FUZZY - PID SPEED CONTROL OF PMSM DRIVE FOR EV (QUTE …

Transcript of FUZZY - PID SPEED CONTROL OF PMSM DRIVE FOR EV (QUTE …

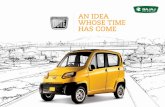

FUZZY - PID SPEED CONTROL OF PMSM DRIVE FOR EV (QUTE

BAJAJ) APPLICATION

By:

Getachew Teshome Teferi

A Thesis Paper Submitted to The Department of Electrical Power and Control

Engineering

School of Electrical Engineering and Computing

In Partial Fulfilment of The Requirement of The Degree of Master of Science

in Electrical Power and Control Engineering

(Specialization in Power Electronics)

Office of Graduate studies

Adama Science and Technology University

Adama, Ethiopia

July,2020

FUZZY - PID SPEED CONTROL OF PMSM DRIVE FOR EV (QUTE

BAJAJ) APPLICATION

Getachew Teshome Teferi

Advisor: Tafesse Asrat (PhD)

A Thesis Paper Submitted to The Department of Electrical Power and Control

Engineering

School of Electrical Engineering and Computing

In Partial Fulfilment of The Requirement of The Degree of Master of Science

in Electrical Power and Control Engineering

(Specialization in Power Electronics)

Office of Graduate studies

Adama Science and Technology University

Adama, Ethiopia

July,2020

I

Approval of Bord of Examiners

We, the undersigned, members of the board of examiners of the final open defence by

Getachew Teshome Teferi have read and evaluated his thesis entitled “Fuzzy - PID Speed

Control of PMSM Drive for EV (QUTE BAJAJ) Application” and examined the

candidate. This is therefore to certify that the thesis has been accepted in partial fulfilment

of the requirement of the Degree of Master of Science Electrical Power and Control (Power

Electronics).

Name Signature Date

____________________________________

___________________

____________

Name of Student

____________________________________

___________________

____________

Advisor

____________________________________

__________________

___________

External Examiner

____________________________________

__________________

___________

Internal Examiner

____________________________________

_________________

___________

Chair Person

____________________________________

_________________

___________

Head of Department

____________________________________

_________________

___________

School Dean

____________________________________

_________________

___________

Post graduate Dean

II

DECLARATION

I hereby declare that this MSc. Thesis is my original work and has not been presented for a

degree in any other university, and all sources of material used for this thesis have been duly

acknowledged.

Name: ____________________________________

Signature: ________

This MSc Thesis has been submitted for examination with my approval as thesis advisor.

Name: ____________________________________

Signature: ________

Date of submission: …………..

III

ADVISOR’S APPROVAL SHEET

To: Electrical Power and Control Engineering department

Subject: Thesis Submission

This is to certify that the thesis entitled “Fuzzy - PID Speed Control of PMSM Drive for EV

(QUTE BAJAJ) Application” submitted in partial fulfilment of the requirements for the degree

of Masters of Master of science Electrical Power and Control (Power Electronics) the

Graduate program of the department of Electrical Power and Control, and has been carried out

Getachew Teshome Teferi Id. No PGR/18156/11 under our supervision. Therefore, we recommend

that the student has fulfilled the requirements and hence hereby he can submit the thesis to the

department.

___________________________

_______________

____________

Advisor Signature Date

IV

ACKNOWLEDGEMENT

First, I would like to thank more my God. Then I want to express a sincere acknowledgement

to my advisor, Dr. Tafesse Asrat for giving me the opportunity to research under his guidance

and supervision. I received motivation, comments, encouragement and continuous guidance

from him during my graduate studies.

My thanks are extended to my Lecturer Dr. P. Palanivel for his contribution and assistance

and fruitful ideas. I further wish to thank all of them who had guided me through all the

technical difficulties throughout the research. This research would not have been successful

without the valuable guidance and constructive criticisms throughout the research.

V

ABSTRACT

This thesis explores speed control of PMSM drive using fuzzy - PID controller strategy which

is used to drive and control the speed and torque of PMSM. These controllers will replace

the conventional PID controller which have the disadvantage of convectional PID controller

which may not accommodate the uncertainties and disturbances. In addition to this the

controller is not really suited for nonlinear plants and not assure the desired performance

for a changing environment/ operating points, and thus present low robustness. Thus fuzzy

- PID improve the drawback for its proper performance. The conventional approach to these

issues is to tune the proportional and integral gains manually by observing the response of

the system. The tuning of the PID parameters must be made on-line and automatic in order

to avoid tedious tasks in manual control. The well-known Ziegler-Nichols method to tune the

coefficients of a PID controller is very simple to implement and tune, but cannot guarantee

to be always effective. For this reason, this thesis proposed the design of an on-line self-

tuning PID controller scheme using fuzzy logic controller. PMSM have the potential to

providing high torque-to-current ratio, high power-to-weight ratio, high efficiency and

robustness. Due to the above favourable point PMSMs are commonly used in latest variable

speed AC drives, particularly in city Electric Vehicle applications and PMSM became at the

top of ac motors in high performance drive systems such as EV like QUTE BAJAJ which

requires frequent start and stop. Electric vehicle is a best solution for reduction global

warming and climate change science it is not providing harmful gases. This thesis also will

describe the methodology and process of modelling the PMSM drive including data analysis

using MATLAB-Simulink will implemented. This project will improve time domain

specifications (Rise Time, Peak Time, Peak Value, Peak Overshoot, Settling Time and Steady

State Error) of PMSM improved by using the fuzzy- PID speed controller over convectional

controller. The obtained results for conventional and proposed approaches will compared.

Keywords - Conventional PID, Electric vehicle, Fuzzy Logic controller, On-line self-tuning

PID Controller, permanent magnet synchronous motor.

VI

Contents

DECLARATION .................................................................................................................. II

ADVISOR’S APPROVAL SHEET .................................................................................... III

ACKNOWLEDGEMENT ................................................................................................... IV

ABSTRACT ......................................................................................................................... V

LIST OF FIGURES .............................................................................................................. X

LIST OF TABLES ........................................................................................................... XIII

LIST OF ACRONYMS .................................................................................................... XIV

LIST OF SYMBOLS ......................................................................................................... XV

CHAPTER ONE .................................................................................................................... 1

1. INTRODUCTION ............................................................................................................. 1

1.1. Background of Study .................................................................................................. 1

1.2. Statement of Problem ................................................................................................. 4

1.3. Objective ..................................................................................................................... 5

1.3.1. General Objective ................................................................................................ 5

1.3.2. Specific Objectives .............................................................................................. 5

1.4. Significance of Study ................................................................................................. 5

1.5. Motivation .................................................................................................................. 6

1.6. Scope .......................................................................................................................... 6

1.7. Limitation ................................................................................................................... 7

1.8. Thesis Outline ............................................................................................................. 7

CHAPTER TWO ................................................................................................................... 8

2. LITERATURE REVIEW .................................................................................................. 8

2.1. Introduction ................................................................................................................ 8

2.2. The drive train of Electric Vehicles .......................................................................... 10

VII

2.3. Types of electric motor ............................................................................................. 13

2.3.1. DC Motor ........................................................................................................... 14

2.3.2. Induction Motor ................................................................................................. 15

2.3.3. BLDC Motor ..................................................................................................... 16

2.3.4. Switched Reluctance (SR) Motor ...................................................................... 17

2.3.5. PMSM ................................................................................................................ 17

2.3.6. Performance of Different Electric Motor for EV Propulsion ............................ 19

2.3.7. Comparison of PMSM with IM and BLDC ...................................................... 22

2.4. Electric Vehicle Batteries ......................................................................................... 25

2.4.1 Advantages of lithium-ion batteries for vehicle ................................................. 25

2.5. PMSM drives ............................................................................................................ 25

2.5.1. Permanent Magnet Materials ............................................................................. 26

2.5.2. Classification of Permanent Magnet Motors ..................................................... 26

2.6. Closely related works on PMSM motor control ....................................................... 28

CHAPTER THREE ............................................................................................................. 33

3. METHODOLOGY .......................................................................................................... 33

3.1. Introduction .............................................................................................................. 33

3.2. Materials ................................................................................................................... 33

3.3. Methods .................................................................................................................... 33

3.4 Electric Vehicle Dynamics ........................................................................................ 35

3.4.1. Motive force, Motive Power and Motive Torque of the Vehicle ...................... 36

3.4.2 Vehicle Specification and Traction Selection .................................................... 44

3.5. Dynamic Modelling of PMSM Drive ....................................................................... 45

3.5.1. Arbitrary Reference Frame Concept.................................................................. 45

3.5.2. Three Phases to Two Phase Transformation .................................................... 46

3.5.3. Transfer Function of PMSM.............................................................................. 51

VIII

3.6. Space Vector Pulse Width Modulation .................................................................... 52

3.6.1. Implementation of SVPWM .............................................................................. 54

3.7. Controller Design ..................................................................................................... 60

3.7.1. Introduction to Fuzzy Logic Controller ............................................................. 60

3.7.1. Fuzzy Logic Controller ...................................................................................... 61

3.7.2. PID Controller ................................................................................................... 63

3.7.3. Fuzzy Logic based self-tuning PI Controller ..................................................... 64

3.8 Software Simulation Modelling and Design ............................................................. 67

3.8.1. MATLAB/SIMULINK model ........................................................................... 67

CHAPTER FOUR ............................................................................................................... 69

4. RESULTS AND DISCUSSIONS ................................................................................... 69

4.1. MATLAB Simulation Result of SVPWM ............................................................... 69

4.1.1. Clarke Transformation Output........................................................................... 69

4.1.2. Switching Pattern of SVPWM Inverter ............................................................ 69

4.1.3. Generated Gate Signal ....................................................................................... 70

4.2. Fuzzy Controller Output ........................................................................................... 71

4.2.1. Fuzzy Logic Output ........................................................................................... 71

4.3. OUTPUT VOLTAGE .............................................................................................. 73

4.3.1. Phase Voltage .................................................................................................... 73

4.3.2. Line to Line Voltage .......................................................................................... 73

4.4. Speed Output of PMSM ........................................................................................... 74

4.4.1 Rotor Speed and Reference Speed of PI Controller ........................................... 74

4.4.2. Rotor Speed and Reference Speed of Fuzzy Controller .................................... 76

4.4.3. Rotor Speed and Reference Speed of Fuzzy-PI Controller ............................... 78

4.4.4. Rotor Speed of Fuzzy-PI Controller for PMSM ................................................ 80

4.5. Torque and Current Response of PMSM ................................................................. 81

IX

4.5.1. Torque Output ................................................................................................... 81

4.5.2. Current Output ................................................................................................... 82

4.6. Steep Response of PMSM ........................................................................................ 84

CHAPTER FIVE ................................................................................................................. 87

5. CONCLUSION AND RECOMMENDATION .............................................................. 87

5.1. Conclusion ................................................................................................................ 87

5.2. Recommendation ...................................................................................................... 88

References ........................................................................................................................... 89

X

LIST OF FIGURES

Figure 2-1: Motor Classification. ........................................................................................ 13

Figure 2-2: (a) DC motor (b) Torque versus speed characteristics of DC motor. ............... 14

Figure 2-3: Torque and power versus characteristic of Induction motor. ........................... 15

Figure 2-4: (a) BLDC motor and (b)Torque speed envelope of a BLDC Motor. ............... 16

Figure 2-5: (a) SRM motor and (b)Classical torque-speed characteristics of SRM motor. 17

Figure 2-6: Torque-speed characteristic of a PMSM drive. ................................................ 18

Figure 2-7: Battery in terms of Power density and Energy density. ................................... 25

Figure 2-8: Rotor configurations studied: (a) Surface PM (SPM) synchronous machine. (b)

Surface inset PM (SIPM) synchronous machine. (c) Interior PM (IPM) synchronous

machine. (d) Interior PM synchronous machine with circumferential orientation.............. 28

Figure 3-1: Flow chart of research methodology. ............................................................... 34

Figure 3-2: Block diagram of the proposed control system. ............................................... 35

Figure 3-3: EV drives. ......................................................................................................... 35

Figure 3-4: External force acting on moving EV. ............................................................... 36

Figure 3-5: Aerodynamic dragging force versus speed of the car in 𝑘𝑚ℎ𝑟. ....................... 38

Figure 3-6: Motive force versus approaching angle of the vehicle. .................................... 39

Figure 3-7: Motive force in N versus speed of the vehicle in 𝑘𝑚ℎ𝑟................................... 40

Figure 3-8: The motor power consumption with respect to approaching angle. ................. 41

Figure 3-9: Consumed power versus speed of vehicle in 𝑘𝑚ℎ𝑟. ........................................ 42

Figure 3-10: Torque developed by motor versus speed of vehicle in 𝑘𝑚ℎ𝑟. ...................... 44

Figure 3-11:Three-phase and two-phase stator windings. ................................................... 47

Figure 3-12: PMSM Dynamic stator q-axis and d-axis equivalent circuit. ......................... 49

Figure 3-13: PMSM equivalent circuits from steady state equations. ................................. 49

Figure 3-14: Transfer function block diagram of PMSM.................................................... 52

Figure 3-15: Three Phase Inverter. ...................................................................................... 53

XI

Figure 3-16: Basic switching vectors, sectors and a reference vector. ................................ 55

Figure 3-17: Voltage space vector and its components in (abc axis). ................................. 56

Figure 3-18: Reference voltage as a combination of adjacent vectors in sector I. .............. 58

Figure 3-19: Space Vector PWM switching patterns for the first two sectors. ................... 58

Figure 3-20: PID control System. ........................................................................................ 64

Figure 3-21: Member ship for (a) Speed error input to FLC (b) change in speed error input

to FLC (c) speed limit output of FLC. ................................................................................. 66

Figure 3-22: Block diagram of FL-PID controller schematic representation. ................... 687

Figure 3-23: MATLAB Simulink model of fuzzy- PID of PMSM. .................................... 68

Figure 3-24:MATLAB Simulink model of fuzzy- PID of PMSM mathematical model. ... 68

Figure 4-1: αβ-transformation output voltage. .................................................................... 69

Figure 4-2: Voltage for three phases (PWM Duty cycles). ................................................. 70

Figure 4-3: Gate signal for IGBT 1 and IGBT 4. ................................................................ 70

Figure 4-4: Gate signal for IGBT 3 and IGBT 6. ............................................................... 71

Figure 4-5: Gate signal for IGBT 5 and IGBT 2. ............................................................... 71

Figure 4-6: Output of fuzzy rule viewer. ............................................................................. 72

Figure 4-7: Fuzzy surface viewer. ....................................................................................... 72

Figure 4-8: Phase voltage 𝑉𝑎𝑛, 𝑉𝑏𝑛 and 𝑉𝑐𝑛. .................................................................... 73

Figure 4-9: Line voltage 𝑉𝑎𝑏. ............................................................................................. 73

Figure 4-10: Line voltage 𝑉𝑎𝑐............................................................................................. 74

Figure 4-11: Line voltage 𝑉𝑏𝑐. ............................................................................................ 74

Figure 4-12: Rotor speed Vs reference speed of PI controller. ........................................... 75

Figure 4-13: Zoom out of rotor speed Vs reference speed of PI controller......................... 75

Figure 4-14: The difference between rotor speed Vs reference speed of PI controller. ...... 75

Figure 4-15: Zoom out of the difference between rotor speed Vs reference speed of PI

controller. ............................................................................................................................. 76

Figure 4-16: Rotor speed Vs reference speed of Fuzzy controller. ..................................... 76

XII

Figure 4-17: Zoom out of rotor speed Vs reference speed of fuzzy controller. .................. 77

Figure 4-18: The difference between rotor speed Vs reference speed of fuzzy controller. 77

Figure 4-19: Zoom out of the difference between rotor speed Vs reference speed of fuzzy

controller. ............................................................................................................................. 77

Figure 4-20: Rotor speed Vs reference speed of Fuzzy-PID controller. ............................. 78

Figure 4-21: Zoom out of rotor speed Vs reference speed of fuzzy-PID controller. .......... 78

Figure 4-22: The difference between rotor speed Vs reference speed of fuzzy- PID controller.

............................................................................................................................................. 79

Figure 4-23: Zoom out of the difference between rotor speed Vs reference speed of fuzzy-

PID controller. ..................................................................................................................... 79

Figure 4-24: Rotor speed of Fuzzy-PID controller. ............................................................. 80

Figure 4-25: zoom out view of Rotor speed of Fuzzy-PID controller. ............................... 81

Figure 4-26: Electromagnetic torque Vs load torque. ......................................................... 82

Figure 4-27: I abc current response. .................................................................................... 82

Figure 4-28: I dq current response. ...................................................................................... 83

Figure 4-29: Electromagnetic torque developed by PMSM. ............................................... 83

Figure 4-30: I dq current response of PMSM. ..................................................................... 84

Figure 4-31: Steep response of PMSM motor. .................................................................... 84

Figure 4-32: Error between steep input and steep output of PMSM. .................................. 85

XIII

LIST OF TABLES

Table 2-1: Electric vehicle available in world. .................................................................... 11

Table 2-2: Advantage and disadvantage of different Electric Motor used for EV propulsion.

............................................................................................................................................. 19

Table 2-3: Electric propulsion systems evaluation. ............................................................. 21

Table 2-4: Comparison of IM and PMSM.. ........................................................................ 22

Table 2-5: Comparison of BLDC and PMSM motors. ........................................................ 23

Table 2-6: Control method of PMSM done by different researcher.................................... 31

Table 3-1: The coefficient of friction for different types of surface. .................................. 40

Table 3-2: Electric Bajaj specification. ............................................................................... 44

Table 3-3: PMSM motor specification. ............................................................................... 45

Table 3-4: Switching vectors, phase voltages and output line to line voltages. .................. 54

Table 3-5: Switching Time Calculation at Each Sector. ..................................................... 59

Table 3-6: Rule Base for Fuzzy Logic Controller. .............................................................. 67

Table 4-1: Comparison of PID, Fuzzy logic and Fuzzy-PID controller. ............................. 80

Table 4-2: Comparison of dynamic performance for PID and Fuzzy- PID controller. ....... 85

XIV

LIST OF ACRONYMS

AC Alternating current

BLDC Brushless DC motor

DC Direct current

DSP Digital signal processing

EV Electric vehicle

FLC Fuzzy logic control

FOC Field-oriented control

IM Induction motor

MATLAB Matrix Laboratory

PI controller Proportional integral controller

PMSM Permanent-magnet synchronous motor

SRM Switched Reluctance motor

SVPWM Space vector pulse width modulation

VCPWS Vector control pulse width modulation

XV

LIST OF SYMBOLS

Symbol Description Unit

B viscous damping coefficient Nm. s

𝐹𝐴 Aerodynamics drag force N

𝐹𝐺 Gradient resistance N

𝐹𝑅 Rolling resistance force N

𝐹𝑇 Total tractive force N

𝑖𝑑 d-axis current in synchronous frame A

𝑖𝑞 q-axis current in synchronous frame A

J moment of inertia of the motor 𝐾𝑔𝑚2⁄

𝐿𝑑 d-axis inductance H

𝐿𝑞 q-axis inductance H

P Number of magnetic poles -

𝑅𝑠 Motor phase resistance Ω

𝑇𝑒 Electromagnetic torque Nm

𝑇𝑙 Load torque Nm

𝑉𝑑 d-axis voltage in synchronous frame V

𝑉𝑞 q-axis voltage in synchronous frame V

ω𝑟 motor electrical angular velocity 𝑟𝑎𝑑𝑠𝑒𝑐⁄

XVI

ω𝑒 machine angle velocity of rotor 𝑟𝑎𝑑𝑠𝑒𝑐⁄

𝜆𝑑 d-axis flux linkage in synchronous frame 𝑊𝑏

𝜆𝑞 q-axis flux linkage in synchronous frame 𝑊𝑏

𝜆𝑚 PM flux linkage in synchronous frame 𝑊𝑏

1

CHAPTER ONE

1. INTRODUCTION

1.1. Background of Study

In recent years, the ac motors are extensively applied in home appliances as well as industrial

applications such as electric vehicles, wind generation systems, industrial robots, air

conditioners, washing machines, etc. There are two main categories of the ac motors: IMs

and PMSM. Nowadays, the IMs are used in about 70% of industrial electric motors due to

their simplicity, ruggedness, and low production costs [1] [2]. Despite that, the PMSMs are

gradually taking over the IMs owing to their low inertia, high-power density, low

noise, high power density, and high energy efficiency which makes the PMSM is best suited

to mitigate worldwide shortage of energy and development of new clean energy which is

important to society. However, the PMSM system is not easy to control because it is a

nonlinear multivariable system and its performance can be highly affected by parameters

variations in the run time [3] [4].

The idea of using electricity instead of fossil fuels for propulsion system of vehicle is not

new. Scientists and manufacturers have attempted to design and improve EV from long time

ago. As the result Rodert Anderson built the first electric carriage in 1839. In 1870 Davied

Salomon developed an electric car with light electric motor. The batteries were heavy at the

time therefore its performance was poor [5]. But, nowadays with the improvement of battery

technology EV have better performance. Engine based vehicle is ono of environmental

pollutant machines. Fossil fuel is expected to be totally finished after few decades. The only

solution to continues the transportation is to replace the engine-based vehicle by electric

based vehicle. EV is essential and simple to use for the developing country like Ethiopian

which are on their way generating large MW of electric power.

Motor is the propelling part of EV. In this study PMSM motor is selected for EV propulsion.

The invention of modern PM with high energy density led to the development of dc machines

with PM field excitation in 1950s. Introduction of PMs to replace the electromagnetic poles

with windings requiring an electric energy supply source resulted in compact dc machines.

Likewise, in synchronous machines, the conventional electromagnetic field poles in the rotor

are replaced by the PM poles and by doing so the slip rings and brush assembly are avoided.

2

With the advent of high switching power transistor and silicon-controlled rectifier devices

in the later part of 1950s, the replacement of the mechanical commutator with an electronic

commutator in the form of an inverter was achieved. These two developments contributed

to the development of PMSMs and BLDC.

Permanent magnet synchronous motors are electrical motors that are widely used in motion-

control applications in the low-to-medium power ratings such as robotics, house

appliances, adjustable speed drives, and electric vehicles. This popularity is justified by

numerous advantages over commonly used motors. The absence of the external rotor

excitation eliminates losses on the rotor, and makes PMSM highly efficient and high torque

to inertia ratio so that it gives fast response. In addition, the absence of the rotor winding

render slip rings on the rotor and brushes obsolete, and thus reduces the maintenance cost.

The replacement of the rotor winding with PM in PMSM makes it compact structure or

smaller in size that results a high-power density. The heat loss in the rotor of PMSM that

affects the machine operation is also negligible [6] [7].

It has both the advantages of reliable operation of AC motor and the advantages of excellent

speed control performance of DC motor which is very suitable for engineering application

Therefore, researchers always desire to design a high performance controller which has a

simple algorithm, fast response, high accuracy, and robustness against the motor parameter

and load torque variations. Control of PMSM motor drives is most important due to

continuous and frequent use in various systems. The governing of AC motor drives can be

mainly divided into ‘scalar’ and ‘vector’ controls. Scalar control is easy to perform and

provide a satisfactorily steady-state response, stable though the changes are stagnant. To get

high accurate and good robust, as well as steady-steady response, ‘vector’ control advances

are to be employed with closed-loop feedback control. The field-oriented control

fundamental depends on the instantaneous control of stator current space vectors. The

research on FOC is effective, with the objective of organizing many progressive features for

highly accurate control, such as sensor less operation, and utilization of accessible

specification adjustments.

The Direct torque control can be applicable to power electronic converter-fed electrical

machines. Direct torque control takes a different look at the machine and the associated

power electronic converter. First, it is recognized that, regardless of how the inverter is

controlled, it is by default a voltage source rather than a current source. Next, it distributes

3

with one of the important characteristics of the vector control, indirect flux, and torque

control by means of two stator current factors [8].

In PID controller the proportional, integral and derivative parameter expressed as 𝐾𝑝, 𝐾𝑖

and 𝐾𝑑. All these parameters are the effect of closed loop control system. It effects the rise

time, settling time, overshoot and steady state error. Proportional, integral plus Derivative

(PID) controller is usually preferable, but due to fixed proportional gain and integral and

derivative time constant the performance of PID controller is affected by parameter

variation, load disturbance and speed variations. The low transient response of PID

controller and high response time is overcome by fuzzy controller [9]. In PID controller the

proportional gain is used to decrease rise time and integral and derivative gain is used to

maintain the error as small as possible.

For widespread industrial applications, such as high-performance motor drives, accurate

motor speed control is required in which regardless of sudden load changes and parameter

variations. Hence, the control system must be design very carefully to attain the optimum

speed operation under the environmental variations, load variations and structural

perturbations. Alternative control strategies have been studied extensively in attempts to

provide accurate control capability. Among many kinds of control schemes, fuzzy logic

controller (FLC) is one of the good solution for plants having difficulties in deriving

mathematical models or having performance limitations with conventional linear control

schemes the FL became a pleasing approach to high performance controllers for nonlinear

systems and has been practical to electrical drives [10].

Theoretically, FL is based on human reasoning, providing algorithms which can convert a

set of linguistic rules based on expert knowledge into an automatic control strategy. There

is no need of mathematical models to deal with a problem, but skill is needed to create the

rules in a particular FL controller [10]. This collaboration is practical as most of the industrial

system that are using conventional PID controller can insert a FLC to their control system

for optimization purposes without changing much of the system topology and scrapping the

conventional controller.

In the vector-controlled motor (PMSM) drive, the outer speed loop provides the PMSM

reference value of the current for the inner current loop and any disturbance in the speed

controller output would cause erroneous currents, thus degrading the system performance.

Hence, proper operation of the speed controller is of great importance for the appropriate

4

drive performance. The use of proportional plus integral plus derivative (PID) controller

suffers from performance degradation under system disturbances due to the fixed

proportional gain and integral and derivative time constant. This problem can be overcome

with fuzzy logic controller since it the error have different values of member ship value [11].

1.2. Statement of Problem

All vehicles rely on the combustion of hydrocarbon fuels to derive the energy necessary for

their propulsion. Combustion is a reaction between the fuel and the air that releases heat and

combustion products. The heat is converted to mechanical power by an engine and the

combustion products are released into the atmosphere. The combustion of fuel in combustion

engines is never ideal. Besides carbon dioxide and water, the combustion products contain a

certain amount of nitrogen oxides (NOx), carbon monoxides (CO), and unburned

hydrocarbons (HC), in addition to this fossil fuels release Sulfur dioxide (SO2) emissions

contribute to acid rain, carbon dioxide which adds to the greenhouse effect and increases

global warming all of which are toxic to human health.

Fossil fuels are non-renewable energy resources and their supply is limited. Eventually they

will run out. Now a days due to draw back fossil fuel-based vehicle Electric vehicle are

predicted to be the next widely used in transportation and technology to minimize energy

conflict and air pollution. Three phase PMSM are widely used in this electric vehicle and

also in industrial and commercial application because it has highly efficient at low speed

which helps the car used to stop easily at low speeds which improves battery utilization

which is main problem of EV and driving range. In addition to this it has also high torque/

volume ratio, smaller size and lighter weight which helps to have better geometrical

integration to reduce total weight of vehicles in addition to this no torque ripple during the

commutation, less core loss, higher maximum achievable speed, low noisy. For vast

application of PMSM for electric vehicle we need to design an effective drive system. The

existing driving system requires mathematical modelling which make it difficult and tidies

as well as they have not efficient during transient conditions. The main advantage of fuzzy

logic control method as compared to conventional control techniques resides in fact that no

mathematical modelling is required for controller design and easily designed as well as no

stability problem. The performance of the FLC is superior only under transient conditions

while the performance of the PID controller is superior under the steady-state condition. The

5

merits of FLC and PID controller can be obtained with a hybrid fuzzy-PID controller. This

study is intended to answer the following basic questions:

How to analyse the propulsion power and other specifications of a motor for EV

propulsion?

How to design efficient and simple control system?

How to model PMSM motor drive for EV propulsion?

How to model PMSM motor drive by using MATLAB/code?

1.3. Objective

1.3.1. General Objective

The general objective of this thesis is modelling and analysing efficient FUZZY - PID speed

control (which is artificial intelligent technique, in conjunction with convectional field-

oriented control) method for three phase PMSM drive for four-wheel Qute Bajaj electric

vehicle application. It is expected that this control scheme can track the reference speed well

under parameter uncertainties and load torque disturbance.

1.3.2. Specific Objectives

Toward achieving the general objective mentioned, the following five specific objectives

will be accomplished in this thesis:

Review of performance of deferent types of motor used for Electric vehicle.

To analyse vehicle dynamics and its mathematical model.

To model three phase PMSM for electric vehicle application.

To model a Fuzzy Logic-PID speed control of the PMSM drive system.

Design three phase inverter for PMSM.

To simulate the modelled system using MATLAB software.

1.4. Significance of Study

Now a day’s energy source is shifting from non-renewable energy source to renewable

energy source. At this time in the world especially in developing country like Ethiopia most

energy source is non-renewable but this energy source is limited. Therefore, this energy

shortage is the main problem in transportation industry. To minimize this problem, we need

renewable energy source in transportation area. Since the electric vehicle is used the DC

6

source this thesis is important to support the trend started by centre of transportation vehicle

engineering in ASTU. In addition to forming clean environment this thesis has contribution

in driving system to have better performance during transient and steady state conditions.

High efficiency (That is no current in the rotor means no copper loss) and reliability.

They have high torque to inertia (lower weight). That is better dynamic performance

than conventional one.

Heat loss is significant science, no heat generated in rotor side.

Low torque ripple generated in a motor which improves performance of vehicle.

1.5 . Motivation

As the future of Transportation tending to be Electrical Vehicles & Electric Train it is very

interesting to do research around this area. The one who is being a professional EV drive

system expert is adeptly beneficial because huge market is coming. The battery technology

is getting better from time to time which gives hope for the easy use and future prospect of

EV. PMSM motor is getting popularity rapidly since it used in a broad power range from

hundreds KWs to MWs. PMSM is increasingly used in Transportation, Public life,

Information and office equipment, Défense forces, Medical and health care equipment,

Aerospace. This is due to its higher efficiency, no torque ripple when motor is commutated,

higher torque, more reliable and less noisy, than other asynchronous motors. In addition to

this it has high performance in both high and low speed of operation and have large

operational life. The ratio of torque delivered to the size of PMSM motor is higher, making

it very interesting in the application where space and weight are critical factors like electric

vehicle application.

1.6. Scope

The scopes of the project are limited as follows:

Mathematical model a Permanent Magnet Synchronous motor (PMSM)

To develop fuzzy- PID controller based on field-oriented control of vector control in

order to control speed of PMSM.

To test the performance of PID, Fuzzy logic and Fuzzy Logic based PID controller

and comparing those controllers by using simulation result. The design analysis of

speed control of a PMSM realized in MATLAB/Simulink software.

7

The study does not include about battery source design and other part of EV.

1.7. Limitation

The comparison of the motor for electric vehicle propulsion is taken from literature because

of time constraint and difficult to get PMSM motor, SR motor and BLDC motor around. The

content was to implement the speed control and torque control of PMSM motor using fuzzy-

PID controller. However, due the unavailability of rated PMSM motor hardware

implementation of the research work could not be conducted.

1.8. Thesis Outline

This thesis is organized into five chapters.

Chapter 1: The first chapter presents introduction of PMSM motor drive, statement of

problem, objective of study, motivation, scope and limitation of the research.

Chapter 2: The second chapter includes literature reviews on background of PMSM motor

drive and different control mechanism.

Chapter 3: This chapter includes the analysis of data’s PMSM motor drive modelling and

proposed system development are covered.

Chapter 4: This chapter discusses on simulation of the drive system on MATLAB/Simulink

including simulation result for proposed system.

Chapter 5: finally, in this chapter draws the conclusions from the work done in this thesis

and recommends further possible research direction in the future.

8

CHAPTER TWO

2. LITERATURE REVIEW

In this chapter the background and varieties of modulation techniques, advantage of PMSM

motor is compared with the other electric motor. In addition to this PMSM today world wide

application, the existing controlling mechanism and other related application of PMSM

motor are also reviewed and discussed.

2.1. Introduction

With the advancement in solid state power electronics devices various inverter control

techniques employing PWM are becoming increasingly popular in AC motor drive

application. This PWM-based drive is used to control frequency and magnitude of voltage

applied to motor. Varies PWM strategy, control schemes and realization techniques have

been developed in the past three decades. PWM strategy plays an important role in

minimization of harmonic and switching losses in converters, especially where three-phase

application is required [11] [12].

The first modulation techniques where developed at mid- 1960 by Kirnnich Heinrick, and

Bowes. The research in PWM schemes has intensified in last two decades. The main aim of

any modulation techniques is to obtain a variable output with a maximum fundamental

component and minimum harmonics [12].

The carrier- based PWM methods were developed first and widely used in most applications.

One of the earliest modulation signals for carrier based PWM is sinusoidal PWM. The

SPWM techniques is based on the cooperation of carrier signal and pure sinusoidal

modulation signal. It was introduced by Schonung and Stemmler in 1964. Utilization of DC

voltage for traditional PWM is only 78 % of DC input voltage. A better filtered sinusoidal

output waveform can be obtained by using a high switching frequency and by varying the

amplitude and frequency of a reference or modulating voltage. In SPWM technique it

maintains the pulses in different widths instead of maintaining in equal widths as in multi

pulse width modulation where the distortion factor and lowest order harmonics are

significantly reduced. The frequency of the modulating wave decides the frequency of the

output voltage. The peak amplitude of modulating wave decides the modulation index and

9

controls the RMS value of output voltage. By changing the modulation index, the RMS value

of the output voltage can be varied [13] [14].

Improving the utilization rate of the input voltage has been research focus on power

electronics. This underutilization of the DC input voltage led to development of THIPWM.

In 1975, Buja developed improved SPWM techniques, which added third- order harmonics

content in sinusoidal reference signal. In three phase systems the Third harmonic injection

PWM is preferred because third harmonic component will not be present in three phase

systems. In utilization of DC source, the THIPWM is better since this method increase

utilization rate 15.5 % of DC input voltage more compared with SPWM. The modulation

range in THIPWM can be extended by injecting the tripled harmonics [13] [14] [15].

Another method to increase the output voltage about that of SPWM technique is the

SVPWM technique which introduced in the mid-1980 and was greatly advanced by Van Der

Broeck in 1988. With the development of microprocessor, SVPWM has become one of the

most important PWM methods for three phase inverters [16]. The SVPWM method is

frequently used in vector-controlled applications. SVPWM refers to a special switching

sequence of the upper power switches of a three-phase power inverter. It has been shown to

generate less harmonic distortion in the output voltages and/or currents applied to the phases

of a power system and to provide more efficient use of supply voltage compared with other

modulation technique [17].

This method is used for adjustable speed drives. This technique can increase the fundamental

up to 27.3% when compared with SPWM. SVPWM uses the rotating synchronous reference

frame [18]. The SVPWM refers to a special switching sequence of the upper three switches

of a three-phase inverter. To implement the space vector PWM the voltages in the abc

reference frame to be transformed in to the stationary dq reference frame which consists of

horizontal and vertical axis. The main objective of the SVPWM is to approximate the

reference voltage vector by using the eight switching patterns. In SVPWM by using sectors

it can identify the location of reference vector and the switches can be operated as per sectors

identified [14].

The SVPWM technique utilize the DC bus voltage more efficiently and generate less

harmonic distortion compared with SPWM. The maximum peak fundamental magnitude of

SVPWM technique is about 91 % of inverter capacity [19].

10

2.2. The drive train of Electric Vehicles

The electric Vehicle drive train available in the world market are given in Table 2-1. From

this table PMSM, IM and BLDC motor are most popular from manufacturer point of view.

In order to select an appropriate motor which can mostly fulfil the EV motor technology

requirement, an overall comparison of electric motor is needed based on EV requirement.

The most important requirement of electric vehicle on electric motor drives is:

High instant power and high-power density.

High torque at low speeds for starting and climbing, as well as high power at high

speed for cruising.

Very wide speed range including constant-torque and constant-power regions.

Fast torque response.

High efficiency over wide speed and torque ranges.

High efficiency for regenerative braking.

High reliability and robustness for various vehicle-operating conditions.

Downsizing, weight reduction, and lower moment of inertia.

Fault tolerance

Reasonable cost

Suppression of electromagnetic interface (EMI) of motor controllers

1. two

11

Table 2-1: Electric vehicle available in world. [20] [21]

No EV name Propulsion

system

Electric Vehicle picture Country

1

PSA Peugeot-Citroën /

Berlingo

DM

France

2

Holden /ECOmmodore

SRM

Australia

3

Nissan/Tino

PMSM

Japan

4

Honda/Insight

PMSM

Japan

5

Toyota/Prius

PMSM

Japan

6

Renault/Kangoo

IM

France

7

Chevrolet/Silverado

IM

USA

8

DaimlerChrysler/Durango

IM

Germany /

USA

12

9

BMW/X5

IM

Germany

10

Nissan Leaf

BLDC

Japan

11

Mitsubishi i- MiEV

BLDC

Japan

12

BYD E6

BLDC

China

The rapid development in the field of Power electronics and control techniques has created

a space for those various types of electric motors to be used in Electric Vehicles as shown

in above Table 2-1. In addition, electrical motor used in EV should have important

characteristics like simple to design, high specific power, low maintenance cost and good /

essay to control. etc. In EVs, only traction motor delivers torque to the driven wheels. Thus,

the EV motor performance is completely determined by the torque speed or power speed

characteristic of the traction motor.

An EV, in order to meet its operational requirement, such as the initial acceleration and

ability to move in uphill road with minimum power mentioned above, operation entirely in

constant power is needed. Operation entirely in constant power is, however, not possible for

any practical vehicle. It can be observed that the EV motor drive is expected to be capable

of offering a high torque for starting and acceleration, and a high power at high speed for

cruising.

13

2.3. Types of electric motor

Nowadays, several types of electric motors are used for electric vehicle propulsion. But all

types of motor are not equally used duo to drawback in some of its characteristic. The

classification of electrical motor is summarized in the following Figure 2-1.

Figure 2-1: Motor Classification.

Out of the different motor listed above PMSM, IM, SRM, BLDCM and DC motor is used

widely in different electric vehicle company.

Universal Motor

Reluctance Motor

Hysteresis Motor Series

Electrical motors

AC motor DC motor

Commutator Homopolar Synchronous Asynchronous

Induction motor

PMSM

BLDCM

Wound Field Permanent Magnet

Compound

Shunt

14

2.3.1. DC Motor

DC motors have been prominent in electric propulsion because their torque–speed

characteristics suit the traction requirement well, decoupling of flux and torque, and their

speed controls are simple. However, dc motor drives have a bulky construction, low

efficiency, low reliability, and higher need of maintenance, mainly due to the presence of

the mechanical commutator (brush), even if interesting progress has been made with slippery

contacts. As current flows through the commutator through the armature windings, the

electromagnetic field repels the nearby magnets with the same polarity, and causes the

winging to turn to the attracting magnets of opposite polarity. As the armature turns, the

commutator reverses the current in the armature coil to repel the nearby magnets, thus

causing the motor to continuously turn. The fact that this motor can be driven by DC voltages

and currents makes it very attractive for low cost applications [22] .

In DC brushed motor, brushes along with commutators provide a nexus between external

supply circuit and armature of the motor. Brushes can be made up of carbon, copper, carbon

graphite, metal graphite and are mostly rectangular in shape. Wearing of commutators due

to continuous cutting with brushes is one of the main drawbacks of DC brushed motors.

Also, friction between brushes and commutators, limits the maximum motor speed [23].

(a) (b)

Figure 2-2: (a) DC motor (b) Torque versus speed characteristics of DC motor.

Moreover, the development of rugged solid-state power semiconductors made it increasingly

practical to introduce AC induction and synchronous motor drives that are mature to replace

dc motor drive in traction applications [20] [23].

15

2.3.2. Induction Motor

Induction motors are of simple construction, reliability, ruggedness, low maintenance, low

cost, and ability to operate in hostile environments. The absence of brush friction permits

the motors to raise the limit for maximum speed, and the higher rating of speed enable these

motors to develop high output. Speed variations of induction motors are achieved by

changing the frequency of voltage. FOC of induction motor can decouple its torque control

from field control. This allows the motor to behave in the same manner as a separately

excited dc motor. This motor, however, does not suffer from the same speed limitations as

in the dc motor. Extended speed range operation beyond base speed is accomplished by flux

weakening, once the motor has reached its rated power capability [20] [23] [24].

Existence of break-down torque in the constant power region, reduction of efficiency and

increment of losses at high speeds, intrinsically lower efficiency in comparison to permanent

magnet motors due to the presence of rotor winding and finally low power factor are among

the shortcomings of induction motors. Many efforts have been made by researchers to solve

these problems, such as: usage of dual inverters to extend the constant power region,

incorporating doubly- fed induction motors to have excellent performance at low speeds and

reducing rotor winding losses at the design stage [21] .

Figure 2-3: Torque and power versus characteristic of Induction motor.

16

2.3.3. BLDC Motor

A Brushless DC motor is an upgraded version of a brushed DC Motor. The development

of semiconductor electronics in the 1970s allowed the commutator and brushes to be

eliminated in DC motors and the absence of brushes gives BLDC motors to have the ability

to rotate at high-speed and increased efficiency. In brushless DC motors, an electronic servo

system replaces the mechanical commutator contacts. The elimination of the sliding contact

allows brushless motors to have less friction and longer life; their working life is only limited

by the lifetime of their bearings. A typical brushless motor has permanent magnets which

rotate around a fixed armature, eliminating problems associated with connecting current to

the moving armature. An electronic controller replaces the brush/commutator assembly of

the brushed DC motor, which continually switches the phase to the windings to keep the

motor turning [20] [25].

Brushless motors offer several advantages over brushed DC motors, including high torque

to weight ratio, more torque per watt (increased efficiency), increased reliability, reduced

noise, longer lifetime (no brush and commutator erosion), elimination of ionizing sparks

from the commutator, and overall reduction of electromagnetic interference (EMI). BLDC

motor is defined as rotating self-synchronous machine with a permanent magnet rotor and

known rotor shaft positions for electronic commutation. The advantage of this motor as

compared to the other motors is that this motor provides higher torque at the peak values of

current and voltage [26] [27].

(a) (b)

Figure 2-4: (a) BLDC motor and (b)Torque speed envelope of a BLDC Motor.

17

2.3.4. Switched Reluctance (SR) Motor

Switched reluctance motor produces torque by variable reluctance method. When stator coils

are energized, variable reluctance is set up in the air gap between the stator and the rotor.

Rotor tends to move to a position of least reluctance thus causing torque. The advantages of

these motors are that they have simple and rigid construction, high fault tolerance and

excellent torque-speed characteristics. It can operate under a wide constant power region.

This type of motor is not seen commonly in electric vehicles as they have high noise, high

torque ripple needs special convertor topology and have an electromagnetic interference [20]

[27] [28].

The torque-speed characteristics of SRM drives match very well with the EV load

characteristics. The SRM drive has high speed operation capability with a wide constant

power region. The motor has high starting torque and high torque-inertia ratio. The rotor

structure is extremely simple without any windings, magnets, commutators or brushes [28].

(a) (b)

Figure 2-5: (a) SRM motor and (b)Classical torque-speed characteristics of SRM motor.

2.3.5. PMSM

A permanent magnet motor is a type of brushless electric motor that uses permanent

magnets rather than winding in the field. This motor is also similar to BLDC motor which

has permanent magnets on the rotor. Similar to BLDC motors these motors also have traction

characteristics like high power density and high efficiency. The difference is that PMSM has

18

sinusoidal back EMF whereas BLDC has trapezoidal back EMF. Permanent Magnet

Synchronous motors are available for higher power ratings. PMSM is the best choice for

high performance applications like cars, buses. Despite the high cost, PMSM is providing

stiff competition to induction motors due to increased efficiency than the latter. PMSM is

also costlier than BLDC motors. Most of the automotive manufacturers use PMSM motors

for their hybrid and pure electric vehicles [20] [27].

The basic construction of PMSM is same as that of synchronous motor. The only difference

lies with the rotor. Unlike synchronous motor, there is no filed winding on the rotor of

PMSM. Field poles are created by using permanent magnet. These Permanent magnets are

made up of high permeability and high coercivity materials like Samarium-Cobalt and

Neodium-Iron-Boron. Neodium-Iron-Boron is mostly used due to its ease of availability and

cost effectiveness. Theses permanent magnets are mounted on the rotor core. PMSM

requires AC (Sinusoidal in nature) to achieve the best performance. This type of drive

current also reduces the noise produced by the motor.

In order to increase the speed range and improve the efficiency of PM brushless motor, the

conduction angle of the power converter can be controlled at above the base speed. The

torque-speed characteristic of a PM brushless motor with conduction angle control is given

in Figure 2.6 below. The speed range may be extended three to four times over the base

speed. However, at very high-speed range the efficiency may drop, the motor may suffer

from demagnetization [21] [29] [30].

(a) Typical characteristic (b) With conduction angle control.

Figure 2-6: Torque-speed characteristic of a PMSM drive.

19

2.3.6. Performance of Different Electric Motor for EV Propulsion

Among all Electric motor used for electric propulsion all are not equally used due to its

advantage and disadvantage of electric motors.

Table 2-2: Advantage and disadvantage of different Electric Motor used for EV propulsion.

[20] [31] [32].

Electric Motor Advantage Disadvantage

DC Motor

Maximum torque at low speed

Good controllability

Linear torque

current curve

Low torque ripple

Bulky structure

Low reliability

Requires maintenance

Low overloading

capability

Low heat dissipation

IM

Excellent dynamics with proper

control

High speed operation possible

Low price and simple construction

Durable

Several suppliers available

Complicated control

Always lagging power factor

Low efficiency with lighter loads

SRM

Have simple and rigid construction

High fault tolerance

Excellent torque-speed

Wide constant power region

High starting torque

High torque-inertia ratio

High noise

High torque ripple

Need special convertor topology

Have an electromagnetic

interference

Complex control mechanism

20

BLDC

High power density and torque-to-

inertia ratio

Good heat dissipation good over

loading capability

Expensive

Torque ripple

Danger of demagnetization of the

magnets

Poor field weakening

PMSM

Smooth torque possible

High efficiency

High torque/volume

High pull-out torque possible

Good heat dissipation

Good overloading capability

Good field weakening

Expensive

Danger of demagnetization of the

magnets

The core element of the EV, apart from Electric Vehicle Batteries, which replaces the

Internal Combustion engines is an Electric motor. The rapid development in the field

of Power electronics and control techniques has created a space for various types of electric

motors to be used in Electric Vehicles. The electric motors used for automotive applications

should have characteristics like high starting torque, high power density, good efficiency,

etc including they need to operate in a harsh environment with the humidity of up to 85%

and the ambient temperature between -40 and 135 degree Celsius. The traction system

commonly used in EV are evaluated based on the factors that listed in Table 2-3, a score out

of 5 is given for each comparation point to each motor. It is concluded that based on this

compression factor IM, BLDC and PMSM motor are more suitable.

Due to the drawback of convectional DC motor BLDC Motors have replace the Brushed DC

Motors, PMSM motors have come across as a better alternative to AC Induction motor. The

following Table 2-3 is describing the comparison between different motors used in EV

applications by using different parameters as a measurement.

21

Table 2-3: Electric propulsion systems evaluation. [20] [33] [34] [35]

Propulsion system

Characteristic

DC IM BLDC PMSM SRM

Power density 2.5 3.5 5 5 3.5

Efficiency 2.5 3.5 5 5 3.5

Controllability 5 5 4 4 3

Reliability 3 5

4 4 5

Technological

maturity

5 5 4 4 3

Cost 4 5 3 3 4

Weight 2 3.5 4.5 4.5 5

Power to weight ratio 2.5 3.2 4.5 4.5 3.2

Speed range 4 4 4.5 5 4.5

Maintenance 3 4 4.5 4.5 4.5

Torque ripple 4 4 3.5 5 3

Total 37.5 45.7 46.5 48.5 42.2

As we observed from above Table 2-3 PMSM and BLDC motors have high power density

due to presence of high-power density permanent magnet. Moreover, they have highest

efficiency because of the absence rotor losses. DC and IM have best controllability and their

flux and torque control can be easily decoupled. The IM has the best reliability due to its

robust and rigid construction.

22

2.3.7. Comparison of PMSM with IM and BLDC

Table 2-4: Comparison of IM and PMSM. [36] [37]

PMSM Advantages in EV

If PMSM is compared to

IM, it has high efficiency

at low speeds.

Advantages for city cars where frequent start-

stops occur at low speeds. This also improves

battery utilization and driving range.

High torque/ volume ratio,

smaller sizes and lighter weight.

It has better geometrical integration into engine

cabinet and reduces total weight of vehicle.

Current rating is lower than IM. Lower current rating for inverter and improved

battery utilization.

Lower rotor inertia Better dynamic characteristic

IM Advantages in EV

For the magnetizing current is

supplied by stator, IM has

flexible efficiency control.

If state of charge is near maximum limit,

efficiency of IM can be reduced by motor drive

system in order to limit the return of

regenerative energy. Efficiency optimization at

light load conditions is possible by control of

flux reference.

IM field weakening is

controlled by reduction of

magnetizing current.

Efficiency of IM is competitive against IPMSM

at high speed region on torque-speed curve.

Cost competitive both in

terms of material and

production technology.

Economical Unlike PMSM, material cost is

independent of magnet price changes.

As we sea from Table 2-4 the high efficiency of PMSM at low speeds improves battery

utilization and driving range. PMSM has better geometrical integration into engine cabinet

and reduces total weight of vehicle.

23

There are a number of similarities in the overall drive scheme of the PMSM and the BLDCM

presented [38]. Table 2-5 gives the brief comparison of Brushless DC Motor i.e. BLDC

drives and PMS Motor.

Table 2-5: Comparison of BLDC and PMSM motors.[38]

BLDCM PMSM

Trapezoidal back emf Sinusoidal back emf

Stator flux position commutation

each 60º

Continuous stator flux position

variation

Only two phases ON at the same

time

Possible to have three phases ON at

the same time

Torque ripple at the commutation No torque ripple at the commutation

Low order current harmonics in the

audible range

Fewer harmonics due to sinusoidal

excitation

High core losses due to harmonic

content Less core loss

Better for lower speed Higher maximum achievable speed

Noisy Low noisy

Doesn’t work with distributed

winding

Work with low-cost distributed

winding

Less efficient and lower torque Higher efficiency and higher torque

Rectangular current waveforms Sinusoidal or quasi- sinusoidal

current waveforms

Used in Toyota Prius (2005) Used in Toyota Prius, Nissan Leaf,

Soul EV

24

PM motors are classified on the basis of the flux density distribution and the shape of current

excitation. They are PMSM and PM brushless motors (BLDC). The PMSM has a sinusoidal

shaped back EMF (it is an induced voltage in the stator by the motion of the rotor).

Generally, the PMSM is designed to develop sinusoidal back EMF waveforms and has a:

Sinusoidal distribution of magnet flux in the air gap

Sinusoidal current waveforms, and

Sinusoidal distribution of stator conductors.

BLDC has a trapezoidal-shaped back EMF and is designed to develop trapezoidal back EMF

waveforms. It has:

Rectangular distribution of magnet flux in the air gap

Rectangular current waveform

Concentrated stator windings

Advantages of PMSM over DC motor, Induction motor and BLDC motor [39] [40]

Advantages of PMSM over DC motor Advantages of PMSM over IM

• Less audible noise • Higher efficiency

• Longer life • Higher power factor

• Sparkless (no fire hazard)

• Higher speed

• Higher power density and smaller

size

• Higher power density for medium

power applications, resulting in

smaller size

• Better heat transfer • Better heat transfer

Advantages of PMSM over BLDC motor

• Higher efficiency than Brushless DC Motors

• No torque ripple when motor is commutated

• Higher torque and better performance

• More reliable and less noisy, than other asynchronous motors

• High performance in both high and low speed of operation

• Low rotor inertia makes it easy to control

• Efficient dissipation of heat

25

2.4. Electric Vehicle Batteries

Batteries have been the major energy source for EV. Lithium-ion batteries become the most

popular battery for plug-in and full-battery electric vehicles (PHEVs and BEVs). While other

types of batteries, including lead-acid and nickel-metal hydride (in the first generation of the

Toyota Prius hybrid) will continue to retain considerable market share in the short term,

lithium-ion batteries are expected to dominate the world market.

2.4.1 Advantages of lithium-ion batteries for vehicle

Lithium-ion batteries are the most suitable existing technology for electric vehicles because

they can output high energy and power per unit of battery mass, allowing them to be lighter

and smaller than other rechargeable batteries. Compared to lead acid and nickel metal

hydride batteries lithium-ion batteries have advantages includes high-energy efficiency, no

memory effects, and a relatively long cycle life [41] [42].

Figure2-7: Battery in terms of Power density and Energy density.

2.5. PMSM drives

The synchronous motors require AC supply for the stator windings and DC supply for the

rotor windings. The motor speed is determined by the AC supply frequency and the number

Power density (W/kg)

Maximum power per

unit of battery mass

Energy density (Wh/kg)

Maximum stored energy per unit of battery mass

26

of poles of the synchronous motor, the rotor rotates at the speed of the stator revolving field

at synchronous speed, which is constant. The variations in mechanical load within the

machine’s rating will not affect the motor’s synchronous speed. One of the types of

synchronous motor is the PMSM. The PMSM consists of conventional three phase windings

in the stator and permanent magnets in the rotor [43].

The purpose of the field windings in the conventional synchronous machine is done by

permanent magnets in PMSM. The conventional synchronous machine requires AC and DC

supply, whereas the PMSM requires only AC supply for its operation. One of the greatest

advantages of PMSM over its counterpart is the removal of dc supply for field excitation.

The PMSMs involve adjustment of the stator supply frequency, proportionally as the rotor

speed is varied, so that the stator field always moves at the same speed as the rotor. The

rotating magnetic fields of the stator (armature) and the rotor (excitation) system are then

always in synchronous motion producing a steady torque at all operating speeds. This is

analogous to the D.C motor in which the armature and excitation fields are synchronous but

stationary for all operating speeds. PMSM requires the very accurate measurement of rotor

speed and position and the very precise adjustment of the stator frequency. Rotor position

sensing is done by an encoder, resolver… etc which forms part of a control loop of an

adjustable frequency inverter feeding the stator winding.

2.5.1. Permanent Magnet Materials

Materials to retain magnetism were introduced in electrical machine research in the 1950s.

There has been a rapid progress in these kinds of materials since then. The properties of the

permanent magnet material affect directly the performance of the motor and proper

knowledge is required for the selection of the materials and for understanding PM motors.

The materials such as alnico-5, ferrites (ceramics), samarium-cobalt, and neodymium boron

iron are available as PMs for use in machines. The particular choice of magnets and other

design factors is important, but does not directly influence the basic principles of power

converter control [6].

2.5.2. Classification of Permanent Magnet Motors

The PMSM are classified based on the direction of field flux are as follows,

a) Radial field

27

b) Axial field

In radial field, the flux direction is along the radius of the machine. The radial field PM

motors are the most commonly used. In axial field, the flux direction is parallel to the rotor

shaft. The axial field permanent magnet motors are presently used in a variety of numerous

applications because of their higher power density and quick acceleration.

In PMSMs, the magnets can be placed in different ways on the rotor. Depending on the

placement they are called either as Surface Permanent Magnet Motor (SPM) or Interior

Permanent Magnet (IPM) Synchronous Motor.

Surface mounted PM motors have a surface mounted permanent magnet rotor. Each of the

PM is mounted on the surface of the outer periphery of rotor laminations. This arrangement

provides the highest air gap flux density as it directly faces the air gap without the

interruption of any other medium such as part of rotor laminations. Drawbacks of such an

arrangement are lower structural integrity and mechanical robustness as they are not tightly

fitted into the rotor laminations to their entire thickness. This configuration is used for low

speed applications because of the limitation that the magnets will fly apart during high-speed

operations. It has practically equal inductances in both quadrature and direct axes. For a

surface permanent magnet motor, q axis inductance 𝐿𝑞 equal to the d axis inductance 𝐿𝑑.

Interior mounted PM Motors have interior mounted permanent magnet rotor. Each

permanent magnet is mounted inside the rotor. The interior PM rotor construction is

mechanically robust and therefore suited for high-speed applications. The manufacturing of

this arrangement is more complex than the surface mount. By designing a rotor magnetic

circuit such that the inductance varies as a function of rotor angle, the reluctance torque can

be produced in addition to the mutual reaction torque of synchronous motors. These motors

are considered to have saliency with q axis inductance 𝐿𝑞 greater than the d axis inductance

𝐿𝑑.

In this thesis IPM radial flux machine with classical winding and lamination has been chosen

due to the following reasons:

SPMSM uses magnetic torque and IPMSM uses both magnetic torque and reluctance

torque, so it can obtain to produce same power density as a SPMSM even with fewer

magnets used.

The topology of a axial flux machine with classical winding and lamination has been

chosen because of the well-known and established technology.

28

Based on the PM volume and output density of the motor, an IPMSM can obtain the

same output with relatively few magnets.

The surface PMSM used for applications which require low speed operations and

interior PMSM are used for applications which require high speed.

(a) (b)

(c) (d)