GRAVITY CONVEYOR · SPEC SHEET CATALOG Ultimation Industries LLC 15935 Sturgeon St. Roseville, MI...

Transcript of GRAVITY CONVEYOR · SPEC SHEET CATALOG Ultimation Industries LLC 15935 Sturgeon St. Roseville, MI...

SPEC SHEET CATALOG

Ul t imat ion Indust r ies LLC

15935 Stu rgeon St.Rosev i l le, MI 48066

Ph. +1-586-771-1881

ul t imat ion inc.com

GRAVITY CONVEYOR

Safety Orange110559RAL-2010

Machinery Grey 110652RAL-7011

Safety Blue110552RAL-5019

Conveyor Blue110549

Dark Green110555RAL-6005

Conveyor Gray Safety Yellow110554RAL-1023

Light Ivory 115174RAL-1015

Gloss Black111233RAL-9005(Textured black available)

Gloss White111232RAL-9003

Colors illustrated below may vary slightly from actual paint colors.

Standard Paint Colors

Conveyor Green115886

nAll safety guarding to be safety yellow unless

otherwise specified.

nOther items available, please contact factory.

nOther colors available on request

Dark Blue 114815

Light BlueRAL-5012

Sky BlueRAL-5015

48 HOUR

SHIP COLOR

Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

TABLE OF CONTENTSBELT CONVEYORS

Horizontal belt conveyor ............................................................... 1-8

Belt curve .........................................................................................9

Incline belt conveyor ..................................................................10-13

Incline dimensional chart ................................................................14

Bed and undertrussing information .................................................15

Troughed belt conveyor..............................................................16-19

LIVE ROLLER CONVEYORS

Belt driven live roller conveyor (transportation) ..........................20-21

Belt driven live roller conveyor (minimum pressure) ...................22-23

Belt driven live roller conveyor (zero pressure) ...................... 23A-23B

Flat motor conveyor (transportation) ..................................... 23C-23E

Flat motor conveyor (zero pressure) ...................................... 23F-23H

V-belt driven live roller conveyor (minimum pressure) ................24-39

Lineshaft conveyor .....................................................................40-43

Chain driven live roller conveyor (transportation) .......................44-54

CHAIN CONVEYORS

Drag chain conveyor (transportation) .........................................55-58

GRAVITY CONVEYOR

Skatewheel conveyor .................................................................59-61

Gravity roller conveyor ...............................................................62-72

Ball transfer table ...........................................................................73

Conveyor rail...................................................................................74

ACCESSORIES

Supports ....................................................................................75-78

Guide rails ......................................................................................79

Stops .........................................................................................80-82

Gates .........................................................................................83-84

ELECTRICAL CONTROLS

ProLogic Accumulation System ..................................................85-86

Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

59Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

WSS/WASGravity skatewheel conveyor is ideal for conveying light packages or for applications where conveyor portability is desired. They are useful for temporary conveyor lines in assembly and delivery operations.

STEEL FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

5' 10' 5' 10' 5' 10' 5' 10'

WSS3-12-10 10 37 70 WSS3-15-10 10 40 73 WSS3-18-16 16 46 87 WSS3-24-20 20 57 103

WSS3-12-12 12 39 74 WSS3-15-12 12 43 78 WSS3-18-18 18 49 92 WSS3-24-24 24 62 112

WSS3-12-16 16 42 81 WSS3-15-16 16 48 87 WSS3-18-20 20 54 98 WSS3-24-28 28 65 118

n 4 widths n Powder coated steel or aluminum frames n Portable or permanent installation

STANDARD SPECIFICATIONSFRAME - 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members

WIDTHS - 12 in., 15 in., 18 in., and 24 in. overall width

LENGTHS - 5 ft. and 10 ft. straight sections

COUPLINGS - Bolts one end, hooks on opposite end

WHEELS - 1 15/16 in. dia. ball bearings run in hardened raceway with life time lubrication. Corrosion-resistant aluminum or zinc plated steel.

AXLES - 1/4 in. dia. threaded one end with locknut on 3 in. centers

LOAD CAPACITY (LBS.)

FRAME MATERIAL

SUPPORT CENTERS

FRAME CAPACITY WHEEL CAPACITY

MAX. DISTRIBUTED LIVE LOAD PER FOOT

MAX. STATIC LOAD PER WHEEL

STEEL5' 260

6510' 35

ALUMINUM5' 142

5010' 16

GRAVITY SKATEWHEEL CONVEYOR

OPTIONAL EQUIPMENTSUPPORTS - Portable Tripod Supports, portable T-stand carriages and stationary floor supports are available in a wide range of adjust-ments

LENGTHS - Other lengths from 2 ft. to 10 ft.

WIDTHS - Other in-between widths from 12 in. to 30 in. overall width

WHEELS / COVERS - Black or white plastic wheels are available in place of steel or aluminum wheels. Black neoprene covers are also available.

BUTT COUPLINGS - In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

BETWEEN FRAME WIDTH

OVERALL WIDTH

1"

2-1/2"

3/8"

CROSS MEMBERAXLE AND SPACERS CENTER SUPPORT BARS

ALUMINUM FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

MODEL NO. WPFWT. (LBS.)

5' 10' 5' 10' 5' 10' 5' 10'

WAS3-12-10 10 20 36 WAS3-15-10 10 22 39 WAS3-18-16 16 25 46 WAS3-24-20 20 30 55

WAS3-12-12 12 21 39 WAS3-15-12 12 23 41 WAS3-18-18 18 27 49 WAS3-24-24 24 32 59

WAS3-12-16 16 23 43 WAS3-15-16 16 26 43 WAS3-18-20 20 28 52 WAS3-24-28 28 34 63

OVERALL LENGTH 1-9/16"

COUPLING BOLT GRAVITY HOOKCROSS MEMBER

60Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

2-1/2"

3/8"

WSC/WACGravity skatewheel curves are compatible with straight section providing flexibility to your conveyor line. The differential action of wheels assures proper orientation of packages.

STEEL FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.)

WSC-12-30 30 30 14 WSC-15-30 30 40 16 WSC-18-30 30 45 18 WSC-24-30 30 60 23

WSC-12-45 45 30 21 WSC-15-45 45 40 23 WSC-18-45 45 45 25 WSC-24-45 45 78 37

WSC-12-60 60 42 30 WSC-15-60 60 56 35 WSC-18-60 60 63 37 WSC-24-60 60 102 54

WSC-12-90 90 63 40 WSC-15-90 90 84 46 WSC-18-90 90 94 49 WSC-24-90 90 156 72

n 4 widths n Powder coated steel or aluminum frames n 30, 45, 60 and 90 degree curves

STANDARD SPECIFICATIONSFRAME - 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members

WIDTHS - 12 in., 15 in., 18 in., and 24 in. overall width

CURVES - 30, 45, 60 and 90 degree curves. See radius chart

COUPLINGS - Hooks and bolts on both ends of curve

WHEELS - 1 15/16 in. dia., ball bearings run in hardened raceway with life time lubrication. Corrosion-resistant aluminum or zinc plated steel.

AXLES - 1/4 in. dia. threaded one end with locknut on 3 in. equivalent centers

RADIUSOVERALL WIDTH INSIDE RADIUS OUTSIDE RADIUS

12" 36" 48"

15" 33" 48"

18" 30" 48"

24" 36" 60"

GRAVITY SKATEWHEEL CURVE CONVEYOR

ALUMINUM FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.) MODEL NO. DEGREE WPC WT. (LBS.)

WAC-12-30 30 30 8 WAC-15-30 30 40 9 WAC-18-30 30 45 10 WAC-24-30 30 60 14

WAC-12-45 45 30 12 WAC-15-45 45 40 14 WAC-18-45 45 45 15 WAC-24-45 45 78 23

WAC-12-60 60 42 17 WAC-15-60 60 56 20 WAC-18-60 60 63 21 WAC-24-60 60 102 33

WAC-12-90 90 63 22 WAC-15-90 90 84 26 WAC-18-90 90 94 28 WAC-24-90 90 156 43

OPTIONAL EQUIPMENTSUPPORTS - Tripod Supports, portable T-stand carriages and sta-tionary floor supports are available in a wide range of adjustments

SPECIAL DEGREE CURVES - Contact factory

WIDTHS - Other in-between widths from 12 in. to 30 in. overall width

WHEELS/COVERS - Black or white plastic wheels are available in place of steel or aluminum wheels. Black neoprene covers are also available.

BUTT COUPLINGS - In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

INSIDE RADIUS

OUTSIDE RADIUS

BETWEEN FRAME WIDTH

OVERALL WIDTH

1"

CROSS MEMBERAXLE AND SPACERS CENTER SUPPORT BARS

61Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

WSL/WSR WAL/WARGravity skatewheel spurs are used to transfer product from one conveying line onto another. They are suitable for merging or diverging applications.

STEEL FRAMES

OAW30° SPUR 45° SPUR 90° SPUR

MODEL NO. "A" WPS WT. (LBS.) MODEL NO. "A" WPS WT. (LBS.) MODEL NO. "A" "B" "R" WPS WT. (LBS.)

12" WS(L/R)-12-30 24 3/8" 51 39 WS(L/R)-12-45 21" 54 39 WS(L/R)-12-90 30" 39 1/8" 36" 46 67

15" WS(L/R)-15-30 30 3/8" 67 43 WS(L/R)-15-45 30" 70 43 WS(L/R)-15-90 39" 35 5/8" 33" 56 72

18" WS(L/R)-18-30 36 3/8" 71 47 WS(L/R)-18-45 30" 77 47 WS(L/R)-18-90 39" 32 11/16" 30" 60 77

24" WS(L/R)-24-30 48 3/8" 83 57 WS(L/R)-24-45 39" 97 57 WS(L/R)-24-90 51" 39 1/2" 36" 94 107

n 4 widths

n Powder coated steel or aluminum frames

n 30, 45 and 90 degree spurs

STANDARD SPECIFICATIONSFRAME – 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members

WIDTHS – 12 in., 15 in., 18 in., and 24 in. overall width

SPUR ANGLES - 30, 45 and 90 degree. Specify right hand or left hand.

COUPLINGS – Hooks and bolts one end. Shelf angle on the opposite end. Specify shelf angle mounting bracket.

WHEELS – 1 15/16 in. dia., ball bearings run in hardened raceway with life time lubrication. Corrosion-resistant aluminum or zinc plated steel.

AXLES – 1/4 in. dia. threaded one end with locknut on 3 in. centers

GRAVITY SKATEWHEEL SPUR CONVEYOR

OPTIONAL EQUIPMENTSUPPORTS – Tripod stands and stationary floor supports are avail-able in a wide range of adjustments

WIDTHS – Other in-between widths from 12 in. to 30 in. overall width

WHEELS/COVERS – Black or white plastic wheels are available in place of steel or aluminum wheels. Black neoprene covers are also available.

BUTT COUPLINGS – In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS – Adjustable channel guide rails, fixed angle and channel guide rails

ALUMINUM FRAMES

OAW30° SPUR 45° SPUR 90° SPUR

MODEL NO. "A" WPS WT. (LBS.) MODEL NO. "A" WPS WT. (LBS.) MODEL NO. "A" "B" "R" WPS WT. (LBS.)

12" WA(L/R)-12-30 24 3/8" 51 26 WA(L/R)-12-45 21" 54 26 WA(L/R)-12-90 30" 39 1/8" 36" 46 45

15" WA(L/R)-15-30 30 3/8" 67 29 WA(L/R)-15-45 30" 70 29 WA(L/R)-15-90 39" 35 5/8" 33" 56 47

18" WA(L/R)-18-30 36 3/8" 71 32 WA(L/R)-18-45 30" 77 32 WA(L/R)-18-90 39" 32 11/16" 30" 60 51

24" WA(L/R)-24-30 48 3/8" 83 38 WA(L/R)-24-45 39" 97 38 WA(L/R)-24-90 51" 39 1/2" 36" 94 71

30°/45° 90°

RIGHT HAND LEFT HANDRIGHT HAND LEFT HAND

SECTION VIEW X-X

CONVEYOR CHANNEL SIZE "H"

ORDER BY MOUNTING BRACKET NO.

2 1/2 x 12 ga. Steel ATL-10313

3 1/2 x 10 ga. Steel ATL-11745

6 1/2 x 12 ga. Steel ATL-13082

H

MOUNTING BRACKET

X

90°

"R""B"

"A"

43-3/8" 60"

60"

31-5/32"

45°30°

"A" "A"

X

SHELF ANGLE

62Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

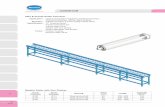

Gravity roller conveyor is ideal for conveying light packages or for applications where conveyor portability is desired. They are useful for temporary or permanent conveyor lines in assembly and warehouse operations.

STEEL FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

5' 10' 5' 10' 5' 10' 5' 10'

RS14G-12-1.5 1 1/2" 55 101 RS14G-15-1.5 1 1/2" 62 112 RS14G-18-1.5 1 1/2" 72 135 RS14G-24-1.5 1 1/2" 91 168

RS14G-12-3 3" 37 68 RS14G-15-3 3" 42 78 RS14G-18-3 3" 47 97 RS14G-24-3 3" 58 108

RS14G-12-4.5 4 1/2" 32 58 RS14G-15-4.5 4 1/2" 33 61 RS14G-18-4.5 4 1/2" 40 73 RS14G-24-4.5 4 1/2" 47 88

RS14G-12-6 6" 29 52 RS14G-15-16 6" 30 55 RS14G-18-6 6" 32 63 RS14G-24-6 6" 42 78

n 4 widths n Powder coated steel or aluminum frames n Portable or permanent installation

STANDARD SPECIFICATIONSFRAME - 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members

WIDTHS - 12 in., 15 in., 18 in., and 24 in. overall width

LENGTHS - 5 ft. and 10 ft. straight sections

COUPLINGS - Bolts one end, hooks on opposite end

ROLLERS - 1 3/8 in. dia. x 18 ga. galvanized steel or heat treated aluminum tube, 1/4 in. dia. spring retained axle, oiled ball bearings both ends

ROLLER CENTERS - 1 1/2 in., 3 in., 4 1/2 in., or 6 in. centers

GRAVITY ROLLER CONVEYOR (1 3/8 in. dia. x 18 ga. rollers)

OPTIONAL EQUIPMENTSUPPORTS - Tripod supports, portable T-stand carriages and station-ary floor supports are available in a wide range of adjustments

LENGTHS - Other lengths from 2 ft. to 10 ft.

WIDTHS - Other in-between widths from 12 in. to 30 in. overall width

BUTT COUPLINGS - In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

BETWEEN FRAME WIDTH

OVERALL WIDTH

1"

2-1/2"

3/32"

CROSS MEMBER1-3/8" DIA. ROLLER

ALUMINUM FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

MODEL NO.ROLL

CENTERSWT. (LBS.)

5' 10' 5' 10' 5' 10' 5' 10'

RS14A-12-1.5 1 1/2" 29 53 RS14A-15-1.5 1 1/2" 33 56 RS14A-18-1.5 1 1/2" 38 70 RS14A-24-1.5 1 1/2" 48 88

RS14A-12-3 3" 20 36 RS14A-15-3 3" 23 41 RS14A-18-3 3" 27 51 RS14A-24-3 3" 30 56

RS14A-12-4.5 4 1/2" 17 30 RS14A-15-4.5 4 1/2" 18 32 RS14A-18-4.5 4 1/2" 20 38 RS14A-24-4.5 4 1/2" 25 46

RS14A-12-6 6" 15 27 RS14A-15-16 6" 16 29 RS14A-18-6 6" 18 33 RS14A-24-6 6" 22 41

OVERALL LENGTH 1-9/16"

COUPLING BOLT GRAVITY HOOKCROSS MEMBER

RS14

FRAME CAPACITY

FRAMEMATERIAL

SUPPORTCENTERS

MAX. DISTRIBUTEDLIVE LOAD PER FOOT

Steel5' 260

10' 35

Aluminum5' 142

10' 16

ROLLER CAPACITY

BETWEEN FRAMES

MAX. STATIC LOAD PER ROLLER (LBS.)

10" 85

13" 65

16" 50

22" 35

28" 25

63Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

2-1/2"

3/32"

Gravity roller curves are compatible with straight sections providing flexibility to your conveyor line. Curves will convey product with a minimum amount of pitch based on weight and size.

STEEL FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.)

RC14G-12-3-30 30 18 RC14G-15-3-30 30 22 RC14G-18-3-30 30 26 RC14G-24-3-30 30 42

RC14G-12-3-45 45 35 RC14G-15-3-45 45 40 RC14G-18-3-45 45 44 RC14G-24-3-45 45 66

RC14G-12-3-60 60 52 RC14G-15-3-60 60 53 RC14G-18-3-60 60 62 RC14G-24-3-60 60 108

RC14G-12-3-90 90 70 RC14G-15-3-90 90 75 RC14G-18-3-90 90 80 RC14G-24-3-90 90 141

n 4 widths n Powder coated steel or aluminum frames n 30, 45, 60 and 90 degree curves

STANDARD SPECIFICATIONSFRAME - 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members.

WIDTHS - 12 in., 15 in., 18 in. and 24 in. overall width

CURVES - 30, 45, 60 and 90 degree curves. See radius chart

COUPLINGS - Hooks and bolts on both ends of curve

ROLLERS - Straight or tapered, oiled ball bearings both ends • Straight rollers - 1 3/8 in. dia. x 18 ga. galvanized steel or heat treated aluminum tube, 1/4 in. dia. spring retained axle • Tapered rollers - 1 1/2 in. dia. large end, galvanized steel tapered tube, 5/16 in. spring retained hex axle

ROLLER CENTERS - 3 in. equivalent centers

RADIUSSTRAIGHT ROLLERS TAPERED ROLLERS

OVERALL WIDTH INSIDE RADIUS OUTSIDE RADIUS INSIDE RADIUS OUTSIDE RADIUS

12" 24" 36" 24" 36"

15" 24" 39" 24" 39"

18" 24" 42" 24" 42"

24" 24" 48" 31 1/2" 55 1/2"

ALUMINUM FRAMES12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.)

RC14A-12-3-30 30 8 RC14A-15-3-30 30 10 RC14A-18-3-30 30 12 RC14A-24-3-30 30 14

RC14A-12-3-45 45 14 RC14A-15-3-45 45 17 RC14A-18-3-45 45 18 RC14A-24-3-45 45 26

RC14A-12-3-60 60 21 RC14A-15-3-60 60 24 RC14A-18-3-60 60 27 RC14A-24-3-60 60 38

RC14A-12-3-90 90 28 RC14A-15-3-90 90 31 RC14A-18-3-90 90 35 RC14A-24-3-90 90 50

OPTIONAL EQUIPMENTSUPPORTS - Tripod supports, portable T-stand carriages and station-ary floor supports are available in a wide range of adjustments

SPECIAL DEGREE CURVES - Contact factory

WIDTHS - Other in-between widths from 12 in. to 30 in. overall width

ROLLER CENTERS - 1 1/2 in. equivalent centers

BUTT COUPLINGS - In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

INSIDE RADIUS

OUTSIDE RADIUS

RC14

STEEL FRAMES - TAPERED ROLLERS12" OAW 15" OAW 18" OAW 24" OAW

MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.) MODEL NO. DEGREE WT. (LBS.)

RC14G-12-3-30T 30 18 RC14G-15-3-30T 30 22 RC14G-18-3-30T 30 26 RC14G-24-3-30T 30 42

RC14G-12-3-45T 45 35 RC14G-15-3-45T 45 40 RC14G-18-3-45T 45 44 RC14G-24-3-45T 45 66

RC14G-12-3-60T 60 52 RC14G-15-3-60T 60 53 RC14G-18-3-60T 60 62 RC14G-24-3-60T 60 108

RC14G-12-3-90T 90 70 RC14G-15-3-90T 90 75 RC14G-18-3-90T 90 80 RC14G-24-3-90T 90 141

BETWEEN FRAME WIDTH

OVERALL WIDTH

1"

CROSS MEMBER1-3/8" DIA. ROLLER

GRAVITY ROLLER CURVE CONVEYOR (1 3/8 in. dia. x 18 ga. rollers)

64Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Gravity roller spurs are used to transfer product from one conveying line onto another. They are suitable for merging or diverging applications.

STEEL FRAMES

OAW30° SPUR 45° SPUR 90° SPUR

MODEL NO. "A" WT. (LBS.) MODEL NO. "A" WT. (LBS.) MODEL NO. "A" WT. (LBS.)

12" R(L/R)14G-12-30 24" 61 R(L/R)14G-12-45 18" 63 R(L/R)14G-12-90 35" 43

15" R(L/R)14G-15-30 30" 70 R(L/R)14G-15-45 22" 73 R(L/R)14G-15-90 35" 47

18" R(L/R)14G-18-30 36" 75 R(L/R)14G-18-45 26" 80 R(L/R)14G-18-90 35" 50

24" R(L/R)14G-24-30 48" 87 R(L/R)14G-24-45 35" 97 R(L/R)14G-24-90 50" 58

n 4 widths n Powder coated steel or aluminum frames n 30, 45, and 90 degree spurs

STANDARD SPECIFICATIONSFRAME - 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel or 1/8 in. aluminum channel with bolt-in cross members

WIDTHS - 12 in., 15 in., 18 in., and 24 in. overall width

SPUR ANGLES - 30, 45 and 90 degree. Specify right hand or left hand.

COUPLINGS - Hook and bolts one end. Shelf angle on the opposite end. Specify shelf angle mounting bracket.

ROLLERS - 1 3/8 in. dia. x 18 ga. galvanized steel or heat treated aluminum tube, 1/4 in. dia. spring retained axle, oiled ball bearings both ends

ROLLER CENTER - 1 1/2 in. centers

OPTIONAL EQUIPMENTSUPPORTS - Tripod supports and stationary floor supports are avail-able in a wide range of adjustments

WIDTHS - Other in-between widths from 12 in. to 30 in. overall width

BUTT COUPLINGS - In place of hooks and bolts, these brackets allow a more permanent connection with adjacent conveyor

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

ALUMINUM FRAMES

OAW30° SPUR 45° SPUR 90° SPUR

MODEL NO. "A" WT. (LBS.) MODEL NO. "A" WT. (LBS.) MODEL NO. "A" WT. (LBS.)

12" R(L/R)14A-12-30 24" 40 R(L/R)14A-12-45 18" 41 R(L/R)14A-12-90 35" 33

15" R(L/R)14A-15-30 30" 46 R(L/R)14A-15-45 22" 48 R(L/R)14A-15-90 35" 35

18" R(L/R)14A-18-30 36" 50 R(L/R)14A-18-45 26" 52 R(L/R)14A-18-90 35" 37

24" R(L/R)14A-24-30 48" 58 R(L/R)14A-24-45 35" 63 R(L/R)14A-24-90 50" 41

30°/45° 90°

RIGHT HAND LEFT HANDRIGHT HAND LEFT HAND

SECTION VIEW X-X

CONVEYOR CHANNEL SIZE "H"

ORDER BY MOUNTING BRACKET NO.

2 1/2 x 12 Ga. Steel ATL-10313

3 1/2 x 10 Ga. Steel ATL-11745

6 1/2 x 12 Ga. Steel ATL-13082

H

MOUNTING BRACKET

X

90°

24"25-1/2"

"A"

43-3/16" 60"

60"

31"

"A" "A"

X

SHELF ANGLE

RL14/RR14GRAVITY ROLLER SPUR CONVEYOR (1 3/8 in. dia. x 18 ga. rollers)

65Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Gravity roller conveyor is ideal for conveying light or medium weight packages. They are useful for assembly, warehousing, or shipping applications.

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLER

CENTERSWT. (LBS.)

1.9" X 16 GA.

UNPLATED GALVANIZED 5' 10'

13" 16"

RS19U-13-2.25 RS19G-13-2.25 2 1/4" 97 193

RS19U-13-3 RS19G-13-3 3" 83 159

RS19U-13-4.5 RS19G-13-4.5 4 1/2" 67 129

RS19U-13-6 RS19G-13-6 6" 60 113

15" 18"

RS19U-15-2.25 RS19G-15-2.25 2 1/4" 103 210

RS19U-15-3 RS19G-15-3 3" 89 170

RS19U-15-4.5 RS19G-15-4.5 4 1/2" 71 137

RS19U-15-6 RS19G-15-6 6" 64 120

17" 20"

RS19U-17-2.25 RS19G-17-2.25 2 1/4" 113 226

RS19U-17-3 RS19G-17-3 3" 97 184

RS19U-17-4.5 RS19G-17-4.5 4 1/2" 77 147

RS19U-17-6 RS19G-17-6 6" 68 127

19" 22"

RS19U-19-2.25 RS19G-19-2.25 2 1/4" 121 242

RS19U-19-3 RS19G-19-3 3" 108 207

RS19U-19-4.5 RS19G-19-4.5 4 1/2" 85 163

RS19U-19-6 RS19G-19-6 6" 73 139

21" 24"

RS19U-21-2.25 RS19G-21-2.25 2 1/4" 129 258

RS19U-21-3 RS19G-21-3 3" 111 211

RS19U-21-4.5 RS19G-21-4.5 4 1/2" 87 168

RS19U-21-6 RS19G-21-6 6" 77 141

23" 26"

RS19U-23-2.25 RS19G-23-2.25 2 1/4" 137 274

RS19U-23-3 RS19G-23-3 3" 118 229

RS19U-23-4.5 RS19G-23-4.5 4 1/2" 93 179

RS19U-23-6 RS19G-23-6 6" 81 152

25" 28"

RS19U-25-2.25 RS19G-25-2.25 2 1/4" 145 290

RS19U-25-3 RS19G-25-3 3" 126 241

RS19U-25-4.5 RS19G-25-4.5 4 1/2" 97 187

RS19U-25-6 RS19G-25-6 6" 85 158

27" 30"

RS19U-27-2.25 RS19G-27-2.25 2 1/4" 153 307

RS19U-27-3 RS19G-27-3 3" 133 255

RS19U-27-4.5 RS19G-27-4.5 4 1/2" 102 196

RS19U-27-6 RS19G-27-6 6" 89 166

31" 34"

RS19U-31-2.25 RS19G-31-2.25 2 1/4" 169 340

RS19U-31-3 RS19G-31-3 3" 146 278

RS19U-31-4.5 RS19G-31-4.5 4 1/2" 112 214

RS19U-31-6 RS19G-31-6 6" 97 179

33" 36"

RS19U-33-2.25 RS19G-33-2.25 2 1/4" 177 356

RS19U-33-3 RS19G-33-3 3" 154 292

RS19U-33-4.5 RS19G-33-4.5 4 1/2" 117 224

RS19U-33-6 RS19G-33-6 6" 101 187

37" 40"

RS19U-37-2.25 RS19G-37-2.25 2 1/4" 193 389

RS19U-37-3 RS19G-37-3 3" 164 311

RS19U-37-4.5 RS19G-37-4.5 4 1/2" 124 238

RS19U-37-6 RS19G-37-6 6" 108 198

39" 42"

RS19U-39-2.25 RS19G-39-2.25 2 1/4" 201 405

RS19U-39-3 RS19G-39-3 3" 173 328

RS19U-39-4.5 RS19G-39-4.5 4 1/2" 130 250

RS19U-39-6 RS19G-39-6 6" 112 207

n 12 widths n 4 roller centers n Powder coated steel frames

STANDARD SPECIFICATIONSFRAME - 3 1/2 in. deep x 1 1/2 in. flange x 10 ga. powder coated steel channel with bolt-in cross members

WIDTHS - 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in. and 39 in. between frames

LENGTHS - 5 ft. and 10 ft. straight sections

COUPLINGS - Butt type for bolting sections together

ROLLERS - 1.9 in. dia. x 16 ga. unplated or galvanized steel tube, 7/16 in. spring hex retained axle, grease packed ball bearings both ends.

ROLLER CENTERS - 2 1/4 in., 3 in., 4 1/2 in. or 6 in. centers

OPTIONAL EQUIPMENTSUPPORTS - Stationary floor supports are available in a wide range of adjustments

LENGTHS - Other lengths from 2 ft. to 10 ft.

WIDTHS - Other in-between widths from 10 in. to 60 in. between frames

ROLLERS SET LOW - Rollers set 3/4 in. low in 4 1/2 in. deep x 1 1/2 in. flange x 10 ga. powdered coated steel channel

ROLLERS - 1.9 in. dia. x 9 ga. unplated steel tube, 7/16 in. spring retained hex axle, grease packed ball bearings both ends

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

RS19GRAVITY ROLLER CONVEYOR (1.9 in. dia. x 16 ga. rollers)

BETWEEN FRAME WIDTH

OVERALL WIDTH

3-1/2"

1/4"

1.9" DIA. ROLLER

1-1/2"

BETWEEN FRAME WIDTH

OVERALL WIDTH

4-1/2"

3/4"

1.9" DIA. ROLLER

ROLLERS SET HIGH

ROLLERS SET LOW

Specification Sheet – 03/09/15 – R1

FRAME CAPACITY

SUPPORTCENTERS

MAX. DISTRIBUTEDLIVE LOAD

PER FOOT (LBS.)

5' 660

10' 120

ROLLER CAPACITY

BETWEEN FRAMES

MAX. STATIC LOAD PER ROLLER (LBS.)

1.9 X 16 GA. 1.9 x 9 GA.

13"-29" 265 290

31"-45" 195 165

47"-60" 100 80

66Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Gravity roller curves are compatible with straight section providing flexibility to your conveyor line. Curves will convey product with a minimum amount of pitch based on weight and size. n 12 widths n Powder coated steel frames n 30, 45, 60 and 90 degree curves

STANDARD SPECIFICATIONSFRAME - 3 1/2 in. deep x 1 1/2 in. flange x 10 ga. powder coated steel channel with bolt-in cross members

WIDTHS - 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in. and 39 in. between frame width

CURVES - 30, 45, 60 and 90 degree curves. 32 1/2 in. or 48 in. radius dependent upon between frame width

COUPLINGS - Butt type for bolting sections together

ROLLERS - 1.9 in. dia. x 16 ga. unplated or galvanized steel tube, 7/16 in. spring retained hex axle, grease packed ball bearings both ends. Note: When between frame width exceeds 21 in., dual lane rollers are supplied.

ROLLER CENTERS - 3 in. equivalent centers

OPTIONAL EQUIPMENTSUPPORTS - Stationary floor supports are available in a wide range of adjustments

SPECIAL DEGREE CURVES - Contact factory

WIDTHS - Other in-between widths from 10 in. to 63 in. between frames. Does not apply to tapered rollers.

ROLLERS SET LOW - Rollers set 3/4 in. low in 4 1/2 in. deep x 1 1/2 in. flange x 10 ga. powdered coated steel channel

ROLLERS - Straight or tapered, 7/16 in. spring retained hex axle, grease packed ball bearings both ends. • 1.9 in. dia. x 9 ga. unplated steel tube • 2 1/2 in. to 1 11/16 in. dia. unplated steel tapered tube

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

INSIDE RADIUS

RC19GRAVITY ROLLER CURVE CONVEYOR (1.9 in. dia. x 16 ga. rollers)

30° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVE

WT. (LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" RC19U-13-30 RC19G-13-30

32 1/2"

7 32

15" 18" RC19U-15-30 RC19G-15-30 7 35

17" 20" RC19U-17-30 RC19G-17-30 7 38

19" 22" RC19U-19-30 RC19G-19-30 7 40

21" 24" RC19U-21-30 RC19G-21-30 7 43

23" 26" RC19U-23-30D RC19G-23-30D 12 53

25" 28" RC19U-25-30D RC19G-25-30D 12 56

27" 30" RC19U-27-30D RC19G-27-30D 12 58

31" 34" RC19U-31-30D RC19G-31-30D

48"

12 70

33" 36" RC19U-33-30D RC19G-33-30D 12 73

37" 40" RC19U-37-30D RC19G-37-30D 12 79

39" 42" RC19U-39-30D RC19G-39-30D 12 82

45° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVE

WT. (LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" RC19U-13-45 RC19G-13-45

32 1/2"

11 50

15" 18" RC19U-15-45 RC19G-15-45 11 53

17" 20" RC19U-17-45 RC19G-17-45 11 58

19" 22" RC19U-19-45 RC19G-19-45 11 63

21" 24" RC19U-21-45 RC19G-21-45 11 67

23" 26" RC19U-23-45D RC19G-23-45D 22 82

25" 28" RC19U-25-45D RC19G-25-45D 22 85

27" 30" RC19U-27-45D RC19G-27-45D 22 89

31" 34" RC19U-31-45D RC19G-31-45D

48"

22 108

33" 36" RC19U-33-45D RC19G-33-45D 22 112

37" 40" RC19U-37-45D RC19G-37-45D 22 120

39" 42" RC19U-39-45D RC19G-39-45D 22 124

60° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVE

WT. (LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" RC19U-13-60 RC19G-13-60

32 1/2"

14 65

15" 18" RC19U-15-60 RC19G-15-60 14 70

17" 20" RC19U-17-60 RC19G-17-60 14 76

19" 22" RC19U-19-60 RC19G-19-60 14 81

21" 24" RC19U-21-60 RC19G-21-60 14 87

23" 26" RC19U-23-60D RC19G-23-60D 32 107

25" 28" RC19U-25-60D RC19G-25-60D 32 113

27" 30" RC19U-27-60D RC19G-27-60D 32 118

31" 34" RC19U-31-60D RC19G-31-60D

48"

32 141

33" 36" RC19U-33-60D RC19G-33-60D 32 147

37" 40" RC19U-37-60D RC19G-37-60D 32 159

39" 42" RC19U-39-60D RC19G-39-60D 32 165

90° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVE

WT. (LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" RC19U-13-90 RC19G-13-90

32 1/2"

22 97

15" 18" RC19U-15-90 RC19G-15-90 22 105

17" 20" RC19U-17-90 RC19G-17-90 22 114

19" 22" RC19U-19-90 RC19G-19-90 22 122

21" 24" RC19U-21-90 RC19G-21-90 22 131

23" 26" RC19U-23-90D RC19G-23-90D 42 161

25" 28" RC19U-25-90D RC19G-25-90D 42 169

27" 30" RC19U-27-90D RC19G-27-90D 42 177

31" 34" RC19U-31-90D RC19G-31-90D

48"

42 211

33" 36" RC19U-33-90D RC19G-33-90D 42 220

37" 40" RC19U-37-90D RC19G-37-90D 42 238

39" 42" RC19U-39-90D RC19G-39-90D 42 247

BETWEEN FRAME WIDTH

OVERALL WIDTH

3-1/2"

1/4"

1.9" DIA. ROLLER

1-1/2"

4-1/2"

3/4"

1.9" DIA. ROLLER

Dual lane rollers shown. Standard on conveyors having a between width greater than 21 inches.

ROLLERS SET HIGH ROLLERS SET LOW

BETWEEN FRAME WIDTH

OVERALL WIDTH

OUTSIDE RADIUS

Specification Sheet – 05/22/15 - R2

67Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

CONVEYOR CHANNEL SIZE "H" ORDER BY MOUNTING BRACKET NO.

3 1/2 x 10 ga. steel ATL-11745

6 1/2 x 12 ga. steel ATL-13082

Gravity roller spurs are used to transfer product from one conveying line onto another. They are suitable for merging or diverging applications.

n 12 widths n 30, 45 and 90 degree spurs n Right hand or left hand

STANDARD SPECIFICATIONSFRAME - 3 1/2 in. deep x 1 1/2 in. flange x 10 ga. powder coated steel channel with bolt-in cross members on 30 and 45 degree spurs; welded cross members in 90 degree spurs

WIDTHS - 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in. and 39 in. between frame width

SPUR ANGLES - 30, 45 and 90 degree. Specify right hand or left hand.

COUPLINGS - Butt type one end. Shelf angle on the opposite end. Specify shelf angle mounting bracket.

ROLLERS - 1.9 in. dia. x 16 ga. unplated or galvanized steel tube, 7/16 in. spring retained hex axle, grease packed ball bearings both ends. Note: When between frame width exceeds 21 in., dual lane rollers are supplied on 90 degree spur.

ROLLER CENTERS - 3 in. centers

OPTIONAL EQUIPMENTSUPPORTS - Stationary floor supports are available in a wide range of adjustments

WIDTHS - Other in-between widths from 10 in. to 63 in. between frames

ROLLERS - 1.9 in. dia. x 9 ga. unplated steel tube, 7/16 in. spring retained hex axle, grease packed ball bearings both ends

GUIDE RAILS - Adjustable channel guide rails, fixed angle and channel guide rails

SECTION VIEW X-X

H

MOUNTING BRACKET

SHELF ANGLE

RL19/RR19

30° SPUR

BETWEENFRAME WIDTH

OVERALLWIDTH

MODEL NO.

"A"WT.

(LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" R(L/R)19U-13-30 R(L/R)19G-13-30 37" 113

15" 18" R(L/R)19U-15-30 R(L/R)19G-15-30 39" 121

17" 20" R(L/R)19U-17-30 R(L/R)19G-17-30 45" 128

19" 22" R(L/R)19U-19-30 R(L/R)19G-19-30 48" 135

21" 24" R(L/R)19U-21-30 R(L/R)19G-21-30 51" 137

23" 26" R(L/R)19U-23-30 R(L/R)19G-23-30 56" 143

25" 28" R(L/R)19U-25-30 R(L/R)19G-25-30 60" 150

27" 30" R(L/R)19U-27-30 R(L/R)19G-27-30 63" 156

31" 34" R(L/R)19U-31-30 R(L/R)19G-31-30 72" 159

33" 36" R(L/R)19U-33-30 R(L/R)19G-33-30 75" 162

37" 40" R(L/R)19U-37-30 R(L/R)19G-37-30 84" 169

39" 42" R(L/R)19U-39-30 R(L/R)19G-39-30 87" 172

GRAVITY ROLLER SPUR CONVEYOR (1.9 in. dia. x 16 ga. rollers)

45° SPUR

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.

"A"WT.

(LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" R(L/R)19U-13-45 R(L/R)19G-13-45 27" 108

15" 18" R(L/R)19U-15-45 R(L/R)19G-15-45 30" 116

17" 20" R(L/R)19U-17-45 R(L/R)19G-17-45 33" 124

19" 22" R(L/R)19U-19-45 R(L/R)19G-19-45 36" 132

21" 24" R(L/R)19U-21-45 R(L/R)19G-21-45 39" 140

23" 26" R(L/R)19U-23-45 R(L/R)19G-23-45 42" 147

25" 28" R(L/R)19U-25-45 R(L/R)19G-25-45 45" 156

27" 30" R(L/R)19U-27-45 R(L/R)19G-27-45 48" 163

31" 34" R(L/R)19U-31-45 R(L/R)19G-31-45 54" 170

33" 36" R(L/R)19U-33-45 R(L/R)19G-33-45 57" 175

37" 40" R(L/R)19U-37-45 R(L/R)19G-37-45 63" 185

39" 42" R(L/R)19U-39-45 R(L/R)19G-39-45 66" 193

90° SPUR

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.

"A" "B"INSIDE RADIUS

WT.

(LBS.)1.9" X 16 GA.

UNPLATED GALVANIZED

13" 16" R(L/R)19U-13-90 R(L/R)19G-13-90 42"

33" 32 1/2"

92

15" 18" R(L/R)19U-15-90 R(L/R)19G-15-90 42" 100

17" 20" R(L/R)19U-17-90 R(L/R)19G-17-90 48" 109

19" 22" R(L/R)19U-19-90 R(L/R)19G-19-90 48" 117

21" 24" R(L/R)19U-21-90 R(L/R)19G-21-90 48" 126

23" 26" R(L/R)19U-23-90D R(L/R)19G-23-90D 54" 156

25" 28" R(L/R)19U-25-90D R(L/R)19G-25-90D 54" 164

27" 30" R(L/R)19U-27-90D R(L/R)19G-27-90D 54" 172

31" 34" R(L/R)19U-31-90D R(L/R)19G-31-90D 68"

48 1/2" 48"

206

33" 36" R(L/R)19U-33-90D R(L/R)19G-33-90D 78" 215

37" 40" R(L/R)19U-37-90D R(L/R)19G-37-90D 78" 233

39" 42" R(L/R)19U-39-90D R(L/R)19G-39-90D 78" 242

30°/45° 90°

RIGHT HAND

LEFT HAND

RIGHT HAND

LEFT HAND

"R""B"

"A"

60"81"

45°30°

90°

"A" "A"

x

x

68Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

The RS25 gravity roller conveyor is ideal for conveying medium or heavy weight packages. They are useful for assembly, warehousing, or shipping applications.

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLER

CENTERSWT. (LBS.)

2.5" X 11 GA.UNPLATED 5' 10'

13" 16 1/4"

RS25U-13-3 3" 185 364

RS25U-13-4 4" 155 303

RS25U-13-6 6" 125 242

15" 18 1/4"

RS25U-15-3 3" 200 390

RS25U-15-4 4" 170 330

RS25U-15-6 6" 135 260

17" 20 1/4"

RS25U-17-3 3" 215 420

RS25U-17-4 4" 180 350

RS25U-17-6 6" 145 280

19" 22 1/4"

RS25U-19-3 3" 234 458

RS25U-19-4 4" 192 375

RS25U-19-6 6" 151 292

21" 24 1/4"

RS25U-21-3 3" 245 480

RS25U-21-4 4" 200 390

RS25U-21-6 6" 160 310

23" 26 1/4"

RS25U-23-3 3" 260 510

RS25U-23-4 4" 210 410

RS25U-23-6 6" 165 320

25" 28 1/4"

RS25U-25-3 3" 282 552

RS25U-25-4 4" 230 447

RS25U-25-6 6" 177 342

27" 30 1/4"

RS25U-27-3 3" 297 594

RS25U-27-4 4" 235 460

RS25U-27-6 6" 180 350

31" 34 1/4"

RS25U-31-3 3" 312 636

RS25U-31-4 4" 267 519

RS25U-31-6 6" 203 391

33" 36 1/4"

RS25U-33-3 3" 345 678

RS25U-33-4 4" 265 520

RS25U-33-6 6" 200 390

37" 40 1/4"

RS25U-37-3 3" 355 700

RS25U-37-4 4" 285 560

RS25U-37-6 6" 215 420

39" 42 1/4"

RS25U-39-3 3" 375 740

RS25U-39-4 4" 285 580

RS25U-39-6 6" 220 430

43" 46 1/4"

RS25U-43-3 3" 415 820

RS25U-43-4 4" 305 620

RS25U-43-6 6" 225 450

47" 50 1/4"

RS25U-47-3 3" 455 900

RS25U-47-4 4" 325 660

RS25U-47-6 6" 235 470

51" 54 1/4"

RS25U-51-3 3" 495 980

RS25U-51-4 4" 345 700

RS25U-51-6 6" 245 490

55" 58 1/4"

RS25U-55-3 3" 535 1,060

RS25U-55-4 4" 365 740

RS25U-55-6 6" 255 550

n 3 roller centers

n Powder coated steel frames

STANDARD SPECIFICATIONSFRAME – 4 in. deep x 1 5/8 in. flange x 4 ga. powder coated steel channel with bolt-in cross members. Roller set high.

WIDTHS – 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in., 39 in., 43 in., 47 in., 51 in. and 55 in. between frames

LENGTH—5 ft. and 10 ft. standard

COUPLINGS – Butt type for bolting sections together

ROLLERS – 2 1/2 in. x 11 ga. unplated steel tube, 11/16 in. spring hex retained axle, grease packed ball bearings both ends.

ROLLER CENTERS – 3 in., 4 in. or 6 in. centers

OPTIONAL EQUIPMENTSUPPORTS– Floor supports are available in a wide range of adjustments

LENGTHS - Other lengths from 2 ft. to 10 ft.

WIDTHS – Other in-between widths from 7 in. to 67 in. between frames

ROLLERS SET LOW - Rollers set 3/4 in. low in 4 in. deep x 1 5/8 in. flange x 4 ga. steel channel with welded cross members

STRUCTURAL STEEL FRAMES – 4 in. x 5.4 lb., 5 in. x 6.7 lb. or 6 in. x 8.2 lb. powder coated structural steel channel. Rollers set high only

GUIDE RAILS - Fixed angle guide rails

END STOP – 6 in. x 8.2 lb. structural channel end stop

RS25GRAVITY ROLLER CONVEYOR (2 1/2 in. dia. x 11 ga. rollers)

BETWEEN FRAME WIDTH

OVERALL WIDTH

4"

3/8"

2-1/2" DIA. ROLLER

BETWEEN FRAME WIDTH

OVERALL WIDTH

4"

3/4"

2-1/2" DIA. ROLLER

ROLLERS SET HIGH

ROLLERS SET LOW

FRAME CAPACITY

SUPPORTCENTERS

MAX. DISTRIBUTEDLIVE LOAD

PER FOOT (LBS.)

5' 1620

10' 288

ROLLER CAPACITY

BETWEEN FRAMES

MAX. STATIC LOAD PER ROLLER (LBS.)

13"-41" 700

43"-55" 485

57"-67" 345

69Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Gravity roller curves are compatible with straight section providing flexibility to your conveyor line. Curves will convey product with a minimum amount of pitch based on weight and size.

n 15 widths n Powder coated steel frames n 30, 45, 60 and 90 degree curves

STANDARD SPECIFICATIONSFRAME – 4 in. deep x 1 5/8 in. flange x 4 ga. powder coated steel channel with bolt-in cross members. Roller set high.

WIDTHS – 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in., 39 in., 43 in., 47 in. and 51 in. between frames

CURVES – 30, 45, 60 and 90 degree curves. 32 1/2 in. or 48 in. inside radius dependent upon between width.

COUPLINGS – Butt type for bolting sections together

ROLLERS – 2 1/2 in. x 11 ga. unplated steel tube, 11/16 in. spring hex retained axle, grease packed ball bearings both ends

SUPPORTS - Floor supports are available in a wide range of adjust-ments

SPECIAL DEGREE CURVES - Contact factory

WIDTHS - Other in-between widths from 10 in. to 51 in. between frames

ROLLERS SET LOW - Rollers set 3/4 in. low in 4 in. deep x 1 5/8 in. flange x 4 ga. powdered coated steel channel with welded cross members

FRAMES – 4 in. x 5.4 lb. powder coated structural steel channel

GUIDE RAILS – Fixed angle guide rails

INSIDE RADIUS

RC25GRAVITY ROLLER CURVE CONVEYOR (2 1/2 in. dia. x 11 ga. rollers)

30° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVEWT. (LBS.)2.5" X 11 GA.

UNPLATED

13" 16 1/4" RC25U-13-30

32 1/2"5

Single

5715" 18 1/4" RC25U-15-30 6117" 20 1/4" RC25U-17-30 6619" 22 1/4" RC25U-19-30 7021" 24 1/4" RC25U-21-30 7523" 26 1/4" RC25U-23-30 8125" 28 1/4" RC25U-25-30 8627" 30 1/4" RC25U-27-30 9131" 34 1/4" RC25U-31-30D

48"13

Double

14333" 36 1/4" RC25U-33-30D 14837" 40 1/4" RC25U-37-30D 16139" 42 1/4" RC25U-39-30D 16743" 46 1/4" RC25U-43-30D 18147" 50 1/4" RC25U-47-30D 19251" 54 1/4" RC25U-51-30D 205

60° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVEWT. (LBS.)2.5" X 11 GA.

UNPLATED

13" 16 1/4" RC25U-13-60

32 1/2"10

Single

12815" 18 1/4" RC25U-15-60 13817" 20 1/4" RC25U-17-60 15019" 22 1/4" RC25U-25-60 15921" 24 1/4" RC25U-21-60 17323" 26 1/4" RC25U-23-60 18325" 28 1/4" RC25U-25-60 19527" 30 1/4" RC25U-27-60 20731" 34 1/4" RC25U-31-60D

48"23

Double

32433" 36 1/4" RC25U-33-60D 33937" 40 1/4" RC25U-37-60D 36639" 42 1/4" RC25U-39-60D 38143" 46 1/4" RC25U-43-60D 41047" 50 1/4" RC25U-47-60D 43851" 54 1/4" RC25U-51-60D 467

BETWEEN FRAME WIDTH

OVERALL WIDTH

4"

1/4"

2-1/2" DIA. ROLLER

1-1/2"

4"

3/4"

2-1/2" DIA. ROLLERROLLERS SET HIGH ROLLERS SET LOW

BETWEEN FRAME WIDTH

OVERALL WIDTH

OUTSIDE RADIUS

45° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVEWT. (LBS.)2.5" X 11 GA.

UNPLATED

13" 16 1/4" RC25U-13-45

32 1/2"8

Single

9115" 18 1/4" RC25U-15-45 9817" 20 1/4" RC25U-17-45 10619" 22 1/4" RC25U-19-45 11321" 24 1/4" RC25U-21-45 12123" 26 1/4" RC25U-23-45 12825" 28 1/4" RC25U-25-45 13627" 30 1/4" RC25U-27-45 14331" 34 1/4" RC25U-31-45D

48"19

Double

31133" 36 1/4" RC25U-33-45D 32337" 40 1/4" RC25U-37-45D 34839" 42 1/4" RC25U-39-45D 36043" 46 1/4" RC25U-43-45D 38547" 50 1/4" RC25U-47-45D 40851" 54 1/4" RC25U-51-45D 434

90° CURVE

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.INSIDERADIUS

ROLLERSPER

CURVEWT. (LBS.)2.5" X 11 GA.

UNPLATED

13" 16 1/4" RC25U-13-90

32 1/2"16

Single

17015" 18 1/4" RC25U-15-90 18517" 20 1/4" RC25U-17-90 20019" 22 1/4" RC25U-25-90 21221" 24 1/4" RC25U-21-90 23023" 26 1/4" RC25U-23-90 24525" 28 1/4" RC25U-25-90 26027" 30 1/4" RC25U-27-90 27631" 34 1/4" RC25U-31-90D

48"37

Double

43233" 36 1/4" RC25U-33-90D 45137" 40 1/4" RC25U-37-90D 48939" 42 1/4" RC25U-39-90D 50843" 46 1/4" RC25U-43-90D 45647" 50 1/4" RC25U-47-90D 48351" 54 1/4" RC25U-51-90D 622

Note: Dual lane rollers from 31" BF through 51" BF

OPTIONAL EQUIPMENT

70Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Gravity tapered roller curves are compatible with straight section providing flexibility to your conveyor line and aid in the alignment of packages.

n 12 widths n 30, 45, 60 and 90 degree curves n Aids in the alignment of packages

STANDARD SPECIFICATIONSFRAME – 4 in. deep x 1 5/8 in. flange x 4 ga. powder coated steel channel with bolt-in cross members. Roller set high.

WIDTHS – 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in., 39 in., 43 in., 47 in. and 51 in. between frames

CURVES – 30°, 45°, 60° and 90° with 39" inside radius

COUPLINGS – Butt type for bolting sections together

ROLLERS – Unplated tapered steel tube, 11/16 in. spring hex retained axle, and grease packed ball bearings both ends. See Chart for tube dimensions.

OPTIONAL EQUIPMENTSUPPORTS – Stationary floor supports are available in a wide range of adjustments

FRAMES – 4" x 4.5 lb. powder coated structural steel channel. Rollers set high only

GUIDE RAILS – Fixed angle guide rails

RC25TGRAVITY ROLLER CURVE CONVEYOR (Tapered rollers)

30° CURVE 45° CURVETAPERED ROLLER

DIMENSIONS

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLERS

PERCURVE

WT. (LBS.)

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLERS

PERCURVE

WT. (LBS.)

19" 22 1/4" RC25U-19-30T

5

93 19" 22 1/4" RC25U-19-45T

7

1222 1/2" TO 3 1/2"

11 Ga.21" 24 1/4" RC25U-21-30T 102 21" 24 1/4" RC25U-21-45T 126

23" 26 1/4" RC25U-23-30T 110 23" 26 1/4" RC25U-23-45T 155

25" 28 1/4" RC25U-25-30T 119 25" 28 1/4" RC25U-25-45T 140 2 1/2" TO 4"

11 GA.27" 30 1/4" RC25U-27-30T 128 27" 30 1/4" RC25U-27-45T 162

31" 34 1/4" RC25U-31-30T 145 31" 34 1/4" RC25U-31-45T 173

33" 36 1/4" RC25U-33-30T 153 33" 36 1/4" RC25U-33-45T 183 2 1/2" TO 4 1/2"

11 GA.37" 40 1/4" RC25U-37-30T 171 37" 40 1/4" RC25U-37-45T 219

39" 42 1/4" RC25U-39-30T 179 39" 42 1/4" RC25U-39-45T 233

43" 46 1/4" RC25U-43-30T 197 43" 46 1/4" RC25U-43-45T 258 2 1/2" TO 5"

11 GA.47" 50 1/4" RC25U-47-30T 214 47" 50 1/4" RC25U-47-45T 282

51" 54 1/4" RC25U-51-30T 231 51" 54 1/4" RC25U-51-45T 306

ROLLERS SET HIGH (ONLY)

60° CURVE 90° CURVETAPERED ROLLER

DIMENSIONS

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLERS

PERCURVE

WT. (LBS.)

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.ROLLERS

PERCURVE

WT. (LBS.)

19" 22 1/4" RC25U-25-60T

10

159 19" 22 1/4" RC25U-25-90T

14

2122 1/2" TO 3 1/2"

11 Ga.21" 24 1/4" RC25U-21-60T 173 21" 24 1/4" RC25U-21-90T 230

23" 26 1/4" RC25U-23-60T 183 23" 26 1/4" RC25U-23-90T 245

25" 28 1/4" RC25U-25-60T 195 25" 28 1/4" RC25U-25-90T 260 2 1/2" TO 4"

11 GA.27" 30 1/4" RC25U-27-60T 207 27" 30 1/4" RC25U-27-90T 276

31" 34 1/4" RC25U-31-60T 324 31" 34 1/4" RC25U-31-90T 432

33" 36 1/4" RC25U-33-60T 339 33" 36 1/4" RC25U-33-90T 451 2 1/2" TO 4 1/2"

11 GA.37" 40 1/4" RC25U-37-60T 366 37" 40 1/4" RC25U-37-90T 489

39" 42 1/4" RC25U-39-60T 381 39" 42 1/4" RC25U-39-90T 508

43" 46 1/4" RC25U-43-60T 410 43" 46 1/4" RC25U-43-90T 456 2 1/2" TO 5"

11 GA.47" 50 1/4" RC25U-47-60T 438 47" 50 1/4" RC25U-47-90T 483

51" 54 1/4" RC25U-51-60T 467 51" 54 1/4" RC25U-51-90T 622

39"INSIDERADIUS DEGREE

71Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

90°

"C" "B" "A"

60"

81" "R"

"D"

45° 30° X

X

CONVEYOR CHANNEL SIZE "H" ORDER BY MOUNTING BRACKET NO.

4" x 4 ga. steel ATL-13609

Gravity roller spurs are used to transfer product from one conveying line onto another. They are suitable for merging or diverging applications.

n 15 widths n 30, 45 and 90 degree spurs n Right hand or left hand

STANDARD SPECIFICATIONSFRAME – 4 in. deep x 1 5/8 in. flange x 4 ga. powder coated steel channel with bolt-in cross members. Rollers set high.

WIDTHS – 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in., 39 in., 43 in., 47 in. and 51 in. between frames

SPUR ANGLES – 30, 45 and 90 degree spurs. Specify right hand or left hand.

COUPLINGS – Butt type one end. Shelf angle on the opposed end. Specify shelf angle mounting bracket.

ROLLERS – 2 1/2 in. x 11 ga. unplated steel tube, 11/16 in. spring hex retained axle, grease packed ball bearings both ends

ROLLER CENTERS - 3 in. centers

OPTIONAL EQUIPMENTSUPPORTS - Floor supports are available in a wide range of adjustments

WIDTHS - Other in-between widths from 10 in. to 51 in. between frames

FRAMES – 4" x 4.5 lb. powder coated structural steel channel. Rollers set high only.

GUIDE RAILS – Fixed angle guide rails

RL25/RR25

30° SPUR

BETWEENFRAME WIDTH

OVERALLWIDTH

MODEL NO.

"A" WT. (LBS.)2.5" X 11 GA.UNPLATED

13" 16-1/4" R(L/R)25U-13-30 39" 28415" 18-1/4" R(L/R)25U-15-30

54"

30217" 20-1/4" R(L/R)25U-17-30 32019" 22-1/4" R(L/R)25U-19-30 33821" 24-1/4" R(L/R)25U-21-30 35523" 26-1/4" R(L/R)25U-23-30

77"

37425" 28-1/4" R(L/R)25U-25-30 38927" 30-1/4" R(L/R)25U-27-30 40331" 34-1/4" R(L/R)25U-31-30 43633" 36-1/4" R(L/R)25U-33-30

96"445

37" 40-1/4" R(L/R)25U-37-30 46639" 42-1/4" R(L/R)25U-39-30 46543" 46-1/4" R(L/R)25U-43-30

114"477

47" 50-1/4" R(L/R)25U-47-30 48451" 54-1/4" R(L/R)25U-51-30 503

GRAVITY ROLLER SPUR CONVEYOR (2 1/2 in. dia. x 11 ga. rollers)

90° SPUR

BETWEENFRAMEWIDTH

OVERALLWIDTH

MODEL NO.

"C" "D"INSIDE RADIUS

"R"WT. (LBS.)2.5" X 11 GA.

UNPLATED

13" 16-1/4" R(L/R)25U-13-90

39"

33" 32 1/2"

133

15" 18-1/4" R(L/R)25U-15-90 139

17" 20-1/4" R(L/R)25U-17-90 152

19" 22-1/4" R(L/R)25U-19-90 158

21" 24-1/4" R(L/R)25U-21-90

54"

164

23" 26-1/4" R(L/R)25U-23-90 170

25" 28-1/4" R(L/R)25U-25-90 175

27" 30-1/4" R(L/R)25U-27-90 180

31" 34-1/4" R(L/R)25U-31-90

77"

48 1/2" 48"

263

33" 36-1/4" R(L/R)25U-33-90 267

37" 40-1/4" R(L/R)25U-37-90 281

39" 42-1/4" R(L/R)25U-39-90 295

43" 46-1/4" R(L/R)25U-43-90 307

47" 50-1/4" R(L/R)25U-47-9096"

315

51" 54-1/4" R(L/R)25U-51-90 326

45° SPUR

BETWEENFRAME WIDTH

OVERALLWIDTH

MODEL NO.

"B" WT. (LBS.)2.5" X 11 GA.UNPLATED

13" 16-1/4" R(L/R)25U-13-45

39"

28215" 18-1/4" R(L/R)25U-15-45 31917" 20-1/4" R(L/R)25U-17-45 32319" 22-1/4" R(L/R)25U-19-45 35421" 24-1/4" R(L/R)25U-21-45

54"

38023" 26-1/4" R(L/R)25U-23-45 38825" 28-1/4" R(L/R)25U-25-45 41727" 30-1/4" R(L/R)25U-27-45 43331" 34-1/4" R(L/R)25U-31-45

77"

47233" 36-1/4" R(L/R)25U-33-45 48337" 40-1/4" R(L/R)25U-37-45 52739" 42-1/4" R(L/R)25U-39-45 53143" 46-1/4" R(L/R)25U-43-45 57747" 50-1/4" R(L/R)25U-47-45

96"559

51" 54-1/4" R(L/R)25U-51-45 568

30°/45°

RIGHT HAND

LEFTHAND

RIGHT HAND

LEFTHAND

90°

SECTION VIEW X-X

H

MOUNTING BRACKET

SHELF ANGLE

Specification Sheet – 09/16/15 R1

72Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

The RS35 gravity roller conveyor is ideal for conveying heavy loads. They are useful for assembly, warehousing, or shipping applications.

BETWEENFRAMEWIDTH

MODEL NO.ROLLER

CENTERSWT. (LBS.)

3.5" X .300 WALLUNPLATED 5' 10'

7"

RS35U-7-4 4" 228 453

RS35U-7-6 6" 177 351

RS35U-7-8 8" 152 300

RS35U-7-12 12" 126 249

11"

RS35U-11-4 4" 300 596

RS35U-11-6 6" 226 449

RS35U-11-8 8" 189 375

RS35U-11-12 12" 153 302

15"

RS35U-15-4 4" 372 740

RS35U-15-6 6" 276 548

RS35U-15-8 8" 227 451

RS35U-15-12 12" 179 355

19"

RS35U-19-4 4" 446 884

RS35U-19-6 6" 325 646

RS35U-19-8 8" 265 527

RS35U-19-12 12" 206 408

23"

RS35U-23-4 4" 515 1,027

RS35U-23-6 6" 375 744

RS35U-23-8 8" 303 602

RS35U-23-12 12" 232 461

27"

RS35U-27-4 4" 587 1,170

RS35U-27-6 6" 423 842

RS35U-27-8 8" 341 678

RS35U-27-12 12" 259 514

31"

RS35U-31-4 4" 659 1,314

RS35U-31-6 6" 472 941

RS35U-31-8 8" 379 754

RS35U-31-12 12" 285 567

35"

RS35U-35-4 4" 728 1,457

RS35U-35-6 6" 521 1,038

RS35U-35-8 8" 416 829

RS35U-35-12 12" 311 619

39"

RS35U-39-4 4" 802 1,600

RS35U-39-6 6" 570 1,136

RS35U-39-8 8" 454 904

RS35U-39-12 12" 338 672

43"

RS35U-43-4 4" 874 1744

RS35U-43-6 6" 619 1235

RS35U-43-8 8" 492 980

RS35U-43-12 12" 365 726

47"

RS35U-47-4 4" 946 1,888

RS35U-47-6 6" 668 1,333

RS35U-47-8 8" 530 1,056

RS35U-47-12 12" 391 779

51"

RS35U-51-4 4" 1,017 2,030

RS35U-51-6 6" 719 1,431

RS35U-51-8 8" 567 1,131

RS35U-51-12 12" 417 831

n 12 widths n 4 roller centers n Powder coated steel frames

STANDARD SPECIFICATIONSFRAME – 5 in. x 6.7 lb. powder coated structural steel channel with welded cross members. Rollers set high

WIDTHS – 7 in., 11 in., 15 in., 19 in., 23 in., 27 in., 31 in., 35 in., 39 in., 43 in., 47 in. and 51 in. between frames

LENGTH – 5 ft. and 10 ft. straight sections

COUPLINGS – Butt type for bolting sections together

ROLLERS – 3 1/2 in. x .300 wall unplated steel tube, 1 1/16 in. hex axle, pin retained, grease packed ball bearings both ends

ROLLER CENTERS – 4 in., 6 in., 8 in. or 12 in. centers

OPTIONAL EQUIPMENTSUPPORTS – Stationary floor supports are available in a wide range of adjustments

LENGTHS – Other lengths from 2 ft. to 10 ft.

WIDTHS – Other in-between widths from 7 in. to 67 in. between frames

ROLLERS SET LOW – Rollers set 3/4 in. low in 5 in. x 6.7 lb. structural steel channel

RS35GRAVITY ROLLER CONVEYOR (3 1/2 in. dia. x .300 rollers)

ROLLERS SET HIGH

ROLLERS SET LOW

SUPPORT CENTERS

FRAME CAPACITY ROLLER CAPACITY

MAX. DISTRIBUTED LIVE LOAD PER FOOT

MAXIMUM LOAD PER ROLLER

5' 16201145

10' 288

3/8"

5"

BETWEEN FRAME WIDTH

COTTER PIN3 1/2" DIA ROLLER

5"

BETWEEN FRAME WIDTH

3/4"

COTTER PIN

3 1/2" DIA ROLLER

73Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Ball transfer tables are ideal where products need to be manually rotated or repositioned at a work station. They are also used when manually transferring products from one conveyor line to another.

n 1 in. ball casters n 4 ball centers n Powder coated steel frames

STANDARD SPECIFICATIONS

FRAME – 2 1/2 in. deep x 1 in. flange x 12 ga. powder coated steel for bolting up to 1 3/8 in. dia. gravity roller conveyor or skatewheel conveyor (specify). 3 1/2 in. deep x 1 1/2 in. flange x 10 ga. powder coated steel for bolting up to 1.9 dia. gravity roller conveyor or other select powered conveyors.

WIDTHS • 2 1/2" frames: 10 in., 13 in., 16 in. and 22 in. between frames

• 3 1/2" frames: 13 in., 15 in., 17 in., 19 in., 21 in., 23 in., 25 in., 27 in., 31 in., 33 in., 37 in. and 39 in. between frames

LENGTHS – 1 ft. through 10 ft. in 1 ft. increments

COUPLINGS – Butt type for bolting sections together

BALL TRANSFERS – 1 in. dia. ball transfers

BALL CENTERS – 2 in., 3 in., 4 in. or 6 in. centers

BTT25/BTT35BALL TRANSFER TABLE

BTT35 (3 1/2 IN. FRAMES)

BETWEEN FRAME WIDTH

OVERALL WIDTH

MODEL NO.WEIGHT

PER FOOT

13" 16"

BTT35-13-2 25.86

BTT35-13-3 18.06

BTT35-13-4 15.33

BTT35-13-6 -

15" 18"

BTT35-15-2 29.15

BTT35-15-3 20.57

BTT35-15-4 17.45

BTT35-15-6 -

17" 20"

BTT35-17-2 32.45

BTT35-17-3 21.53

BTT35-17-4 18.41

BTT35-17-6 16.07

19" 22"

BTT35-19-2 35.72

BTT35-19-3 23.99

BTT35-19-4 20.48

BTT35-19-6 16.97

21" 24"

BTT35-21-2 39.28

BTT35-21-3 25.50

BTT35-21-4 21.43

BTT35-21-6 18.70

23" 26"

BTT35-23-2 42.27

BTT35-23-3 27.45

BTT35-23-4 23.55

BTT35-23-6 19.66

25" 28"

BTT35-25-2 45.52

BTT35-25-3 29.92

BTT35-25-4 24.45

BTT35-25-6 20.56

27" 30"

BTT35-27-2 48.81

BTT35-27-3 32.43

BTT35-27-4 26.58

BTT35-27-6 22.90

31" 34"

BTT35-31-2 55.35

BTT35-31-3 35.85

BTT35-31-4 29.61

BTT35-31-6 24.15

33" 36"

BTT35-33-2 58.65

BTT35-33-3 38.37

BTT35-33-4 30.57

BTT35-33-6 25.86

37" 40"

BTT35-37-2 65.19

BTT35-37-3 41.79

BTT35-37-4 33.60

BTT35-37-6 27.75

39" 42"

BTT35-39-2 68.48

BTT35-39-3 44.30

BTT35-39-4 35.72

BTT35-39-6 29.48

BTT25 (2 1/2 IN. FRAMES)

BETWEEN FRAME WIDTH

OVERALL WIDTH

MODEL NO.WEIGHT

PER FOOT

10" 12"

BTT25-12-2 19.77

BTT25-12-3 15.09

BTT25-12-4 12.75

BTT25-12-6 -

13" 15"

BTT25-13-2 25.86

BTT25-13-3 18.06

BTT25-13-4 15.33

BTT25-13-6 -

16" 18"

BTT25-16-2 29.60

BTT25-16-3 21.02

BTT25-16-4 17.90

BTT25-16-6 15.56

22" 24"

BTT25-22-2 42.27

BTT25-22-3 27.45

BTT25-22-4 23.55

BTT25-22-6 19.66

LOAD CAPACITY (LBS.)

FRAME SIZE SUPPORT CENTERS

MAXIMUM DISTRIBUTED

LIVE LOAD PER FOOT

MAX. STATIC LOAD

PER BALL

2 1/2" X 1" X 12 ga.5' 270

6510' 38

3 1/2" x 1 1/2" x 10 ga.5' 620

10' 135

3/8" FOR SKATEWHEEL3/32" FOR 1-3/8" GRAVITY ROLLER

OPTIONAL EQUIPMENTSUPPORTS – Stationary floor supports are available in a wide range of adjustments

GUIDE RAILS – Adjustable channel guide rails, fixed angle and channel guide rails

LESS FRAME – Pans with ball transfers only

Specification Sheet – 05/22/15 - R3

1.837

2.40

1.531

74Roseville, Michigan • Phone: (586) 771-1881 • www.ultimationinc.com

Conveyor rails utilize standard skatewheels mounted to various frame configurations. They are ideal for gravity storage flow racks.

CRCONVEYOR RAILS

CONVEYOR RAIL LOAD CAPACITY

SUPPORT CENTERS

MAXIMUM LOAD PER FOOT (LBS.)

TYPE 1 TYPE 2 TYPE 3S TYPE 3P TYPE 4 TYPE 5

3' 260 223 260 260 260 260

4' 260 92 233 233 260 210

5' 146 50 125 125 198 113

6' 83 28 71 71 112 64

7' 51 17 44 44 69 40

8' 35 12 38 38 49 27

10' 18 6 15 15 24 14

Wheel capacity = 65 lbs. each

2-1/2"

1"

2 7/8"

3"

2"

1"

2-3/8"

2-3/16"

2"

1-3/4"

3-3/4"

1" 1"

6"

3"

3"3 3/4"

2-3/16"

1" 1"

2"

1-3/4"

n 5 frame configurations

n 12 ga. powder coated steel frames

n Ideal for gravity storage flow racks

TYPE 4 – Rail weight: 3.5 lbs./ft.

TYPE 1 – Rail weight: 2.5 lbs./ft.

TYPE 2 – Rail weight: 2.1 lbs./ft.

TYPE 3S (Wheels staggered) – Rail weight: 3.5 lbs./ft.

TYPE 3P (Wheels paired) – Rail weight: 4.2 lbs./ft.

TYPE 5 – Rail weight: 3.0 lbs./ft.