GEE Electrode

description

Transcript of GEE Electrode

WELDIRECTORYWELDIRECTORY

Qua

lity

Wel

ding

Ele

ctro

des

Qua

lity

Wel

ding

Ele

ctro

des

é

é

é

é

é

é

é

é

é

é

é

é

Toyo Engineering India Ltd.

Tecnimont I C B Ltd.

Thermax Ltd.

NTPC

Jindal Steel & Power Limited.

HPCL

BPCL

Reliance Industries Limited.

Essar Oil Ltd.

BHPV, Vizag

TATA Steel Ltd.

Voith Siemens

GEE - Your Welding PartnerGEE - Your Welding PartnerGeneral Electrodes and Equipments Limited was established in 1969, in technical collaboration with Messr Griesheim Gmbh of Frankfurt, Germany for the manufacture of Quality Welding Electrodes.

We manufacture a wide range of welding electrodes for applications of general fabrication to construction of nuclear equipment. All our electrodes are manufactured at our modern plants located at Thane, Kalyan and Kolkata, equipped with a dry mixer of 1 ton capacity, one of the biggest in the industry along with one of the biggest extruders, giving our customers the advantage of consistency and reliability of quality in bigger sizes as well – a distinction that few in the industry can match. This is actively supported by a dedicated team of professionals who deliver products that meet the stringent quality code requirements of various agencies and clients. We are an ISO 9001: 2000 company accredited by Det Norske Veritas.

é

é

é

é

é

é

é

é

é

é

é

é

é

é

é

é

American Bureau of Shipping

Bureau Veritas

Bureau of Indian Standards

BHEL, Trichy

Det Norske Veritas

Engineers India Ltd.

ESSAR Steels

Indian Register of Shipping

Indian Boiler Regulation

Kvaerner Powergas

Lloyds Register of Shipping

Larsen & Toubro Ltd.

M. N. Dastur & Company Ltd.

Petron Engineering Construction Ltd.

Project & Development India Ltd.

Research Design & Standards Organization

ApprovalsApprovals

E

E

R T

T NOR E I A

S

S

K V

D

ANA

T YST M

C T

GE E

RT FI A

M

E

E

N S

M

CEI

MIE LI

TED

GE

r

a

E

o o- R

o 7 We

st aa

h n - 40 ,

A

t y.

agd

r e T a e 0

I D

ac oP t N

1o d

. , I u

t

N I

F: l

E,

N

l ni l st

,

0 6 4

d

K

ur

e

ac oD u

a hu r

, H -n

h

H

g l2 I

I

Fr :

lI

ir

6 a , n

Mi o r h W st

a - 7 1 N

g r n

l PaN

, a dA d l

u ,

B 1 3

D A

th a

st ak

u

a ,w a

e n 0 ,

y

Tsi

y

o c i t

se f

t

hit t

hr

a

Ql t

t e u

e

i Ma a m

t s e

ha y

ge Sy m

nn

t

of

6cat

1 7

fiNo.

-

A

erti

07 AQ-Iv

Ce

2-20

ND-R

ta

eeu d

n r toa

a e ey

ta d

h sn

to th

la

m ns m

bfo n co fo m

e Qu ityn g

S

n a d:

a

M

t te

Sr

I

19 00 02 0

SO 0 :

iT s C r is va

fo

u ce n e

h

a

e fo

w g

r s rr

s

ti

tli

r ll

p od c v g

e fice

dth

o in rt o e

a:

i

E

U

SD V LO

F

ETIN

OUM

IG E E

,

AI

MR

G O

C

ABLES

N &

P EMA

CTUR NG & A K

WEL INN

M NT N

DGS

D

F

ARKN F TIG WIR

I G

ES

MET

O

G

U

F WEL I

AG

,

IMP R &P L O

COUMA L

TI

W

O T P Y

B ES MW,

EF

,

S

D NNS

M

WIRS CA

A

F

WI LUX

W RES

S

&

r n C

t

O gi aer if c io

il

t i a nt da e:

-2

-03 2

01

13

a

land

te:

Pad

ce

C

7-

e ai 002- 6

h nn , 20 2

he

d U t

orc e t e

:

t A cr din

f

i

RI

F

ON

TIT

CCA I

E

V,

NV

D

. .B

LE HE

A

H

R

E T

N TNDS

it s a

u l

s C t ci

di

T i er i ai

t

h f

e v ln :

-300

19-1

22

CI

OIF

ERTCA I N

T

a sts

3 7C R

th r d T L I1

9F

36 7

D

.

e h ,

rT e Ne

,

31 8 .

X:+ 0 4

N

B V H aa t

0 tte da

e n s E.

22 6

1 19

68

-tr c tr

7 D o

, h la

. NT :

08 A

7

V

a9

m

+2

d

o p

en r e e t

is o

n e to h a

p

e n ic

e

C m lt

tad n r

to th ate

ia

dis c

dc p

cS o

rd

Y t Np

et e

a

b ' h r

ee

e e

e f

Da

is r d :

isi ie

V p v d r g

d Te m L a r

v. e

K

iak m N R

r shr

u a.

n

nme

t Rs t

Ma

npe

a

a ge r

tive

e

en

P. rR h ff

S o

ea A d r

L d u i ott ou

md

c of

o

p n

L

lm nc n

s as s e

e ix ay rr is C

ate v.

lfile of

ition t

in th A p d en e

tific

alid

a kfu

t

e

her

in

d

t

APPLICATIONS

MILD STEEL ELECTRODES1

GRICON WHITE

GRICON VIOLET

GEECON GREY

GRICON RED

GRICON BLACK

GEECON PINK

GEECON PINK(SPL)

GRICON BLUE

GRICON BROWN

GRICON LOWSIL

GRICON ROSE

GRICON ORANGE

GRICON GOLD

GRICON YELLOW

GRICON INDIGO

ClassificationAWS/SFA

0.14

0.06

0.14

-----

0.10

-----

0.12

-----

0.12

-----

0.1

0.05

0.1

0.05

0.10

0.05

0.10

-----

0.09

0.06

0.10

0.05

0.10

0.05

0.10

0.05

0.1

0.095

E6010

E6011

E6012

E6013

E6013

E6013

E6013

E6013

E6013

E6013(Nearest)

E6022

E7014

E7024

E7024

E6020

0.3

0.6

0.3

0.6

0.35

0.55

0.35

0.55

0.35

0.5

0.35

0.6

0.4

0.6

0.4

0.65

0.35

0.6

0.20

0.6

0.4

0.85

0.4

0.65

0.45

0.85

0.4

0.65

0.35

0.60

0.20

0.55

0.20

0.4

0.20

0.45

0.14

0.3

0.6

0.95

-----

0.05

0.18

0.35

0.18

0.4

0.14

0.3

0.12

0.3

0.15

0.3

0.15

0.3

0.15

0.35

0.10

0.4

0.10

0.4

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

-----

0.03

460

550

460

570

470

550

450

550

460

550

460

550

460

550

460

550

460

550

400

480

430

550

500

600

500

600

500

600

450

560

370

480

430

510

430

520

390

460

340

430

370

480

430

500

370

480

370

480

370

480

360

470

390

460

390

490

390

490

390

470

22

30

22

30

22

28

22

28

22

28

22

30

24

30

24

30

24

30

24

32

22

28

22

28

24

28

24

28

22

32

027+2 C

50-90

00 C

50-90

00 C

50-90

00 C

50-100

027+2 C

50-100

027+2 C

50-100

00 C

50-100

00 C

50-100

0-20 C

47-75

00 C

50-100

00 C

50-90

00 C

50-100

00 C

50-100

0-30 C

50-80

0-30 C

50-80

IMPACT/J

EL%(L=4d)

YS/Mpa

UTS/Mpa

Mechanical Properties of Weld Metal Range

PSSiMnC

Chemical Properties of Weld Metal (%) Range

Product Name

High cellulose deep penetration X-ray quality welds on low & high pressure pipes

Steel sheets, pipes, general fabrication

Corroded & tarnished steel; general fabrication

Structural steels fabrication work, pipe welding, storage tanks, etc.

Highly stressed joints, steel structures, pipelines, general fabrication

Radiographic quality welding of boilers, pipelines pressure vessels, storage tanks, etc

Radiographic quality welding of boilers, pipelines, pressure vessels, storage tanks, etc

Radiographic quality welding of boilers, pipelines pressure vessels, storage tanks, etc

Radiographic quality welding of boilers, pipelines, pressure vessels, storage tanks, etc

Fabrication and repair of hot dip galvanising baths

Radiographic quality welding of thick plates

Radiographic quality welding of heavy structural steels. Deposition efficiency 115%

Radiographic quality welding of heavy structural steels. Deposition efficiency 140%

Radiographic quality welding of heavy structural steels. Deposition efficiency 180%

A medium-heavy coated electrode producing fluid slag, for flat, horizontal and vertical welding.

The Power of Welding

P

LOW HYDROGEN ELECTRODES2

Product Name

GEECONPURPLE

GRICONGREEN

GRICONGREEN(SPECIAL)

GRICONGREEN NC

GRICONGREEN (SPL) H4R(VAC PACK)

E7016

E7018

E7018-1

E7018-1NACEGRADE

E7018-1H4R

0.040.10

0.040.10

0.040.10

0.040.09

0.040.10

0.81.6

0.81.6

0.81.6

0.81.4

1.01.6

0.20.5

0.200.5

0.20.60

0.20.75

0.20.75

-----0.03

-----0.03

-----0.03

-----0.03

-----0.03

-----0.025

-----0.01

-----0.015

-----0.025

-----0.025

Ni-0.3max,Mo-0.3maxCr-0.2max,V-0.08max

Mn+Ni+Cr+Mo+V=1.75max

Ni-0.3max,Mo-0.3maxCr-0.2max,V-0.08max

Mn+Ni+Cr+Mo+V=1.75max

Ni-0.3max,Mo-0.3maxCr-0.2max,V-0.08max

Mn+Ni+Cr+Mo+V=1.75max

Ni-0.3max,Mo-0.3maxCr-0.2max,V-0.08max

Mn+Ni+Cr+Mo+V=1.75max

Ni-0.10max,Mo-0.08maxCr-0.08max,V-0.02max

Mn+Ni+Cr+Mo+V=1.75max

510610

510610

510610

510610

510690

440570

440540

440540

440540

440540

2430

2430

2430

2430

2230

-30°C60-120

-30°C60-140

-46°C50-120

-46°C40-120

-46°C55-110

Medium high tensile steel, pressure vessels, boilers, welding metals of unknown composition

Radiographic quality welding of ships, boilers and pressure vesels. Deposition efficiency 110% minimum.

Radiographic quality welding of ships, boilers and pressure vessels. High impact strength at -46°C

Radiographic quality welding of Nace grade pipes, process platforms and pressure vessels. High impact strength at -46°C

The electrode deposits weld metal, which is of radiographic quality and meets impact requirements at -46°C.

ClassificationAWS/SFA

C Mn Si S OthersUTS/Mpa

YS/Mpa

EL%(L=4d)

IMP-ACT/J

APPLICATIONS

Chemical Properties of Weld Metal (%) Range

Mechanical Properties of Weld Metal Range

The Power of Welding

HIGH TENSILE LOW ALLOY STEEL ELECTRODES3

GRIDUCT-2

GRIDUCT-2R

GRIDUCT-3

GRIDUCT-3R

GRIDUCT-4

GRIDUCT-4R

GRIDUCT-5

GRIDUCT-6

GRIDUCT-8

GRIDUCT-8M

GRIDUCT-9

GRIDUCT-60

GRIDUCT-66W

GRIDUCT-75 A1

GRIDUCT-78C2L

GRIDUCT-86C1

GRIDUCT-86C2

GRIDUCT-88C1

Fine grained and creep resistant steel, chemical process plants

Boilers, power plants, heat exchangers, oil refineries,

Radiographic quality welding of fine grained and creep resistant steel, Cr-Mo alloy steels

Ideal for welding Chromium-Molybdenum alloy steels, boilers, pressure vessels, headers, high pressure piping, heat exchangers and condensers, power generation, oil refineries, petrochemical industries.

Radiographic quality welding of fine grained and creep resistant steel, Cr-Mo alloy steels.

Chemical and petrochemical industries where resistance to hydrogen attack corrosion from sulphur bearing crude oil and stress corrosion cracking in sour atmosphere is required.

0 For impact at sub-zero (up to -50 C) temperature for welding heavy sections and stressed joints, etc.

0 For impact at sub-zero (up to -30 C ) temperature high tensile fine grained steels.

High tensile, fine grained steels, HSLA, Q & T steels, HY-80, etc.

Penstock, high tensile steels, used for heavy steel fabrication. ASTM A517 Grade F

High tensile low alloy steels, quenched and tempered steels

High-pressure vessels, storage tanks, pipelines chemical industries, etc. Excellent for welding Nickel-alloyed steels up to 1.0% Nickel.

For Welding / Joining carbon steels to C-Mn steels

For high stressed joints in Molybdenum bearing steel structures. High-pressure vessels, boilers, storage tanks, pipelines, high temperature/pressure applications in oil refineries, chemical industries, etc.

Construction of cryogenic plant and associated pipe work e.g petrochemical industry.

Off-shore fabrication, LPG tanks, fabrication of storage tanks, process plants and associated pipework

Construction of cryogenic plants and associated pipingeg. Petrochemical industry, offshore fabrication

Fabrication of storage tanks, process plant and associated pipework eg. Petrochemical industry.

Product Name APPLICATIONS

E7018 A1

E7013 G

E8018 B2

E8013 G

E9018 B3

E9013 G

E7018 G

E8018 G

E10018 G

E11018 M

E9018 G

E8018 G

E7016

E7015 A1

E7018 C2L

E8016 C1

E8016 C2

E8018 C1

0.05-0.12

0.10max

0.05-0.12

0.05-0.12

0.05-0.12

0.05-0.12

0.04-0.09

0.0450.09

0.045-0.095

0.10max

0.08max

0.05-0.10

0.04-0.1

0.12max

0.05max

0.12max

0.12max

0.12max

1.25max

1.25 max

1.25 max

1.25 max

0.50-0.90

0.6-1.2

1.0-1.60

1.0-1.65

1.3-1.8

1.3-1.8

1.0-1.7

0.9-1.5

0.5-0.9

0.90max

0.5-0.9

0.4-0.9

0.4-0.9

0.4-0.9

0.80max

0.60max

0.8max

0.50max

0.6max

0.200.55

0.30-0.75

0.2-0.6

0.2-0.6

0.5max

0.20.5

0.2-0.55

0.2-0.6

0.250.6

0.2-0.6

0.8max

0.80max

0.2-0.8

0.03max

0.03max

0.030max

0.03max

0.03max

0.03max

0.020max

0.03max

0.02max

0.03max

0.025max

0.025-0.03

0.025max

0.03max

0.025max

0.03max

0.03max

0.03max

0.03max

0.025max

0.030max

0.03max

0.03max

0.03max

0.020max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

0.03max

Ni=2.0-2.75

Ni=3.0-3.75

Ni=2.0-2.75

Ni=3.0-3.75

Mo=0.40-0.65

Ni=0.3maxMo=0.3maxCr=0.2maxV=0.08max

Ni=0.40-0.80,Mo=0.05-0.30

Ni=1.0-1.8Mo=0.2-0.5

Ni=1.25-2.5, Mo=0.25-0.5Cr=0.25-0.4, V=0.05max

Ni=2.0-2.5, Mo=0.3-0.5

Cr=0.15-0.25

Ni=0.5-1.0Cu=0.2-0.4

Ni=0.4-0.85

Cr=2.0-2.50,Mo=0.90-1.25

Mo=0.9-1.25, Cr=2.0-2.5

Mo=0.40-0.65, Cr=1.0-1.50

Mo=0.40-0.65, Cr=1.0-1.50

Mo=0.40-0.65

Mo=0.40-0.65

550 min

550 min

550 min

480 min

480 min

480-580

630-690

760 min

700-840

550 650

480-580

620-740

620 740

550690

550690

500620

490590

440540

440520

480590

480590

550 620

530-620

440-550

460 560

630-740

680-760

550-590

460 min

550 min

430-500

390 min

390 min

460 min

460 min

460 min

24-30

19 min

24-30

25 min

25 min

22-30

22 min

17-22

20 min

19-25

22-28

24-30

17-24

18-24

19-26

19-26

22-28

25-30 00 C

70-160

027 C 60-100

00 C

50-100

027+2 C 55-100

027+2 C 40-90

027+2 C 40-90

0-50 C

40-100J

0-20 C 70-150J

00 C

30-90

0-51 C 27J

0-50 C

40-95J

0-40 C

47-100J

-30°C 50-120J

0-0 C

70-120J

0-100 C

40-100J

0-60 C 30-80J

0-80 C 35-80J

0-60 C

30-80J

ClassificationAWS/SFA

C Mn Si S P OthersUTS/Mpa

YS/Mpa

EL%(L=4d)

IMPACT/J

Mechanical Properties of Weld Metal Range

Chemical Properties of Weld Metal (%) Range

The Power of Welding

APPLICATIONS

HIGH TENSILE LOW ALLOY STEEL ELECTRODE3

Off-shore fabrication, fabrication of storage tanks, process plant and associated pipework, petrochemicals industries

For welding low alloy steel AISI 4130, 4140 for the repair and fabrication of manganese molybdenum casting. Pressure vessels, forgings, castings.

For welding high tensile steels for pressure vessels and otherapplications where high strength is maintained after extendedPWHT cycles such as normalizing and stress relieving.

Fabrication of higher strength steels for off-shore oil well head process pipe work and fittings. Repair of medium strength low alloy steel castings.

For welding DMR 249 A steel. Welding of fine grained steels for pressure vessels, tanks, penstocks, where high strength and sub-zero temperature toughness properties are of importance

For welding low alloy steel AISI 4130, 4140 for repair and fabrication of manganese molybdenum castings, pressure vessels, forgings, castings.

Surfacing / rebuilding hot forging dies, repairing hot working tools, surfacing hammer dies etc. For reclamation and surfacing of hot forging dies.

For boilers, super heater tubes, heat exchangers, piping and pressure vessels in oil refineries and power plants

For welding Cr-Mo alloy steel, coal liquification plants, pressure vessels, oil refineries.

For welding creep resistant steels in chemical and petrochemical plants.

For welding creep resisting steels, resistant to corrosion and hydrogen cracking

0For elevated temperature service upto 600 C

For welding high tensile steels used for pressure vessels and other applications.

For welding weathering steels type Cor-Ten A, Cor-Ten B or equivalent steels

Welding of higher strength steel structure where post-weld heat-treatment is impracticable, offshore construction, pressure vessels, pipelines etc.

For welding Q & T high tensile steels type HY 130 and equivalent normalised + tempered fine grain structural steels with yield stress up to 900 Mpa

GRIDUCT-88C2

GRIDUCT-88C3

GRIDUCT-88D3

GRIDUCT-88W2

GRIDUCT-98G

GRIDUCT-98M

GRIDUCT-98D1

GRIDUCT-100

GRIDUCT-108D2

GRIDUCT-138G

GRIDUCT-5350

GRIDUCT-B2L

GRIDUCT-B3L

GRIDUCT-B6

GRIDUCT-B6L

GRIDUCT-B8

GRIDUCT-B8L

Product Name

Chemical Properties of Weld Metal (%) Range

Ni=3.0-3.75

Cr=1.0-1.5, Mo=0.4-0.65

Ni=0.90max,Mo=0.40-0.65

Cu=0.10max,Mo=0.3-0.50Ni=0.8-1.45

Ni=0.90max,Mo=0.25-0.45

Ni=1.90-2.60, Mo=0.15max

Ni=0.90max,Mo=0.25-0.45

Cr=2.4-3.3,Mo=1.2-1.65Ni=1.8-2.50

Cr=8.0-10.5,Mo=0.85-1.20

Ni=0.40max

Cr=2.0-2.5, Mo=0.9-1.20

Cr=4.0-6.0,Mo=0.45-0.65

Ni=0.40max

Cr=4.0-6.0,Mo=0.45-0.65

Ni=0.40max

Cr=8.0-10.0,Mo=0.9-1.20Ni=0.40max

Cr=0.15max,Mo=0.20-0.35Ni=1.40-1.80,

V=0.05max

Cr=0.45-0.70,Cu=0.3-0.75Ni=0.4-0.8,V=0.05max

Cr=0.15max,Mo=0.35maxNi=0.8-1.10,V=0.05max

Cr=0.70,Mo=0.60

Ni=2.0-2.60,V=0.05max

E8018 C2

E8018 C3

E8018 D3

E8018 W2

E9018G

E9018M

E9018-D1

E8018G

E10018D2

E12018G

E12015G

E7018-B2L

E8018-B3L

E8018-B6

E8018-B6L

E8018-B8

E8018-B8L

ClassificationAWS/SFA

C Mn Si S Others

0.08max

0.12max

0.05-0.12

0.04-0.12

0.09max

0.10max

0.04-0.10

0.08max

0.05-0.15

0.050.10

0.070-0.15

0.050max

0.050max

0.05-0.10

0.05max

0.05-0.10

0.05-0.10

0.50-1.00

0.50-1.00

0.5-1.0

0.5-1.0

0.5-0.9

0.5-0.9

1.30-1.85

1.201.80

1.60-2.00

0.70-1.30

1.25-1.75

0.60-1.25

1.0-1.5

0.70-1.3

1.0-1.80

0.8-1.25

0.50-1.0

0.25-0.65

0.20.90

0.20-0.50

0.20.55

0.2-0.8

0.20-0.60

0.300.60

0.20-0.8

0.20-0.55

0.25-0.60

0.20-0.80

0.20-0.45

0.35-0.8

0.20-0.70

0.20-0.50

0.90max

0.030max

0.030max

0.03max

0.03max

0.03max

0.03max

0.03max

0.025

0.030max

0.015max

0.025max

0.03max

0.02max

0.03max

0.015max

0.020max

0.020max

0.20-0.50

P

0.030max

0.030max

0.03max

0.03max

0.03max

0.03max

0.03max

0.025

0.030max

0.020max

0.025max

0.03max

0.025max

0.03max

0.020max

0.025max

0.025max

EL%(L=4d)

YS/Mpa

UTS/Mpa

Mechanical Properties of Weld Metal Range

IMPACT/J

19-26470-560

560-650

19-26390500

530650

027 C+2 55-100J

20-28460-560

560-670

0-51 C 30-70

0-40 C

60-120

18-24550-640

620-780

16-25550-670

630-780

0-51 C

30-70J

24-30500-580

600-690

0-50 C 50-125J

16 min

620 min

690 min

0-51 C 30-80

16-20800900

9401120

027 C+2 30-60J

19-24460-560

550-670

N.A.

17-25460-580

570-650

0-0 C

30-90J

19-24460-590

580-690

00 C 70-120J

19-24460-590

580-690

00 C

70-120J

19-25460-560

550-670

027+2 C 30-80J

620min

540min

24min 0-51 C 27min

19-26460-590

550-700

0-18 C 27 min

0-50 C 50-120

24-30470-550

550-650

14 min

740 min

830 min

027 C+2 70-140J

0-80 C35-80

For welding Cr-Mo alloy steels, boilers, pressure vessels, oil refineries.

The Power of Welding

APPLICATIONSProduct NameClassificationAWS/SFA

C Mn Si PS HardnessOthers

GRIDUR-350 0.15-0.30

0.40-0.80

0.180.40

0.03max

0.03max

Abrasion and impact resistant hardfacing of machine parts of mild steel, structural steels and cast steel. Steel mill parts, couplings, rollers, conveyors

Cr=2.0-3.0 HARDNESS 330-425 BHNN. A.

GRIDUR-300 HARDNESS 275-325 BHN For medium hardness hardfacing with high

resistance to abrasion both by sliding and

rolling action

0.1max

0.025max

2.8-3.7

0.9-1.3

0.025max

N. A. N. A.

Typical Chemical Composition of deposited Weld Metal (%)

GEECON-650 LH 0.45-0.65

0.41.2

0.71.6

0.03max

0.03max

HARDNESS 580-630 BHNCr=7-9Mo=0.4-0.7

N. A. High hardness resistant to extra abrasion, impact resistant.

FOR HARDFACING4

Cr=7.0-9.0V=0.40-0.50Mo-0.40-0.50

GRIDUR-600 0.50-0.65

0.40-1.20

1.00 max

0.03max

0.03max

Abrasion-proof hardfacing machine parts subjected to impact friction and rolling, air-hardenable

N. A. HARDNESS = 550-600 BHN

GRIDUR-200 R For joining rails with tensile strength 2up to 1100 N/mm

0.10max

0.0251.5 0.6 0.025N. A. N. A. UTS / MPA = 530-630

GRIDUR-250 0.15-0.25

0.35-0.45

1.0max

0.03max

0.03max

Impact and abrasion resistant hardfacing of machine parts made out of mild steel, structural steels and cast steel. Rails, couplings, rollers, pulleys, wheel rims, conveyer screws, axles, shafts, hammers etc.

Cr=0.40-0.75Mo=1.0-1.5

N. A. HARDNESS 225-275 BHN

GRIDUR-600 R 0.5-0.8

0.5-1.5

1.0max

0.03max

0.03max

Abrasion-proof hardfacing machine parts subjected to impact friction rolling, air-hardenable.

Cr=7.0-9.0Mo=0.5 maxV=0.5 max

N. A. HARDNESS 55-60 HRC

GRIDUR-35 4.35 1.0 1.0 Suitable for hardfacing wear parts subject to mineral abrasion such as conveyor screws, mixerblades, concrete pump parts, slurry pumps, crusher parts, excavator bucket edges, coal planes subject to corrosion at elevated temperatures.

Cr=33-370.03max

0.03max

N. A. HARDNESS 2 LAYERS 58-62 HRC

GRIDUR-20 CR 2.0-2.50

0.30-0.65

0.40-0.90

0.03max

0.03max

Coal crushing hammers, plough shares, dragline bucket lips cane knives, tractor grousers, rolling mill guides.

Cr=19.0-22.50N. A. HARDNESS 55-60 HRC

Cr=3-5,Mo=7-9.5

V=0.8-1.30W=1.0-2.50

GRIDUR TLK 0.50-0.90

0.30-0.60

0.25-0.70

0.03max

0.03max

EFe5 -B Cutting and piercing tools, dies and drills, punches and knives, ingot tongs blanking dies, hear blades, milling tools, rolling mill guides etc.

HARDNESS AS WELDED 59-63 HRC

GRIDUR-M 0.601.4

12.0-14.0

1.20max

0.03max

0.03max

Abrasion-proof hardfacing of different parts made out of mild steel, structural steels, austenitic manganese, hard steel and cast steel which are loaded by impact friction and rolling

N. A. N. A. HARDNESS AS WELDED 170-220 BHNHARDNESS AFTER COLD WORKING:400-500 BHN

Mechanical Propertyof Weld Metal Range

GRIDUR-555 2.10-2.90

0.80-1.20

2.2-3.60

0.03max

0.03max

Cr=2.90-4.0N. A. HARDNESS ON 3-LAYER DEPOSIT : 576-610 BHN

Oil expeller worms, concrete mixer blades, scrapper blades, screw conveyors, cement die rings, Muller tyres, ploughshares, dippers, excavator teeth, etc.

The Power of Welding

Product Name APPLICATIONS

CuUTS/Mpa

550-650

35-45 00 C

70-100

550-650

35-45 00 C 70-100

520-640

30-40 00 C

70-120J

460-640

20-26 HARDNESS 200-280

Hv10

550-640

25-32 00 C 60-100J

760-940

15-20 00 C 50-80J

520-690

20-28 HARDNESS 325-380

BHN

590 30-45 N. A.

550-680

35-45 N. A.

N. A. N. A.

1034 10 N. A.

550 min 30-40 00 C 70-100

520-660

30-40 00 C 70-100

560-660

30-40 00 C

70-100

520 min

30-40 00 C

70-100

490 min

30-40 00 C 70-100

550-660

30-40 00 C

70-100

520-660

30-40 00 C

70-100

550-640

30-40 00 C

70-100

760-860

15-30 00 C

45-80J

GRINOX-4

GRINOX-4L

GRINOX-47

GRILOY-43N

GRINOX-18

GRINOX-134L

GRINOX-41N

GRILOY-7N

GRINOX-16-8-2

GRINOX-124LN

GRINOX-175

GRINOX-9

GRINOX-9L

GRINOX-10

GRINOX-16

GRINOX-16L

GRINOX-9Mo

GRINOX-9MoL

GRINOX-9Cb

GRINOX-2553

GRINOX-12

0.50max

0.50max

0.50max

0.3max

Cb=6 X %C1.0max

0.75max

0.50 max

0.50max

0.50max

N=0.12-0.25

1.5-2.5

0.50max

0.50max

0.50max

0.50max

0.50max

0.50max

0.50max

0.50 max

N=0.12-0.25

Cu=1.5-2.5

0.50max

600-850

22-32 00 C 70-100

For welding 18%Cr, 10%Ni steel including 301,302,303, cast steel CF3, Gf8

Extra low carbon 18%Cr/10%Ni stainless steel

For welding stainless steel types 321, 347, and 304

Surfacing valves, suitable for welding Cr-Si-Al steels (Sicranals) with upto 18% Cr used for furnace parts, petrochemical and steam generating industries

For welding 18% Cr, 9% Ni, 3% Mo steel, difficult-to-weld steel

For welding hydraulic turbines, valve bodies, pump bowls, compressor cones

Cast valve bodies, turbine parts, burner nozzles, run-out rolls in steel mills, hydro cracker reaction vessels, furnace parts suitable for surfacing mild and low alloy steels

18% Cr / 8% Ni / 5% Mn austenitic stainless steel

Catalytic crackers, cyclone transfer lines, furnace parts, thick wall steam piping

For rebuilding of continuos casting rolls, slab caster rolls, straightening and leveling rolls, crane wheels, gear wheel, bearing and shaft housing

Pump shafts, impellers, hydraulic equipments, oil and gas industries, petrochemical plants, marine and nuclear engineering

For welding 23% Cr / 13% Ni stainless steel

Extra low carbon 23% Cr / 13% Ni stainless steel

25% Cr/20% Ni Stainless steel.

For welding 18% Cr, 12%Ni, 2.5%Mo steel including CF3M, CF8M, pulps & papermill equipments, paint & dye industries etc.

Extra low carbon 18% Cr 12% Ni 2.5%Mo stainless steel

For welding 23% Cr, 13% Ni, 2.5%Mosteel, difficult-to-weld steel

For welding 23% Cr,13%Ni, 2,5%Mo steel, difficult-to-weld steel

For joining stainless steel types AISI 304,304L etc.

For welding of super, duplex stainless steel pumps and valves, corrosion/wear resisting parts and process equipment for use in offshore oil and gas industries, pulp, paper

High carbon hardenable tool, die and spring steels, 13%Mn steels, free cutting steels, high temperature steels, dissimilar joints between stainless and high carbon steels, surfacing metal-to-metal

STAINLESS STEEL ELECTRODES5

Mechanical Propertyof Weld Metal Range

ClassificationAWS/SFA

Mn SiC Cr Ni Mo

0.50-2.5

0.30-0.90

0.08max

18.0-21.0

9.0-11.0

0.75max

0.5-2.5

0.35-0.90

0.04max

18.0-21.0

9.0-11.0

0.75max

0.70-2.50

0.90max

0.08max

18.0-21.0

9.0-11.0

Cb=1.0max

0.25-0.90

0.25-0.65

0.1max

15-18 0.60max

0.60max

1.0-2.5

0.9max

0.08max

17.0-20.0

11.0-14.0

2.0-3.0

1.0max

0.90max

0.06max

11.0-12.5

4.0-5.0

0.4-0.7

0.35-0.80

0.25-0.55

0.08max

11-13.5

0.60max

0.50max

4.50-6.50

0.30-0.70

0.12max

18-21.50

8.5-10.50

0.50max

0.5-2.50

0.30-0.60

0.04-0.08

14.5-16.5

7.5-9.5

1.0-2.0

0.9 0.40.038 12.4 4 0.55

1.0max

0.8max

0.10max

14.0-16.5

3.5-4.5

N. A.

0.5-2.5

0.30-0.90

0.09max

22-25 12.0-14.0

0.75max

0.5-2.5

0.30-0.90

0.04max

22-25 12.0-14.0

0.75max

1.0-2.5

0.9max

0.08-0.16

25-28 20.0-22.50

0.75max

0.5-2.5

0.30-0.90

0.08max

17.0-20.0

11.0-14.0

2.0-3.0

0.50-2.50

0.30-0.90

0.04max

17.0-20.0

11.0-14.0

2.0-3.0

0.5-2.5

0.9max

0.08max

22.0-25.0

12.0-14.0

2.0-3.0

0.5-2.5

0.30-0.70

0.04max

22.0-25.0

12.0-14.0

2.0-3.0

0.5-2.5

0.9max

0.10max

22.0-25.0

12.0-14.0

Cb=0.7-1.0

0.5-1.5

1.0max

0.025-0.06

24.0-27.0

6.5-8.5

2.9-3.9

E308-16

E308L-16

E347-16

E430-15

E318-16

E410NiMo-16

E410-16

E307-15

E 16-8-2-16

E410NiMo-16

E630-16

E309-16

E309L-16

E310-16

E316-16

E316L-16

E309Mo-16

E309MoL-16

E309Cb-16

E2553-16

E312-16 0.5-2.5

0.40-0.90

0.15max

28.0-32.0

8.0-10.5

0.75max

Typical Chemical Composition of deposited Weld Metal (%)

HARDNESS38-45HRC

IMPACT/J

EL%(L=4d)

The Power of Welding

Product Name APPLICATIONS

Tanks, process piping, heat exchangers, agitators and rotors, cast pumps and valves

Widely used particularly in petrochemical and chemical process plants, particularly for the fabrication of cyclone transfer lines catalytic crackers.

Suitable for welding stainless steels extra low carbon or stabilized by Titanium or Niobium such as AISI grades 316L.317L and 318, S.S. clad pleas, chemical plants, and paint and dye industries

Extra low carbon 18% Cr / 10% Ni type 304L, 304 austenitic stainless steel.

Extra low carbon 23% Cr / 13% Ni austenitic stainless steel.

A rutile type flux coated electrode which deposits a 23% Cr / 13% Ni / 2.5% Moaustenitic stainless steel weld metal

Fabrication of stainless steel structures and assemblies such as plate, pipe work, vessels

For fabrication of cryogenic liquid air plants

For fabrication of cryogenic liquid air plants, for welding AISI 316L stainless steel in fertilizer plants

Extra low carbon molybdenum alloyed acid resisting stainless steel of similar composition

Extra low carbon 23% Cr / 13% Ni / 2.5% Mo stainless steel

19% Cr / 10% Ni / 4.5% Mo typestainless steel

23%Cr/9%Ni/3%Mo/ferrite duplex stainless steel of about FN 45.

For cryogenic applications involving use of stainless steels types AISI 304, 304L etc., tanks, forgings and castings, in chemical, power and pharma plants

For surfacing of foot rolls of slab casters and various rolls of steel plants, for hardfacing C-Mn steels, low alloy steels etc.

Extra low carbon 18% Cr / 10% Ni type304L, 304 austenitic stainless steel

Suitable for austenitic ferrite joints. Especially suited to fabricating tough joints between unalloyed low alloyed steels

Tanks, Process Piping, Heat exchangers, Agitators and Rotors. Cast Pumps for use in the chemical processing, metal cleaning and pickling industries

STAINLESS STEEL ELECTRODES5

ClassificationAWS/SFA

E309MoL-17

GRINOX-904L

GRINOX-308H

GRINOX-316L NF

GRITINOX-308L

GRITINOX-309L

GRITINOX-309Mo

GRIBINOX-316L

GRIBINOX-316L NF

GRIBINOX 316L CF

GRITINOX-316L

GRITINOX-309MoL

GRITINOX-347

GRITINOX-2209

GRINOX-308LT

GRINOX-123V

GRIBINOX-308L

GRIBINOX-308Mo

GRIBINOX 320

E385-16

E308H-16

E316L-16

E308L-17

E309L-17

E309Mo-17

E316L-15

E316L-15

E316L-15

E316L-17

E347-17

E2209-17

E308L-16

N. A.

E308L-15

E308Mo-15

E320-15

Typical Chemical Composition of deposited Weld Metal (%)

C

0.03max

0.04-0.08

0.04max

0.035max

0.04max

0.12max

0.040max

0.040max

0.040max

0.04max

0.04max

0.08max

0.04max

0.04max

0.080-15

0.04max

0.08max

0.07max

1.0-2.5

0.50-2.5

1.0-2.0

0.50-2.5

0.50-2.0

0.5-2.5

0.5-2.5

2.0-5.0

1.0-2.50

0.5-2.5

0.5-2.5

0.5-2.5

0.5-2.5

0.5-2.5

0.7-1.25

0.5-2.5

0.5-2.5

1.0-2.50

Si

0.75max

0.30-0.90

0.9max

0.50-0.90

0.50-0.90

0.50-0.90

0.30-0.90

0.25-0.60

0.25-0.60

0.50-0.90

0.50-0.90

0.50-0.90

0.35-0.90

0.25-0.55

0.75max

0.90max

0.90max

0.3 max

Cr

19.5-21.5

18.0-21.0

17.0-20.0

18.0-21.0

22.0-25.0

22.0-25.0

17.0-20.0

17.0-20.0

17.0-20.0

17.0-20.0

22.0-25.0

18.0-21.0

21.5-23.5

18.0-21.0

11.5-13.0

18.0-21.0

18.0-21.0

19.0-21.0

Ni

24.0-26.0

9.0-11.0

12.0-14.0

9.0-11.0

12.0-14.0

12.0-14.0

11.0-14.0

11.0-14.0

11.0-14.0

11.0-14.0

12.0-14.0

9.0-11.0

8.5-10.5

9.0-11.0

2.5-3.7

9.0-11.0

9.0-11.0

32.0-36.0

Mo

4.2-5.2

0.75max

2.0-3.0

0.75max

0.75max

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

0.75max

2.50-3.50

0.75max.

0.7-1.15

Nb=0.30max

N. A.

2.0-3.0

2.0-3.0

Mn Cu

1.2-2.0

0.75max

0.75max

0.75max

0.75max

0.75max

0.75max

0.50max

0.50max

0.75max

0.75max

0.75max

0.75max

0.75max

0.08max

Ti=0.05max

N. A.

0.75max

Cu=3.0

-4.0

Nb=8XC%

1.0 max

EL%(L=4d)

30-40

35-45

30-40

35-45

30-40

30-40

30-45

30-45

30-45

35-45

30-40

30-42

20-25

35-45

N. A.

35-45

N. A.

30-40

00 C 70-100J

00 C 70-100J

0-196 C 35-50J

00 C

70-100J

00 C

70-100J

00 C

70-100J

00 C

60-105J

0-196 C 30-50J

0-196 C 30-50J

00 C 70-100J

00 C

70-100J

00 C

70-100J

00 C 50-80J

0-196 C 35-70J

N. A.

00 C

50-70J

00 C 55-85J

N. A.

IMPACT/J

Mechanical Propertyof Weld Metal Range

UTS/Mpa

530-630

550-640

490-640

520-630

550-660

550-660

490-650

570-690

530-630

530-640

520-660

560-660

700-800

530-630

520-630

N. A.

550-650

HARDNESS OF THE WELD

METAL 35HRC MIN

The Power of Welding

Product Name

Typical Chemical Composition of deposited Weld Metal (%)

AWS/SFA

C PS NiMn Fe Cu

Classification

GRICAST-CN ENi-Cu-B 66 3031.0 0.03 0.03-----

GRICON CUT CUTTING ELECTRODE

GRICONGOUGE

GOUGING ELECTRODE

GRICAST-NF ENi-Fe-CI 53 0.5450.50 0.03 0.030.75

GRICAST-N ENi-CI 98 0.501.51.0 0.03 0.03-----

GRICAST-LH Est ----- ----- ----- ----- ----- ----- -----

Monel based cast iron welding – machinable

GRINI ENi-Cu-7 62-69 282.50maxTi=1.0max

0.08 0.015 0.024.0max Welding NiCu alloys such as monel

For cutting and piercing

For gouging

Ferro-nickel cast iron welding – machinable.

Pure nickel deposit cast iron welding

Non-machinable welding of cast iron

For welding tin, bronze and copperGRICU-2 ECu-SnA 930.03 0.2-0.35----- ----- Sn5to7%

-----

APPLICATIONS

CAST IRON, NON FERROUS & OTHERS6

Chemical Properties of Weld Metal (%) Range

C

Product NameClassificationAWS/SFA

Mn Cr Mo CuNiSi S P

APPLICATIONS

Others

TIG FILLER WIRES7

-----0.1

-----1.31.7

----- ----- -----0.5

-----0.40.75

-----0.03

-----0.03

0.070.12

-----0.40.7

1.21.5

0.40.65

-----0.35

-----0.20

0.40.7

-----0.025

-----0.025

----------0.1

0.40.7

4.56

0.450.65

-----0.35

-----0.6

-----0.75

-----0.025

-----0.025

----------0.1

0.40.7

810.5

0.81.2

-----0.35

-----0.5

-----0.5

-----0.025

-----0.025

0.070.12

-----0.40.7

2.32.7

0.91.2

-----0.35

-----0.2

0.40.7

-----0.025

-----0.025

-----0.07

0.91.4

----- ----- -----0.5

-----0.40.70

-----0.02

-----0.025

Zr-0.02-0.12,Al-0.05-0.15,Ti-0.05-0.15

-----0.07

0.91.4

----- ----- -----0.5

-----0.40.70

-----0.015

-----0.015

Zr-0.04-0.70Al-0.05-0.15,Ti-0.05-0.15

0.30.65

12.5

19.522

9.011

-----0.02

-----0.03

-----0.03

-----

For general purpose Tig welding

For welding of creep resisting steel

For welding 5% Cr / 0.5% Mo steel

For welding 9% Cr / 1.0% Mo steel

For welding 2.4% Cr / 1.0% Mo steel

For welding structural pressure vessels and boilers involving micro aloyed structural steels

For welding structural steel pressure 0vessels -35 joules at (-45 C)

For welding ASTM A304/A304L steel, 321 & 347 stainless steel

GETIG 70S-G

GETIG 80S-B2

GETIG 80S-B6

GETIG 80S-B8

GETIG 90S-B3

GETIG 70-S2

GETIG 70-S2(SPL)

GETIG 308L

ER 70S-G

ER 80S-B2

ER 80S-B6

ER 80S-B8

ER 90S-B3

ER 70S-2

ER 70S-2(SPL)

ER 308L -----0.75

-----0.75

The Power of Welding

Chemical Properties of Weld Metal (%) Range

C

Product Name

Others

ClassificationAWS/SFA

Mn Cr Mo CuNiSi S P

APPLICATIONS

TIG FILLER WIRES7

-----12.5

-----0.03

1820

-----0.75

-----0.75

-----0.75

1114

2.03.0

0.30.65

-----0.03

-----0.03

-----0.08

12.5

1820

2.03.0

1114

0.30.65

-----0.03

-----0.03

Nb-8X% C MIN/ 1.0% MAX

-----0.08

12.5

1921.5

-----0.75

-----0.75

911

0.30.65

-----0.03

-----0.03

Nb-10 X % C MIN/ 1.0% MAX

----- 0.51.5

----- ----- 94-----

-----2.84

----- ----- Fe-0.3 max,Zn-0.2 max, Sn-1.0 max

-----0.10

-----0.5

2023

810

58-----

-----0.5

-----0.015

-----0.02

-----0.5

Nb+Ta-3.15-4.15,Fe-5.0 max,

Ti-0.4Max, Al-0.4 max

-----0.15

-----4

----- ----- Rema-inder

6269

-----1.25

-----0.015

-----0.02

Al-1.25 max,Fe-2.5 max,Ti-1.5-3.0

----- 0.51

----- ----- Rema-inder

3032

-----0.1

-----0.01

-----0.01

Ti-0.2-0.5,Fe-0.4 max,Al-0.03 max

-----0.1

2.53.5

1822

----- -----0.5

67-----

-----0.5

-----0.015

-----0.03

Nb+Ta-2.0-3.0,Fe-3.0 max

Ti-0.75 Max

-----0.025

12.5

19.521.5

4.25.2

-----2426

0.250.65

-----0.015

-----0.015

Cu-1.20 - 2.0

-----0.02

-----1

14.516.5

1517

-----0.75

Rema-inder

-----0.08

-----0.03

-----0.04

W-3.0-4.5Fe-4.0-7.0,Co-2.5max, V-0.35max

0.30.65

0.040.08

12.5

19.522

911

-----0.03

-----0.03

-----0.75

-----0.75

-----

12.5

0.30.65

2325

1214

----------0.03

-----0.03

-----0.03

-----0.75

-----0.75

-----0.75

12.5

0.30.65

0.080.15

2528

2022.5

----------0.75

-----0.75

-----0.03

-----0.03

0.30.6

0.040.08

12.5

1820

1114

----------0.03

-----0.03

2.03.0

12.5

0.30.65

2832

810.5

-----0.15

----------0.75

-----0.75

-----0.03

-----0.03

12.5

0.30.65

2325

1214

-----

For welding high Ni alloys for furnace parts for welding 6.0% Mo super austenitic stainless steels.

Suitable for welding ASTM 316/316L as well as Nb or Ti stabilised stainless steel

ASTM/ ASME type 316Ti, 316Cb, CF 10 MC

Suitable for welding AISI 321, 347& 348 type grade that are commonly used in refinery,petrochemical industries

Joining alloys, brass CuMn2, CuSi2Mn, CuSi3Mn, galvanised steels, surfacing mild steel, low alloy steels and cast iron.

For joining and surfacing of Ni-Cu clad steel.

For welding similar cupro nickel alloys,

For welding 5% and 9% Ni-steels for cryogenic applications

Corrosion resistance steels of 904L type ASTM UNS No-8094, DIN-1.4500, 1.4539 widely used in chemical process plants.

For cladding steel with Ni-Cr-Mo weld metal.

For welding ASTM A304/A304L steel, 321& 347 stainless steel

Buffer layer on mild and low alloy steel joining type, 304/304L, 347, 321, 316/316L. Duplex stainless steel

For joining difficult-to-weld steels such as armour plate, ferritic stainless steels as well as dissimilar steels in furnace and heat treatment equipment

For welding similar alloys also used in application involving special alloys for high temperature services

Buffer layer on mild and low alloy steel joining type, 304/304L, 347, 321, 316/316L. Duplex stainless steel

Buffer layer on mild and low alloy steel joining type, 304/304L, 347, 321, 316/316L. Duplex stainless steel

GETIG 316L

GETIG 318

GETIG 347

GETIG 702

GETIG 625

GETIG 811

GETIG 812

GETIG 821

GETIG 904L

GETIG 3276

GETIG 308H

GETIG 309L

GETIG 310

GETIG 316H

GETIG 312

GETIG 309MoL

ER316L

ER 318

ER 347

ER Cu Si-A

ER Ni CrMo3

ER Ni Cu-7

ER Cu-Ni

ER Ni Cr-3

ER 385

ER Ni Cr Mo4

ER 308H

ER 309L

ER 310

ER 316H

ER 312

ER 309MoL 2.03.0

-----0.03

-----0.03

-----0.03

The Power of Welding

Product Name Description Hardness & Alloy Basis

TUBULAR ELECTRODES8

Application

GEECOR 10

GEECOR 20

GEECOR 40

GEECOR 80

GEECOR 90

GEECOR 404

GEECOR 505

Low heat input hardfacing tubular electrode having excellent abrasion resistance properties.

Low heat input hardfacing tubular electrode having excellent abrasion resistance properties.

Tungsten carbide tubular electrode for high pressure abrasion.

Tubular hardfacing low heat input electrodes for surface roughening of sugarcane crusher rolls.

Complex carbide tubular electrode to resist abrasion at high temperature.

Low heat input hardfacing tubular electrode for highly abrasion resistant cladding subjected to extremely sliding mineral abrasion

Tubular electrode for joining & surfacing of high strength grades of cast iron.

Alloy basis : 10 to 14% Mn in Ni - Fe system.

Alloy basis: Mo, W, Nb, C, V hardness: Single layer-59 to 63 Rc / Multi-63-67Rc

Alloy basis: C, Cr, Mo, V hardness: 59 to 63 Rc

Alloy basis: C, Cr, Ni, Si hardness: 57 to 61 Rc

Alloy basis: C, Co, W hardness: 56 to 63 Rc

Alloy basis: C, Cr, Mo, B, V hardness: 59 to 63 Rc

Hardness on 2 layer deposit: 55 to 60 Rc

Filling cavities in cast irons, correcting machining errors, repair and surfacing of high strength grades of cast iron

Working parts of steel mills, sliding mineral surfacing on earth moving equipments.

Coal burner nozzles, linker conveyor chains, railway tampers, etc

Arcing of sugarcane crusher rolls.

Rock drills, oil well drills, pug mill augers and knives, choppers, mixers etc.

Fan blades, liner plates, abrasive slurry mixers etc.

Impellers castings, conveyor chains, buldozer cutting edges etc.

The Power of Welding

Product Name Wire Classification AWS / SFA

SAW WIRE & FLUX COMBINATION9

Application

GEEFLUX 500

GEEFLUX 502

GEEFLUX 504

GEEFLUX 521

GEEFLUX 522

GEEFLUX 541

GEEFLUX 303

GEEFLUX 376

GEE SAW EL8 / EM12K

GEE SAW El8

GEE SAW EH14 /GEE SAW EM12K

GEE SAW ENi2

GEE SAW EM12K

GEE SAW EH14 / GEE SAW EM12K /GEE SAW EH10K

GEE SAW ER308L / GEE SAW ER309L /GEE SAW ER316L /GEE SAW ER347

GEE SAW ER308L / GEE SAW ER316L

N. A.

N. A.

F7 A (P)2-EH14 / EH10K

F7 A (P)2-EM12K

F8 A6 ENi2-Ni2

F7 A (P)2-EH14F7 A (P)2-EM12K

F7 A (P)Z-EL8

F7 A (P)Z-EL8F7 A (P)O-EM12KF8 A (P)O-EM12K

Agglomerated Alumina - Basic Type Flux for Welding Pressure Vessels, Pipe Steels, Fine Grained Steel, Structural Steels etc.

Agglomerated Alumina - Basic Type Flux for Welding Pressure Vessels, Pipe Steels, Fine Grained Steel, Structural Steels etc.

Agglomerated Alumina - Basic Type Flux for Welding Pressure Vessels, Pipe Steels, Fine Grained Steel, Structural Steels etc.

Agglomerated fluoride basic type flux recommended for welding of high tensile fine grained steels for Naval applications

Agglomerated submerged are welding flux to be used with EM12K

Agglomerated fluoride basic type flux recommended for welding medium tensile steels

Agglomerated flux for welding of austenitic stainless steels, type AlSI 304 & 316L for cryogenic applications.

0Excellent impact properties at - 196 C

Agglomerated flux for welding of various grades of austenitic stainless steels such as AlSI 304, 304L, 316L, 347 etc.

The Power of Welding

UTS/Mpa

YS/Mpa

EL%(L=4d)

Typical Chemical Composition of deposited weld metal (%)

OTHERSSSi PMnC

Product NameClassificationAWS/SFA

IMPACT/J

APPLICATIONS

FLUX CORED WIRE10

580 550 25N. A. 00 C 85J0.04 1.29 0.49 0.009 0.01E71T-1 All position welding of ships,bridges, machinery, vehicles

590 40Cr=18Ni=12

Mo=2.5

N. A. 0-20 C 50J0.03 1.2 0.7 0.01 0.025E316LT1-1/4 Welding of stainless steel and dissimilar steels

610 45Cr=19.5Ni=10

Cb=0.40

N. A. 0-20 C 60J0.04 1.2 0.8 0.01 0.025E347T1-1/4 Welding of stainless steel, boilers and gas turbines

620 570 26N. A. 0-30 C 70J0.06 1.39 0.39 0.014 0.013E71T-5 Welding of mild and high tensile

strength steels for ships, bridgesand heavy plants

550 45 0-20 C 60JCr=19.5

Ni=10N. A.0.03 1.45 0.65 0.01 0.025E308LT1-1/4 Welding of 18c R/8 Ni type of

stainless steel

590 40 0-20 C 50JCr=23Ni=12.5

N. A.0.03 1.3 0.65 0.01 0.025

GFC-71

GFC-316L

GFC-347

GFC-75

GFC-308L

GFC-309L E309LT1-1/4 Welding of dissimilar steels, carbon steels, low alloy and stainless steels

Mechanical Propertiesof Weld Metal Range

ProductName

AWS/ SFA

CrSi NiMn MoC

12-14 0.15 max0.30-0.65 23-251.0-2.5ER 309L 0.03 max

0.30-0.65 23-251.0-2.5 12-15 2.0-3.0ER 309MoL 0.03 max

0.30-0.65 18-201.0-2.5 11-14 2.0-3.0ER 316L 0.03 max

0.50 max 15.5-17.00.60 max 0.60 max 0.75 maxER 430 0.10 max

0.10 max Fe = 0.75-1.5Zn = 0.02 max Pb = 0.07 max Cu = RemainderER Cu Al-A2 Al = 9.0-11.0

4.5-6.0 Zn = 0.02 max0.05 max Fe = 0.80 max Cu = 0.30 maxER 4043 Al = Balance

1.0-2.5 0.30-0.65 19.5-21 0.75 max9-11.0ER 308L 0.03 max

-----0.80-1.15 -----1.40-1.60 -----ER 70S-6 0.07-0.12

ER 307 0.10 max 4.0-7.0 0.30-0.65 18-21 7.5-9.5 0.75 max

MIG WIRES11

2.8-4.0 Zn = 0.02 max1.50 max Fe = 0.80 max Sn = 1.0 max

GEMIG 309L

GEMIG 309MoL

GEMIG 316L

GEMIG 430

GEMIG 715

GEMIG 4043

GEMIG 308L

GM-70

GEMIG 307

GEMIG 702 ER Cu Si-A Cu = Remained

The Power of Welding

GEE Manufacturing Centres

GEE’s manufacturing facility is a new greenfield electrode

plant endowed with a rated capacity of 6,000 tons per annum.

All the machinery and support systems commissioned for the

operation are the best in their class in terms of technology

and performance for maximum productivity. The plant is ISO

9001: 2000 certified and is already on stream with electrodes

under many categories, catering to the requirements of the

eastern region and export markets of South East Asia.

Kolkata Plant

The second and entirely new plant at Kalyan will considerably

enhance the company’s erstwhile mother plant located

originally at Thane. With the installation of a fully automatic

flux batching system and packing line, the plant is shortly

expected to be one of its kind in this part of the country.

Kalyan Plant

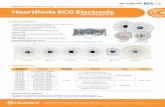

GEE Standard Packing

C

A

B D

a

b

c f

e

d

5kg 20kg

Covered Electrodes

The Power of Welding

a = 7 cm d = 7.5 cmb = 5.5 cm e = 24 cmc = 45.5 cm f = 47.5 cm

A = 46 cm C = 122 cmB = 13 cm D = 96 cm

15 kg

a

b

C

MIG Wire & FCW

a = 10.5 cmb = 26 cmc = 26 cm

A = 64 cmB = 13 cmC = 108 cmD = 86 cm

No. of spools = 72Pallet weight = 1080 kg.

25kg

a

b

c

a = 8.5 cmb = 44 cmc = 43 cm

A = 78 cmB = 13 cmC = 88 cmD = 88 cm

No. of spools = 32Pallet weight = 800 kg.

SAW Wire

a = 31 cmb = 38 cm

A = 76 cmB = 13 cmC = 122 cmD = 96 cm

No. of Drums = 24Pallet weight = 600 kg.

SAW Flux

a = 52 cmb = 80 cm

A = 80 cmB = 13 cmC = 105 cmD = 105 cm

No. of Drums = 4Pallet weight = 1000 kg.

Pail Pack

a

b

250kg

a

b

No. of boxes = 50Pallet weight = 1000 kg.

25kg

Regd. Head OfficePlot No. E-1, Road No. 7, Wagle Industrial Estate.Thane - 400 604Tel. : (022) 2582 1277 / 0619 / 2620 / 8023Fax : (022) 2582 8938Email : [email protected]

Kalyan PlantPlot No. 12/B, Saravali MIDC, Kalyan-Bhiwandi Road,Kalyan (W) - 421311Tel. : (02522) 281176 / 80 / 88 Fax : (02522) 281199Email : [email protected]

Kolkata PlantJalan Industrial Park,NH-6, Dhulagori,P. O. - Kanduah,Hawrah - 711 302 (W. Bengal)Tel. : (033) 3250 1526Fax : (0091-33) 248 2855Email : [email protected]

Location E-mail

Ahmedabad [email protected]

Aurangabad [email protected]

Bangalore [email protected]

Baroda [email protected]

Bhillai [email protected]

Bhopal [email protected]

Bhubaneshwar [email protected]

Chennai [email protected]

Delhi [email protected]

Hyderabad [email protected]

Jabalpur [email protected]

Jamshedpur [email protected]

Kochi [email protected]

Kolhapur [email protected]

Kolkata [email protected]

Nagpur [email protected]

Pune [email protected]

Rajasthan [email protected]

Rajkot [email protected]

Ranchi [email protected]