Extreme heavy-duty applications, sustained heavy loads and shock loads. Severe environmental conditions. A wide range of ambient temperatures and significant daily and seasonal

temperature variations.

Long operating hours with a focus on productivity and minimum, planned downtime for maintenance.

It meets increasingly challenging equipment manufacturers lubricant performance requirements.

-

Copyright of Royal Dutch Shell plc 11

Shell Gadus S4 OG Exceeds Load-Carrying Needs

The Shell Gadus S4 OG product range helps to prevent damage to gear teeth from shock loading, for reduced downtime and maintenance costs and extended equipment life. It incorporates:

A specially designed anti-wear, extreme-pressure (EP) additive package*: >15% solid additives, including 5% MoS2.

Optimised for use with the aluminium complex thickener.

Ultra-high-viscosity base oils that: Far exceed equipment manufacturers requirements.

Offer heavy-duty protection.

Synthetic technology, which: Maintains excellent flow properties across the operational temperature range.

Has flow properties that are achieved without viscosity modifiers.

Our products meet the essential 800-kg four-ball weld load specification.

-

Copyright of Royal Dutch Shell plc 12

Shell Gadus S4 OG Exceeds Load-Carrying Needs

*Calculated from data obtained from the Four-Ball EP method according to ASTM D2596

0 50 100 150 200

Load wear index, kg

Warm Weather Products

(-20C or higher)

Cold Weather Products

(-20C or lower)

Shell Competitors

120

Better Protection

Shell Gadus S4 OG lubricants all comfortably exceed the minimum threshold of 120 in the load wear index*, which measures the ability of a lubricant to prevent wear under applied loads.

-

Copyright of Royal Dutch Shell plc 13

Shell Gadus S4 OG Outstanding Adhesiveness in Harsh Conditions

To protect effectively, open-gear lubricants must prevent metal-to-metal gear tooth contact, even under sustained and shock loads, in the presence of water and other contaminants. Adhesiveness is critical. Shell Gadus S4 OG lubricants offer: Minimal wash-off, fling-off or squeeze out

(displacement under load).

A highly persistent lubricant film on gear teeth.

Outstanding protection, even in challenging wet or dusty environments.

In water spray-off tests, Shell Gadus S4 OGT showed negligible loss.*

* Based on ASTM D4049 water spray-off test

80 60 40 20 0

Water spray off, %

Shell Competitors

Better Water-Wash-Off Resistance

-

Copyright of Royal Dutch Shell plc 14

Shell Gadus S4 OG Outstanding Adhesiveness in Harsh Conditions

Shell Gadus S4 OG is formulated with: A special aluminium complex thickener modified for adhesiveness. High-quality, high-viscosity base oils to deliver good film thickness, even under high

pressure.

Anti-rust additives to enhance corrosion protection for components.

Caterpillar shovel showing good product film adherence with Shell Gadus S4 OG

TZ shovel at the same site showing poor lubricant adherence (competitor product)

-

Copyright of Royal Dutch Shell plc 15

Helping You Add Value

Meets the specifications of leading equipment manufacturers, including Caterpillar and P&H.

Shells optimised aluminium complex thickener formulation.

Ultra-high viscosity base oil, with synthetic or semi-synthetic components.

Specially formulated additive package, including 5% moly, and overall >15% solids.

Formulated without solvents or bitumen.

SHELL GADUS S4 OG

Maintains high productivity across long working hours with limited downtime for servicing and maintenance.

Extends component life and reduces component failure caused by wear or corrosion.

Simplifies lubricant inventory.

DESIGNED TO HELP MINING OPERATORS

NEXT LEVEL OF PERFORMANCE

Provides the high level of protection required by equipment manufacturers.

Outstanding adhesiveness.

Persistent lubricant film.

Long effective lubricant lifetime.

Reliable pumpability and sprayability.

Environmentally considerate.

-

Copyright of Royal Dutch Shell plc 16

Shell Gadus S4 OG Clear Oil 20000 Advanced Open Gear Lubricant

Shell Gadus S4 OG Clear Oil 20000 is advanced part-synthetic non-bitumastic viscous lubricant specifically developed to satisfy the demands of heavily loaded open gearing.

This product was primarily designed for fixed plant (mills, kilns) for gears in vertical orientation. Shell Gadus S4 OG Clear 20000 is approved and recommended for the main Mills & Kilns OEMs as Metso, FLSmidth and Ferry Capitain.

-

Copyright of Royal Dutch Shell plc 17

Shell Gadus S4 OG Clear Oil 20000 Exceeds Load-Carrying Needs

The Shell Gadus S4 OG Clear Oil 20000 helps to prevent damage to gear teeth heavily loaded, for reduced downtime and maintenance costs and extended equipment life. It incorporates: Extreme pressure performance: The high viscosity base oils are combined with extreme pressure additives to give the lubricant

very high film strength and extreme load carrying capability needed for the protection or heavily loaded open gearing.

Ultra-high-viscosity base oils The use of synthetic oil with thickening has produced a lubricant with high viscosity index, which

provides good pumpability at low temperatures while maintaining high viscosity at elevated temperatures.

Easier gear inspections: Static and dynamic inspections are much easier to view the gear condition without cleaning off the

grease or oil, as the lube film is clear, can inspect the gearing through the lube film

Shell Gadus S4 OG Clear Oil 20000 meets the essential 800-kg four-ball weld load specification.

-

Copyright of Royal Dutch Shell plc 18

Shell Gadus S4 OG Clear Oil 20000 Easier Gear Inspections

Open gear with Shell Gadus S4 OG Clear Oil 20000 (much easier to view the gear condition)

Open gear with a typical OGL (much harder to view the gear condition)

-

Copyright of Royal Dutch Shell plc 19

Complete Range of Open-Gear Lubricants

Products Applications

Shell Gadus S4 OG Advanced protection for mobile mining equipment that meets the latest specifications from leading equipment manufacturers.

Shell Gadus S2 OG

A comprehensive, versatile range with a long service history and established reputation for use in mobile and fixed plant applications, including gears and journal bearings on mills and kilns, as well as on wire ropes.

Shell Gadus S2S4 OG Clear Oils

Lubricants for fixed plant, including mills and kilns, whatever the lubricant delivery system, offering easier gear inspections because of the clear lubricant film.

Shell Gadus S3 Repair A sprayable running-in and repair grease for open gears. Smoothes surface roughness, increases contact area for loading and helps to reduce maintenance requirements.

-

Copyright of Royal Dutch Shell plc 20

Gadus S3 V460XD Premium Multipurpose Grease for Mining Equipments

Shell Gadus S3 V460XD Greases are premium heavy-duty greases designed for use in a wide range of mining applications with shock loaded, heavy-duty slow moving bearings and non-bearing applications in Shovels, Excavators, Haul Trucks, Tractor and industrial equipments.

Shell Gadus S3 V460XD Greases help improve the life of moving bearings and non-bearings heavily loaded, reducing downtime and maintenance costs: Wide Operating Temperature Range: Prolonged Grease Service Life Excellent Mechanical Stability For Shock Loaded Conditions Enhance Extreme Pressure and Antiwear Properties Low Water Wash-Out Effective Corrosions Protection

Approvals and Recommendations Shell Gadus S3 V460XD meets following OEM specifications: Komatsu Komatsu Trucks Terex Liebherr Trucks P&H BE (certified) Caterpillar (exceeds specification)

-

Copyright of Royal Dutch Shell plc 21

Shell Gadus Product Chart for Mining

-

Copyright of Royal Dutch Shell plc 22

SHELL LUBEEXPERT

-

Copyright of Royal Dutch Shell plc 23

Shell LubeExpert

1994

Australia

Experts Team

deep knowledge in mining equipment

wide expertise in lubrication

Critical Assets

-

Copyright of Royal Dutch Shell plc 24

Shell LubeExpert

MTTR MTBS

Components Life Identify Premature Failures Unscheduled Downtime

-

Copyright of Royal Dutch Shell plc 25

Shell LubeExpert Focus in Critical Assets

Mills

Draglines

Shovels

Excavators

Haul Trucks

Reclaimers

-

Copyright of Royal Dutch Shell plc 26

Shell LubeExpert

Management Operational Support

Productivity

Availability

Reliability

Safety

+

Help them stay in control

Extending best practices

Total Productivity Maintenance (TPM) and Reliability Centered Maintenance (RCM)

Only successful with proactive personnel like LSEs

-

Copyright of Royal Dutch Shell plc 27

Shell LubeExpert: Developing LSE Capability

Lubrication Audits Setting Performance Standards

Three years to fully train a LSE to be competent in all aspects of the role

Three increasing levels of competency development

Five years of experience assembling and rebuilding critical equipment Shells comprehensive training and field coaching

-

Copyright of Royal Dutch Shell plc 28

Shell LubeExpert Services Overview

Operational inspections Visual, Temperature, and Strobe-O-Scope Thermal Imaging Vibration analysis

Shut Down Inspections Visual inspections, Lubrication system audit, and spray

pattern monitoring Tooth profiling Hardness testing Deflection checks Specialty product conversion

-

Copyright of Royal Dutch Shell plc 29

Shell LubeExpert Operational Inspections

Mills, kilns and draglines dont shut down often Visual, temperature and strobe-o-scope Inspected for: Blockages

Correct spray patterns

Leaking seals

Identify gear teeth misalignment

-

Copyright of Royal Dutch Shell plc 30

Shell LubeExpert Operational Inspections

Quality Inspection Reports

Checklist of inspection points Comprehensive review and issue report Also provide advice on required repairs Assessment of open gear and bearing lubrication Complete report using iPad/tablet Should be conducted monthly

-

Copyright of Royal Dutch Shell plc 31

Shell LubeExpert Advanced Operational Inspections

Thermal Imaging

Video 01

Video 02

-

Copyright of Royal Dutch Shell plc 32

Shell LubeExpert Advanced Operational Inspections

Vibration Monitoring

Temperature Tags

Used while in operation Accelerometers and Tachometers Compared over time, detecting possible wear All rotating equipment vibrates to some degree Older bearings and components vibrate more dramatically Monitoring identifies this before it becomes a problem LSEs with level 2 or above certification Correlating vibration with oil analysis can be provided

-

Copyright of Royal Dutch Shell plc 33

Shell LubeExpert Basic Shut down Inspections

Equipment is switched off and isolated for maintenance Its the only time LSEs can access the isolated machine Reveal hidden facts How often and how much Check gearing alignment and lubricants evenness View the gears condition See any damage or fatigue Involve detailed work that can be time consuming Every lubricant injector is operated and examined Should be conducted at least twice a year

-

Copyright of Royal Dutch Shell plc 34

Shell LubeExpert Basic Shut down Inspections

Routine spray pattern checks Too much air pressure Not enough air pressure

-

Copyright of Royal Dutch Shell plc 35

Shell LubeExpert Shut Down Inspections

Tooth Tape Carbon Impressions

(used to monitor fatigue, pitting,

spalling)

Tooth Measuring

Hardness Testing

-

Copyright of Royal Dutch Shell plc 38

Shell LubeExpert Support Focus Troubleshooting

Bull Gear

New Pinion

-

Copyright of Royal Dutch Shell plc 39

Shell LubeExpert Support Focus Failure Diagnostics

Understanding how it failed

The root cause of failure, has to be know to prevent it from occurring again in the future

-

Copyright of Royal Dutch Shell plc 40

Shell LubeExpert Support Focus Training

Skills and competences

Safe working procedures (SWP)

Job Safety Analysis (JSA)

-

Copyright of Royal Dutch Shell plc 41

Success Case (Demonstrated Value Records DVRs)

-

Copyright of Royal Dutch Shell plc 42

Success Case 01 Chaneme (Hitachi Dealer) Shell Gadus S2 OG 85 Pins & Bushes Hitachi Excavators

1 2 3 CHALLENGE SOLUTION OUTCOME

VALUE 4

Chaneme (Hitachi Dealer in Colombia) in coal mine in Calenturitas Colombia maintains 5 excavators Hitachi EX 3600-5.

Chaneme wanted to increase the pins & bushes life beyond the current 4,000 hrs.

Shell, through Shell LubeExpert, identified the failures causes and proposed the use of a high-performance grease (Shell Gadus S2 OG 85).

By identifying the failures causes, implementation of a routine inspection process of lubrication system and critical components, together with the application of high performance grease (Shell Gadus S2 OG 85) the pins and bushes life increased from 4,000 hrs to 16,000 hrs.

Savings of over USD 600,000.00 with increase of productivity and with life extension of pins and bushes

Increased pins and bushes life from 4,000 hrs to 16,000 hrs

The savings indicated are specific to the calculation date and mentioned site. These calculations may vary from site to site, depending on the application, the operating conditions, the current products being used, the condition of the equipment and maintenance practices.

-

Copyright of Royal Dutch Shell plc 43

Success Case 02 Albian Sands Energy Shell Gadus S4 OGK/OGXK Saddle Block Liners

1 2 3 CHALLENGE SOLUTION OUTCOME

VALUE 4

Albian Sands Energy in Fort McMurray Canada operates 10 Bucyrus 495 HF shovels.

The key challenge was cold temperature and the ability of the product to not just pump through the system, but be robust enough that it provided the best lubrication during winter.

Shell, through Shell LubeExpert, made a detailed analysis and inspection of the application and proposed the use of a high-performance lubricant for saddle block liners, open gears, boom and revolving frame (Shell Gadus S4 OGK/OGXK).

By implementing of a routine inspection process of the lubrication system and the critical components of the shovels, together with the application of high performance grease (Gadus S4 OGK/OGXK) the saddle block liners life achieved over 32,000 hrs against a estimated life of 10,000 hrs.

Savings of over USD 1,800,000.00/year with increase of productivity and with life extension of saddle block liners

Increased saddle block liners life from 10,000 hrs to 32,000 hrs

The savings indicated are specific to the calculation date and mentioned site. These calculations may vary from site to site, depending on the application, the operating conditions, the current products being used, the condition of the equipment and maintenance practices.

-

Copyright of Royal Dutch Shell plc 44

Success Case 03 Iron Ore Mining in Brazil Shell Gadus S3 V220C 2 Bearing of the Bucket Wheel

1 2 3 CHALLENGE SOLUTION OUTCOME

VALUE 4

Iron ore mining in Brazil operates a ThyssenKrupp 5PA5A reclaimer.

The challenge was increase the bearing of the bucket wheel life beyond the current 4,000 hrs.

Shell, through Shell LubeExpert, identified the failures causes and proposed the use of a high-performance grease (Shell Gadus S3 V220C 2).

By implementation of a routine inspection process of the lubrication system, resizing of bearings sealing and application of a high performance grease (Gadus S3 V220C 2), the bearing life increased from 4,000 hrs to over 8,600 hrs.

Savings of over USD 2,000,000.00/year with increase of productivity and with life extension of the bucket wheel bearing

Increased bucket wheel bearing life from 4,000 hrs to 8,600 hrs

Significantly reduction the reclaimer unavailability and therefore increased its productivity

The savings indicated are specific to the calculation date and mentioned site. These calculations may vary from site to site, depending on the application, the operating conditions, the current products being used, the condition of the equipment and maintenance practices.

-

Copyright of Royal Dutch Shell plc 45

Success Case 04 The Lagunas Norte Mine in Peru Shell Tactic EMV Conveyor Belt Bearings

1 2 3 CHALLENGE SOLUTION OUTCOME

VALUE

Lagunas Norte was previously using Shell Gadus S2 V220 2 grease for manual lubrication. The greasing schedule was not always completed, and irregular lubrication, together with contamination by dirt, dust and water, was causing the production belt bearings to wear. Consequently, the company experienced unscheduled stoppages and production losses.

Shell Lubricants recommended the installation of a Shell Tactic EMV automated grease dispensing unit pre-filled with Shell Gadus S3 T220 2 grease, and staff training using the Shell LubeCoach service. Shell Tactic EMV lubricating units were installed at two critical production points to supply precise, reliable and regular amounts of grease to the machines.

After implementing the recommended solution, Lagunas Norte experienced: a decrease in manual lubrication time that enabled technical staff to attend previously neglected areas. the elimination of premature bearing failures through reliable and regular lubrication. peace of mind from knowing that the greasing was automated and set specifically for the machines requirements.

By identifying the mines need for greasing support and a premium grease to perform well in a high-contamination environment, Shell was able to recommend a solution that met both requirements. Lagunas Norte reported a potential annual saving of US$167,417 as a result of implementing the solution.

The savings indicated are specific to the calculation date and mentioned site. These calculations may vary from site to site, depending on the application, the operating conditions, the current products being used, the condition of the equipment and maintenance practices.