Glazing Ceramics Glaze vs Underglaze. 3 components of glaze Glass formers Fluxes (lower the firing...

9

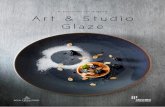

Glazing Ceramics Glaze vs Underglaze

-

Upload

arline-chambers -

Category

Documents

-

view

221 -

download

1

Transcript of Glazing Ceramics Glaze vs Underglaze. 3 components of glaze Glass formers Fluxes (lower the firing...

3 components of glaze

Glass formersFluxes (lower the firing temp.)Refractories (slows the flow)

GLAZESRemember to wipe the bottom of any ceramic work with a spongebefore placing glazed pieces in the kiln room