geoho.com.twgeoho.com.tw/carter/WDX STD/diedesweb/wdxbook/wdx25... · wear plates will consist of...

-

Upload

truongkhuong -

Category

Documents

-

view

221 -

download

0

Transcript of geoho.com.twgeoho.com.tw/carter/WDX STD/diedesweb/wdxbook/wdx25... · wear plates will consist of...

NORTH AMERICA ONLY

���� ������

���

� ���� ���1FEB. 2006

����� ��������

1. DRAW DIES WILL HAVE A SIX (6) PIECE MODULAR CONSTRUCTION CONSISTING OF THE FOLLOWING MAJOR COMPONENTS; DIE SHOE, DIE CAVITY, PUNCH BASE, PUNCH CAP, BLANK HOLDER BASE AND BLANK HOLDER CAP.

2. THE BLANK HOLDER TO DIE SHOE GUIDANCE WILL BE HEEL BLOCKS AND DOUBLE WEAR PLATES.

3. THE BLANK HOLDER TO PUNCH GUIDANCE WILL BE HEEL BLOCKS AND DOUBLE WEAR PLATES.

4. WEAR PLATES WILL CONSIST OF ONE STEEL WEAR PLATE AND ONE GRAPHITE IMPREGNATED STEEL WEAR PLATE. 5. CASTING RIBS WILL BE IN LINE BEHIND HEEL BLOCKS TO PROVIDE MAXIMUM SUPPORT.

6. CASTING WALL THICKNESS AS DEPICTED IN W-DX12-50M PAGES 1 AND 2 WILL BE INCREASED BY 50 %.

7. MATERIALS FOR DRAW DIE WILL BE DETERMINED IN ACCORDANCE WITH THE FOLLOWING TABLE.

HIGH CONTACT PRESSURE FORM RADII

BLANK HOLDER CAP

PUNCH CAP

DIE CAVITY

DRAW BEADS

DRAW RADII

BLANK HOLDER BASE

COMPONENTDIE SHOE

PUNCH BASE

AISI M2/EUREKA 1216

AISI M2/EUREKA 1216

CARMO GRANSHOTS/UDDEHOLM

CARMO GRANSHOTS/UDDEHOLM

CARMO GRANSHOTS/UDDEHOLM

AISI M2/EUREKA 1216

DIE MATERIAL

D4512/NAAMS

D4512/NAAMS

D4512/NAAMS

8. MAXIMUM SIZE FOR CARMO CASTINGS IS 4 METRIC TONS. CARMO CASTINGS WILL BE DELIVERED TO THE CONSTRUCTION SOURCE IN THE ANNEALED CONDITION. HARDNESS WILL BE 180-220 HBN.

9. RETAINING SCREW ORIENTATION FOR CARMO CASTINGS WILL BE AS FOLLOWS: FOR STRETCH DRAW APPLICATIONS THE RETAINING SCREWS WILL BE THREADED INTO THE BASE OF THE CARMO DIE CAVITY WITH THE SCREW HEADS BEARING AGAINST THE D4512 DIE SHOE. FOR TOGGLE DRAW APPLICATIONS THE RETAINING SCREWS WILL BE THREADED INTO THE CARMO PUNCH CAP AND THE CARMO BLANK HOLDER CAP WITH THE SCREW HEADS BEARING AGAINST THE D4512 BASES.

10. HIGH CONTACT PRESSURE FORM RADII ARE THOSE RADII ON THE DRAW PUNCH AND DRAW DIE WHICH ARE SUBJECT TO A CONTACT PRESSURE OF 200 MPa OR GREATER. LOADS ON RADII WILL BE DETERMINED BY COMPUTER SIMULATION. THE DESIGN SOURCE WILL OBTAIN INFORMATION ON RADII REQUIRING AISI M12 FORM DIE ENGINEERING / STAMPING CAE.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���2FEB. 2006

����� ��������

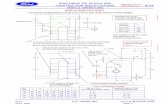

11. AISI M2 DRAW BEADS, DRAW RADII AND HIGH CONTACT PRESSURE FORM RADII WILL HAVE CROSS-SECTIONAL GEOMETRIC CONFORMING TO THE FOLLOWING SCHEMATIC.

FEMALE DRAW BEAD

MALE DRAW BEAD

R5

6

AISI M2 WELD DEPOSTR

R5

AISI M2 WELD DEPOST

DRAW RADIIFORM RADII WITH CONTACT

PRESSURES GREATER THAN 200 MPa

6

R

AISI M2 WELD DEPOSIT

R5

AISI M2 WELD DEPOSIT

R

R5

DRAW DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONS

R5

R

STEP BEAD

AISI M2 WELD DEPOSIT (TYP.) BINDER SURFACE

6

MEAN LOCATION OFMACHINING CUSPSLEFT BY A Ø10CUTTER.

6

6

6

6

666

66

6

6

6

6

6

FOR PRODUCTION VOLUMES GREATER THAN 50,000 PER YEAR

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���3FEB. 2006

����� ��������

12. UPON COMPLETION OF DIE TRYOUT THE BUILD SOURCE WILL VERIFY THAT THE DIE SURFACES MATCH CNC MACHINING DATA. IF THERE HAVE BEEN ANY MANUAL CHANGES TO THE FORMING DIE SURFACE THE DIE WILL REQUIRE SCANNING.

13. UPON COMPLETION OF DIE SURFACE VERIFICATION AND/OR SCANNING; DRAW RADII, DRAW BEADS AND HIGH CONTACT PRESSURE FROM RADII WILL BE MACHINED OUT IN PREPARATION FOR AISI M2 WELD DEPOSIT. THE DEPTH OF CUT BACK ARE SHOWN IN THE SCHEMATIC DRAWING ON PAGE 2.

14. UPON COMPLETION OF WELDING THE DIE WILL BE RETURNED TO THE CONSTRUCTION SOURCE FOR MACHINING THE DRAW BEADS, DRAW RADII AND APPLICABLE FORM RADII BACK TO FINISHED DIMENSIONS. THE M2 WELD DEPOSIT WILL HAVE A HARDNESS OF 58-61 Rc.

15. UPON COMPLETION OF MACHINING THE DIE WILL BE RETURNED TO THE WELD SOURCE FOR TEMPERING. THE DIE WILL BE TRIPLE TEMPERED IN A FURNACE. HOLD TWO (2) HOURS AT 500-525 DEGREES CELSIUS FOR EACH TEMPER. RESULTING HARDNESS OF DRAW BEAD WILL BE 63-65 Rc.

16. UPON COMPLETION OF TEMPERING THE BINDER SURFACE WILL BE FLAMED OR INDUCTION HARDENED.

17. ALL FORM RADII WHICH HAVE NOT BEEN OVER-WELDED WITH AISI M2 WILL BE FLAME/INDUCTION HARDENED. RESULTING HARDNESS OF FORM RADII ON CARMO CASTINGS WILL BE 58-62 Rc.

DRAW DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUMES GREATER THAN 50,000 PER YEAR

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

"The welding source will label the die to indicate that the beads and radii have been over-welded with AISI M2. The label will read the following; "Beads and Draw Radii Over-Welded with AISI M2". Identifying lettering will be engraved or embossed and the font will have a minimum height of 15 mm. The lettering can be directly on the cast surface or on a metal plate attached to the cast surface. The label will appear adjacent to foundry cast-in letters which identify the base material of the casting."

NORTH AMERICA ONLY

���� ������

���

� ���� ���11FEB. 2006

����� ��������

1. MAXIMUM TRIM STEELS ENTRY WILL BE SIX (6) TIMES METAL THICKNESS. MINIMUM TRIM STEEL ENTRY WILL BE THREE (3) TIMES METAL THICKNESS. THE TRIM EDGE BETWEEN THE MINIMUM AND MAXIMUM ENTRIES WILL BE TAPERED WITH 1 DEGREE OF SHEAR.

3. WHEN TRIMMING THE PART ALL OFFAL/SCRAP PIERCES SHOULD BE CUT ON AT LEAST TWO (2) 90 DEGREE ADJACENT SIDES DURING THE SAME STROKE. MAXIMUM LENGTH OF CUT WITHOUT A 90 DEGREE TURN IS 300mm. SEE ILLUSTRATION BELOW.

4. ALL TRIM STEELS WILL BE REMOVABLE INSERTS. NO TRIMMING WITH SOLID POST OR SOLID RING.

6. MINIMUM HEIGHT OF LOWER TRIM STEELS WILL BE 40mm. RETAINING SCREWS, DOWELS AND JACK SCREW HOLES WILL BE LOCATED TO FACILITATE SHARPENING VIA SURFACE GRINDING/MACHINING AND SHIMMING.

2. DIE CLEARANCE SHOULD BE 10% - 15% OF METAL THICKNESS.

5. LOWER TRIM STEELS WILL BE MANUFACTURED FROM WROUGHT STOCK. NO CASTING.

NOT RECOMMENDED

RECOMMENDED

1st TRIM

SCRAP BREAKERS

1st TRIM PANEL

1st TRIM PANEL

1st TRIM

2nd TRIM

2nd TRIM PANEL

2nd TRIM PANEL

OFFALSCRAP BREAKERS

OFFAL

2nd TRIM

TRIMMING DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUMES GREATER THAN 50,000 PER YEAR

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���12FEB. 2006

����� ��������

(SHOWN IN INVERTED POSITION FOR ILLUSTRATION)

45°

2 MACHINEALLOWANCE

PREFERRED LOCATION FORDIE, DETAIL NUMBER ANDMATERIAL. CAST IN RAISEDLETTERS. NO PATTERNSHOP LOGO.

30

END ELEVATION

5 MACHINEALLOWANCE

THESE SURFACES MUSTBE TAKEN FROM THE DRAW

PATTERN MAKER NOTE:

10 MACHINEALLOWANCE

30

5

10

25 DEVELOPMENT.

45°

14. UPPER AND LOWER TRIM STEELS WILL BE BACKED UP PER W-DX5-55M PAGE 3. UPPER TRIM STEELS CASTINGS WILL BE 30mm THICK WITH 15mm THICK RIBS. SEE ILLUSTRATION.

13. LOWER SCRAP CUTTERS SHOULD BE NESTED TO THE ADDENDUM.

12. UPPER TRIM STEELS, AS WELL AS UPPER AND LOWER SCRAP CUTTERS WILL BE MANUFACTURED FROM CARMO GRANSHOTS. TRIM EDGES WILL BE FLAME HARDENED TO 58-62 Rc.

11. UPPER TRIM STEELS SHOULD BE NO TALLER THAN ANY ADJACENT STANDARD PIERCE PUNCHES. UPPER STEELS HEIGHT SHOULD BE THE SHALLOWEST THAT PART CONTOUR CONSIDERATION ALLOW.

10. THE UPPER CASTING WILL HAVE AT LEAST AS MANY STAIRCASES AS THE LOWER CASTING.

9. FOR LOWER STEELS MOUNTED ON THE STAIRCASE THE FOOTPRINT WILL BE 1 X HEIGHT AT THE TALLEST POINT. ENOUGH STAIRCASE WILL BE PROVIDED SO THAT THE TRIM STEELS CAN MEET THESE CRITERIA. THE FOOTPRINT FOR ALL OTHER LOWER TRIM STEELS WILL BE A MINIMUM OF 1.5 X HEIGHT.

8. FOR TIP ANGLES TRIM THE SUPPORT CASTINGS WILL BE DESIGNED FOR STAIRCASE MOUNTING OF TRIM STEELS.

TRIMMING DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUMES GREATER THAN 50,000 PER YEAR

7. TOO FACILITATE GRINDING AND MINIMIZE DISTORTION DURING THE HARDENING PROCESS THE BASIC SHAPE OF LOWER TRIM STEELS WILL APPROXIMATE A RECTANGLE. SINGLE INSERTS THAT CAP THE POST FOR PARTS WITH HAT TYPE CROSS-SECTION WILL NOT BE USED. SINGLE INSERTS THAT CUT BOTH PRODUCT TRIM LINE AND ADDENDUM WILL NOT BE USED. DETAILS THAT ARE (L) OR (U) SHAPED IN PLAN VIEW ARE UNDERSIRABLE. STOCK REMOVAL DURING THE MANUFACTURE OF TRIM STEELS SHOULD BE LESS THAN 15 % BY WEIGHT.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���13FEB. 2006

����� ��������

TRIMMING DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUMES GREATER THAN 50,000 PER YEAR

16. DURING TRIM LINE DEVELOPMENT NO COMPOSITE WELDING OF TRIM STEELS WILL BE ALLOWED. COMPOSITE WELDING IS DEFINED AS THE USE OF WELDING CONSUMABLE, WHICH DO NOT MATCH THE CHEMISTRY OF THE BASE ALLOY. CALDIE TRIM STEELS WILL ONLY BE WELDED WITH CALDIE FILLER METAL. ALL CALDIE TRIM STEELS WILL BE DOUBLE TEMPERED AFTER WELDING.

15. LOWER TRIM STEELS WILL BE MANUFACTURED FROM CALDIE AND FURNACE HARDENED TO 60-62 Rc. FOR TRIM DIES BUILT AT DEARBORN TOOL AND DIE CALDIE WILL BE PURCHASED IN THE PRE-HARDENED CONDITION 30-32 Rc WITH THREE ADJACENT SIDES GROUND FLAT AND SQUARE. AT DEARBORN TOOL AND DIE THE TRIM EDGES WILL BE FLAME HARDENED.

UPPER AND LOWER SCRAP CUTTERS

BASE OF TRIM POST

COMPONENTUPPER DIE SHOE

LOWER DIE SHOE

STRIPPER PAD

UPPER TRIM STEELS

CARMO GRANSHOTS/UDDEHOLM

CARMO GRANSHOTS/UDDEHOLM

CALDIE BAR STOCK

DIE MATERIAL

D4512/NAAMS

G2500/NAAMS

G2500/NAAMS

17. MATERIALS FOR THE TRIM DIE WILL BE IN ACCORDANCE WITH THE FOLLOWING TABLE.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���14FEB. 2006

����� ��������

D4512/NAAMS

D6510/NAAMS

S7FLANGE STEELS

FORM AND FLANGE POST

DIE SHOE

COMPONENT DIE MATERIAL

FLANGE DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR VOLUMES GREATER THAN 50,000 PER YEAR

1. MATERIALS FOR THE FLANGE DIE WILL BE IN ACCORDANCE WITH THE FOLLOWING TABLE.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���16FEB. 2006

����� ��������

1. DRAW DIES WILL HAVE A SIX (6) PIECE MODULAR CONSTRUCTION CONSISTING OF THE FOLLOWING MAJOR COMPONENTS; DIE SHOE, DIE CAVITY, PUNCH BASE, PUNCH CAP, BLANK HOLDER BASE AND BLANK HOLDER CAP.

2. THE BLANK HOLDER TO DIE SHOE GUIDANCE WILL BE HEEL BLOCKS AND DOUBLE WEAR PLATES.

3. THE BLANK HOLDER TO PUNCH GUIDANCE WILL BE HEEL BLOCKS AND DOUBLE WEAR PLATES.

4. WEAR PLATES WILL CONSIST OF ONE STEEL WEAR PLATE AND ONE GRAPHITE IMPREGNATED STEEL WEAR PLATE. 5. CASTING RIBS WILL BE IN LINE BEHIND HEEL BLOCKS TO PROVIDE MAXIMUM SUPPORT.

6. CASTING WALL THICKNESS AS DEPICTED IN W-DX12-50M PAGES 1 AND 2 WILL BE INCREASED BY 50 %.

7. MATERIALS FOR DRAW DIE WILL BE DETERMINED IN ACCORDANCE WITH THE FOLLOWING TABLE.

BLANK HOLDER CAP

PUNCH CAP

DIE CAVITY

BLANK HOLDER BASE

COMPONENTDIE SHOE

PUNCH BASE

CARMO GRANSHOTS/UDDEHOLM

CARMO GRANSHOTS/UDDEHOLM

CARMO GRANSHOTS/UDDEHOLM

DIE MATERIAL

D4512/NAAMS

D4512/NAAMS

D4512/NAAMS

8. MAXIMUM SIZE FOR CARMO CASTINGS IS 4 METRIC TONS. CARMO CASTINGS WILL BE DELIVERED TO THE CONSTRUCTION SOURCE IN THE ANNEALED CONDITION. HARDNESS WILL BE 180-220 HBN.

9. RETAINING SCREW ORIENTATION FOR CARMO CASTINGS WILL BE AS FOLLOWS: FOR STRETCH DRAW APPLICATIONS THE RETAINING SCREWS WILL BE THREADED INTO THE BASE OF THE CARMO DIE CAVITY WITH THE SCREW HEADS BEARING AGAINST THE D4512 DIE SHOE. FOR TOGGLE DRAW APPLICATIONS THE RETAINING SCREWS WILL BE THREADED INTO THE CARMO PUNCH CAP AND THE CARMO BLANK HOLDER CAP WITH THE SCREW HEADS BEARING AGAINST THE D4512 BASES.

10. HIGH CONTACT PRESSURE FORM RADII ARE THOSE RADII ON THE DRAW PUNCH AND DRAW DIE WHICH ARE SUBJECT TO A CONTACT PRESSURE OF 200 MPa OR GREATER. LOADS ON RADII WILL BE DETERMINED BY COMPUTER SIMULATION. THE DESIGN SOURCE WILL OBTAIN INFORMATION ON RADII REQUIRING AISI M12 FORM DIE ENGINEERING / STAMPING CAE.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���18FEB. 2006

����� ��������

1. MAXIMUM TRIM STEELS ENTRY WILL BE SIX (6) TIMES METAL THICKNESS. MINIMUM TRIM STEEL ENTRY WILL BE THREE (3) TIMES METAL THICKNESS. THE TRIM EDGE BETWEEN THE MINIMUM AND MAXIMUM ENTRIES WILL BE TAPERED WITH 1 DEGREE OF SHEAR.

3. BASIC DIE CONSTRUCTION FOR THE UPPER TOOL WILL BE A CAST IRON DIE SHOE WITH CAST STEEL INSERTS FOR THE CUTTER EDGES. BASIC DIE CONSTRUCTION FOR THE LOWER WILL BE A STEEL TRIM CAP MOUNTED ON A CAST IRON DIE SHOE..

5. INCOMING HEAT TREAT CONDITION AND FINAL HEAT TREAT CONDITION FOR CASTING IS SPECIFIED

IN W-DX25-55M SECTION..

2. DIE CLEARANCE SHOULD BE 10% - 15% OF METAL THICKNESS.

TRIMMING DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUME LESS THAN 50,000 PER YEAR

4. MATERIALS FOR THE TRIM DIE WILL BE IN ACCORDANCE WITH THE FOLLOWING TABLE.

UPPER AND LOWER SCRAP CUTTERS

UPPER TRIM STEELS

STRIPPER PAD

LOWER DIE SHOE

UPPER DIE SHOE

COMPONENT

BASE OF TRIM POST

CAST CUT #1

CAST CUT #1

G2500/NAAMS

G2500/NAAMS

D4512/NAAMS

DIE MATERIAL

G2500/NAAMS

CAP FOR TRIM POST CARMO GRANSHOTS/UDDEHOLM

6. UPPER TRIM STEELS SHOULD BE NO TALLER THAN ANY ADJACENT STANDARD PIERCE PUNCHES. UPPER STEELS HEIGHT SHOULD BE THE SHALLOWEST THAT PART CONTOUR CONSIDERATION ALLOW.

8. LOWER SCRAP CUTTERS SHOULD BE NESTED TO THE ADDENDUM.

7. UPPER AND LOWER TRIM STEELS WILL BE BACKED UP PER W-DX5-55M PAGE 3. UPPER TRIM STEELS CASTINGS WILL BE 30mm THICK WITH 15mm THICK RIBS. SEE ILLUSTRATION.

9. DURING TRIM LINE DEVELOPMENT NO COMPOSITE WELDING OF TRIM STEELS WILL BE ALLOWED. COMPOSITE WELDING IS DEFINED AS THE USE OF WELDING CONSUMABLE, WHICH DO NOT MATCH THE CHEMISTRY OF THE BASE ALLOY. ALL TRIM EDGES MUST BE TEMPERED AFTER WELDING.

10. WHEN TRIMMING THE PART ALL OFFAL/SCRAP PIERCES SHOULD BE CUT ON AT LEAST TWO (2) 90 DEGREE ADJACENT SIDES DURING THE SAME STROKE. MAXIMUM LENGTH OF CUT WITHOUT A 90 DEGREE TURN IS 300mm. SEE ILLUSTRATION BELOW.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���19FEB. 2006

����� ��������

TRIMMING DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR PRODUCTION VOLUME LESS THAN 50,000 PER YEAR

OFFAL

OFFAL

RECOMMENDED

NOT RECOMMENDED

1st TRIM PANEL

SCRAP BREAKERS

1st TRIM PANEL

1st TRIM

1st TRIM

2nd TRIM PANEL

SCRAP BREAKERS

2nd TRIM PANEL

2nd TRIM

2nd TRIM

END ELEVATION

45°

(SHOWN IN INVERTED POSITION FOR ILLUSTRATION)

SHOP LOGO.LETTERS. NO PATTERNMATERIAL. CAST IN RAISEDDIE, DETAIL NUMBER ANDPREFERRED LOCATION FOR

ALLOWANCE2 MACHINE

30

5 MACHINEALLOWANCE

PATTERN MAKER NOTE:

THESE SURFACES MUSTBE TAKEN FROM THE DRAW

10 MACHINEALLOWANCE

45°

30

5

25

10

DEVELOPMENT.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��

NORTH AMERICA ONLY

���� ������

���

� ���� ���21 ENDFEB. 2006

����� ��������

D4512/NAAMS

D6510/NAAMS

S7FLANGE STEELS

FORM AND FLANGE POST

DIE SHOE

COMPONENT DIE MATERIAL

FLANGE DIE DESIGN STANDARDS FOR HIGH LOAD APPLICATIONSFOR VOLUME LESS THAN 50,000 PER YEAR

1. MATERIALS FOR THE FLANGE DIE WILL BE IN ACCORDANCE WITH THE FOLLOWING TABLE.

���� �� �������������������� �����

�����������������������

������������������������

���������� � ��