Fostering ethical, responsible use of online technology Hans Martens, Insafe.

Good Dirt - Indiana Health and Safety conferenceGood Dirt ! Trenching & Excavation Safety Presented...

Transcript of Good Dirt - Indiana Health and Safety conferenceGood Dirt ! Trenching & Excavation Safety Presented...

1

Monday, February 11, 2019

Good Dirt !Trenching & Excavation Safety

Presented by Bryan Thais, INSafe Safety Consultant

Objectives

• Soil mechanics and classification

• Protective systems

• Other specific requirements of the excavation standard

1

2

2

Monday, February 11, 2019

Trenching

• New NEP October 1, 2018 - replaces 1985 program• Trenching fatalities trending upward - 120 fatalities last 5

years • 71% the last 3 years• Objective to reduce and eliminate hazards related to

trenches and excavations

• Enforcement to initiate inspections when open excavation observed – regardless of whether violation observed

• Consultation Outreach activities

Monday, February 11, 2019

Subpart P – Excavations ---(1926.650 - 652)

2017• Federal

• 1119 citations --- $5.5 million in fines• Indiana

• 46 citations --- nearly $60,000 in fines• Cave-in protection in excavations - Protective system use• Inspections by competent person• Egress from trench excavations• Protection from falling/rolling materials/equipment

3

4

3

Why employees continue to get hurt in a trenches

• Lack of Soil Analysis

• Lack of Protective System

• Lack of Competent Person

• Competent Person = capable of recognizing existing and predictable hazards in excavation work and able to take prompt corrective measures. Specific training in and be knowledgeable in soils analysis, protective systems, requirements of standard.

Excavation – any man-made cut, cavity, trench, or depression in the earth’s surface formed by earth removal

5

6

4

Trench – narrow excavation made below the surface of the ground. Generally depth is greater than the width but the width is not greater than 15 feet.

7

8

5

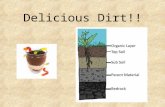

Soils and Soil Strength

• Saturation• Amount of water soil is currently holding. Complete saturation

less stable than soil that is only slightly damp. Soil with no water content is unstable

• Cohesiveness• How well the soil sticks together

• Clay• Soft, very small particles, shiny, sticky when wet, can form a

ball, cohesive• Silt

• Smoother medium particles, non sticky, plastic feel, retains some water but low cohesion

• Sand• Large particle size, rough and gritty, cannot be molded,

crumbles easy, low cohesion

Soil Strength is Dependent Upon

• Type of soil

• Amount of moisture in the soil

• Whether the soil has

been previously disturbed.

9

10

6

Soil Types• Stable Rock• Type A• Type B• Type C

12

Stable Rock

A natural solid mineral matter that can be excavated with vertical sides and remain intactwhile exposed.

11

12

7

Type A Soil

• Not Type A if:

• Fissured

• Subject to vibration

• Previously disturbed

• Subject to other factors that would require it to be classified as a less stable material

• Unconfined compressive strength of 1.5 TSF or greater• Clay• Silty clay• Clay loam• Cemented soils

Type B Soil• Unconfined compressive strength of .5 TSF but less than

1.5 TSF• Granular soils, gravel, silt, loam, or sandy loam• Soil that meets Type A but is fissured or subject to

vibration• Some previously disturbed soils

13

14

8

Type C Soil• Unconfined compressive strength of .5 TSF or less

• Granular soils, gravel, sand, and sandy loam• Submerged soil or soil from which water is freely seeping• Previously disturbed soil

Classification of Soil

• Soils need to be classified by a competent person

• Based on the results of at least one visual and one manual analysis conducted by a competent person

• Acceptable visual test:

• Soil adjacent to excavation and soil forming the sides of the open excavation

• Soil taken as samples from excavated material

• Estimate range of particle sizes

• Evidence of surface water and water seeping

• Sources of vibration that may affect stability

• Evidence of previously disturbed soil

15

16

9

Acceptable manual test

• Plasticity

• Ribbon and thread test

• Dry strength test

• Thumb penetration test

• Other strength test

• Pocket pentrometer

• Hand-operated shearvane

Thumb Penetration Test• Attempt to press thumb firmly into the soil in question

A. Indentation in the soil only with great difficulty

B. Thumb penetrates no further than the length of the thumb nail

C. Thumb penetrates the full length of the thumb

17

18

10

The Ribbon Test • Mix soil + water to make into

plastic mass

• Roll mass into cylindrical shape 1/2 to 3/4 inch diameter

• Lay across palm of hand

• Press between thumb and second joint of index finger

• Pass through thumb

• Squeeze until it takes the shape of a 1/8 to 1/4 inch thick strip

• Allow to hang freely from hand

The Ribbon Test • Clay loam will barely ribbon

and break easily

• Clay = relatively long ribbon 6 to 8 inches or more

• More clay = longer and stronger ribbon

• Silt has tendency to produce short ribbon with broken appearance

19

20

11

Plasticity or Penciling

If a 2 inch or longer thread can be held without breaking, the soil is cohesive.

Field Sedimentation Test • Glass jar

• 1 1/2 to 2 inches of soil in jar

• 5 inches of water on top of soil

• Shake, set down, twist jar

21

22

12

Shearvane/Torvane

• Measures soil‘s sheer strength• Maximum stress that particular soil can offer against

failure• How easily the soil will sheer and cave-in

Pocket Penetrometer Test• Measures unconfined compressive strength

• Amount of pressure in tons per square foot (tsf) required to cause the soil to fail in compression

23

24

13

Monday, February 11, 2019

• Can weigh 100 to 140 pounds per cubic foot• Can weigh 2700 - 3200 pounds (1 to 1 ½ tons) per cubic

yard• Each foot of depth adds more side pressure• Failure or cave-in is possible once the pressure exceeds

the ability of the soil to support itself

Soil

Cave-in• Soil or rock suddenly falls or slides into an excavation

• Weight of the soil causes it to gravitate downward and the pressure pushes soil inward toward the trench

• Motion typically causes the bottom third of wall to fail first

• Soil above the collapsed lower portion of the trench wall will also fail

25

26

14

Protective Systems• 1926.652(a)(1) -- Employees have to be protected from

cave-ins unless in stable rock or less than 5 feet and when there is no indication of a potential cave-in

• Sloping and benching

• Support systems, shield systems, or other protective systems

• Excavations over 20 feet require the design of a protective system by a licensed, professional engineer.

Sloping and Benching

• 1926.652(b) – Design - 4 options

• Sloped 1½ H:1V - at angle not less than 34o

• Use of appendices A and B

• Use of other tabulated data

• Design by Registered Professional Engineer (RPE)

27

28

15

Slope Configurations

Soil or Rock Type

Maximum Allowable Slopes for Excavations Less Than 20 feet

Unconfined Compressive Strength

Stable Rock Vertical 90° N/A

Type A ¾ to 1 53° ≥ 1.5 tons/sq ft

Type B 1 to 1 45° .5 – 1.5 tons/sq ft

Type C 1½ to 1 34° ≤ .5 tons/sq ft

Type A Soil Slope – ¾:1

Type C Soil Slope – 1½:1

Type B Soil Slope – 1:1

29

30

16

Type A simple bench

Type B simple bench

Type A multiple bench

Type B multiple bench

Supported or shielded vertical sided lower portion must extend at least 18 inches above the top of the vertical side.

Type A soil Type B Soil

Type C Soil

31

32

17

Support systems and shield systems

• 1926.652(c) -- Design = 4 options

• Use of appendices A, C, and D – designs for timber shoring and aluminum shoring

• Design using manufacturers data

• Use of other tabulated data

• Designs not utilizing above approved by RPE

33

34

18

Shoring• Timber / Aluminum / Hydraulic / Pneumatic

• System must fit tight against trench walls

• Design and materials depend upon trench dimensions

Appendix C – Timber Shoring • Table has the minimum sizes of timber members for

particular type of soil

• Timbers must be Douglas Fir or Oak

• Spacing of cross braces, uprights, and walers

35

36

19

Appendix D – Aluminum Hydraulic Shoring

• Spacing of various aluminum members (vertical shore rails and horizontal walers) and various hydraulic cylinder sizes

37

38

20

Shield Systems – Trench Boxes

• Shields do not prevent cave-in – they just protect when a wall collapses

• Can be used with all classes of soils

• Rated by manufacturer for specific depths in different classes of soil

• Tabulated data must be on-site

39

40

21

Shield systems

• Free from defects that would impair function

• When damaged a competent person needs to examine and evaluate if shield will support intended loads -- RPE

• Shields can be moved horizontally with workers inside but worker must stay inside shields

• No employees in the excavation when the shield is installed, removed, or raised vertically

Monday, February 11, 2019

You may not exceed the rated capacity of any shield.

41

42

22

Shield Systems • No excavating more than 2 feet below the bottom of the

shield

Shield Systems • Must be stabilized to prevent lateral movement

43

44

23

Shield Systems • Shield system must extend at least 18” above toe

of trench slope or vertical side

Monday, February 11, 2019

• 1926.652 does not apply to house/basement excavations when formwork, foundations, or walls are constructed.

House Foundations

45

46

24

Monday, February 11, 2019

• 1926.652 does not apply provided:• Less than seven and one-half feet in depth or is benched for at

least two (2) feet horizontally for every five (5) feet or less of vertical height

• The minimum horizontal width at the bottom of the excavation not less than two (2) feet

• No water, surface tension cracks, nor other environmental conditions present that reduce the stability of the excavation

• There is no heavy equipment operating in the vicinity that causes vibration to the excavation while employees are in the excavation

House Foundations

Monday, February 11, 2019

• 1926.652 does not apply provided:• All soil, equipment, and material surcharge loads are no closer

in distance to the top edge of the excavation than the excavation is deep

• Work crews in the excavation are the minimum number needed to perform the work

• The work is planned and carried out in a manner to minimize the time employees are in the excavation

Utility excavations (trenches) in conjunction with house foundation are not exempt

House Foundations

47

48

25

Monday, February 11, 2019

Specific Requirements

Monday, February 11, 2019

Surface Encumbrances• Must be supported or removed

49

50

26

Monday, February 11, 2019

• Utilities must be determined prior to excavating• When operations approach estimated location the

installations have to be found by safe and acceptable means

• Installations must be protected, supported, or removed to safeguard employees

Underground Installations

Monday, February 11, 2019

• A stairway, ladder, ramp, or other safe means of egress must be provided if 4 feet or more in depth so as to require no more than 25 feet of lateral movement

Means of Egress

51

52

27

Monday, February 11, 2019

• Must wear warning hi-vis vests • Class 2 or 3

Vehicular Traffic

Monday, February 11, 2019

• Cannot be under loads handled by lifting or digging equipment

Falling Loads

53

54

28

Monday, February 11, 2019

• Stop logs, barricades, or other system used at the edge of excavations when mobile equipment operated adjacent to excavation

Mobile Equipment

Monday, February 11, 2019

• Oxygen deficient atmospheres - <19.5% or >23.0%• Combustible gas >10% LEL (LFL)• Near a sewer, landfill, storage area for hazardous

substances, pipe systems used for fuel, etc.• Testing atmosphere

• before workers enter an excavation deeper than 4 feet• if equipment is operating in the trench• if welding, cutting, or burning is done in the trench

Hazardous Atmospheres

55

56

29

Monday, February 11, 2019

• No work unless precautions taken for hazards posed by accumulating water

• Special shield systems or support systems• Water removal equipment and monitored by competent

person• Use of dikes, ditches or other means when natural drainage

is affected

Water Accumulation

Monday, February 11, 2019

• Adjoining buildings, walls, other structures have to be supported by shoring bracing or underpinning

• No excavating below the base of a footing or foundation unless underpinning provided or approved by RPE

• Sidewalks, pavements, other structures not undermined unless supported

Stability of Adjacent Structures

57

58

30

Monday, February 11, 2019

• Loose rock/soil rolling into excavation• Place and keep excavated spoil

at least 2 feet from edge• Scaling to remove loose material• Protective barricades or shields –

retaining devices

Protection

Inspections by a Competent Person

• Daily and before the start of work and as needed throughout the shift

• As work conditions change

• After every rainstorm

• When fissures, cracks, undercutting, water seepage, bulging at bottom, etc. occur

• When there is a change in the size, location or placement of the spoil pile

• When there is any indication of change or movement in adjacent structures

• After any hazard increasing occurrence

• Employees REMOVED until hazards are safe

59

60

31

Monday, February 11, 2019

• Walkways provided when required to cross over excavations• Guardrails when more than 6 feet above lower levels.• Subpart M – Employees at the edge of an excavation shall

be protected from falling by guardrail systems, fences, or barricades when the excavation is not readily because of plant growth or other visual barrier

Fall Protection

Monday, February 11, 2019

• Employer shall instruct each employee in the recognition and avoidance of unsafe conditions and in the regulations applicable to their work to control and eliminate hazards or other exposures to injury

Training

61

62

32

Summary

• Soil mechanics and classification

• Protective systems

• Other specific requirements of the excavation standard

• Confidential* and cost-free• On-site consultation• Full or limited-scope audit• Air and noise sampling

[email protected](317) 232-2688

www.in.gov/dol/INSafeConsultation

63

64