Giant magnetoresistance, structural and magnetic properties of glass-coated Fe–Ni–Cu microwires

Transcript of Giant magnetoresistance, structural and magnetic properties of glass-coated Fe–Ni–Cu microwires

Journal of Magnetism and Magnetic Materials 249 (2002) 73–78

Giant magnetoresistance, structural and magnetic properties ofglass-coated Fe–Ni–Cu microwires

J. Tanga,*, K.-Y. Wangb, L. Spinub, H. Srikanthc, P.J. Schillingd, N. Moelderse

aDepartment of Physics, University of New Orleans, New Orleans, LA 70148, USAbAdvanced Materials Research Institute, University of New Orleans, New Orleans, LA 70148, USA

cDepartment of Physics, University of South Florida, Tampa, FL 33620, USAdDepartment of Mechanical Engineering, University of New Orleans, New Orleans, LA 70148, USA

eThe J. Bennett Johnston, Sr. Center for Advanced Microstructures and Devices, Louisiana State University, Baton Rouge, LA 70803,

USA

Abstract

Glass-coated Fe–Ni–Cu microwires prepared by Taylor’s technique exhibit negative magnetoresistance (MR) of

8.15% at 77K and 6.35% at 300K in a magnetic field of 9.0 T. The MR is of the same origin found in the granular giant

magnetoresistance (GMR) materials and is distinguishable from the giant magnetoimpedance (MI) commonly seen in

soft magnetic microwires. MI displays a peak at zero field for RF currents with frequencies less than 20MHz and it

crosses over to a sharp dip at higher frequencies. This crossover is ascribed to the skin-depth-limited response primarily

governed by the field dependence of the permeability. Micro-X-ray absorption near edge structure (micro-XANES)

spectroscopy data were collected at the K edges of Cu, Ni and Fe and revealed that the Fe atoms in the as-cast sample

are in FCC configuration and they remain in the FCC phase throughout the annealing processes. The MR decreases to

B2.5% as the annealing temperature increases to 5001C. The loss of GMR upon annealing is attributed to the growth

of FCC Fe–Ni-rich magnetic particles. The increase in the Fe–Ni particle size also results in higher room temperature

coercivity. When the annealing temperature is increased to 5001C, a wasp-waisted hysteresis loop is observed which

arises from the locking-in of the domain walls by the directional order of atoms due to diffusion under the influence of

the local magnetic field. A magnetically hard glass-coated microwire with coercivity of 600Oe is obtained after

annealing at 7001C for 1 h.

r 2002 Elsevier Science B.V. All rights reserved.

Keywords: Microwires; Giant magnetoresistance; Giant magnetoimpedance; XANES; Fe–Ni–Cu

Since Baibich et al. discovered the negative giantmagnetoresistance (GMR) in Fe–Cr magneticmultilayers, it has been found that GMR occursin many other multilayered magnetic films [1–3].GMR has also been found in granular structures

where metallic ferromagnetic nanoparticles aredispersed in a non-magnetic metal matrix. Gran-ular system exhibiting GMR has been preparedapplying a variety of sample preparation techni-ques including thin film deposition and mechanicalalloying [4,5].Recently, glass-coated microwires have at-

tracted significant research interest since theyexhibit a rich variety of magnetic properties. The

*Corresponding author. Tel.: +1-504-280-6713; fax: +1-

504-280-6048.

E-mail address: [email protected] (J. Tang).

0304-8853/02/$ - see front matter r 2002 Elsevier Science B.V. All rights reserved.

PII: S 0 3 0 4 - 8 8 5 3 ( 0 2 ) 0 0 5 0 8 - 5

diameter of the microwires is in the range of5–20 mm and the thickness of the coating is around2–10 mm. Most of the studies have focused on thesoft magnetic properties. The microwires show alarge magnetoimpedance (MI) effect although theyusually do not exhibit GMR effect [6–8]. Recently,glass-coated Fe–Ni–Cu microwires prepared byTaylor’s technique have been shown to exhibitnegative GMR [9]. The GMR observed in themicrowires is believed to originate from the spin-dependent scattering of electrons by the magneticnanoparticles imbedded in the non-magnetic Cu-rich matrix.In this paper, detailed structural examinations,

magnetic and magnetotransport studies on theas-cast and heat-treated samples are presented.The microwires were prepared as follows. The

Fe–Ni–Cu alloy (Fe 20%, Ni 20% and Cu 60%)was first prepared by induction melting appro-priate amounts of the constituent elements Fe, Ni,Cu. It was then put into a Pyrex glass tube andmelted using an induction heating coil. A glass-coated microwire was extracted from the lowerend of the glass tube [7]. The morphology of thewires were examined by a scanning electronmicroscope (SEM), JEOL Model 5410. Fig. 1shows the image of a segment of the as-castglass-coated Fe–Ni–Cu microwire. It can be seenthat the thickness of glass-coat is 10 mm, and thediameter of the metal core is 5 mm. The metal corewas covered by the glass coat.

X-ray diffraction patterns were recorded with aPhilips X’Pert diffractometer using CuK!a radia-tion. Fig. 2 shows the X-ray diffraction pattern ofthe as-cast Fe–Ni–Cu (Fe 20%, Ni 20% and Cu60%) microwires. The three major peaks are thoseof the (1 1 1), (2 0 0) and (2 2 0) reflections of FCCCu lattice. The peaks are slightly shifted to higherdegrees, which indicates that Ni and, perhaps,some Fe are dissolved in the Cu lattice leading tosmaller lattice parameter.X-ray absorption near edge structure (XANES)

spectroscopy was performed to elucidate thestructure of the microwires. Micro-XANES mea-surements were performed using the X-ray microp-robe at the Center for Advanced Microstructuresand Devices (CAMD). The results of the micro-XANES measurements are presented in Fig. 3.The Ni and CuK edge spectra of the polycrystal-line FCC Ni and Cu standards, respectively, canbe used to identify the main features of theXANES spectra for these transition metals in anFCC structure. By comparison to these standards,it can be seen that all sample spectra reflect theFCC structure. For the CuK edge and NiK edgedata, this is not unexpected. Cu atoms can beexpected to be in an FCC environment, whether

Fig. 1. SEM image of an as-cast glass-coated Fe–Ni–Cu

microwire (Fe 20%, Ni 20% and Cu 60%).

20 30 40 50 60 70 80

(220

)

(200

)

(111

)

Inte

nsity

(ar

b.un

it)2 Θ (degree)

Fig. 2. X-ray diffraction pattern of the as-cast Fe–Ni–Cu

microwire.

J. Tang et al. / Journal of Magnetism and Magnetic Materials 249 (2002) 73–7874

alloyed or segregated. Similarly, Ni atoms wouldbe expected to be in an FCC environment.The results at the FeK edge are more interest-

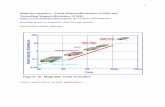

ing. If Fe atoms segregate out of the matrix, the Fenanoclusters would be expected to have a BCCstructure, which would be reflected in the XANESspectrum. However, the local coordination of theFe atoms is clearly FCC in the as-cast and theannealed microwires. The existence of GMR in theas-cast microwire indicates the presence of mag-netic nanoparticles dispersed in a non-magneticmatrix. In a granular Fe–Cu system, the GMR isdue to the precipitation of nanoclusters of BCC Fein the (mainly) Cu matrix [4,5]. In the microwires,however, the FeK edge XANES results indicatethat Fe does not precipitate as BCC grains.Rather, the data suggest that the magnetic phaseis an FCC Ni–Fe alloy. This is consistent with theternary phase diagram, which shows that FCC Ni–Fe (g1 phase) and FCC Cu (g2 phase) co-existaround composition 20Fe–20Ni–60Cu over thetemperatures the annealing was conducted. Thespinodal decomposition into g1 and g2 phases andrelated magnetic properties have been studied inbulk samples [10–14]. Our micro-XANES studysuggests that the Fe atoms remain in the FCC g1phase throughout the annealing processes.The magnetoresistance (MR) was measured at

77 and 300K with a Physical Property Measure-ment System (Quantum Design) using a four-probe method. The measurements were conductedin applied magnetic fields 0oHo9T. In thispaper, we use the following definition for MR:

MR ¼ DR=R ¼ ½RðHÞ � Rð0Þ�=Rð0Þ%;

where RðHÞ and Rð0Þ are resistance at an appliedfield H and H ¼ 0; respectively. The magnetic fieldwas applied both parallel and perpendicular to thewires, i.e., current direction. Both orientationsshow negative MR of the same magnitude. This ischaracteristic of GMR and it can be ruled out thatthe observed MR arises from anisotropic magne-toresistance (AMR). Fig. 4 shows the MR of theas-cast microwires measured at 77 and 300K withcurrent perpendicular to the field. MR reaches8.15% in a magnetic field H ¼ 9T at 77K. Theobserved MR shows no indication of saturation insuch a high field. As the temperature increases to

7.10 7.12 7.14 7.160.0

0.5

1.0

1.5

2.0

2.5 Fe K edge

600˚

300˚

500˚

as cast

Fe std

8.32 8.34 8.36 8.38

0.0

0.5

1.0

1.5

2.0

2.5 Ni K edge

600˚

300˚

500˚

as cast

Ni std

Nor

mal

ized

Abs

orba

nce

8.96 8.98 9.00 9.02

Cu K edge

600˚

300˚

500˚

as cast

Cu std

0.0

0.5

1.0

1.5

2.0

2.5

Energy (keV)

Fig. 3. Micro-XANES spectra collected at the Fe, Ni, and

CuK edges. The micro-XANES spectra for the as-cast wire and

wires annealed at 300, 500, and 6001C (collected in fluorescence)

are shown, along with transmission spectra from polycrystalline

Fe, Ni, and Cu standards.

J. Tang et al. / Journal of Magnetism and Magnetic Materials 249 (2002) 73–78 75

300K, the MR decreases to 6.35%. The GMRoriginates from the spin-dependent scattering bythe magnetic FCC g1 nanogranules imbedded inthe Cu-rich g2 matrix.Low-frequency AC MR was measured at room

temperature from 1 to 975Hz. AC MR taken at975Hz is shown in Fig. 4 along with the DC data.There is no observable frequency dependence ofthe MR over the frequency range used. It shouldbe pointed out that the GMR presented above isdistinct from the giant magnetoimpedance (GMI)found in amorphous and nanocrystalline softmagnetic microwires. GMI arises from a combina-tion of skin effect and strong field dependence ofcircumferential magnetic permeability associatedwith circular domain wall movements. It di-minishes at zero frequency and depends on theorientation of the magnetic field relative to thecurrent. The effect is seen in very low field. Theseare not characteristic of the Fe–Ni–Cu microwirespresented in this paper. High-frequency MI datawill be discussed later.Fig. 5 shows the room temperature MR of the

as-cast and 3001C and 5001C annealed wires. TheMR is about 6.5% for the as-cast sample, anddecreases to 2.5% as annealing temperatureincreases to 5001C. The loss of GMR upon

annealing is attributed to the growth of g1 phasemagnetic Ni–Fe grains. It has been shown thatgrains of both g1 and g2 phases undergo progres-sive coarsening upon annealing at increasinglyhigher temperatures and longer duration [14]. Thegrain growth upon annealing has been demon-strated in our microwires in the magnetic suscept-ibility versus temperature plots where the blockingtemperature increases with the annealing. The datashown in Fig. 5 also suggest that, although thegrain growth starts as low as 3001C, rapidcoarsening occurs at a higher temperature, some-where between 3001C and 5001C. An interestingfeature of the MR data taken from the microwiresannealed at 5001C is that, in addition to the muchreduced magnitude, MR exhibits a large positivecurvature (low-field region), which is absent fromthe as-cast and 3001C samples. The lack of anysign for saturation in MR in very high field hasbeen attributed to the extremely small magneticparticles typically present in granular materials.This is the situation for the as-cast and 3001Cmicrowires. Upon heating to 5001C, grain growthreduces the number of very fine particles, and thehigh-field MR decreases significantly. Even in this

-100 -60 -40 -20 0 20 40 60 80 100

-8

-6

-4

-2

0

AC 300 K

DC 300 K

DC 77 K

MR

(%

)

H (kOe)

-80

Fig. 4. MR of the as-cast microwires measured at 77K and

300K from �9 to 9T. Both DC and low-frequency AC

(f ¼ 975Hz) data were taken at 300K.

-90000 -60000 -30000 0 30000 60000 90000-7

-6

-5

-4

-3

-2

-1

0

1

300 oC

500 oC

as-cast

-MR

(%

)

H (Oe)

Fig. 5. Room temperature MR of the as-cast microwires and

those annealed at 3001C and 5001C, respectively.

J. Tang et al. / Journal of Magnetism and Magnetic Materials 249 (2002) 73–7876

sample the magnitude of MR increases almostlinearly with the field in high-field region, whichsuggests that there exists still significant particlesize distribution in the 5001C annealed microwires[15].The MI of the microwires was investigated for

longitudinal radio frequency currents up to200MHz using a RF lock-in amplifier method.Fig. 6 shows the MI of the microwires atfrequencies from 10 to 100MHz. It displays apeak structure (negative MI) at zero field for RFcurrents of frequency less than 20MHz andcrosses over to a sharp dip (positive MI) at higherfrequencies. This crossover is attributed to theskin-depth-limited response primarily governed bythe field dependence of the permeability [16]. Themagnitude of the positive MI initially increaseswith the frequency and eventually decreases withthe frequency. The largest MI change is about10% at f ¼ 100MHz. There are several differencesbetween our MI data and results on other softferromagnetic wires including higher saturationfield (300–600Oe) and lower MI values in ourmicrowires, which may indicate the possibleinfluence of the GMR in our wires.The magnetization of the microwires was

measured using a quantum design superconduct-ing quantum interference device. Fig. 7 shows theroom temperature hysteresis loops of the as-castglass-coated Fe–Ni–Cu microwires and wiresannealed at 3001C and 5001C, respectively. Onecan see that the annealing temperature changes theshape of magnetization curves in addition to

having a great effect on the GMR. For theas-cast wires, the loop is almost an anhystereticone. The small hysteresis is due to the very smallsuperparamagnetic Fe–Ni-rich (g1) particlesimbedded in Cu-rich (g2) matrix produced in thequenching process. The coercivity (Hc) increases to100Oe after annealing the sample at 3001C for 1 h.The increase is associated with the increase of theg1 phase particle size. Upon further increasing theannealing temperature to 5001C, the g1 particlesize continues to increase, which is demonstratedby the magnetotransport behaviors discussedabove. In addition, a constricted (wasp-waisted)hysteresis loop is observed for the 5001C sample.The magnetization near zero field is almostreversible and it is clearly anhysteretic. The loopopens up and becomes hysteretic at slightly higherfields. Similar behavior has been found in theannealed bulk Fe–Ni samples. The phenomenonarises from self-magnetic annealing when thesample is heated in the presence of its own internal

-0.3 -0.2 -0.1 0.0 0.1 0.2 0.3 0.4

3%

10MHz20MHz50MHz75MHz100MHz

Ma

gn

eto

-im

pe

da

nce

([Z

(H)-

Z(0

)/Z

(0)]

%ch

ange

)

H (T)

Fig. 6. MI of the microwires at frequencies from 10 to

100MHz.

-2000 -1500 -1000 -500 0 500 1000 1500 2000

as-cast

M (

arb.

units

)

H (Oe)

300 oC

500 oC

Fig. 7. Magnetic hysteresis loops of the as-cast and annealed

(at 3001C and 5001C) glass-coated Fe–Ni–Cu microwires (the

duration of the annealing was 1 h).

J. Tang et al. / Journal of Magnetism and Magnetic Materials 249 (2002) 73–78 77

field to a temperature where there is substantialdiffusion to cause directional order [10]. Thisdirectional order of the like atoms in the alloy isfrozen in when the sample is cooled, and thedomain walls tend to be locked in very small fields.Fig. 8 shows the magnetic hysteresis loop of a

sample annealed at 7001C for an hour. Thecoercivity Hc rapidly increases to 600Oe after theannealing, and this value is close to the maximumvalue of the Fe–Ni–Cu magnet. The mechanism ofthe coercivity for the 7001C sample is differentfrom that of 3001C. For Fe–Ni–Cu alloy, g phaseis homogenous at high temperature (B10501C). Itdecomposes spinodally into g1 and g2; and hard-ening occurs after cold deformation or heating gphase at 600–7001C. It has been suggested that thelarge magnetic anistropy of the rolled sheets iscaused by the precipitation of g2 along definitecrystal directions or planes in the oriented crystalsin such a way that the internal strains themselvesare anisotropic [10].In summary, glass-coated Fe–Ni–Cu microwires

prepared by Taylor’s technique have been studiedin terms of their structural, magnetic and magne-totransport properties. Fe and Ni exist as an FCCalloys in the Cu matrix. GMR of the as-cast wires

can reach 6.5% at room temperature and 8.15% at77K. After annealing at 5001C the MR decreasestoB2.5%. The reduction in GMR upon annealingis attributed to the growth of FCC Fe–Ni-richmagnetic particles. The annealing also has adrastic effect on the shape of the hysteresis loops.The room temperature coercivity changes from afew Oe to 100Oe by annealing at 3001C due to theparticle size increase. As the temperature isincreased to 5001C, a constricted hysteresis loopis observed resulting from the stable domain wallsdue to the diffusion-driven directional order.Rapid increase in the coercivity is found after 1 hof annealing at 7001C.

This work was supported by Louisiana Board ofRegents Support Fund Grant No. LEQSF(2000-03)-RD-B-10 and Sharp Laboratories of America.

References

[1] M.N. Baibich, J.M. Broto, A. Fert, F. Nguyen van Dau,

F. Petroff, P. Etienne, G. Creuzet, A. Friederich, J.

Chazeles, Phys. Rev. Lett. 61 (1988) 2472.

[2] S.S. Parkin, R. Bhadra, K.P. Roche, Phys. Rev. Lett. 66

(1991) 2152.

[3] J.Q. Xiao, J.S. Jiang, C.L. Chien, Phys. Rev. Lett. 68

(1992) 3749.

[4] W.P. Pratt, S.-F. Lee, J.M. Slaughter, R. Loloec,

P.A. Schroeder, J. Bass, Phys. Rev. Lett. 66 (1991) 3060.

[5] S.S. Saxena, J. Tang, Y.S. Lee, C.J. O’Connor, J. Appl.

Phys. 76 (1994) 6820.

[6] M. Vazquez, A. Hernando, J. Phys. D. 29 (1996) 939.

[7] M. Vazquez, A.P. Zhukov, J. Magn. Magn. Mater. 160

(1996) 223.

[8] D.-X. Chen, J.L. Munoz, A. Hernando, M. Vazquez, Phys.

Rev. B 57 (1998) 10699.

[9] K.-Y. Wang, L. Feng, C.J. O’Connor, J. Tang, D.-X.

Chen, M. Vazquez, A. Hernando, J. Appl. Phys. 85 (1999)

4474.

[10] R.M. Bozorth, Ferromagnetism, Van Nostrand, Prince-

ton, New York, 1951.

[11] B.D. Cullity, Introduction to Magnetic Materials, Addi-

son-Wesley, Reading, MA, 1972.

[12] H. Baker, in: ASM Handbook, Vol. 3, ASM International,

Metals Park, OH, 1990.

[13] I. Joffe, P. Gaunt, J. Phys. D 4 (1971) 586.

[14] E.P. Butler, G. Thomas, Acta Metall. 18 (1970) 347.

[15] Yu.G. Pogorelov, M.M.P. de Azevedo, J.B. Sousa, Phys.

Rev. B 58 (1998) 425.

[16] J. Wiggins, H. Srikanth, K.-Y. Wang, L. Spinu, J. Tang, J.

Appl. Phys. 87 (2000) 4810.

-2000 -1500 -1000 -500 0 500 1000 1500 2000

700 oC

M (

arb.

units

)

H (Oe)

Fig. 8. Magnetic hysteresis loop of the glass-coated Fe–Ni–Cu

microwires annealed at 7001C for 1 h.

J. Tang et al. / Journal of Magnetism and Magnetic Materials 249 (2002) 73–7878