Gazebo - Fh00jau

-

Upload

neon-mercury -

Category

Documents

-

view

37 -

download

1

description

Transcript of Gazebo - Fh00jau

®

PROJECT PLAN

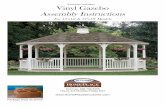

GazeboThis article originally appeared in The Family Handyman magazine.

For subscription information, visit www.familyhandyman.com

Please note that pages that appeared in the magazine as advertisements will not be included with this pdf. Page numbering may beinterrupted if an advertisement ran within the original story. Addresses, phone numbers, prices, part numbers and other informationmay have changed since original publication.

Copyright ©2005 Home Service Publications, Inc. All rights reserved. Unauthorized reproduction, in any manner, is prohibited. The Family Handyman, Handy Hints and Great Goofs are regis-tered trademarks of RD Publications, Inc. Ask Handyman, Handyman Garage, How a House Works, Re.Do, Re.Mod, TFH Reports, The Home Improvement Authority, Using Tools,Woodworks, Wordless Workshop, Workshop Tips, You Can Fix It, You Can Grow It are trademarks of RD Publications, Inc.

32 JULY /AUGUST 2000 THE FAMILY HANDYMAN

THE FAMILY HANDYMAN JULY /AUGUST 2000 33

esides gracing the back yard with its splendor andcalming presence, a gazebo is the perfect place toentertain. One look at this beauty and you’ll bepicturing it filled with family and friends, cele-brating a graduation or even a backyard wedding.

We designed this 12-ft. dia. gazebo with plenty of eye-pleasing trim, from the pattern-cut rails that surround theseating area to the ball-shaped finial atop the cupola. Yet it’seasy to build if you follow our special hints, tips, technical

illustrations and Cutting List.

You’re no doubtwondering what thisgem costs to build.Well, you could pay$15,000 and let a contractor have all thefun, or you could buildit yourself for about$3,800. You can pocketthe savings—or throwone really great party.

This project is not as dif-ficult as it looks. Think ofit as a series of severalshorter projects with anend goal in sight for each.You can make all the dec-orative parts in yourgarage or shop (especiallyon rainy days). If youhave several friends helpyou with the slab andframing (promise themanything), you canspread these two tasksover several weeks. Aproject like this wouldtake two experienced car-penters nine workingdays from start to finish.An intermediate do-it-yourselfer who has built adeck should plan this as awhole summer project.NOTE: You must have asite that slopes less than 4 in. over 12 ft. (any morethan this will requiresome excavating).

This gazebo isbuilder-friendly

by David Radtke

Solid construction—hidden steel fasteners

Complex roof made simplewith step-by-step photos

Decorative trim—patterns provided

B

34 JULY /AUGUST 2000 THE FAMILY HANDYMAN

Fig. A

3-1/2" DIA. WOOD BALL

4"

5-1/2"

1-1/2"

1-1/2"

12"

13-1/2"

2" SCREW (TYPICAL)

14-1/4"

12" METAL STRAP

12" METAL STRAP

METAL STANDOFF

3/4" QUARTER ROUND TRIM; MITER ENDS (TYPICAL)

2" x 18" x 18" INLAID STONES

CONCRETE SLAB

TRIM TO OCTAGON SHAPE

2-1/4"

1-1/2" 5-1/2"7-1/2"

67-1/2 DEGREE BEVEL

CUT FROM 2x6s

CUT FROM 1" THICK DECKING

CUT SAW KERF IN POST TO FIT METAL STRAP (SEE FIG. B)

67-1/2°

3/8" x 3" BOLT

S2

S2

CUPOLA SECTION

S1

S1

M

M

R2

R1

R1

T1

T1

T1

T2

H2

G3

G3L

LNN

N

K1P

Q

Q

P

A

D1, D2

C2

C1

D2

D1A

A

A

B

B

B, E, F, H1, H2

E

F

F

F

F

G2

G1

J

J

K1

K2

H1

H1

H1

C1, C2

Story Number— Story Name—Gazebo Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

G A Z E B OOverview

THE FAMILY HANDYMAN JULY /AUGUST 2000 35

You don’t have to get the slab dimen-sions perfect, but the closer theycome to it, the easier things will belater. If you hate doing concretework, skip this section, photocopy itand give it to your concrete mason. Acrew can do the work for about$1,200 while you’re out shopping forlumber or cutting parts (but you cancut the cost to a couple of hundred ifyou do it!). There’s also an article inour May ’00 issue on pouring con-crete that’ll fill in a lot of gaps in thissubject area. (To order a copy, see p. 114.) Follow Fig. B closely if youdecide to do it yourself.

Begin by driving a 2-ft. piece ofrigid electrical conduit at theintended center of the gazebo. Drive

it in 18 in. Remove the sod with arented sod cutter. You’ll need toexcavate a 9-in. deep area radiatingout about 78 in. from the conduit.After that you’ll set forms and put ina layer of 1/4-in. gravel to the dimen-sions shown in Fig. B. The idea is tohave the outside foot or more of theslab thicker to support the weight ofthe structure.

Build your forms after carefullyexamining Fig. B. Set your circularsaw at 22-1/2 degrees and cut eight2x8 exterior forms with the short sidemeasuring 57-1/2 in. Screw the formstogether with 3-in. deck screws. Havea friend help you align the forms sothe eight corners of the forms are all

KEY QTY. SIZE AND DESCRIPTION A 8 3-1/2” x 3-1/2” x 102” postsB 8 1-1/2” x 5-1/2” x 56-1/2”

top platesC1 16 7/8” x 3-1/2” x 31” cedar

wrap*C2 16 7/8” x 3-1/2” x 36” cedar

wrap*D1 16 7/8” x 5-1/4” x 31” cedar

wrap*D2 16 7/8” x 5-1/4” x 36” cedar

wrap*E 8 1-1/2” x 3-1/2” x 50-3/4”

cedar headersF 30 1-1/2” x 3-1/2” x 50” cedar

railsG1 56 3/4” x 5-1/2” x 27” balustersG2 96 3/4” x 3-1/2” x 8” spandrel

picketsG3 16 3/4” x 3-1/2” x 13” cupola

pickets (wilson pickets)H1 280 ft. 3/4” x 3/4” retainer strips

(cut to fit)H2 16 ft. 3/4” x 3/4” retainer strips

(cut to fit)J 16 1-1/8” x 9-1/4” x 22-1/2”

corner bracesK1 8 1-1/2” x 5-1/2” x 102” lower

raftersK2 8 1-1/2” x 7-1/4” x 24” rafter

tail buildupsL 8 3/4” x 1-1/2” x 34” inner

vertical rafter tiesM 8 1-1/2” x 5-1/2” x 32” cupola

raftersN 1 3-1/2” x 3-1/2” x 50”

octagonal rafter hub P 8 1-1/2” x 3-1/2” x 32” outer

vertical rafter tiesQ 16 1-1/2” x 3-1/2” x 10”

horizontal rafter tiesR1 8 7/8” x 8-1/2” x 6’ lower

fascia (cut to length)R2 8 7/8” x 5-1/2” x 2’ upper

fascia (cut to length)S1 1 See Fig. AS2 2 See Fig. AT1 300 ft. 1” x 2-3/4” lower roof

sheathing (5/4 decking cut in two)

T2 320 ft. 1” x 5-1/2” upper roof sheathing (5/4 decking)

Cutting List

4-3/4"

7"

2"GRAVEL

3-1/2"

3/8" DIA. HOLE

CONCRETE SLAB

3/8" x 2" CROSS BOLT

12" STEEL ANCHOR

POST CENTER

57-1/2"

72-1/2"

45 DEGREES

45 DEGREES

INSET STONES 2" x 18" x 18"

70" TO POST CENTER

74-3/4" TO SLAB POINT

12" STEEL ANCHOR (SEE SECTION VIEW)

CL

CL

22-1/2 DEGREES

C L

4"

Story Number— Story Name—Gazebo / Slab Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

4-3/4"

7"

2"GRAVEL

3-1/2"

3/8" DIA. HOLE

CONCRETE SLAB

3/8" x 2" CROSS BOLT

12" STEEL ANCHOR

POST CENTER

57-1/2"

72-1/2"

45 DEGREES

45 DEGREES

INSET STONES 2" x 18" x 18"

70" TO POST CENTER

74-3/4" TO SLAB POINT

12" STEEL ANCHOR (SEE SECTION VIEW)

CL

CL

22-1/2 DEGREES

C L

4"

Story Number— Story Name—Gazebo / Slab Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

The slab

G A Z E B O

Fig. BConcrete Slaband Paver Detail

18" x 18" PAVERS INSET

CONCRETE SLAB

36 JULY /AUGUST 2000 THE FAMILY HANDYMAN

CARRIAGEBOLT

KERFCUT FORSTEELANCHOR

ALUMINUM POST STANDOFF

G A Z E B O

TIGHTEN THE NUTonto the carriage bolt.Temporarily brace the4x4s if necessary. Besure you have thestandoff screwed tothe posts before youmark and drill thehole.

2

side. Center it as shown and drive inthe stakes on the inside of the formsand screw them together.

The slab will require about 1-1/2yds. of concrete and four 10-ft. piecesof No. 4 rebar. Have plenty of help (atleast three strong backs and twoheavy-duty wheelbarrows). Wheel-barrow the concrete and dump it into

the same distance from the conduitcenter. If these measurements are allequal, your slab will be a perfect octa-gon—get it as close as you can. Drive3/4 in. x 2-1/2 in. stakes along theoutside of the forms at each intersec-tion, level the forms and screw theforms to the stakes.

Now build a square inner form forthe patio inlay, 72-1/2 in. on each

CUT THE POSTS TO LENGTH and mountthe aluminum standoff underneath. Trans-fer the hole locations in your steelanchors to the sides of the post.Drill a 1-1/4 in. recessedhole followed by a 3/8-in. hole forthe 3-in.carriagebolt,

washer and nut.

1

G A Z E B OG A Z E B O

the forms, lay rebar 4 in. in along theperimeter, screed the concrete with astraight 2x4, then run the hand floatover it. Set your anchors in at thelocations shown in Fig. B. Wait tillthe concrete is firm (you should haveto push hard to leave a thumbprint).Smooth it with a steel trowel, cover itwith 4-mil clear plastic and let it setfor two days. Keep kids and petsaway.

4x4 POSTS(A)

2x6 TOPPLATES

3

SCREW THE 2x6 TOPPLATES to the 4x4 posts with3-in. galvanized screws. If yourposts are set properly, the topplates should all be the same

length. Make any adjustmentsto ensure the posts will all be

plumb. Use a level to plumb theposts and install temporary

bracing (shown in Photo 7). Cutand install the post wraps C1

and C2 at this time.

G A Z E B O

Make the anchors by cutting 12-in.lengths of 1/8-in. x 1-1/8 in. steel andboring 7/16-in. dia. holes into themas shown in Fig. B. You can find steelstock next to the threaded rod at yourhome center. For extra grabbingpower for your posts, be sure you puta bolt and nut into the base beforeyou push the steel into the concrete.The 6 in. of steel anchor above theconcrete fits into a saw kerf (Photo 1)at the base of each post. Cut this kerfwith a circular saw. The blade won’tcut all the way through, so flip thepost over to continue the cut in theother side. Make the kerf wideenough so you don’t have to struggleto slip it over the steel anchor.

Before you mark your anchor hole

Cut your posts to length and boltthem to the steel strap anchors

locations, screw the aluminum poststandoff to the base of the post. Thesestandoffs keep the post elevated forprotection against rot. Mark theanchor hole locations as shown inPhoto 1, then drill a 1-1/4 in. hole 1/2 in. deep on each side of the post,followed by a 3/8-in. hole all the waythrough. The 1-1/4 in. hole recessesthe bolt head and nut to make roomfor the piece you’ll nail over the postlater. Grab a buddy to help set thepost while you push the bolt throughthe hole and tighten it. Once all theposts are in place, cut the 2x6 topplates and screw them to the top ofthe posts with a pair of 3-in. deckscrews. Plumb this framework withsome temporary braces.

Nail the 1x4 (C1 andC2) cedar wrap ontothe posts first, thenmeasure this widthand rip-cut the wider1x6 to fit (D1 and D2).Nail the wider wrap tothe post with 8d galva-nized casing nails.

Give theposts somebeef anddimensionby nailingthe cedarwrap to thetops andbottoms

40 JULY /AUGUST 2000 THE FAMILY HANDYMAN

These ornate parts do take time, but there’s nothing difficultabout cutting them. Use the scale drawing in Figs. C and D tomake a full-size template and trace the shapes onto boards.Don’t think you have to cut all of them in one day. This is thekind of task you can chip away at by knocking off several piecesevery day after work. Cut the lower balusters from 1x6 pine andthe upper pickets (G2 and G3) from 1x4 pine. Use a circular sawfor end cuts and a jigsaw for curves. Once you’ve finished cut-ting these pieces, sand the edges and prime and paint them.

Set up and cut out the gingerbread pieces

BEVEL CUTON SIDESPEED

SQUARE

1-1/2" DIA.HOLES

3/4" DIA.HOLES

(J)

CUT THE 16 CORNER BRACKETS from 5/4 x 9-1/4in. pine (which is 1-1/8 in. thick). Note that there areeight left- and eight right-hand pieces.

2"

0"

0"

0"

0"

4"

4"

4"

4"

8"

8"

8"

8"

12"

12"

12"

12"

16"

0"

0" 4"

4"

8"

8"

12"

12"

16"

16" CUT

FROM 2x6 x 32"

20"

CURVED RAFTER BUILDUP CUT FROM 2x8

91"

0"

4"

BEVEL BOTH SIDES AT 22-1/2 DEGREES

8"

45 DEGREES

45 DEGREES

12"

16"

20"

20"

24"

0"

4"

8"

12"

16"

3" SCREWS

16"

16"

20"

24"

28"

2-1/8"

4-1/2"

4-1/2"

2-1/2"

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

2-1/8"

1-1/2" DIA.

3/4" DIA.

GLUE

CL

M

K1

K2

J

G1

G2

G3

Story Number— Story Name—Gazebo / Patterns Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

2"

0"

0"

0"

0"

4"

4"

4"

4"

8"

8"

8"

8"

12"

12"

12"

12"

16"

0"

0" 4"

4"

8"

8"

12"

12"

16"

16" CUT

FROM 2x6 x 32"

20"

CURVED RAFTER BUILDUP CUT FROM 2x8

91"

0"

4"

BEVEL BOTH SIDES AT 22-1/2 DEGREES

8"

45 DEGREES

45 DEGREES

12"

16"

20"

20"

24"

0"

4"

8"

12"

16"

3" SCREWS

16"

16"

20"

24"

28"

2-1/8"

4-1/2"

4-1/2"

2-1/2"

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

2-1/8"

1-1/2" DIA.

3/4" DIA.

GLUE

CL

M

K1

K2

J

G1

G2

G3

Story Number— Story Name—Gazebo / Patterns Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

JIGSAW

BALUSTERS(G1)

CUT THE BALUSTERS and the pickets from 1x6 and 2x6material. See Fig. C. Sand, prime and paint the pieces beforeinstalling them.

4

5

G A Z E B O Fig. C

Fig. D

Picket and Baluster Patterns

Bracket Pattern

TEMPORARYUPPER

BRACES

TOP PLATE

TEMPORARYLOWER

BRACES

MITER AND SCREW THE RAILSAND HEADERS to the posts with 3-in. galvanized screws. Nail thebalusters (G1) to the cleats, which arenailed to the cedar rails. Use 1-1/4 in.galvanized nails. A power finish naileris handy here.

SCREW UPPER BRACES to the topplates (B). These will help stabilize thestructure as you assemble the roof. Be

sure the posts are anchored withbraces as well.

Cut the corner braces (J) from 5/4(1-1/8 in. thick) pine (Photo 5). Afteryou cut the shape, bevel-cut one sidewith your circular saw set at 22-1/2

7

G A Z E B O

degrees. Keep in mind that there’s aleft and a right corner brace for eachpost. Prime and paint these as well.Nail the corner braces to the post andrail with 8d galvanized casing nailsafter you install the rails, lower balus-ters, upper pickets and all the cleats.Use 4d galvanized casing nails to nailthe cleats to the rails.

FH1

CEDARWRAP (C2)

F

BALUSTER (G1)BALUSTER (G1)

6

42 JULY /AUGUST 2000 THE FAMILY HANDYMAN

44 JULY /AUGUST 2000 THE FAMILY HANDYMAN

Study Figs. A, E and F and Photo 10.Cut your lower rafters (K1) and screwcurved rafter tail buildups (K2) to theends of the lower rafter. Cut the 1x2inner and outer vertical rafter ties (Land P). Notice that these 2x4 outervertical rafter ties have slots cut inthem to slip over the upper and lower

The cupola practically builds itselfwith this unique rafter system

UPPERRAFTERPATTERN

SAWBEVELSET AT 45DEGREES

4x4 BLANKFOR CENTERHUB (N)1"

CUT THE CUPOLA RAFTERS from the template shownin Fig. E. Cut the rafters and the curved rafter tailbuildups using the information in Fig. F.

SHAPE THE CENTER HUB (N)into an octagon. Measure infrom each side about 1 in. andcut along this line with yoursaw bevel set at a 45-degreeangle. The finished octagonshould be about 1-1/2 in. on aside.

2"

0"

0"

0"

0"

4"

4"

4"

4"

8"

8"

8"

8"

12"

12"

12"

12"

16"

0"

0" 4"

4"

8"

8"

12"

12"

16"

16" CUT

FROM 2x6 x 32"

20"

CURVED RAFTER BUILDUP CUT FROM 2x8

91"

0"

4"

BEVEL BOTH SIDES AT 22-1/2 DEGREES

8"

45 DEGREES

45 DEGREES

12"

16"

20"

20"

24"

0"

4"

8"

12"

16"

3" SCREWS

16"

16"

20"

24"

28"

2-1/8"

4-1/2"

4-1/2"

2-1/2"

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

2-1/8"

1-1/2" DIA.

3/4" DIA.

GLUE

CL

M

K1

K2

J

G1

G2

G3

Story Number— Story Name—Gazebo / Patterns Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

2"

0"

0"

0"

0"

4"

4"

4"

4"

8"

8"

8"

8"

12"

12"

12"

12"

16"

0"

0" 4"

4"

8"

8"

12"

12"

16"

16" CUT

FROM 2x6 x 32"

20"

CURVED RAFTER BUILDUP CUT FROM 2x8

91"

0"

4"

BEVEL BOTH SIDES AT 22-1/2 DEGREES

8"

45 DEGREES

45 DEGREES

12"

16"

20"

20"

24"

0"

4"

8"

12"

16"

3" SCREWS

16"

16"

20"

24"

28"

2-1/8"

4-1/2"

4-1/2"

2-1/2"

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

CUT EIGHT WITH 22-1/2 DEGREE BEVELS ON THIS SIDE

2-1/8"

1-1/2" DIA.

3/4" DIA.

GLUE

CL

M

K1

K2

J

G1

G2

G3

Story Number— Story Name—Gazebo / Patterns Issue— Editor—Dave Radtke Art Director—Bob Unger Tech Art Version—3D 5/15/00

8

9

rafters. You can cut these slots with atable saw or circular saw, workingfrom each end. First cut one side withmultiple passes and then flip therafter tie over and cut multiple passesfrom the other side. You’ll get anangled slope at the end of the slotfrom the roundness of the blade.

Fig. E

Fig. F

Cupola Rafter

Rafter Assembly

G A Z E B O

RAFTERASSEMBLYSCREWED TOCENTER HUB

CENTERHUB (N)

L

TEMPORARYBRACE

RAFTERASSEMBLYSCREWED TOCENTER HUB

46 JULY /AUGUST 2000 THE FAMILY HANDYMAN

NAIL THE ANGLED PLATES (seeBuyer’s Guide, p. 53) to the rafter andto the top plates to secure the rafters tothe structure.

ATTACH TWO OPPOSITE RAFTERS to the center hub. Thengrab a partner and care-fully walk the assemblyup to position. See Photo11 for nailing detail.

RAFTERTAILBUILDUP(SEE FIG. F)

ANGLEDPLATE

STEELSTRAP

VERTICALRAFTERTIES (P)

UPPERRAFTER (M)

CENTERHUB (N)

FASTEN EACH RAFTER SYSTEM tothe center octagonal hub. Install oppo-site sides one after the other to main-tain the shape of the octagon.

11 12

10

Assemble the rafter sectionsbefore hauling them to the roof

G A Z E B O

NOTE: DON’T DO THIS ON A WINDY DAY

48 JULY /AUGUST 2000 THE FAMILY HANDYMAN

LOWERFASCIA(R1)

NAIL THE LOWER FASCIA (R1) tothe rafter tail ends. Miter the ends withthe saw set at 22-1/2 degrees.

13"

Q

P

Q

SCREW THE HORIZONTAL RAFTERTIES to the sides of each outer verticalrafter tie.

5/4 x 6" CEDARDECKING

STARTER COURSESARE RIP-CUT TOMAKE THE CURVE

FASCIA BOARD

12" STEELSTRAP

MIND LIKE ASTEEL TRAP

NAIL THE ROOF DECK-ING to the rafters with 8dnails. Be sure to screw (use3/4-in. screws) the steelstrap to the lower roofboards for extra support.The strap ties the narrowerboards together to preventsagging.

S2

S1

SHINGLE THE CUPOLA before shin-gling the lower roof. Otherwise, you’lldamage the lower shingles when yougo up and down.

Lay out the rafter parts (not includingthe center octagonal piece N) on alarge flat area like a garage floor or adriveway (look at the upper left dia-gram of Fig. A). Fasten the upper andlower rafter to the 1x2 (L) with 2-in.screws. These rafters run parallel,with a 14-1/2 in. space between them.Next screw part P into the sides of theupper and lower rafter so that it’sparallel to part L. Build the rest of theassemblies and then mount a pair tothe center hub (N; see Photo 9). Fol-low Photos 10 – 12 to mount therafter assemblies to the top plates.

Cut your lower fascia from 1x10cedar. Hold it 7/8 in. above the endsof the rafters so your roof decking willbe flush with the fascia.

Rip 5-1/2 in. decking in half for thefirst seven courses so they’ll be able tobend around the lower curved sec-tion. Cut each end of the decking at22-1/2 degrees for the first course andchange the angle slightly until youfinally reach about 16 degrees for therest of the full-width courses.

There are a few things you need toknow about using the CarriageHouse Shangle roofing material. Firstof all, these shingles are heavy, and abit tougher to work with than ordi-nary asphalt shingles. They also costabout twice as much, but we thoughtthe finished look was well worth it.Don’t buy the special cap shingles forthe ridges; full cap shingles will lookout of place. Instead, buy a matchingcolor of ordinary asphalt shingles.You can cut these to fit the width andproportion of this small structure.

At the cupola where the surfacesare all curved, you’ll need to removethe top one-third of each shingle toget it to lie flat. The cap over theseams should be cut narrower andshorter to follow the concave curve.Another thing to remember for thelower section: The cap shinglesshould be full width, but the lengthon the bottom four rows of cap needsto be cut down several inches to makethe curve.

13 14

15

16

Shingle thecupola first

Deck the roof

50 JULY /AUGUST 2000 THE FAMILY HANDYMAN

Prime and paint if you please, but keep in mind that painting thegazebo means a lot of prep and repainting work in the future. It’s bestto paint just the gingerbread features as accents, and then seal theunpainted parts with a brush-on oil sealer. I’d recommend applyingthe oil first, then painting the next day. Don’t bother oiling theunderside of the roof. Because it’s out of the weather and direct sun,it’ll look fresh for years to come.

EXTENDSHINGLEBEYONDFASCIA3/4"

DECORATIVESHINGLE (SEEBUYER’S GUIDE)

DECORATIVESHINGLE (SEEBUYER’S GUIDE)

NO. 15ROOFINGFELT

NO. 15ROOFINGFELT

SHINGLE EACH LOWER ROOF SECTION, then move to the oppositeside. Keep the exposure consistent fromside to side by measuring as you go.

17

Painting your gazeboG A Z E B O

THE FAMILY HANDYMAN JULY /AUGUST 2000 53

n Tape measuren String linen Sod cutter to remove the turf

n Shovel to level the ground

n Circular saw to cut the forms

n Screw gun

Here’s what you need to do the concrete base:

Given the scope of this project, you’d expect itto take an arsenal of carpentry tools—not so

Here are the tools you need to build the gazebo:n String linen Tape measuren Wrench setn Drilln Circular sawn Jigsaw (with lots of blades)

n Framing square

Buyer’s Guide

The following three products are available atmost home centers and hardware stores. Ifyou need help finding them, call SimpsonStrong-Tie at (800) 999-5099 or check out itsWeb site at www.strongtie.com.n The steel straps at the top plate and on theroofing are Simpson No. LSTA12.n The angles for the rafter holddowns areSimpson No. A23.n The standoffs are Simpson No. APS4.

Carriage House Shangles are made by CertainTeed. Call (800) 345-1145 to find adealer near you.

Savannah shingles also are decorativeasphalt shingles and are made by Georgia-Pacific. Call (800) 284-5347 for a dealer nearyou. Or check the Web at www.gp.com.

Shopping List

DESCRIPTION QTY.4x4 x 10’ cedar (posts) 82x6 x 10’ cedar (top plates) 41x4 x 14’ cedar (wrap) 71x4 x 8’ cedar (wrap) 11x6 x 14’ cedar (wrap) 71x6 x 8’ cedar (wrap) 12x4 x 10’ cedar (rails and headers) 201x6 x 14’ cedar (balusters) 101x4 x 8’ cedar (pickets) 111x6 x 10’ cedar ripped (3/4”strips) 65/4 x 10 x 8’ cedar (corner braces) 42x6 x 10’ cedar (rafters) 82x8 x 8’ cedar (rafter buildups) 21x2 x 12’ cedar (parts L) 22x6 x 8’ cedar (cupola rafters) 34x4 x 5’ cedar (octagonal hub) 12x4 x 8’ cedar (outer ties P) 32x4 x 14’ cedar (horizontal ties Q) 11x10 x 12’ cedar (lower fascia) 41x6 x 8’ cedar (upper fascia) 25/4 x 6 cedar decking 10-ft. lengths 50 Shangles (asphalt shingles) 3-1/2

squares15-lb. roofing felt 1 rollRoofing nails 10 lbs.Simpson straps, No. LSTA12 16Simpson angles, No. A23 16Simpson standoffs, No. APS4 8Joist hanger nails (galvanized) 5 lbs.1-1/8” x 1/8” x 8’ steel (anchors) 13/8” x 3” carriage bolts 83/8” x 3” hex bolts 83/8” nuts and washers 166d galvanized casing nails 5 lbs.8d galvanized casing nails 5 lbs.4d galvanized casing nails 5 lbs.8d galvanized common nails 5 lbs.Hook blades for shingle cutting 33” galvanized screws 5 lbs.

Art Direction • BOB UNGARPhotography • BILL ZUEHLKEIllustrations • GENE THOMPSONProject Design • DAVID RADTKE

n Sledgehammer to drive the stakes

n Level to even the forms

n 2x4 screed to even the concrete

n A hand float to smooth the concrete

n A steel trowel for final finishing

n 12-in. Speed squaren Hammern Screw gunn Utility knife (standard blades

and hook blades)

n Power miter saw (optional)

G A Z E B O