Glass Bottle Manufacturing Plant

Transcript of Glass Bottle Manufacturing Plant

2018/06/21

1

1

Glass Bottle Manufacturing Plant proposed by SAB and partners

SCOPING AND EIA

Public Information Sharing Meeting

20 June 2018

1

2

Agenda

2

1. Welcome and introductions

2. Purpose of the meeting

3. Background and introduction to the project

4. Enviro-legal context

5. Questions and Discussion

6. Way forward

2018/06/21

2

3

Purpose of the meeting

3

• Give you information on/an introduction to:

– the proposed glass bottle manufacturing plant,

– the environmental assessment process,

• Provide you an opportunity to:

– ask questions.

– raise any issues and concerns,

– make input on environmental sensitivities & impacts

4

EIA Background

4

• The project requires:

environmental applications assessment authorisation decisions

• A scoping and environmental impact assessment (EIA) process

informs decision-making by:

– identifying potential impacts on the environment,

• with inputs from public and government departments

– assessing the significance of potential impacts,

• with involvement from specialists

– identifying any mitigation measures or monitoring requirements

should the project be approved.

• SLR Consulting is appointed to plan, manage and co-ordinate

the EIA.

2018/06/21

3

Project Background and Motivation

• Creation of the first majority Black owned industrial glass bottle supplier in SA;

• SAB wishes to create opportunities for the entrance of a new black economic

industrialists;

• Opportunity to contribute to the investment, inclusive growth and transformation

goals of the government and society.

WHAT?

WHY?

5

Key Elements

Investment

• Total investment of approximately R3.0bn

• Equity: c. 80% BO Partner ; c. 20% AB InBev

Plant

Capacity

• ~ 30% of current market volume in SA

Raw Material • Glass is made from non-organic oxides found in

sand, soda ash, limestone and other raw

materials, melted together at high temperature

Plant Design • The facility would be a large industrial

installation, comprising a batch plant, main

manufacturing building and warehouse.

Site • The proposed site (Portion 1/238 of the Farm

Leeuwkuil 596 IQ) is appropriately located in a

developing industrial area in Vereeniging

Plant Volumes

Year 1 Year 3 Year 10

Volume

(tonnes)262 904 292 469 292 469

CAGR 3.62 % 1.07 %

6

2018/06/21

4

Batch

Plant

Warehouse

Cullet

Bays

Main

Manufacturing

Building

SAB Depot

9

Urban Expansion: Emfuleni Local Municipality SDF – 2017 to 2025

2018/06/21

5

Proposed Glass Bottle Manufacturing Plant

11

Proposed Glass Bottle Manufacturing Plant

11

• The batch plant would be used to receive, store and mix the various raw

materials required in glass manufacture. The raw materials are stored in silos,

hoppers and bunds.

• Materials are mixed according to specific recipes for each glass product. Cullet

(crushed glass), from internal and external sources is a key material.

• Once mixed, the raw material batches would be conveyed across to the main

manufacturing building.

• The two furnaces would utilise natural gas or Liquid Petroleum Gas (LPG) as a heat

source.

• In the furnace the raw materials would be melted into glass at temperatures of up

to 1 530°C and degassed.

• The green glass furnace would feed three bottle manufacturing lines.

• The amber glass furnace would feed four bottle manufacturing lines.

2018/06/21

6

12

Proposed Glass Bottle Manufacturing Plant

12

• Molten glass is channelled to a series of glass forming machines that cool and

meter the glass.

• Mechanical and pneumatic means are used to create the specific glass containers.

• The bottles are hot end coated to enhance surface resistance and cooled in an

annealing oven (lehr) to avoid internal stresses.

• Bottles are further coated and subject to inspection for defects by high precision

equipment that measure capacity, dimensions, impact, pressure resistance and

other tests.

• Out-of-spec bottles are crushed and conveyed back to the furnaces, where the

cullet is re-used in the raw material mix.

• Completed bottles are packaged by automated palletizers and moved to the

warehouse for storage and distribution.

• Storage of the bottles would be in plastic wrapped, bulk pallets up to three pallets

high.

Prelim Design Final Design

Construction

Town Planning and approvals

Environmental Authorisation

Commercial and

ownership negotiations

Time

Operations

Corporate Social Investment

Employment and procurement

current

SAB Future Owner

2018/06/21

7

14

Scoping and EIA Process: Why?

14

• The project triggers activities set out in Listing Notice 1 and 2

made in terms of Chapter 5 of the National Environmental

Management Act, (No. 107 of 1998), which may not

commence until approved

• An Environmental Authorisation is required.

• The project triggers waste management activities listed in

terms of Chapter 5 of the National Environmental

Management: Waste Act, (No. 59 of 2008).

• A Waste Management Licence is required.

15

Scoping and EIA Process: What?

15

• A Scoping and Environmental Impact Assessment (EIA)

process as stipulated in the EIA Regulations (GNR 982, 8

December 2014) is required to inform the competent

authorities decision.

• EIA is the “systematic process of identifying, assessing and

reporting on environmental impacts” to inform a decision on

environmental authorisation.

• The GDARD is the competent authority for both the EA and

WML.

• Application to be made for an integrated environmental

authorisation (as provided for in section 24L of the NEMA)

2018/06/21

8

16

Scoping and EIA Process: What2?

16

• The project triggers one of the minimum emission categories

made in terms of Chapter 5 of the National Environmental

Management: Air Quality Act, (No. 39 of 2004).

• An Atmospheric Emissions Licence is required.

• The Atmospheric Emissions Licence application will be

informed by the Environmental Authorisation issued in terms

of the NEMA.

• The Sedibeng District Municipality is the competent

authority.

17

Scoping and EIA Process: Outline

17

Appeal Process

Sco

pe

Issu

es

Stu

die

s &

imp

act

asse

ssm

en

t

S&EIA PROCESST

IME

Make Application (Day 1)

Pre application

GDARD decision on EA (by Day 300)

Submit EIA Report (by Day 194)

GDARD accept/refuse

Scoping Report (Day 88)

Submit Scoping Report (by Day 45)

Pu

blic p

art

icip

ation

inp

ut

Notice to IAPS

Incl. 30 days Public review

Incl. 30 days Public review

2018/06/21

9

18

Public Participation

18

• Aim is to provide information to I&APS (and receive from)

which may influence the decision.

• Adverts, notices, letters, BID & meetings.

• Process is on-going and will continue through the EIA.

• Please submit comments to SLR, c/o Matthew Hemming, via:

– Fax: 011-467-0978

– Postal: PO Box 1956, Cramerview 2060

– Email: [email protected]

19

Scoping phase (current)

19

• Objective is to identify the key issues that need to be

addressed in the assessment phase.

• Document the issues and concerns raised by I&APs.

• Detail what issues will be investigated further, and how.

• I&APs will have 30 days to review the Scoping Report.

2018/06/21

10

20

The Site

Site Photos

From the R28 looking North

From SAB Depot entrance looking south-west

From Lager Road looking North East

21

Specialist Studies

21

• Specialist consultants have been commissioned to undertake

studies on:

– Hydrology - Geohydrology

– Air Quality - Noise

– Visual - Heritage

– Biodiversity - Social and land use

– Economic - Traffic

– Soils and land capability.

• The findings of the these studies will inform the assessment of impacts

and guide recommendations on mitigation and management measures.

2018/06/21

11

22

EIA phase (after Scoping)

22

• Objective is to assess the impacts to determine significance,

and identify measures to avoid, manage or mitigate these.

• Detail impact mitigation and management measures in an

Environmental Management Programme (EMPr).

• I&APs will have 30 days to review the EIA report.

• EIA report will inform the authorities decision.

• EMPr and authorisation conditions are legally binding.

23

EIA Schedule

23

– Apply for Integrated Environmental Authorisation (July 2018)

– Scoping phase (May to September 2018)

• Scoping Report review (August 2018)

– EIA phase (October to February 2019)

– Decision on Integrated Environmental Authorisation (~early

2019)

– Appeal period

– Commence 2 year design/construct programme.

2018/06/21

12

24

QUESTIONS OR COMMENTS

25

Way forward

25

• Notes from this meeting will be included in the environmental reports;

• The Scoping Report will be made available for 30-day public review

(estimated for August). All I&APs will be notified by email or post;

• Please submit comments to SLR, c/o Matthew Hemming, via:

– Fax: 011-467-0978

– Postal: PO Box 1956, Cramerview 2060 (if using post please notify us

telephonically)

– Email: [email protected]

• SLR will update the Scoping Report with comments received, and submit

the Scoping Report to the GDARD.

• I&APs will be notified of GDARD decision on Scoping Report.

• If accepted, the assessment will move onto the EIA phase.

2018/06/21

13

26

Thank you for your time and participation

27

Close

27

1

GLASS BOTTLE MANUFACTURING PLANT PROPOSED BY

SOUTH AFRICAN BREWERIES (PTY) LIMITED SAB AND PARTNERS

MINUTES OF PUBLIC SCOPING MEETING

DATE 20 June 2018, 4pm

VENUE: General Smuts High School, Vereeniging

SLR COMPANY: SLR Consulting (South Africa) (Pty) Ltd (SLR)

PROJECT NUMBER: 720.19124.00005

PURPOSE: The purpose of the meeting was to:

To provide information on/an introduction to:

o the proposed glass bottle manufacturing plant

o the environmental assessment process

Provide attendees an opportunity to:

o ask questions.

o raise any issues and concerns,

o make input on environmental sensitivities & impacts

ATTENDANCE: An attendance register is presented in Appendix 2.

1. OPEN AND INTRODUCTION

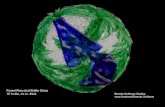

Nondumiso Gwala (NG) commenced the meeting and introduced herself as the meeting’s facilitator. She outlined the meeting protocol and requested that questions be asked at the end of the presentation. She stated that the presentation would be conducted in English but that attendees could ask their questions in any South African language. The presentation given at the meeting is included as Appendix 1. Copies of the background information document and comment sheets were made available to attendees at the meeting. Maps, indicating the regional setting and current land use and a conceptual illustration of the plant and manufacturing process of the project were displayed on the walls at the meeting. 2. OVERVIEW OF THE PROJECTS AND ENVIRONMENTAL ASSESSMENT PROCESSES

Matthew Hemming (MH) from SLR introduced himself as the environmental assessment practitioner. He conducted the presentation on the project background and motivation and the Scoping and EIA process. 3. QUESTION SESSION

The floor was opened for attendees to raise any questions, comments or concerns. None were raised by the attendees. 4. WAY FORWARD

The way forward presented at the meeting is outlined below.

2

Notes from this meeting will be included in the environmental reports;

The Scoping Report will be made available for 30-day public review (estimated for August). All I&APs will be notified by email or post;

Please submit comments to SLR, c/o Matthew Hemming, via:

- Fax: 011-467-0978

- Postal: PO Box 1956, Cramerview 2060 (if using post please notify us telephonically)

- Email: [email protected]

SLR will update the Scoping Report with comments received, and submit the Scoping Report to the GDARD.

I&APs will be notified of GDARD decision on Scoping Report.

If accepted, the assessment will move onto the EIA phase.

5. CLOSE

NG thanked attendees for their input and for making the time to attend the meeting. The meeting was closed at 4:30 pm.

3

APPENDIX 1: MEETING PRESENTATION

4

APPENDIX 2: ATTENDANCE REGISTER

5

Project: SAB'S PROPOSED GLASS BOTTLE MANUFACTURING PLANT PROJECT

SLR Company: SLR Consulting (South Africa) (Pty) Ltd

Date: 20 June 2018

Venue: Generaal Smuts School

Meeting: Public information sharing meeting

Name and Surname Community/organisation Postal address Contact numbers E-mail

Jacob Lesemela Lesa and Netsh Holdings 0781270315 [email protected];

Muzi Nhlapo Nampak 0713537694 [email protected];

Danielle Sanderson Nomad 0722598319 [email protected];

Mpho Lesalaisa Lesa and Netsh Holdings 0712210629 [email protected];

Vivian Ferreira 0837037483 [email protected];

Lehlohonolo Netshivhale Lesa and Netsh Holdings 0631887473 netshivholelehlohonolo@g

mail.com;

Note: SLR will use your contact information to communicate future project information and by providing your details on this

attendance register it does not mean that you are giving your consent for the project.

Project: SAB'S PROPOSED GLASS BOTTLE MANUFACTURING PLANT PROJECT SLR Company: SLR Consulting (South Africa) (Pty) Ltd Date: 20 June 2018 Venue: Generaal Smuts School Meeting: Public information sharing meeting

Name and Surname Community/organisation Postal address Contact numbers E-mail

Jacob Lesemela Lesa and Netsh Holdings 0781270315 [email protected];

Muzi Nhlapo Nampak 0713537694 [email protected];

Danielle Sanderson Nomad 0722598319 [email protected];

Mpho Lesalaisa Lesa and Netsh Holdings 0712210629 [email protected];

Vivian Ferreira 0837037483 [email protected];

Lehlohonolo Netshivhale Lesa and Netsh Holdings 0631887473 [email protected];

Note: SLR will use your contact information to communicate future project information and by providing your details on this attendance register it does not mean that you are giving your consent for the project.