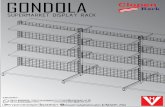

Gondola Unit details

-

Upload

rasmante-sedleckaite -

Category

Documents

-

view

36 -

download

3

Transcript of Gondola Unit details

7845

410

3721

0322

7

5679

8

3161093315

1378

2273

798

1002

1037

1704

870

1719

1105

959

600

915

2274

1002

1037

Stainless steel clamps to support the plastic sneeze guard

Sneeze guardAcrylic plastic manufactured into a curve

Stainless steel support

Stainless steel clamp fixed to granite base

Granite surface finish supported by timber framed structure

MDF panel manufactured with copper and steel sheetsOverall thickness of 15mm

44x44mm timber framing studs

6mm Plywood sheets as shelving units

Steel sheet base cover

Void for food storade services

Stainless steel food storage units

Aclyric plastic joined to steel studs

Steel Salad Storage

Steel support framing

Granite stone 30mm as unit surface finish

Timber framing studs 44x44mm

MDF Timber panel with bonded copper finish

MDF Panel with manufacture bondedcopper and stainless steel sheets 15mmoverall thickness

Timber standing supports for the gondolaunit coated with staineless steelthroughout

Stainless steel clamps to support the plastic sneeze guard

Shelving Area Void

6mm Plywood sheets

Steel frame angle to be fixed to the timberdryline surface for structural support of theframe

50mm Dry line screws fixing the plywood to the framing

www.autodesk.com/revit

Scale

LECTURER

Drawn by

Date

Project number

Institute of Technology CarlowBSc. in Architectural Technology

Year 3 2015-2016

As indicated

15/0

1/20

16 0

7:08

:46

Gondola Unit Details

1

Student Diner & Bar

20 October 2015

Rasmante Sedleckaite

Dan O'Sullivan / Noel Dunne /Mark Duffy

A107

No. Description Date

Gondola Unit1

1 : 20Gondola Unit Front View

2

1 : 20Gondola Unit Back View

3

1 : 20Gondola Unit Left Side Elevation

4

1 : 20Gondola Unit Right Side Elevation

5

Gondola Unit Section6

1 : 10Gondola Unit Framing

7