Fuel Specs

-

Upload

georgiadisg -

Category

Documents

-

view

216 -

download

0

Transcript of Fuel Specs

-

7/24/2019 Fuel Specs

1/6

1

Cr ea t i ng f u t u r e f ue l s

Refinery Technologies MeetingFuture Fuel Specifications

Catalytic Technologies for Petroleum Refining

Dr G Murali Dhar

Indian Institute of Petroleum

Dehradun2

Cr ea t i ng f u t u r e f ue l s

Petroleum Refining Industry has been Processing

Crude oil and upgrading quality of Petroleum Products

to meet the Energy Requirement of Mankind

Transportation Sector Accounts for 40% of Oil Consumption in

USA

Crude Oil reserves could come to an end by middle of 21st Century

Consumption continue to grow (0.2 Btoe/ annum)

Realization that crude oil reserves are limited

Attention focused on raw materials which were considered less

important in the past for converting to transportation fuel

Natural Gas

Heavy Oil

3

Cr ea t i ng f u t u r e f ue l s

Last Decade: Natural Gas Reserves Increased considerably

Enormous Methane Reserves

Gas Hydrates Bottom of Ocean

Coal Bed Methane

Gradual Take over to Gas Era from Oil Era by Middle of the 21st

century

Renewable Energy Sources

Solar (Photovoltaic)

Bio Mass : Substitute for Transportation Fuel (Diesel)

Hydrogen: Fuel Cells

4

Cr ea t i ng f u t u r e f ue l s

Developments in Refining Quality Trends /

Environmental Concern

World Oil Crisis in 1970s

Search for substitute for fossil fuels Alternative fuels

Refining Heavier Fractions Resid Catalytic Cracking

End 1970 Protect Environment from Noxious Emissions -

Strong Impact on Refining

Gasoline - Lead Phase Out: Complete ban since Jan 2000 in

Europe

Sulfur (

-

7/24/2019 Fuel Specs

2/6

7

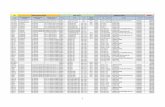

Cr ea t i ng f u t u r e f ue l s

Evolution of Motor Fuel Specifications in Europe

Since 1994

< 340360-

340

360-370Distillation, 95% TC

max

< 211-311--PolyNuclear Aromatics

PNA (wt%) max

< 1050/10350-2000Sulfur (ppm) max

> 5551-5351-49Cetane number, min

0.84-0.820.845-

0.840

0.845--Density (g/ ml) max

Diesel Oil

20102005200019951994Fuel

8

Cr ea t i ng f u t u r e f ue l s

5050Particulate mg/ Nm3

450450NOx mg/Nm3

1700400SO2 mg/ Nm3

Power < 300 MWPower > 500 MWPollutant

Emission Limits Europe 2007

Exhaust Emissions: Gaseous Streams main

concern NOx, SOx, VOC

9

Cr ea t i ng f u t u r e f ue l s

0.0

1.0

2.0

3.0

4.0

Gasoline LPG Gasoil Jet/ Kerosene

Liquid Fuels: Main transportation fuel demand increase, 2000 - 2010

%

Demand Shifting from Gasoline to Middle Distillates: JET/ Kerosene/ Diesel

10

Cr ea t i ng f u t u r e f ue l s

Catalysis play a vital role in petroleumindustry

More than 90% of finished refineryproducts come through a catalytic process

Importance of Purely Thermal Processesdeclined in past 40 years due to high

performance and cost effectiveness ofcatalytic processes.

11

Cr ea t i ng f u t u r e f ue l s Petroleum Refining

12

Cr ea t i ng f u t u r e f ue l s

Hydrocracking

Hydrocracking : High Pressure: 100 200 bar ,Temp : 300- 450C

Bifunctional Catalyst: Metal Hydrogenation Function

Acid Sites Support - Acid function for cracking

Flexible Products :Gasoline, Diesel -By changing reaction

parameters.

Catalysts:Sulfides NiMo, NiW on SiO2/ Al2O3NiW > NiMo > Co Mo Hydrogenation Activity

Conventional Amorphous SiO2/ Al2O3 has been replaced by

USY Ultra Stable Zeolite

Pt/Pd also added in some catalyst as Additives

Perfect Balance between hydrogenation / Acid Function

- A weak Acid / Strong hydrogenation combination Suit Middle

Distillates (Diesel)

- A Strong Acid / Weak Hydrogenation Suit Gasoline Production.

-

7/24/2019 Fuel Specs

3/6

13

Cr ea t i ng f u t u r e f ue l s

Hydrocracking a Two Stage Process

Pretreatment: HDS/ HDN

HDN Hydrodenitrogenation NiMo/ Al2O3 important as nitrogen in the

feed forms NH3 and poison acid sites of the cracking catalyst

AKZO Nobel Developed Improved HDN Catalyst NiMo

0

6

1965 1980 1990 2000 2005

Relative volume activities for hydrocrackers pretreater catalysts

Years

Relative activity

14

Cr ea t i ng f u t u r e f ue l s

Hydrotreating

Widely used Process in Refinery

Purification of Different Petroleum Fractions

Organo-S-Compound + H2 ! H2S + Hydrocarbons - HDS (Hydrodesulfurization)

Organo-N-Compound + H2 ! NH3 + Hydrocarbons - HDN (Hydrodenitrogenation)

Organo-O-Compound + H2 ! H2O + Hydrocarbons - HDO (Hydrodeoxygenation)

Improve Quality of Products- Desulfurize Naphtha prior to Reforming

- Reduce S & Aromatics in Kerosene & Diesel

- Improve Color & Stability of waxes & Lube Base Oil

- Lower S & Metal Content in Hydrocracker & FCC Feedstock

Catalysts: CoMo > NiMo > NiW / Al2O3 (HDS)

NiMo > CoMo / Al2O3 . (HDN)

Active Metal : Mo, W 15 25% MoO3 / WO3Promoters: Co, Ni 4 8 % CoO, NiO

Used in sulfided form. Very stable: Long Life 5 years

15

Cr ea t i ng f u t u r e f ue l s

16

Cr ea t i ng f u t u r e f ue l s

Reaction Rates of DBT

Relative Rate

40 f

10 f

Intermediate

f(slowest)

S

R1

R2

+ H2 + H2S

S

R+ H2

R+ H2S

+ H2S+ H2

R2

R1

SR3

R1

R2

R2

R1

S

R1

R2

+ H2 + H2S

R4 R3R4 R3

R3

17

Cr ea t i ng f u t u r e f ue l s

0

Low Temperature

Reactor Temperature and Catalysts Effects

High Temperature

50

100

150

200

250

Product Sulfur ppm

Co Mo cat

Ni Mo cat

Smart cat system

18

Cr ea t i ng f u t u r e f ue l s

Deep HDS: Costly H2 Consumption

Alternative Routes explored:

Bio - Desulphurization: Last decade Much Progress

Technically viable but economic viability to be explored.

Oxidative Desulfurization

Sulfur Compounds! Sulphones / Extracted with solvent

Oxidizing Agents: H2O2, Organic Peroxides

Hydrocarbon Sulphones Adsorbed on Alumina/Adsorbents.

-

7/24/2019 Fuel Specs

4/6

19

Cr ea t i ng f u t u r e f ue l s

Fluid Catalytic Cracking ( FCC )

1930 - First Catalytic cracking - Silica- Alumina

1960 - Y- zeolite Containing Rare Earth (REY) Increased Gasoline Yields

1980 - USY ( Dealuminated Y ) + ZSM-5 Octane Booster1990 USY -ZSM-5 regulation to Maximize Olefins ( Propylene )

FCC Gasoline - Represents 35% of Gasoline Pool contributes

- 95% of Sulfur in Gasoline

Process Conditions: Temp. -500 -550 C, Press.15-20 psi, Res. Time 1-10sRegeneration : 650 700C , Res. Time >10s

Feed : VGO, Resid

Moving Bed Operation: Sufficient Attrition Resistance

Catalyst Fines Formed , Make up Fresh Catalyst 0.5 -1 ton /day for plant1000 #ton catalyst

Catalyst : Silica-Alumina Matrix with binder primary cracking ofRecipe heavy molecules

Zeolite Y (USY ) - secondary cracking in pores of zeolite

ZSM -5 Additive ( small % ) - Gasoline, Olefins productionReactions : Acid catalyzed cracking reaction - Carbenium ion mechanism

20

Cr ea t i ng f u t u r e f ue l s

Alkylation

MTBE Phase Out -- USA -- California Banned MTBE

Refineries have To Manage : -

Loss in Octane in gasoline pool

Demand of Gasoline with Lower Aromatics < 35% , Lower Benzene (

-

7/24/2019 Fuel Specs

5/6

25

Cr ea t i ng f u t u r e f ue l s Gasoline Blend

Light Naphtha Alkylation / Isomerization

Heavy Naphtha Cat. Reforming

Reformulated

Gasoline (RFG )

Light Olefins MTBE

FCC Gasoline DHDS/ Isomerization

26

Cr ea t i ng f u t u r e f ue l s

Hydrogen Economy -- Enormous Impact on Energy Industry/ Existing Infrastructure

Hydrogen Generation/ Consumption : Technology Emerging

Link between H2 Generation & Distribution No Convincing Technology

H2 Distribution : Storage / Transportation / Release on Demand ----- Barriers

Transportation Gas State Pipelines Risky

Liquefication Cryogenic Technology --- Expensive

Chemical Storage : Metal Hydrides / Carbon Nano tubes --- Small Scale Only

Production of Hydrogen Based on Hydrocarbon Feed Stock ---- CO2 as a Byproduct

Chemical Sequestration of CO2 ------- Additional Technology Required

Two Ways Producing Mechanical Energy From Hydrogen: Direct Use in IC Engine

Through a Fuel Cell

Options: 1. H2 in Fuel Cell in-situ on board car or 2. From Residential units

Sulfur Should be very Low- Poison Every stage of Processing Chain of Fuel Cell

Future Catalytic Technologies

Alternative Fuels : Hydrogen

27

Cr ea t i ng f u t u r e f ue l s

Alternative Fuels

Hydrogen Production :

Catalytic Reforming of Naphtha

Steam Reforming of Light Naphtha

Steam Reforming of Natural Gas

Gasification of Coal / Petroleum residues

Syn Gas / WGS Reaction

Bio- Mass

Electrolysis

Fuel processor for small-scale hydrogen production for fuel cell28

Cr ea t i ng f u t u r e f ue l s

Natural Gas

Transformation of Natural Gas ( > 95% Methane) to Syn Gas Followed by

Fischer- Tropsch Synthesis ! Hydrocarbons ---- GTL (Gas to Liquid ) Technology

Steam Reforming : CH4 + H2O --( Ni Cat./ 800oC,20 bar) -! 3H2+ CO

Partial Oxidation : 2CH4 + O2 ( 1200-1500oC),>140 bar ) ----! 2CO + 4 H2

Potential FT Catalyst : Carbon Rich Source ( Coal) -- Ni /Fe / Alumina or Silica

Hydrogen Rich Source ( Natl. Gas ) Co / Alumina

FT Process Since 1920 : Catalyst & Process Development Still in Progress

Production of Syn Gas itself Accounts for 60% of the Capital Cost

FT Synthesis : Temp. 200 300 oC , Press. 10 40 bar

n CO + ( 2n+1) H2 ----! Cn H2n+2 + n H2O ("H = - 39.4 Kcal/ mol)

FT Diesel Quality : S < 5ppm, Aromatics < 1%, Cetane >70, Density

-

7/24/2019 Fuel Specs

6/6

31

Cr ea t i ng f u t u r e f ue l s

Catalysis in 21st Century Would be Centered around

A Shift from Oil to Gas Era

Environmentally Benign Technologies

Sulfur Reduction : Deep HDS : Diesel

FCC Gasoline

Aromatics / Benzene : Gasoline -- Alkylation / Isomerization

Alternative Fuels : Natural Gas

GTL SynGas -- FT HC ( Diesel/ Gasoline )DME ( Diesel)

Bio-mass Jatropha Seeds Diesel

Methane Activation

C1 C4 Alkane Oligomerization ( Aromatics)

Hydrogen Fuel Cell

Catalytic Combustion : DeNOx Catalyst Pollution Abatement -- Diesel Fuel

Petrochemicals : Propylene ---- FCC ( DCC)

BTX

32

Cr ea t i ng f u t u r e f ue l s

33

Cr ea t i ng f u t u r e f ue l s

Thank You