General Catalogue 2005 - Pedrollo

Click here to load reader

Transcript of General Catalogue 2005 - Pedrollo

GENERAL CATALOGUE 2005

PEDROLLO S.p.A. Via Enrico Fermi 7 - P.O. BOX 58 37047 San Bonifacio (Verona) ITALY paid-up capital 30.000.000 Tel. +39 045 6136311 Fax +39 045 7614663 e-mail: [email protected] www.pedrollo.com

Pedrollos aim is to move water all over the world, with creativeness and passion. Our pumps are suitable for all purposes, easy to use, ecological, accessible to everyone, everywhere. Our mission is to make water available everywhere, supporting life, development and comfort.

Organized on an area of 70,000 m2 our company makes use of a production process characterised by a high level of technology and automation, putting it at the top of its sector both for the amount of investments and for the ability to ensure quality throughout the production process. Pedrollo pumps are distributed in 160 countries, thus allowing our company to assume an international role that results in a yearly production of close to 2,000,000 units. The range comprises more than 60 families of pumps (drainage pumps, submerged and surface pumps) covering the majority of applications in the domestic, civil, agricultural and industrial sectors.

A highly advanced research and development centre, endowed with the most sophisticated work tools, both hardware and software, allows the continuous updating of the existing range as well as the planning of new products using materials of the latest generation.

The heart of the pump is certainly the electric motor. It is therefore necessary to guarantee not only the best quality of the components used, but also that the execution of the various passages of the winding (insulation, coils, impregnation, etc.) is carried out using the most advanced automatic machines, to guarantee the precision and constancy of the various steps.

Before obtaining approval for the production phase, a technologically advanced test room, equipped with the latest test benches, allows strict electrical and hydraulic testing to ensure the quality and effectiveness of the design phase.

The final assembly of our pumps is carried out on automatic lines which guarantee maximum precision in the assembly phase and a high speed of execution, to ensure that the finished product is available in a short time.

1979 - GOLD MEDAL:Awarded by the Verona Chamber of Commerce for having achieved a top level on the technical and commercial plain, in both the national and international field.

1993 - MARCO POLO Prize:Awarded by the Foreign Trade section of the Chamber of Commerce of the Veneto as the best firm, having distinguished itself in 1992 for its economic growth in the international field.

1994 - GOLD MEDAL:Awarded by the Verona Chamber of Commerce for having carried out considerable technical improvements in the firm.

1995 - COMPANY TO WATCH:Awarded by the DATABANK as company of the year for the results achieved.

1997 - PUMP TO WATCH:Awarded by the DATABANK to the TOP submersible pump of the year for its design and advanced technology.

2000 - PUMP TO WATCH:Awarded by the DATABANK to the 4SR submerged pump of the year for its advanced technological features.

2000 - QUALITY OF LIFE prize:awarded the entrepreneur and the firm for greater sensitivity to the companys impact on the community and for the ability to integrate the growth of the company with continuous and coherent programmes for the support of culture, art, the environment and the social scene. (Milan - Assolombarda)

2001 - ENTREPRENEUR OF THE YEAR Prize 2001:awarded, at national level, the entrepreneur and the firm for sensitivity to the social scene and continuous attention to the most needy populations, for the product which responds to the primary needs of man, such as certainly the availability of water. (Milan - Assolombarda)

2002 - ENTERPRISE AND CULTURE Prize:Prize of the Italian Manufacturers Association, awarded to the project with the highest social value. For efficacy in using culture as a primary resource of social communication and cooperation, in some economically handicapped and problematic countries on the world scene. (Naples - Palazzo Reale)

2002 - CREATIVITY AND INNOVATION Prize:Awarded by the Association of Industrialists of the province of Verona for having achieved world leadership in the sector of pumps.

2003 - CEREC Prize:Awarded by the European Committee for the approach to Economy and Culture for the Pedrollo for life project in favour of developing countries, in particular for the recovery of Albanian culture and for commitment in favour of the development of Bangladesh. (Naples - Palazzo Reale)

2004 - DOMUS MERCATORUM Prize:Awarded by the Verona Chamber of Commerce for the development of new technologies, taking the company to the top world levels in the production of pumps for civil, industrial and agricultural applications.

PERIPHERALPK PQ PQ 3000 PQA PVpage 16

VERTICAL

BRONZEPK PQ CPpage 101 page 102 page 103

VLpage 20

page 118

page 22

VLE

page 122

SUBMERGED4SKpage 108 page 110

page 24

5SK

page 26

STAINLESS STEELAL-REDpage 30

4BLOCK

page 126

CENTRIFUGALCPpage 28 page 32

PRO-NGA

SUMOpage 48

page 114

4SR 3-4 CR CP DINpage 38 page 60

page 130

6SR JCRpage 72

page 144

HF

page 40

TOP MULTI page 112

SELF-PRIMINGNFpage 44

PKS

page 18

SUBMERSIBLENGApage 46

JSW

page 62

TOP

page 156

TOP FLOOR page 158 Fpage 82

JDW

page 68

TOP VORTEX page 160 PLURIJETpage 74

MULTI-STAGE2CP CK RXpage 78 page 162

page 50

3-4CP

page 58

CKR

page 80

RX VORTEX page 164

ZD

page 166

MC

page 188

ZX

page 168

PVXC

page 190

D

page 170

PMC

page 192

VX

page 172

PORTABLEBETTYpage 104

BETTYNOX page 107 MCpage 174

HYDROFRESHVX-Ipage 176 page 196

MC-I

page 178

COMBIPRESSDCpage 180 page 201213

VXC

page 182

MOTORSMCpage 184

Km1 5690 page 218

VXC

page 186

ACCESSORIESpage 220

pumps with peripheral impeller

RANGE OF PERFORMANCE Flow rate up to 90 l/min (5.4 m3/h) Head up to 100 m LIMITS OF USE Manometric suction lift up to 8 m Liquid temperature up to + 60C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60 335-1 IEC 335-1 CEI 61-150 EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

INSTALLATION AND USEThey are recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. FOR THEIR RELIABILITY, SIMPLICITY OF USE AND ECONOMY THEY ARE SUITABLE FOR DOMESTIC USE AND IN PARTICULAR FOR DISTRIBUTING WATER IN COMBINATION WITH SMALL PRESSURE SETS, FOR IRRIGATING GARDENS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

PUMP BODY: cast iron, with threaded ports ISO 228/1. MOTOR BRACKET (patent n 1289150): aluminium with brass insert; reduces starting difficulties due to seizure of the impeller after long periods of inactivity. IMPELLER: brass, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PKm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PK: three-phase 230/400 V- 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753. PKm 60 is a REGISTERED TRADE MARK n 602636.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

16

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PK300

PK200 PK90 PK100

PK80 PK70

Head H (metres)

PK65

PK60

Flow rate Q

TYPESingle-phase PKm 60 PKm 65 PKm 70 PKm 80 PKm 90 PKm 100 PKm 200 Three-phase PK 60 PK 65 PK 70 PK 80 PK 90 PK 100 PK 200 PK 300

POWERkW HP

Q

m3/h l/min

0 0

0.3 5 38 50 62 66 82 80 86 95

0.6 10 33.5 45.5 57 61 71 75 81 90

0.9 15 29 40.5 52 56 60 70 76 85

1.2 20 24 36 47 51 49 65 71 80

1.5 25 19.5 31 42 46 38 60 65.5 75

1.8 30 15 27 37 41 27 55 60 70

2.1 35 10 22 32 36.5 17 50 55 65

2.4 40 5 17 27 31 5 45 50 60

3.0 50 8 18 22 35 40 50

3.6 60

4.2 70

4.8 80

5.4 90

0.37 0.50 0.60 0.75 0.75 1.1 1.5 2.2

40 0.50 55 0.70 65 0.85 1 H metres 70 90 1 85 1.5 90 2 100 3

25 30 40

15 20 30

10 20

10

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

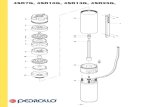

DIMENSIONS AND WEIGHTSfDN2

i

h2

DN1

h3

h1

a

w

m

s

n1 n

TYPE Single-phase Three-phase PKm 60 PK 60 PKm 65 PK 65 PKm 70 PK 70 PKm 80 PK 80 PKm 90 PK 90 PKm 100 PK 100 PKm 200 PK 200 PK 300

PORTSDN1 DN2

1" 1" 1" 1" 1" 3/4" 1" 1" 1"

1" 1" 1" 1" 1" 3/4" 1" 1" 1"

a 42 48 55 55 55 58 55 55 55

f 243 258/250 285 285 285 288 322 348 342/322 342

h 152 152 152 179 179 179 203 212 203

h1 63 63 63 71 71 71 80 80 80

h2 75 80 85 85 85 95 94 94 94 94

DIMENSIONS mm h3 i m 138 20 80 80 143 20 80 156 20 90 156 156 20 90 20 166 20 90 174 20 100 174 174 20 100 174 20 100

h

kg n 120 120 120 138 138 138 158 158 158 n1 100 100 100 112 112 112 112 125 125 125 125 w 55 55 55 62 62 62 85 85 95 95 s 7 7 7 7 7 7 9 9 9 1~ 5.3 7.7 10.1 10.3 10.3 10.3 15.0 16.0 3~ 5.3 6.4 9.2 9.9 9.3 13.1 15.2 18.0

17

self-priming pumps with peripheral impeller

RANGE OF PERFORMANCE Flow rate up to 50 l/min (3 m3/h) Head up to 70 m LIMITS OF USE Manometric suction lift up to 9 m Liquid temperature up to + 60C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. FOR THEIR COMPACTNESS, RELIABILITY AND ECONOMY THEY ARE SUITABLE FOR DOMESTIC USE AND IN PARTICULAR FOR DISTRIBUTING WATER IN COMBINATION WITH SMALL PRESSURE SETS, FOR IRRIGATING GARDENS, DRAWING WATER FROM TANKS OR WELLS DOWN TO A DEPTH OF 9 METRES AND IN ALL CASES WHERE THERE IS THE PRESENCE OF AIR OR GAS IN THE LIQUID TO BE PUMPED; the pump is provided with a check flap valve on the intake so that it is no longer necessary to fit a foot valve. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. CHECK FLAP VALVE: incorporated in the suction port. MOTOR BRACKET (patent n 1289150): aluminium with brass insert; reduces starting difficulties due to seizure of the impeller after long periods of inactivity. IMPELLER: brass, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PKSm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PKS: three-phase 230/400 V- 50 Hz INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

18

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PKS80 PKS70

PKS65

Head H (metres)

PKS60

Flow rate Q

TYPESingle-phase PKSm 60 PKSm 65 PKSm 70 PKSm 80 Three-phase PKS 60 PKS 65 PKS 70 PKS 80

POWERkW HP

Q

m3/h l/min

0 0 40 55 65 70

0.3 5 38 50 62 66

0.6 10 33.5 45.5 57 61

0.9 15 29 40.5 52 56

1.2 20 24 36 47 51

1.5 25 19.5 31 42 46

1.8 30 15 27 37 41

2.1 35 10 22 32 36.5

2.4 40 5 17 27 31

2.7 45 12.5 22 27

3.0 50 8 18 22

0.37 0.50 0.60 0.75

0.50 0.70 H metres 0.85 1

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

n fDN2

k i

h2

DN1

a

s

h1

w

m

n1

TYPE Single-phase Three-phase PKSm 60 PKS 60 PKSm 65 PKS 65 PKSm 70 PKS 70 PKSm 80 PKS 80

PORTSDN1 DN2

1" 1" 1" 1" 1"

1" 1" 1" 1" 1"

a f h 29 230 192 192 29 238/230 192 29 29 260 200 200 29 260 200

h1 156 156 156 164 164 164

h2 34 34 34 34 34

DIMENSIONS h3 i 190 110 190 190 110 110 198 110 198 198 110

mm m 80 80 80 90 90 90

h3

h

kg n 150 150 150 160 160 160 k 120 120 120 138 138 138 n1 100 100 100 112 112 112 w 55 55 55 62 62 62 s 7 7 7 7 7 1~ 6.1 7.7 10.7 10.8 3~ 6.1 7.1 9.6 9.7

19

pumps with peripheral impellerrecommended for industrial uses

RANGE OF PERFORMANCE Flow rate up to 90 l/min (5.4 m3/h) Head up to 100 m LIMITS OF USE Manometric suction lift up to 8 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. THE HYDRAULIC CHARACTERISTICS OF THESE PUMPS, TOGETHER WITH THEIR COMPACTNESS, MAKE THEM SUITABLE FOR USE IN THE INDUSTRIAL SECTOR. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. PUMP BODY: brass for PQ 81-Bs MOTOR BRACKET (patent n 1289150): aluminium with brass insert; reduces starting difficulties due to seizure of the impeller after long periods of inactivity. IMPELLER: brass, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PQm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PQ: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753

OPTIONS ON REQUEST

pump shaft in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanical seal protection IP 55 other voltages or frequency 60 Hz

20

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PQ300

PQ200 PQ100

PQ80 PQ70

Head H (metres)

PQ65

PQ60

PQ81-81Bs PQ90

Flow rate Q

TYPESingle-phase PQm 60 PQm 65 PQm 70 PQm 80 PQm 90 PQm 100 PQm 200 Three-phase PQ 60 PQ 65 PQ 70 PQ 80 PQ 90 PQ 100 PQ 200 PQ 300

POWERkW HP

Q

m3/h l/min

0 0

0.3 5 38 50 62 66 82 80 86 95

0.6 10 33.5 45.5 57 61 71 75 81 90 0.12 2 80 80

0.9 15 29 40.5 52 56 60 70 76 85 0.24 4 71 71

1.2 20 24 36 47 51 49 65 71 80

1.5 25 19.5 31 42 46 38 60 65.5 75

1.8 30 15 27 37 41 27 55 60 70 0.48 8 54 54

2.1 35 10 22 32 36.5 17 50 55 65 0.60 10 45 45

2.4 40 5 17 27 31 5 45 50 60

3.0 50 8 18 22 35 40 50 0.72 12 37 37

3.6 60

4.2 70

4.8 80

5.4 90

0.37 0.50 0.60 0.75 0.75 1.1 1.5 2.2

40 0.50 55 0.70 65 0.85 1 H metres 70 90 1 85 1.5 90 2 100 3 m /h3

25 30 40 0.84 14 28 28

15 20 30 0.96 16 19 19

10 20

10 1.08 18 10 10

TYPESingle-phase PQm 81 PQm 81-Bs Three-phase PQ 81 PQ 81-Bs

POWERkW HP Q

0 0 90 90

0.36 6 63 63

l/min

0.50 0.50

0.70 H metres 0.70

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTSfDN2

i

h2

DN1

h3

h1

s

a

w

m

n1 n

TYPE Single-phase Three-phase PQm 60 PQ 60 PQm 65 PQ 65 PQm 70 PQ 70 PQm 80 PQ 80 PQm 81 PQ 81 PQm 81-Bs PQ 81-Bs PQm 90 PQ 90 PQm 100 PQ 100 PQm 200 PQ 200 PQ 300

PORTSDN1 DN2

1" 1" 1" 1" 1" 1/2" 1/2 " 1/2" 3/4" 1" 1" 1" 1"

1" 1" 1" 1" 1" 1/2" 1/2 " 1/2" 3/4" 1" 1" 1" 1"

a 22 22 22 22 22 18 18 18 22 25 25 25 25

f 223 234/227 253 253 253 227/220 227/220 227/220 253 292 312/292 318 312

h 152 152 152 179 179 179 152 152 152 179 203 203 212 203

h1 108 113 121 121 121 118 118 118 126 140 140 140 140

h2 30 30 30 30 30 23 23 23 27 30 30 30 30

DIMENSIONS mm h3 i m 138 78 80 78 80 143 78 80 151 83 90 151 83 90 151 83 90 141 71 80 141 71 80 141 71 80 153 84 90 170 89 100 170 89 100 170 100 170 89 100

h

kg n 120 120 120 138 138 138 120 120 120 138 158 158 158 158 n1 100 100 100 112 112 112 100 100 100 112 125 125 125 w 55 57 62 62 62 58 58 58 62 85 85 85 85 s 7 7 7 7 7 7 7 7 9 9 9 9 1~ 5.3 7.1 9.9 10.0 6.7 6.8 10.0 14.8 15.7 3~ 5.3 6.3 8.9 8.8 6.8 6.8 9.0 14.3 14.8 15.7

21

pump with peripheral impellerfor industrial uses

RANGE OF PERFORMANCE Flow rate up to 50 l/min (3 m3/h) Head up to 180 m LIMITS OF USE Manometric suction lift up to 8 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEIt is recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. THE HYDRAULIC CHARACTERISTICS OF THIS PUMP, TOGETHER WITH ITS COMPACTNESS AND STURDINESS, MAKE IT SUITABLE FOR USE IN THE INDUSTRIAL SECTOR. The pump must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: brass with front shim disk in stainless steel. MOTOR BRACKET (patent n 1289150): aluminium with brass and stainless steel insert; eliminates seizure of the impeller after long periods of inactivity. IMPELLER: bronze, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PQ 3000: three-phase 230/400 V - 50 Hz. INSULATION: class H. PROTECTION: IP 55.

OPTIONS ON REQUEST

pump shaft in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanical seal other voltages or frequency 60 Hz

22

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PQ3000

Head H (metres)

Flow rate Q

TYPEThree-phase PQ 3000

POWERkW HP Q

m3/h l/min

0 0 180

0.6 10 160

0.9 15 145

1.2 20 132

1.5 25 118

1.8 30 105

2.1 35 92

2.4 40 78

2.7 45 63.5

3.0 50 50

2.2

3

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

fDN2

i

h2DN1

h3

s a w m n1 n

TYPE Three-phase

PORTSDN1 DN2

DIMENSIONS mm a 34 f 329 h 212 h1 142 h2 38 h3 180 i 65 m 100 n 166 n1 125 w 97 s 9

h1

h

kg 3~ 19.0

PQ 3000

3/4"

3/4"

23

pumps with peripheral impellerrecommended for industrial applications

RANGE OF PERFORMANCE Flow rate up to 50 l/min (3 m3/h) Head up to 90 m LIMITS OF USE Manometric suction lift up to 8 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. NON-FERROUS CONSTRUCTION WITH WETTED PARTS IN HIGH PERFORMANCE TECHNOPOLYMER AND BRASS TO ELIMINATE THE POSSIBILITY OF CORROSION. CONSEQUENTLY THEY ARE RECOMMENDED FOR INDUSTRIAL APPLICATIONS INCLUDING COOLING, CONDITIONING AND BOILER FEED. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: high-performance technopolymer with metal threaded port insert ISO 228-1 for secure pipe connection without damage to the pump body. BODY BACK-PLATE: brass . MOTOR BRACKET (patent n 1289150): aluminium with brass insert; eliminates seizure of the impeller after long periods of inactivity. IMPELLER: brass, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PQAm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PQA: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL

OPTIONS ON REQUEST

pump shaft in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanical seal protection IP 55 other voltages or frequency 60 Hz

24

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PQA90

PQA82 PQA80 PQA72 PQA70

Head H (metres)

PQA60

Flow rate Q

TYPESingle-phase PQAm 60 PQAm 70 PQAm 72 PQAm 80 PQAm 82 PQAm 90 Three-phase PQA 60 PQA 70 PQA 72 PQA 80 PQA 82 PQA 90

POWERkW HP

Q

m3/h l/min

0 0 40 65 65 70 70 90

0.1 2 38 62 66 86

0.3 5 35 58 62 62 66 79

0.6 10 29 52 57 56 61 68

0.9 15 23.5 45.5 52 49.5 56 56.5

1.2 20 18 39.5 47 43 51 45.5

1.5 25 12.5 33 42 37 46 34

1.8 30 7 27 37.5 31 41.5 23

1.9 32 5 24 35.5 28 39.5 18.5

2.3 38 16.5 29.5 20.5 37.5 5

2.7 45 8 22.5 12 26.5

3.0 50

0.37 0.55 0.55 0.75 0.75 0.75

0.50 0.75 0.75 H metres 1 1 1

18 22

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

fDN2

i

h2DN1

h3

h1

s a w m

n1 n

TYPE Single-phase Three-phase PQAm 60 PQA 60 PQAm 70 PQA 70 PQAm 72 PQA 72 PQAm 80 PQA 80 PQAm 82 PQA 82 PQAm 90 PQA 90

PORTSDN1 DN2

1/2" 1/2" 1/2" 1" 1/2" 1" 1/2"

1/2" 1/2" 1/2" 1" 1/2" 1" 1/2"

a 25 28 28 28 28 28 27

f 226 258 258 258 258 258 257

h 152 179 179 179 179 179 179

h1 103 116.5 121 116.5 121 121 121

DIMENSIONS mm h2 h3 i 33 136 72.5 72.5 32.5 149 72.5 30 151 83 32.5 149 72.5 30 151 83 35 156 76

h

kg m 80 90 90 90 90 90 n 120 138 138 138 138 138 138 n1 100 112 112 112 112 112 112 w 55 62 62 62 62 62 s 7 7 7 7 7 7 7 1~ 4.8 10.3 10.4 10.5 10.5 10.4 10.4 3~ 4.8 9.3 9.4 9.5 9.5 9.4 9.4

25

pump with peripheral impellerrecommended for industrial applications

RANGE OF PERFORMANCE Flow rate up to 10 l/min (0.6 m3/h) Head up to 42 m LIMITS OF USE Manometric suction lift up to 8 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water without abrasive particles and liquids that are chemically non aggressive to the materials from which the pump is made. THE CONSTRUCTION OF THIS PARTICULARLY COMPACT BRASS PUMP ELIMINATES THE POSSIBILITY OF RUST AND CORROSION. THIS MAKES IT SUITABLE FOR TRANSFERRING LIQUIDS IN THE MECHANICAL PROCESSING SECTOR, FOR CONTROLLING THE TEMPERATURE OF MOULDS, COOLING, CONDITIONING AND FOR BEVERAGE DISPENSING MACHINES. The pump must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: brass, with threaded ports ISO 228/1. MOTOR BRACKET (patent n 1289150): aluminium with brass insert; eliminates seizure of the impeller after long periods of inactivity. IMPELLER: brass, of the type with radial peripheral vanes. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - EPDM. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PVm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PV: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL

OPTIONS ON REQUEST

pump shaft in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanikcal seal pump body rotated 90 in anti-clockwise direction protection IP 55 other voltages or frequency 60 Hz

26

CURVES AND PERFORMANCE DATA AT n= 2900 1/min0 40 0 0.5 0.5 1 1 1.5 1.5 2 2 2.5

120 35

PV55

30

100

25

80

Head H (metres)

20 60

15 40

1020 5

0

00

10.1

2

30.2

4

50.3

60.4

7

80.5

9

100.6

0

Flow rate Q

TYPESingle-phase PVm 55 Three-phase PV 55

POWERkW HP

Q

m3/h l/min

0 0 42

0.12 2 35

0.18 3 31

0.24 4 28

0.30 5 25

0.36 6 21.5

0.42 7 18

0.48 8 14.5

0.54 9 11

0.60 10 8

0.18

0.25 Hmetres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

i fDN1 DN2

h2

h3

s a w m

h1

n1 n

TYPE Single-phase Three-phase

PORTSDN1 DN2

DIMENSIONS mm a 10 f 203 h 141 h1 56 h2 42 h3 98 i 25 m 72 n 110 n1 90 w 67 s 6 1~ 4.1

h

kg 3~ 4.1

PVm 55

PV 55

1/4"

1/4"

27

centrifugal pumps

RANGE OF PERFORMANCE Flow rate up to 160 l/min (9.6 m3/h) Head up to 58 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Liquid temperature up to + 40C in the CPX version (with technopolymer impeller) Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. RELIABLE AND MAINTENANCE FREE THEY ARE WIDELY USED IN THE DOMESTIC AND CIVIL SECTOR, IN PARTICULAR FOR WATEER DISTRIBUTION IN COMBINATION WITH SMALL OR MEDIUM PRESSURE SETS, FOR TRANSFER IN GENERAL, FOR IRRIGATING GARDENS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304 or cast iron on higher powered models. BRASS IMPELLER: CP 100-CP 132-CP 152-CP 150-CP 170-CP 190-CP 200 STAINLESS STEEL IMPELLER: CP 130-CP 158 MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. CPm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector built into the winding. CP: three-phase230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753.

OPTIONS ON REQUEST

impeller in technopolymer (CPm...X - CP...X) special mechanical seal other voltages or frequency 60 Hz

28

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

CP200

CP190

Head H (metres)

CP170 CP158 CP152 CP150 CP170M

CP130

CP132A CP132B

CP100

Flow rate Q

TYPESingle-phase CPm 100 CPm 130 CPm 132B CPm 132A CPm 152 CPm 150 CPm 158 CPm 170 CPm 170M CPm 190 Three-phase CP 100 CP 130 CP 132B CP 132A CP 152 CP 150 CP 158 CP 170 CP 170M CP 190 CP 200

POWERkW HP

Q

m3/h l/min

0 0 16 23 20 23 33 29.5 36 41 36 50 58

0.6 10 15 22 32 34

1.2 20 14 21 18 22 31 29 33.5

1.8 30 12.5 20 17 21.5 29.5 28.5 33 38 35 46 55

2.4 40 11 19 16 21 28.5 28 32.5 37 34.5 44.5 54.5

3.0

3.6

4.2

4.8

5.4 90

6.0

6.6

7.2

7.8

8.4 140

9.0

9.6

0.25 0.37 0.45 0.60 0.55 0.75 0.75 1.1 1.1 1.5 2.2

0.33 0.50 0.60 0.85 0.75 H metres 1 1 1.5 1.5 2 3

50 60 70 80 9 7 18 17 15.5 14 15 13.5 12 10.5 20 19 18 17 27 25 23 19 27.5 26.5 26 24.5 31.5 30 28.5 27 36 35 33.5 32 33.5 33 32 31 43 41.5 40 38 53.5 52 51 49.5

100 110

120 130

150 160

9 16 23 25 30 30 36 48

7 14 21

12 18

9 15

27.5 25 22 29 28 26.5 25 23 34.5 32.5 30.5 28 26 46 44.5 42.5 40.5 38.5

21 36

19

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTSf aDN2

n

h2DN1

w TYPE Single-phase Three-phase CPm 100 CP 100 CPm 130 CP 130 CPm 132B CP 132B CPm 132A CP 132A CPm 152 CP 152 CPm 150 CP 150 CPm 158 CP 158 CPm 170-170M CP 170-170M CPm 190 CP 190 CP 200 PORTSDN1 DN2

n1 DIMENSIONS mm h1 h2 n 77 110 148 82 123 165 123 165 82 123 165 82 123 165 92 148 190 92 148 190 92 148 190 110 150 206 115 175 242 242 115 175 115 175 242

s kg n1 118 135 135 135 135 160 160 160 165 206 206 206 w 45 41 41 41 38 38 38 44.5 32.5 32.5 32.5 s 10 10 10 10 10 10 10 10 11 11 11 1~ 6.8 7.8 8.0 8.4 11.5 12.5 12.1 19.2 25.0 3~ 6.9 7.6 7.5 8.1 11.5 11.3 11.6 18.5 24.2 25.5

1" 1" 1" 1" 1" 1" 1" 1" 11/4" 11/4 1/4" 1 " 11/4"

1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1" 1"

a 34 42 42 42 42 42 42 42 51 51 51.5

f 247 259 259 259 266/259 285 285 285 367 338 364 338

h 187 205 205 205 240 240 240 260 290 290 290

h1

h

29

stainless steel centrifugal pumps

RANGE OF PERFORMANCE Maximum flow rate 160 l/min (9.6 m3/h) Maximum head 23 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 55C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

INSTALLATION AND USEIt is recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. THE CONSTRUCTION OF THESE CENTRIFUGAL PUMPS MAKES THEM SUITABLE FOR USE IN THE DOMESTIC, AGRICULTURAL AND INDUSTRIAL SECTOR. ALL THE WETTED PARTS ARE IN STAINLESS STEEL AISI 340 TO GUARANTEE TOTAL HYGIENE AND MAXIMUM RESISTANCE TO CORROSION. The pump must be installed in enclosed places, or at least protected against inclement weather.

PUMP BODY: stainless steel AISI 304, with threaded ports ISO 228/1. BODY BACK-PLATE AND DIFFUSER: AISI 304. IMPELLER: stainless steel AISI 304, of the type with centrifugal radial flow. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. AL-RED 135m: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. AL-RED 135: three-phase 230/400 V - 50 Hz. INSULATION : class F. PROTECTION: IP 44. REGISTERED MODEL n 72753. AL-RED is a REGISTERED TRADE MARK

OPTIONS ON REQUEST

version in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanical seal other voltages or frequency 60 Hz

30

CURVES AND PERFORMANCE DATA AT n= 2900 1/min0 5 5 10 10 15 15 20 20 25 30 25 35 30 40 35 45 40 feet 90 0

30

25

80

AL-RED135

7051 54

20Head H (metres)

60

15

=56%

50

4053

1030

20

510

0

00 1

252

503 4

755

100Flow rate Q1.2 20 21 2.4 40 20.56 7

1258

1509 10

17511

l/minm3/h

0

TYPESingle-phase Three-phase AL-RED 135m AL-RED 135

POWERkW HP

Q

m3/h l/min

0 0 23

3.6 60 20

4.8 80 18.5

6.0 100 17

7.2 120 15

8.4 140 13

9.6 160 10

0.75

1

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

DN1

h2s w n1 TYPE Single-phase Three-phase PORTSDN1 DN2

DIMENSIONS mm a 31.5 f 295 h 206 h1 97 h2 103 h3 200 n 182 n1 115 w 93 s 10 1~ 9.1

h1

h3

h

kg 3~ 9.1

AL-RED 135m AL-RED 135

11/4"

1"

31

close-coupled centrifugal pumps with threaded ports

Electric pumps with high efficiency motor for reduced energy consumption

RANGE OF PERFORMANCE Flow rate up to 900 l/min (54 m3/h) Head up to 75 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. RELIABLE AND MAINTENANCE FREE THEY ARE WIDELY USED IN THE CIVIL, AGRICULTURAL AND INDUSTRIAL SECTORS, FOR SUPPLYING WATER, FOR CONDITIONING OR COOLING SYSTEMS, FOR IRRIGATION, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: cast iron. IMPELLER: brass for pumps CP 220, CP 230. IMPELLER: cast iron for pumps CP 250. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, with high efficiency (class EFF1), quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. CP: three-phase 230/400 V - 50 Hz up to4 kW. 400/690 V - 50 Hz from 5.5 to 11 kW. INSULATION: class F. PROTECTION IP 44. REGISTERED MODEL n 72753 PATENTED ELECTRIC MOTOR

OPTIONS ON REQUEST

pump shaft in stainless steel EN 10088-3 - 1.4401 (AISI 316) special mechanical seal protection IP 55 other voltages or frequency 60 Hz

32

PERFORMANCE RANGE AT n= 2900 1/min

Head H (metres)

Flow rate Q

33

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

CP220AH CP220A50 54 56 57 58

=60%

Head H (metres)

CP220C

NPSH (metres)

Absorbed power P2 (kW)

AH A B C

Flow rate Q

TYPESingle-phase Three-phase

POWERkW HP

Q

m3/h l/min

0 0 32 38 49 52

3 50 31.5 37.5 48.5 51.5

6 100 31 37 48 51

12 200 30 36 46 49

18 300 28 33.5 43.5 47

24 400 24 29 39.5 44

27 450 21 25 36 42

CPm 220C CPm 220B

CP 220C CP 220B CP 220A CP 220AH

2.2 3 4 5.5

3 4 5.5 7.5

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

34

P2 (HP)

NPSH (feet)

H (feet)

CP220B

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPESingle-phase Three-phase

POWERkW HP

Q

m3/h l/min

0 0 30 39 46

6 100 29.5 38.5 45.5

12 200 28.5 38 44.5

18 300 27 36 42

24 400 25 34 40

30 500 22 31 37

36 600 19.5 28 32.5

42 700 15.5 24 27.5

48 800 11.5 18.5 21.5

51 850 9 15 18

54 900 13 15

CPm 230C CP 230C CP 230B CP 230A

3 4 5.5

4 5.5 7.5

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

P2 (HP)

NPSH (feet)

H (feet)

35

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPEThree-phase CP 250C CP 250B CP 250A CP 250CR CP 250BR CP 250AR

POWERkW HP

Q

m3/h l/min

0 0 57 66 74 57 66 74

6 100 56 65 73 56 65 73

12 200 54.5 62.5 71 54.5 62.5 71

18 300 52.5 60 68 52.5 60 68

24 400 49.5 57 65 49.5 57 65

30 500 46 53 61 46 53 61

36 600 41.5 49 57 41.5 49 57

42 700 35.5 43.5 51 35.5 43.5 51

48 800 30 37.5 45 30 37.5 45

54 900 24 30 37 24 30 37

7.5 9.2 11 7.5 9.2 11

10 12.5 15 H metres 10 12.5 15

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

36

P2 (HP)

NPSH (feet)

H (feet)

DIMENSIONS AND WEIGHTSf aDN2

n

h2DN1

s w n1 n2

TYPE Single-phaseCPm 220C CPm 220B CPm 230C

PORTSDN1 DN2

DIMENSIONS mm a70 70 70 70 70 70 70 65 65 65 92 92 92

h1

h

kg n1170 190 190 190 190 190 190 230 230 230 230 230 230 230

Three-phaseCP 220C CP 220B CP 220A CP 220AH CP 230C CP 230B CP 230A CP 250C CP 250B CP 250A CP 250CR CP 250BR CP 250AR

f421/402 459 505 459 505 507 571 571 571 534 598 598 598

h315 328 328 328 328 328 328 392 392 392 392 392 392 392

h1132 136 136 136 136 136 136 160 160 160 160 160 160 160

h2183 192 192 192 192 192 192 232 232 232 232 232 232 232

n255 273 273 273 273 273 273 322 322 322 322 322 322 322

n2230 250 250 250 250 250 250 294 294 294 294 294 294 294

w40 40 40 40 40 40 40 40 45 45 45 45 45 45 45

s14 14 14 14 14 14 14 14 14 14 14 14 14 14

1~ 33.3 44.0 41.3 -

3~ 30.5 33.3 41.0 47.6 33.0 41.3 47.6 74.0 96.0 103.0 78.0 100.0 107.0

2"2" 2" 2" 2" 2" 2" 2" 2" 2" 4" 4" 4" 4"

2"2" 2" 2" 2" 2" 2" 2" 2" 2" 3" 3" 3" 3"

459/421 328/315 136/132 192/183 273/255 190/170 250/230

2"

2"

459/421 328/315 136/132 192/183 273/255 190/170 250/230

37

standardised centrifugal pumps to EN 733 - DIN 24255

RANGE OF PERFORMANCE Flow rate up to 250 l/min (15 m3/h) Head up to 57 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. THE PUMPS IN THIS SERIES ARE MADE TO STANDARDS EN 733 - DIN 24255 AND ARE SPECIFICALLY USED IN THE CIVIL, INDUSTRIAL OR AGRICULTURAL SECTORS WHERE THEIR CHARACTERISTICS OF STURDINESS AND RELIABILITY CAN BE BEST APPRECIATED. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, made to standards EN 733 - DIN 24255 and UNI 7467- NF E-44-111, with threaded ports ISO 228/1. IMPELLER: brass, of the type with centrifugal radial flow. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. CPm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector up to 1.5 kW. CP: three-phase 230/400 V - 50 Hz. INSULATION : class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

38

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

CP25/200A42 45

CP25/200B

47

Head H (metres)

=49%CP25/160AR CP25/160A CP25/160B50 47 53 45

=56%53 50

42

Flow rate Q

TYPESingle-phase CPm 25/160B CPm 25/160A CPm 25/200B Three-phase CP 25/160B CP 25/160A CP 25/160AR CP 25/200B CP 25/200A

POWERkW HP

Q

m3/h l/min

0 0 33 38 42 49 57

3.0 50 32.5 37 41 48 56

3.6 60 32 36.8 41 47.5 55.8

4.2 70 31.5 36.5 40.5 47 55.5

4.8 80 31 36 40 46.5 55

5.4 90 30.5 35.5 39.5 45.5 54.5

6.0 100 30 35 39 45 53.5

6.6 110 29 34 38 44 53

7.5 125 28 33 37 43 52

8.4 140 26.5 31.5 36 41 50.5

9.6 160 24 29.5 34 38.5 48.5

10.8 180 21.5 27 31 36 46

12.0 200 18 24 28 32 43.5

13.2 220 20 24 28 40

15.0 250

1.1 1.5 2.2 2.2 3

1.5 2 3 3 4

H metres

22 33

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2DN1

w1

w2

n1

s

TYPE Single-phase Three-phase CPm 25/160B CP 25/160B CPm 25/160A CP 25/160A CP 25/160AR CPm 25/200B CP 25/200B CP 25/200A

PORTSDN1 DN2

11/2" 11/2" 11/2" 1/2" 11/2" 11/2"

1" 1" 1" 1" 1" 1"

a 56 56 56 56 60 60 60

f 360 386 380 384/359 384

h 260 260 260 260 305 305 305

h1 105 105 105 125 125 125

DIMENSIONS mm h2 n 155 206 206 155 155 206 180 252 252 180 180 252

h1

h

kg n1 150 150 150 210 210 210 w1 27.5 27.5 27.5 23.5 23.5 23.5 w2 27.5 27.5 27.5 39.5 39.5 39.5 s 10 10 10 10 11 11 11 1~ 20.7 21.7 31.0 3~ 18.7 21.0 21.8 28.6 30.7

39

centrifugal pumpsmedium flow rates

RANGE OF PERFORMANCE Flow rate up to 600 l/min (36 m3/h) Heads up to 39 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USETHE HF SERIES IS RECOMMENDED FOR CIVIL, AGRICULTURAL AND INDUSTRIAL APPLICATIONS. THE HIGH FLOW RATES AND CONTINUOUS RATING MAKE IT IDEAL FOR IRRIGATION WITH FLOWING AND SPRINKLING WATER, FOR DRAWING WATER FROM LAKES, RIVERS, WELLS, OR FOR INDUSTRIAL APPLICATIONS THAT NEED TO ACHIEVE LARGE FLOW RATES AT MEDIUM-LOW HEADS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. IMPELLER: brass, of the type with centrifugal radial flow. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. HFm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. HF: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

40

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

HF70A

HF70B

HF60

Head H (metres)

HF5AM HF51A HF51B HF5A HF5B HF5C HF5BM

HF50A HF50B

Flow rate Q

TYPESingle-phase HFm 50B HFm 50A HFm 51B HFm 51A HFm 60 HFm 70B HFm 5C HFm 5B HFm 5A HFm 5BM HFm 5AM Three-phase HF 50B HF 50A HF 51B HF 51A HF 60 HF 70B HF 70A HF 5C HF 5B HF 5A HF 5BM HF 5AM

POWERkW HP

Q

m3/h l/min

0 0 9 12 18.2 21.2 29 33 39 12.5 13.7 14.5 20.2 22.5

3 50 8.5 11.5 17.2 20.2 28 32 38

6 100 8.2 11.2 16 19 26.5 30.5 36.5 12 13.2 13.8 19.2 22

9 150 7.5 10.6 14 17 24.5 28.5 34.5 11.7 13 13.5 19 21.5

12 200 6.3 9.6 11.5 14.5 22 26 32 11 12.5 13.2 18 21

15 250 4.9 8 9 11.6 18.5 22.5 28.5 10.2 11.6 12.6 17 20

18 300 2.8 6 5.4 8.4 15 19 25 9.2 10.5 11.8 16 18.5

21 350

24 400

30 500

36 600

0.37 0.55 0.60 0.75 1.1 1.5 2.2 0.60 0.75 1.1 1.1 1.5

0.50 0.75 0.85 1 1.5 2 H metres 3 0.85 1 1.5 1.5 2

8 9.2 10.5 14 16.6

6.5 8 9.2 12 14.5

5 6.5 7.5 10

3

Q = Flow rate H = Total manometric head f aDN2

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTSn

h2DN1

w TYPE Single-phase HFm 50B HFm 50A HFm 51B HFm 51A HFm 60 HFm 70B HFm 5C HFm 5B HFm 5A HFm 5BM HFm 5AM PORTS Three-phase HF 50B HF 50A HF 51B HF 51A HF 60 HF 70B HF 70A HF 5C HF 5B HF 5A HF 5BM HF 5AMDN1 DN2

n1 DIMENSIONS mm h1 h2 n 82 118 165 82 118 165 82 118 165 92 133 190 92 133 190 92 133 190 114 155 216 114 155 216 114 155 216 114 155 216 97 141 196 97 141 196 97 141 196 97 141 196 110 150 206 110 150 206 110 150 206

s kg n1 135 135 135 160 160 160 171 171 171 171 160 160 160 160 160 160 w 1 1 1 4 4 4 12 12 12 14 14 14 14 1 1 1 s 10 10 10 10 10 12 12 12 11 11 11 11 11 1~ 8.3 8.9 15.5 13.0 20.0 22.2 15.3 15.1 15.5 20.3 22.2 3~ 8.2 8.4 15.1 12.1 19.3 21.6 22.8 14.2 14.3 15.2 19.5 21.8

11/2" 11/2" 11/2" 11/2" 1/2" 11/2" 11/2" 11/2" 2" 2" 2" 2" 2" 2"

11/2" 11/2" 11/2" 11/2" 1/2" 11/2" 11/2" 11/2" 2" 2" 2" 2" 2" 2"

a 45 45 45 45 45 48.5 48.5 48.5 48.5 60 60 60 60 51 51 51

f 276 283/276 300 300 300 347 373 367 332 332 332 360 386 380/360

h 200 200 200 225 225 225 269 269 269 238 238 238 260 260 260

h1

h

41

centrifugal pumpshigh flow rates

RANGE OF PERFORMANCE Flow rate up to 1800 l/min (108 m3/h) Head up to 24.5 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USETHE HF SERIES IS RECOMMENDED FOR USE IN THE CIVIL, AGRICULTURAL AND INDUSTRIAL FIELD. THE HIGH FLOW RATES AND CONTINUOUS RATING MAKE IT IDEAL FOR IRRIGATION WITH FLOWING AND SPRINKLING WATER, FOR DRAWING WATER FROM LAKES, RIVERS, WELLS, OR FOR INDUSTRIAL APPLICATIONS THAT NEED TO ACHIEVE LARGE FLOW RATES AT MEDIUM-LOW HEADS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. IMPELLER: brass, of the type with centrifugal radial flow. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty.. HFm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. HF: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

42

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

HF8A HF30A HF8B

HF6A-6AR

HF20A HF30B

Head H (metres)

HF20B HF6B-6BR

HF6C-6CR

HF4

100

Flow rate Q

TYPESingle-phase HFm 4 HFm 6C HFm 6B HFm 6CR HFm 6BR HFm 8B HFm 20B Three-phase HF 4 HF 6C HF 6B HF 6A HF 6CR HF 6BR HF 6AR HF 8B HF 8A HF 20B HF 20A HF 30B HF 30A

POWERkW HP Q

m3/h l/min

0

12 200 9.3 11.7 14.5 18.1 11.7 14.5 18.1 21 24 -

18 300 8.7 11.3 14 17.8 11.3 14 17.8 20.7 23.5 -

24 400 8 10.7 13.5 17.2 10.7 13.5 17.2 20 23 15.5 18.5 -

30 500 7 10.2 12.8 16.8 10.2 12.8 16.8 19.5 22.5 15.4 18.4 -

36 600 6 9.2 12 16 9.2 12 16 18.8 21.8 15.3 18.3 18 23

42 700 4.7 8 11 15 8 11 15 17.8 20.8 15.2 18.2 18 23

48 800 3 6.7 9.7 13.8 6.7 9.7 13.8 16.5 19.5 15 18 18 23

54

60

66

72

84

96

102 108 120 132

0.75 1.1 1.5 2.2 1.1 1.5 2.2 3 4 3 4 5.5 7.5

1 1.5 2 3 1.5 2 3 4 5.5 4 5.5 7.5 10

0 10 11.9 14.7 18.5 11.9 14.7 H metres 18.5 21.5 24.5 16 19 18 23

900 1000 1100 1200 1400 1600 1700 1800 2000 2200 5 8.2 12.2 5 8.2 12.2 15 18.3 14.5 17.5 18 23 3 6.7 10.5 3 6.7 10.5 13.5 16.8 14 17 18 23

5 8.3

6

5 8.3 6 11.2 9 15 13 13 12 9 4.8 2 16.2 15.2 12 7.8 5 2 17.5 17 16.5 15.5 15 14.5 13 22.5 22.5 22.5 22 21.5 21 19.5

18

Q = Flow rate H = Total manometric head f aDN2

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTSn

h2DN1

w TYPE Single-phase Three-phase HFm 4 HF 4 HFm 6C HF 6C HFm 6B HF 6B HF 6A HFm 6CR HF 6CR HFm 6BR HF 6BR HF 6AR HFm 6B HF 8B HF 8A HFm 20B HF 20B HF 20A HF 30B HF 30A PORTSDN1 DN2

n1 a 55 68 68 68 68 70 70 70 70 80 80 80 80 80 82 82 82 f 323 385 405/385 411 405 387 407/387 413 407 462/429 462 462/429 462 585 585 585 h 240 312 312 312 312 312 312 312 312 312 312 312 370 370 370 DIMENSIONS mm h1 h2 n 97 143 190 120 192 240 120 192 240 120 192 240 120 192 240 120 192 240 120 192 240 120 192 240 132 180 245 132 180 245 132 180 245 132 180 245 132 180 245 160 210 292 160 210 292 160 210 292

s kg n1 155 190 190 190 190 190 190 190 190 190 190 190 212 212 212 w 0 6 6 6 6 6 6 6 30 30 30 30 30 30 30 s 10 12 12 12 12 12 12 12 14 14 14 14 14 14 14 1~ 15.6 28.1 29.1 29.7 32.0 41.0 40.5 3~ 14.2 26.2 28.5 29.4 29.2 31.4 32.3 36.1 41.0 35.3 40.5 60.9 65.2

21/2" 3" 3" 3" 3" 4" 4" 4" 4" 4" 4" 4" 4" 4" 4"

21/2" 3" 3" 3" 3" 4" 4" 4" 4" 4" 4" 4" 4" 4" 4"

h1

h

43

centrifugal pumps with flanged ports

RANGE OF PERFORMANCE Flow rate up to 1200 l/min (72 m3/h) Head up to 22.5 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USETHE NF SERIES, FROM THE POINT OF VIEW OF BOTH PERFORMANCE AND MECHANICAL DIMENSIONS, HAS BEEN EXPRESSLY DESIGNED FOR USE IN THE CIVIL, AGRICULTURAL AND INDUSTRIAL FIELD. THE HIGH FLOW RATES AND CONTINUOUS RATING MAKE IT IDEAL FOR IRRIGATION WITH FLOWING AND SPRINKLING WATER, FOR DRAWING WATER FROM LAKES, RIVERS, WELLS, AND FOR TRANSFER IN GENERAL. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded suction and delivery FLANGES ISO 228/1. IMPELLER: brass, of the type with centrifugal radial flow. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. NFm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. NF: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

44

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

NF129A

NF129B

NF130A

Head H (metres)

NF130B

NF128 AR NF128A NF128BNF130C

Flow rate Q

TYPESingle-phase NFm 128B NFm 128A NFm 128AR NFm 129B NFm 129A NFm 130C NFm 130B Three-phase NF 128B NF 128A NF 128AR NF 129B NF 129A NF 130C NF 130B NF 130A

POWERkW HP

Q

m3/h l/min

0 0

6 100

9 150 11.7 13 13.5 19 21.5

12 200 11 12.5 13.2 18 21 11.7 14.5 18.1

15 250 10.2 11.6 12.6 17 20 11.5 14.2 18

18

21

24 400

30 500

36 600

42 700

48 800

54

60

66

72

300 350 9.2 10.5 11.5 16 18.5 11.3 14 17.8 8 9.2 10.5 14 16.6 11.1 13.7 17.5

900 1000 1100 1200

0.60 0.75 1.1 1.1 1.5 1.1 1.5 2.2

0.85 1 1.5 1.5 H metres 2 1.5 2 3

12.5 12 13.7 13.2 14.5 13.8 20.2 19.2 22.5 22 11.9 14.7 18.5

6.5 8 5 9.2 6.5 12 7.5 14.5 10 10.7 10.2 13.5 13.2 17.2 16.8

3

9.1 12 16

8 11 15

6.7 5 9.7 8.2 13.8 12.2

3 6.7 5 10.5 8.3

6

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h

h2DN1

w1

w2

n1 DIMENSIONS mm h2 h3 n 167 264 196 167 264 196 167 264 167 264 196 159 269 206 159 269 206 159 269 206 193 313 240 193 313 193 313 240 193 313 240

s

TYPE Single-phase Three-phase NFm 128B NF 128B NFm 128A NF 128A NFm 128AR NF 128AR NFm 129B NF 129B NFm 129A NF 129A NFm 130C NF 130C NFm 130B NF 130B NF 130A

PORTSDN1 DN2

h12" 2" 2" 2" 2" 2" 3" 3" 3" 3" 2" 2" 2" 2" 2" 2" 3" 3" 3" 3" a 65 65 65 56 56 56 71 71 71 f 344 344 344 344 372 398 392/372 390 416 410/390 410 h 271 271 271 276 276 276 320 320 320 h1 97 97 97 110 110 110 120 120 120 n1 160 160 160 160 160 160 190 190 190 w1 8 8 8 1 1 1 6 6 6 kg* w2 s 1~ 3~ 60 12 19.8 17.1 60 12 18.3 17.0 60 12 18.3 18.3 62 11 23.3 22.7 62 11 62 11 26.0 24.6 66 12 33.5 31.5 12 34.4 33.4 66 66 12 34.6 (*weight includes counterflanges)

h3

45

centrifugal pumps with open impeller

Centrifugal pumps made of cast iron, equipped with open impeller, ideal for transferring liquids containing impurities.

RANGE OF PERFORMANCE Flow rate up to 350 l/min (21 m3/h) Head up to 20 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Liquid temperature up to + 40C in the NGAX version (with technopolymer impeller) Environment temperature up to + 40C Passage of solid bodies 10 mm CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping water and liquids that are chemically non aggressive to the materials from which the pump is made. THE OPEN IMPELLER DESIGN ALLOWS THE PUMPING OF LIQUIDS WITH RELATIVELY HIGH LEVELS OF IMPURITIES WITHOUT RISK OF CLOGGING THE IMPELLER. FOR THIS REASON THE NGA SERIES ARE SUITABLE FOR USE IN INDUSTRY, FOR THE TRANSFER OF WATER FROM CANALS, RIVERS, RESERVOIRS, TANKS, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. OPEN IMPELLER: stainless steel AISI 316. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. NGAm: single-phase 230V - 50 Hz with capacitor and thermal overload protector. NGA: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

impeller in technopolymer (NGAm...X - NGA...X) special mechanical seal other voltages or frequency 60 Hz

46

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

NGA1A NGA1B

Head H (metres)

Flow rate Q

TYPESingle-phase NGAm 1B NGAm 1A Three-phase NGA 1B NGA 1A

POWERkW HP

Q

m3/h l/min

0 0 18 20

3 50 17 19.5

6 100 16 18

9 150 14.5 16.5

12 200 13 15

15 250 10.5 12.5

18 300 8 10

19.5 325 6 8

21 350 6

0.55 0.75

0.75 H metres 1

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2DN1

w

n1

TYPE Single-phase Three-phase NGAm 1B NGA 1B NGAm 1A NGA 1A

PORTSDN1 DN2

11/2" 11/2" 11/2" 11/2" 11/2" 11/2"

a 41 41 41

f 297 297 297

h 227 227 227

DIMENSIONS mm h1 h2 n 92 135 190 135 190 92 92 135 190

h1s

h

kg n1 160 160 160 w 50 50 50 s 10 10 10 1~ 12.7 12.8 3~ 11.8 11.9

47

stainless steel pumps

Centrifugal pumps made of stainless steel AISI 316, equipped with an open impeller, ideal for transferring liquids containing impurities.

RANGE OF PERFORMANCE Flow rate up to 350 l/min (21 m3/h) Head up to 20 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Environment temperature up to + 40C Passage of solid bodies 10 mm CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping water and liquids that are chemically non aggressive to the materials from which the pump is made. THE OPEN IMPELLER DESIGN ALLOWS THE PUMPING OF LIQUIDS WITH RELATIVELY HIGH LEVELS OF IMPURITIES WITHOUT RISK OF CLOGGING THE IMPELLER. FOR THIS REASON THE PRO-NGA SERIES ARE SUITABLE FOR USE IN SYSTEMS FOR WASHING FRUIT, VEGETABLES, FISH, SHELLFISH, MEAT, IN INDUSTRIAL SYSTEMS FOR WASHING METAL PARTS, GLASS CONTAINERS, AND FOR THE CIRCULATION OF COOLING LIQUIDS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: stainless steel AISI 316, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 316. OPEN IMPELLER: stainless steel AISI 316. MOTOR SHAFT: stainless steel AISI 316. MECHANICAL SEAL: ceramic - graphite - viton - AISI 316 ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. PRO-NGAm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. PRO-NGA: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz protection IP 55

48

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

PRO-NGA1A PRO-NGA1B

Head H (metres)

Flow rate Q

TYPESingle-phase Three-phase PRO-NGAm 1B PRO-NGA 1B PRO-NGAm 1A PRO-NGA 1A

POWERkW HP

Q

m3/h l/min

0 0 18 20

3 50 17 19.5

6 100 16 18

9 150 14.5 16.5

12 200 13 15

15 250 10.5 12.5

18 300 8 10

19.5 325 6 8

21 350 6

0.55 0.75

0.75 H metres 1.00

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2DN1

w

s n1

TYPE Single-phase Three-phase PRO-NGAm 1B PRO-NGA 1B PRO-NGAm 1A PRO-NGA 1A

PORTSDN1 DN2

11/2" 11/2" 11/2"

11/2" 11/2" 11/2"

a 41 41 41

f 297 297 297

h 227 227 227

DIMENSIONS mm h1 h2 n 92 135 190 135 190 92 92 135 190

h1

h

kg n1 160 160 160 w 50 50 50 s 10 10 10 1~ 13.0 13.1 3~ 12.0 12.1

49

two stage centrifugal pumps

Two stage pumps recognised for their high efficiency, versatility and quiet running.

RANGE OF PERFORMANCE Flow rate up to 400 l/min (24 m3/h) Head up to 112 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 90C Liquid temperature up to + 40C in the 2CPX version (with technopolymer impeller) Environment temperature up to+ 40C CONSTRUCTION AND SAFETY STANDARDS EN 60034-1 IEC 34-1 CEI 2-3 INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. THEIR HIGH EFFICIENCY AND ADAPTABILITY TO THE MOST VARIED, EVEN UNUSUAL APPLICATIONS, MAKE THEM THE IDEAL CHOICE IN THE DOMESTIC, CIVIL AND INDUSTRIAL FIELD; IN PARTICULAR FOR DISTRIBUTING WATER IN COMBINATION WITH PRESSURE SETS, FOR INCREASING PRESSURE IN THE MAINS, FOR FIREFIGHTING SETS. The pumps must be installed in enclosed places, or at least protected against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, with high efficiency (class EFF1 for powers from 4 to 7.5 kW), quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. 2CPm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector (up to 1.5 kW). 2CP: three-phase 230/400 V - 50 Hz up to 4 kW. 400/690 V - 50 Hz from 5.5 to 7.5 kW. INSULATION: class F. PROTECTION: IP 44.

2CP 25/130N

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. IMPELLER: stainless steel AISI 304 of the type with centrifugal radial flow.

Other 2CP

PUMP BODY: cast iron, with threaded ports ISO 228/1. IMPELLERS: brass, of the type with centrifugal radial flow.

OPTIONS ON REQUEST

impeller in technopolymer (2CPm...X - 2CP...X) special mechanical seal other voltages or frequency 60 Hz

50

RANGE OF PERFORMANCE AT n= 2900 1/min

Head H (metres)

Flow rate Q

51

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPESingle-phase 2CPm 25/130N 2CPm 25/140H 2CPm 160/160 Three-phase 2CP 25/130N 2CP 25/140H 2CP 160/160

POWERkW HP

Q

m3/h l/min

0 0 42 54 66

1.2 20 39 53 64

1.8 30 37 51 62

2.4 40 34 49 60

3.0 50 31 46 57

3.6 60 28.5 42 53

4.2 70 25.5 38 49

4.8 80 22 34 44

5.4 90 18 29 39.5

6.0 100 15 24 35

0.75 1.1 1.5

1 1.5 2

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

52

P2 (HP)6.6 110 30

NPSH (feet)

H (feet)

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPESingle-phase2CPm 25/140M 2CPm 25/160B

POWERkW 1.1 1.5 2.2 HP 1.5 2 3 Q

m3/h l/min

0 0 47

1.2 20 46 56

1.8 30 45.5 55

2.4 40 44 54 65

3.0 50 43 53 63

3.6 60 42 52 62

4.2 70 41 50 60

4.8 80 38 48 58

5.4 90 36 46 56

6.0 100 34 44 54

6.6 110 31 41 51

7.5 125 27 37 47

8.4 140 22 33 42

9.6 160 26 35

Three-phase2CP 25/140M 2CP 25/160B 2CP 25/160A

H metres 58 68

66.5 65.5

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

P2 (HP)10.8 180 28

NPSH (feet)

H (feet)

53

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPESingle-phase2CPm 32/200C

POWERkW 3 4 HP 4 5.5 Q

m3/h l/min

0 0 70 85

2.4 40 81

3.0 50 80

3.6 60 65 79

4.2 70 64 78

4.8 80 63 77

5.4 90 62 76

6.0 100 60.5 75

6.6 110 59 74

7.5 125 57 72

8.4 140 55 69

9.6 160 52 66

10.8 12.0 15.0 180 62 200 58 250 36 49

Three-phase2CP 32/200C 2CP 32/200B

H metres

66.5 65.5

49.5 46.5

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

54

P2 (HP)

NPSH (feet)

H (feet)

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPEThree-phase 2CP 32/210B 2CP 32/210A

POWERkW HP Q

m3/h l/min H metres

0 0 94 112

2.4 40 94 111

3.0 50 93.5

3.6 60 93

4.2 70 92

4.8 80 91 110

5.4 90 90 109

6.0 100 89 108

6.6 110 87 107

7.5 125 85 105

8.4 140 83 102

9.6 160 79 99

10.8 180 75 94

12.0 200 70 89

15.0 250 56 74

5.5 7.5

7.5 10

110.8 110.5 110.3

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

P2 (HP)

NPSH (feet)

H (feet)

55

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Head H (metres)

NPSH (metres)

Absorbed power P2 (kW)

Flow rate Q

TYPEThree-phase 2CP 40/180C 2CP 40/180B 2CP 40/180A

POWERkW HP

Q

m3/h l/min

0 0 64 76 88

6.0 100 62 73 85

6.6 110 61 72.5 84.5

7.5 125 60 72 84

8.4 140 59 71 83

9.6 160 58 70 82

10.8 180 56 69 81

12.0 200 54.5 67.5 79.5

15.0 250 49 64 76

18.0 300 43 59.5 72

21.0 350 35 54 67

24.0 400 46 60

4 5.5 7.5

5.5 7.5 10

H metres

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

56

P2 (HP)

NPSH (feet)

H (feet)

DIMENSIONS AND WEIGHTS

f aDN2

n

h2DN1

w

s n1

TYPE Single-phase2CPm 25/130N 2CPm 25/140H 2CPm 160/160 2CPm 25/140M 2CPm 25/160B 2CPm 32/200C

PORTSDN1 DN2

DIMENSIONS mm a73 74 84 74 86 86 86 95 95 95 108 108 108 108 108 108

h1

h

kg n1142 162 185 162 185 185 185 206 206 206 232 232 232 232 232 232

Three-phase2CP 25/130N 2CP 25/140H 2CP 160/160 2CP 25/140M 2CP 25/160B 2CP 25/160A 2CP 32/200C 2CP 32/200B 2CP 32/210B 2CP 32/210A 2CP 40/180C 2CP 40/180B 2CP 40/180A

f330 382 405 382 401/381 407 401 464 464 464 542 542 542 496 542 542 542

h201 225 263 225 263 263 263 304 304 304 334 334 334 334 334 334

h192 93 110 93 110 110 110 132 132 132 139 139 139 139 139 139

h2109 132 153 132 153 153 153 172 172 172 195 195 195 195 195 195

n180 200 225 200 225 225 225 266 266 266 292 292 292 292 292 292

w1 23 26 23 26 26 26 19 19 19 21 21 21 21 21 21

s10 10 10 11 10 11 11 11 14 14 14 14 14 14 14

1~14.5 20.1 24.8 20.1 24.6 42.9 -

3~14.0 19.4 24.1 19.2 25.2 26.1 39.1 42.9 56.0 61.7 49.8 55.1 60.8

11/4" 1 11/4" 1/4" 11/4" 11/2" 11/2"

1" 1" 1" 1" 1" 1" 11/4" 11/4" 11/4" 11/4" 11/2"

1"

11/2" 1/2"11/2" 11/2" 2" 2"

11/4"

2" 2"2" 2"

11/2" 1/2" 111/2"

57

multi-stage centrifugal pumps

Particularly quiet running with high efficiency and low power consumption. Suitable for domestic applications.

RANGE OF PERFORMANCE Flow rate up to 130 l/min (7.8 m3/h) Head up to 50 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 40C Environment temperature up to+ 40C CONSTRUCTION AND SAFETY STANDARDS EN 60 335-1 IEC 335-1 CEI 61-150 EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. IMPELLERS: of the type with centrifugal radial flow, made of technopolymer (approved for drinking water). MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104 MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty.. 2-3-4CPm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. 2-3-4CP: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL

INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. DUE TO THEIR RELIABILITY, QUIET RUNNING AND LOW MAINTENANCE, THEY ARE SUITABLE FOR DOMESTIC APPLICATIONS INCLUDING WATER SUPPLIES (AS A PRESSURE SET), GARDEN IRRIGATION, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

OPTIONS ON REQUEST

other voltages or frequency 60 Hz

58

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

4CP80E

4CP100E

3CP80E

Head H (metres)

3CP100E

2CP80E

Flow rate Q

TYPESingle-phase 2CPm 80E 3CPm 80E 4CPm 80E 3CPm 100E 4CPm 100E Three-phase 2CP 80E 3CP 80E 4CP 80E 3CP 100E 4CP 100E

POWERkW HP

Q

m3/h l/min

0 0 27 38 50 36 46

0.3 5 26 36 48 35.5 45

0.6 10 25 35 47 35 44

0.9 15 24 34 45 34 43

1.2

1.5

1.8

2.4

3.0

3.6

4.2 70 5 10 16 23 30

4.8 80

5.4 90

6.0

6.6

7.2

7.8

0.37 0.45 0.60 0.60 0.75

0.50 0.60 0.85 H metres 0.85 1

20 25 30 40 50 60 22.5 21 20 16.5 13 9 33.5 31 29 25 20 15.5 43 40.5 38.5 33.5 28 22.5 33.5 32.5 32 30 28 26 42 41 40 38 35.5 33

100 110

120 130

5 10 20 17 13.5 26.5 22.5 19

10 15

5 10

5

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

DN1

h2w n1 s PORTSDN1 DN2

TYPE Single-phase Three-phase 2CPm 80E 2CP 80E 3CPm 80E 3CP 80E 4CPm 80E 4CP 80E 3CPm 100E 3CP 100E 4CPm 100E 4CP 100E

1" 1" 1" 1" 1" 1"

1" 1" 1" 1" 1" 1"

a 110 110 110 135 110 135

f 334 334 334 367/359 342/334 378

h 172 172 172 172 172 191

DIMENSIONS mm h1 h2 n 134 38 158 134 38 158 158 38 134 38 158 134 38 158 134 61 158

h1

h

kg n1 116 116 116 116 116 116 w 2 2 2 2 2 s 9 9 9 9 9 1~ 8.6 9.4 10.8 10.2 13.4 3~ 8.6 8.9 10.2 9.4 12.3

59

multi-stage centrifugal pumpsstainless steel pump body

Particularly quiet running with high efficiency and low power consumption. Suitable for domestic applications.

RANGE OF PERFORMANCE Flow rate up to 120 l/min (7.2 m3/h) Head up to 50 m LIMITS OF USE Manometric suction lift up to 7 m Liquid temperature up to + 40C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60 335-1 IEC 335-1 CEI 61-150 EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: stainless steel AISI 304, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. IMPELLERS: of the type with centrifugal radial flow, made of technopolymer (approved for drinking water). MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite - NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty.. 3-4CRm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. 3-4CR: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44.

INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. DUE TO THEIR RELIABILITY AND QUIET RUNNING, THEY ARE SUITABLE FOR DOMESTIC APPLICATIONS INCLUDING WATER SUPPLIES (AS A PRESSURE SET), GARDEN IRRIGATION, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

OPTIONS ON REQUEST

special mechanical seal other voltages or frequency 60 Hz

60

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

4CR80

3CR80

Head H (metres)

3CR100

Flow rate Q

TYPESingle-phase 3CRm 80 4CRm 80 3CRm 100 Three-phase 3CR 80 4CR 80 3CR 100

POWERkW HP

Q

m3/h l/min

0

0.3 5 36 48 35.5

0.6 10 35 47 35

0.9 15 34 45 34

1.2

1.5

1.8

2.4 40 25 33.5 30

3.0 50 20 28 28

3.6 60 15.5 22.5 25.5

4.2 70 10 16 23

4.8 80 5 10 20

5.4 90

6.0 100

6.6 110

7.2 120

0.45 0.60 0.60

0 0.60 38 0.85 H metres 50 36 0.85

20 25 30 32.5 31 29 43 40.5 38.5 33.5 32.5 32

17

13.5

10

5

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2 h h1DN1

w

s n1

TYPE Single-phase Three-phase 3CRm 80 3CR 80 4CRm 80 4CR 80 3CRm 100 3CR 100

PORTSDN1 DN2

1" 1" 1" 1"

1" 1" 1" 1"

a 90 90 90

f 345 353/345 353/345 353/345

h 174 174 174

DIMENSIONS mm h1 h2 n 122 52 160 52 160 122 52 160 122 52 160

kg n1 120 120 120 w 95 95 95 s 9 9 9 1~ 6.9 7.6 7.5 3~ 6.3 6.9 6.9

61

JET self-priming pumps

RANGE OF PERFORMANCE Flow rate up to 50 l/min (3 m3/h) Head up to 47 m LIMITS OF USE Manometric suction lift up to 9 m Liquid temperature up to + 40C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60 335-1 IEC 335-1 CEI 61-150 EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. EJECTOR ASSEMBLY: technopolymer (approved for drinking water). IMPELLER: brass. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite -NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty.. JSWm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. JSW: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753.

INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. JSW SELF-PRIMING PUMPS ARE DESIGNED FOR SUCTION LIFTS AND CAN BE POSITIONED ABOVE THE WATER SOURCE, INCLUDING APPLICATIONS WITH AIR ENTRAINED IN THE WATER. DUE TO THEIR RELIABILITY AND LOW MAINTENANCE, THEY ARE RECOMMENDED FOR DOMESTIC USE, INCLUDING WATER DISTRIBUTION (AS PART OF A PRESSURE SET), GARDEN IRRIGATION, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

OPTIONS ON REQUEST

impeller in technopolymer (JSWm1...X - JSW1...X) other voltages or frequency 60 Hz

62

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

JSW1AHS

JSW1B

JSW1C

Head H (metres)

Flow rate Q

TYPESingle-phase JSWm 1C JSWm 1B JSWm 1A Three-phase JSW 1C JSW 1B JSW 1A

POWERkW HP

Q

m3/h l/min

0 0 35 41 47

0.3 5 32 36 42

0.6 10 27 31 38

0.9 15 24 27 34

1.2 20 21 24 31

1.5 25 19 22 28.5

1.8 30 17 20 26

2.1 35 16 19 24

2.4 40 15 17 22

2.7 45 14 16 21.5

3.0 50 13 15 19

0.37 0.50 0.60

0.50 0.70 H metres 0.85

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2DN1

h3

h1

w

s n1

TYPE Single-phase Three-phase JSWm 1C JSW 1C JSWm 1B JSW 1B JSWm 1A JSW 1A

PORTSDN1 DN2

1" 1" 1" 1"

1" 1" 1" 1"

a 115 115 115 115

f 379 379 379 387/379

h 171 171 171 171

h1 127 127 127

DIMENSIONS mm h2 h3 33.5 160.5 160.5 33.5 33.5 160.5

h

kg n 160 160 160 n1 124 124 124 w 24 24 24 s 10 10 10 1~ 9.3 10.0 10.2 3~ 9.1 9.5 10.1

63

JET self-priming pumps

RANGE OF PERFORMANCE Flow rate up to 80 l/min (4.8 m3/h) Head up to 70 m LIMITS OF USE Manometric suction lift up to 9 m Liquid temperature up to + 40C Environment temperature up to + 40C CONSTRUCTION AND SAFETY STANDARDS EN 60 335-1 IEC 335-1 CEI 61-150 EN 60034-1 IEC 34-1 CEI 2-3

GUARANTEE 2 YEARS subject to our general terms of sale. CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1. BODY BACK-PLATE: stainless steel AISI 304. EJECTOR ASSEMBLY: technopolymer (approved for drinking water). IMPELLER: brass. MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104. MECHANICAL SEAL: ceramic - graphite -NBR. ELECTRIC MOTOR: the pumps are close-coupled to a carefully matched PEDROLLO electric motor, quiet running, totally enclosed fan cooled (TEFC), suitable for continuous duty. JSWm: single-phase 230 V - 50 Hz with capacitor and thermal overload protector. JSW: three-phase 230/400 V - 50 Hz. INSULATION: class F. PROTECTION: IP 44. REGISTERED MODEL n 72753.

INSTALLATION AND USEThey are recommended for pumping clean water and liquids that are chemically non aggressive to the materials from which the pump is made. JSW SELF-PRIMING PUMPS ARE DESIGNED FOR SUCTION LIFTS AND CAN BE POSITIONED ABOVE THE WATER SOURCE, INCLUDING APPLICATIONS WITH AIR ENTRAINED IN THE WATER. DUE TO THEIR RELIABILITY AND LOW MAINTENANCE, THEY ARE RECOMMENDED FOR DOMESTIC USE, INCLUDING WATER DISTRIBUTION (AS PART OF A PRESSURE SET), GARDEN IRRIGATION, ETC. The pumps must be installed in enclosed places, or at least protected against inclement weather.

OPTIONS ON REQUEST

impeller in technopolymer (JSWm...X - JSW...X) other voltages or frequency 60 Hz

64

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

JSW15H

JSW12H

JSW10H JSW15M JSW12M

Head H (metres)

JSW10M

Flow rate Q

TYPESingle-phase JSWm 10H JSWm 12H JSWm 15H JSWm 10M JSWm 12M JSWm 15M Three-phase JSW 10H JSW 12H JSW 15H JSW 10M JSW 12M JSW 15M

POWERkW HP

Q

m3/h l/min

0 0 56 64 70 46 50 55

0.3 5 51 58 66 42 48 52

0.6 10 47 54 62 40 46 50

0.9 15 44 51 58 38 44 48

1.2 20 41 48 54 37 42 46

1.5 25 39 45 51 35 41 45

1.8 30 36 43 48 33 39 43

2.4 40 32 38 43 30 36 40

2.7 45 30 36 41 29 35 39

3.0 50 28 34 38 27 33 37

3.6 60

4.2 70

4.8 80

0.75 0.90 1.1 0.75 0.90 1.1

1 1.25 1.5 H metres 1 1.25 1.5

25 31 35

23 29 33

21 27 30

Q = Flow rate H = Total manometric head

Tolerance of the performance curves according to EN ISO 9906 App. A.

DIMENSIONS AND WEIGHTS

f aDN2

n

h2 h3DN1

h1

w

n1

s

TYPE Single-phase Three-phase JSWm 10H JSW 10H JSWm 12H JSW 12H JSWm 15H JSW 15H JSWm 10M JSW 10M JSWm 12M JSW 12M JSWm 15M JSW 15M

PORTSDN1 DN2

1" 1" 1" 1" 1" 1" 1"

1" 1" 1" 1" 1" 1" 1"

a 113.5 113.5 113.5 113.5 113.5 113.5 113.5

f 402 402 402 402 402 402 402

h 201 201 201 201 201 201 201

h1 147 147 147 147 147 147 147

DIMENSIONS mm h2 h3 35 182 35 182 35 182 35 182 35 182 35 182 35 182

h

kg n 180 180 180 180 180 180 180 n1 142 142 142 142 142 142 142 w 22 22 22 22 22 22 22 s 10 10 10 10 10 10 10 1~ 13.7 15.0 15.2 13.7 15.0 15.2 3~ 13.8 14.0 14.2 13.8 14.0 14.2

65