Fuel Processing Technology - unina.it · PDF fileand freeze-dried. Then, 10.0 mg of sample...

-

Upload

trinhnguyet -

Category

Documents

-

view

213 -

download

0

Transcript of Fuel Processing Technology - unina.it · PDF fileand freeze-dried. Then, 10.0 mg of sample...

Fuel Processing Technology 131 (2015) 175–181

Contents lists available at ScienceDirect

Fuel Processing Technology

j ourna l homepage: www.e lsev ie r .com/ locate / fuproc

Molecular composition of water-soluble lignins separated from differentnon-food biomasses

Davide Savy, Antonio Nebbioso, Pierluigi Mazzei, Marios Drosos, Alessandro Piccolo ⁎Centro Interdipartimentale di Ricerca sulla Risonanza Magnetica Nucleare per l'Ambiente, l'Agro-Alimentare ed i Nuovi Materiali (CERMANU), Via Università 100, 80055 Portici, Italy

⁎ Corresponding author.E-mail address: [email protected] (A. Piccolo

http://dx.doi.org/10.1016/j.fuproc.2014.11.0110378-3820/© 2014 Published by Elsevier B.V.

a b s t r a c t

a r t i c l e i n f oArticle history:Received 30 July 2014Received in revised form 1 October 2014Accepted 7 November 2014Available online xxxx

Keywords:LigninAlkaline hydrogen peroxideGiant reedMiscanthusDFRC1H–13C HSQC-NMR31P-NMR

Separation of water-soluble lignins from lignocellulosic biomass provides a new and still poorly exploited feed-stock to increase the sustainability of biorefineries. We applied derivatization followed by a reductive cleavage(DFRC) method, 2D-HSQC-NMR, and 31PNMR after 31P-labeling, to investigate molecular composition inwater-soluble lignins obtained by alkaline oxidation from three biomass materials for energy (miscanthus,giant reed and an industrially pre-treated giant reed). Chromatographic identification of lignin products cleavedby DFRC showed a large predominance of guaiacyl (G) units in all biomasses and a lesser abundance of syringyl(S) and p-coumaryl (P) monomers. Our S/G ratios disagree with those reported in literature by other lignin sep-aration methods. Carboxyl functions (ferulic and pcoumaric acids) were revealed by heterocorrelated 1H–13CHSQC-NMR, and confirmed by 31P-NMR spectra of 31 P-labeled lignin molecules. An understanding of molecularcomposition of water-soluble lignins from biomass sources for energy is essential for lignin most efficientexploitation in either industrial or agricultural applications.

© 2014 Published by Elsevier B.V.

1. Introduction

The ideal biomass for providing chemicals for the biorefinery indus-try should be perennial, large in productiveness, and capable of growingwithout any or significant soil management. The most popular bio-masses for biorefineries are miscanthus (Miscanthus χ Giganteus,Greef et Deuter) and giant reed (Arundo donax, L.) [5]. Biomasses aremainly composed of cellulose, lignin and hemicellulose. Cellulose, themost abundant constituent of plant cell wall, undergoes abiotic and bi-otic transformations leading to production of either bio-based ethanolor starch for food purposes [35]. There is a growing trend to devise use-ful industrial applications also for lignin andhemicellulose. In particular,lignin can be exploited to yield either simple aromatic compounds, suchas toluene, phenol, 4-hydroxy-3-methoxybenzaldehyde (vanillin) [37],or nanotubes [31]. In addition, lignin has been demonstrated to be an ef-ficient sorbent for heavy metals [16], as well as to increase agriculturalbiomass production, if employed as plant growth biostimulant [25].

A number of different methods have been applied to separate ligninfrom plant biomass [37]. One of the most environment-friendly tech-niques is based on the use of hydrogen peroxide (H2O2) at alkaline pH[13] to separate both depolymerised water-soluble phenols and hemi-cellulose from lignocellulosicmaterials. Lignin is recovered after separa-tion of hemicellulose by lowering the solution pH to 1.5–2.0 with a 5.5%HCl solution [30]. Such lignin was found to be largely water-soluble,

).

lower inmolecularweight and richer in carbonyl and carboxyl function-alities than lignin residues extracted by other techniques, such as Kraftor sulfite methods [15].

While the chemical–physical properties of water-soluble lignins ex-tracted from different biomasses by alkaline oxidationwere recently re-ported [28], a detailed molecular characterization can be achieved byfully depolymerising their still relatively large fragments and identifyingthe structures of singlemonomers. Themethod based on DerivatizationFollowed by Reductive Cleavage (DFRC) is a powerful technique thatcombines depolymerization with analytical determination. The DRFChas been extensively applied in lignin research [20,36] and it has beenessential to discover new lignin trimeric biosynthetic pathways [24].In fact, DFRC is a mild technique that promotes a conservative splittingof lignin components, and produces relatively stable monomersand oligomers, which can then be characterized in details by GasChromatography-Mass Spectrometry (GC-MS) [21].

A large body of literature demonstrated that liquid-state NMR spec-troscopy is an efficient analytical technique to characterize lignin. Inparticular, it provides information on both dimers and inter-unit link-ages present in the lignin mixture [27,36]. These materials can be alsocharacterized by a derivatization technique that labels hydroxyl groupswith a 31P marker [14], whose position in the lignin residue is theninvestigated by 31P-NMR spectroscopy [32]. This technique is usefulfor both analysis of lignin and investigations into the chemical mecha-nisms for specific lignin degradations [7].

Themolecular knowledge of lignin structure is important for identi-fying its potential utilization. The aim of this work was the molecular

176 D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

characterization of water-soluble lignins extracted by an oxidativealkaline extraction from three different lignocellulosic biomasses:miscanthus, giant reed, and a pre-treated giant reedmaterial. In particu-lar, GC-MS was employed to characterize lignins after depolymerisationby the DFRC method, while a further molecular characterization wasachieved by 1H-13C-HSQC- and 31P-NMR spectroscopy.

2. Materials and methods

2.1. Biomass sources

Miscanthus (Miscanthus χ Giganteus, Greef et Deuter, MG) was pro-vided by the Institute of Biological Environmental and Rural Sciences(IBERS) of the University of Birmingham, in collaboration with PhytatecLtd (UK), while Giant Reed (Arundo donax, Linn., AD) came from the ex-perimental farm of theUniversity of Naples Federico II located in Bellizzi(Salerno, Italy). The third biomass (RL) was provided by Mossi &Ghisolfi (Alessandria, Italy), andwas obtained by applying the PROESA®technology on Giant Reed. This biomass underwent a pre-treatmentstep able to break up the lignocellulosic matrix and avoid the formationof undesired, inhibitor compounds using only steam and water withoutthe requirement of additional chemical products. For more informationon this technology, please see the following web page: http://betarenewables.neencloud.it/proesa/what-is.

2.2. Lignin extraction procedure

Lignin from the three biomasses was extracted as reported by Savyand Piccolo [28]. Briefly, five (5.0) grams of sample were placed in a150 mL of distilled water containing a 2% H2O2 (v/v) solution. Then,the pH of the mixture was raised to 11.5 with a 4 M NaOH solution.The mixture was stirred for 24 h at 323 K, and then, was centrifuged(10,000 rpm × 20 min). The pH of the supernatant (formed by ligninand hemicellulose)was lowered to 5.5 and ethanol (in a ratio 3 volumesof ethanol:1 volume of supernatant) was added to flocculate the hemi-cellulose, which was then separated by filtration. The ethanol in the fil-trate was evaporated and the pH was lowered to 1.5–2.0 to precipitatethe lignin. The reactionmixturewas centrifuged (10,000 rpm×15min)and the residue containing lignin was first dialyzed (cut-off 1000 Da)and then freeze-dried.

2.3. Derivatization Followed by Reductive Cleavage (DFRC)

The DFRC method by Tohmura and Argyropoulos [32] was appliedhere. Briefly, 50.0mg of ligninwas treatedwith 25mL of a 1:9 (v/v) ace-tyl bromide:acetic acid for 3 h at 323 K under magnetic stirring. Aftersolvent evaporation under vacuum, the sample was dissolved in a5:4:1 dioxane:acetic acid:water solution, and Zn powder (250 mg)added to the solution, in order to cleave the β-O-4 aryl-alkyl ether link-ages and enable the formation of a double bond between Cα and Cβ.After 30 min at room temperature, the mixture was quantitativelytransferred to a saturated NH4Cl aqueous solution (7.5mL) in a separat-ing funnel, using dichloromethane (7.5 mL). The aqueous phase waswashed twice with dichloromethane (2 × 7.5 mL), and the extractswere dried under vacuum after treatment with anhydrous Na2SO4.The residue was then dissolved again in a 85:15 dioxane:water solutionand freeze-dried. Then, 10.0 mg of sample were mixed with pyridine(0.5 mL) and acetic anhydride (0.1 mL), in order to derivatize the hy-droxyl substituents that arose from the reaction of lignin with Zn. Theacetylation reaction was allowed to proceed under stirring for 30 minat room temperature. The resulting products were dried under a gentleN2 stream and dissolved in 1 mL of dichloromethane containing0.773 ppm of hexadecane, as internal standard for GC-MS analysis. Two(2.0) microliters was then injected (splitless mode) into a Perkin-ElmerAutosystem XL gas chromatograph equipped with a RTX-5MS WCOTcapillary column, (Restek, 5% diphenyl–95% dimethylpolysiloxane,

length 30 m, 0.25 mm ID, and 0.25 μm df) and coupled to a PETurbomass-Gold quadrupole mass spectrometer. The injector tempera-ture was set at 543 K, while the oven temperature was raised from 373to 553 K with a gradient of 281 K min−1. The amount of lignin mono-mers and carbohydrates (μmol g−1 of lignin sample) was calculatedusing a response factor of 6.96 and 1.98, respectively, by runningcathecol, xylose and hexadecane (used as internal standard) at thesame chromatographic conditions used for lignin samples.

2.4. Nuclear magnetic resonance spectroscopy

A 400 MHz Bruker Avance spectrometer, equipped with a 5 mmBruker Inverse Broad Band (BBI) probe, working at 1H frequency of400.13 MHz, was employed to conduct all liquid-state NMR measure-ments at a temperature of 298 ± 1 K. All spectra were processed byusing MestReC NMR Processing Software (v.4.8.6.0).

2.4.1. 2D-HSQCLignin samples (around 7 mg) were dissolved in deuterated DMSO

(800 μL) and placed in 5 mm NMR tubes. HSQC (Heteronuclear Single-Quantum Correlation) experiments were acquired to examine the mo-lecular composition of lignin sub-units. Each HSQC was composed by512 experiments (F1) and 2048 acquisition points (F2). The spectralwidths were 16 (6,410.3 Hz) and 250 (25,155.7 Hz) ppm for 1H and13C nuclei, respectively. The 2D spectra consisted of 16 dummy scans,80 total transients, and 0.5 μs of trim pulse length. The optimal valueof 145 Hz, as 1H–13C scalar J-coupling, was accounted for to optimizethe acquisition parameters. The center of the solvent peak was used asinternal reference (δC/δH 39.5/2.49) to calibrate the frequencies axes.

2.4.2. 31P-nuclear magnetic resonanceLignin samples (12.0 mg) were dissolved with 674 μL of CDCl3, 13 μL

of N,N-dimethylformamide, and 13 μL of pyridine. Then, 2 mg oftriphenyl phosphate (TPP) and 320 μg of chromium(III) acetylacetonatewere added to solution, where the former represented a reference peakfor the 31P frequency axis calibration, while the latter was used as a re-laxation agent. Finally, 100 μL of 2-chloro-4,4,5,5-tetramethyl-1,3,2-dioxa-phospholane (Sigma-Aldrich) (CTMP) was added to solution as31P derivatization agent. Each NMR tube was ultrasonicated for 1 minprior to be loaded into the NMR spectrometer. 31P-NMR spectra wereobtained by an inverse gated pulse sequence, a 80 μs length (15.6 dBpower level) Waltz16 scheme to decouple phosphorous from protonnuclei, a 45° pulse length of 7.8 μs and a spectral width of 400 ppm(64,935.066 Hz), where the on-resonance frequency was set to100 ppm. 1D-Spectra consisted in a 10 s thermal delay, 304 transients,8 dummy scans and 65,536 time domain points. The Fourier Transformof FIDs (Free Induction Decays) was conducted by applying a 1.5 Hzexponential multiplication and no zero-filling. 31P spectra were phaseand baseline corrected as well as the frequency axis was calibrated byassociating the value of −17.495 ppm to the TPP resonance.

3. Results and discussion

3.1. Yield and composition of DFRC products

The general physical–chemical characteristics of the lignins extract-ed by alkaline oxidation from the biomass investigated in this studywere reported elsewhere [28]. Yields of such water-soluble ligninswere about 20, 22 and 32% of the lignin obtained by the Klason methodforMG, AD and RL, respectively. The isolated ligninswere assumed to beoxidatively depolymerised during the alkaline oxidative extraction [17],providing a weight-average molecular weight smaller than 3000 Da, asnominally determined by high performance size exclusion chromatog-raphy (HPSEC).

The GC-MS analysis of products obtained by the DFRC treatment oflignins extracted from MG, AD and RL allowed identification of more

Table 1Yields (μmol g−1 of lignin) and structural attribution of monomeric DFRC products frommiscanthus (MG), giant reed (AD) and a pre-treated giant reed (RL) biomass, as calculatedfrom GC-MS chromatograms.

Compoundnumber

RT (min) Attribution MG AD RL

1. 5.98 G\CH3 51.7 2.4 2.62. 7.20 Hydroquinone 3.4 0.7 ND3. 7.39 P\CH2CH2CH3 79.1 2.1 27.04. 7.53 P\CH2COCH3 3.8 7.0 1.85. 7.78 P\CH_CH2 ND 3.8 ND6. 8.19 G\CH2CH_CH2 2.8 1.4 0.77. 8.31 G\CHO 25.7 2.7 2.88. 8.37 G\CH2CH2CH3 ND ND 1.29. 8.68 P\CH2OH 2.1 0.3 0.610. 8.72 S\CH3 3.0 3.6 1.411. 9.31 Hexadecane – – –

12. 9.34 G\cPr 10.2 1.2 ND13. 9.46 G\CH_CHCH3 ND 3.5 1.114. 9.57 G\OH ND 0.2 0.515. 9.63 G\COCH3 32.2 1.8 1.816. 9.79 G\CH_CH2 ND 0.1 ND17. 10.06 G\C ≡ CCH3 3.3 2.4 1.118. 10.47 G\CH2COCH3 48.2 14.4 17.919 10.55 G\CH2CH2CHO ND 0.6 ND20. 10.65 cis-S\CH_CHCH3 1.2 1.7 1.021. 10.72 trans-S\CH_CHCH3 1.2 0.7 0.522. 10.88 G\CH2OH 25.3 8.7 3.923. 10.91 G\CO\CH2CH3 4.5 3.1 1.324. 11.16 S\CH2\CH_CH2 4.2 5.0 ND25. 11.68 cis-P\CH_CHCH2OH 5.9 1.2 ND26. 11.76 cis-G\cPr\OH 6.8 4.5 1.827. 11.84 S\cPr 6.6 2.4 1.028. 11.98 P\CH2CH2CH2OH 2.5 3.2 1.629. 12.58 trans-P\CH_CH-CH2OH 40.0 9.4 1.630. 12.71 S\CH2CO\CH3 13.5 4.2 5.431. 12.77 S\COCH_CH2 3.1 0.6 1.332. 13.09 S\CH2OH ND 5.1 0.7

177D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

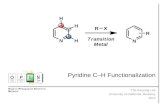

than 50 different monomers for each biomass. The Total Ion Chromato-grams (TIC) of DFRC products are shown in Fig. 1, while the identifiedmolecular structures and their concentrations are reported in Tables 1and 2. Current symbolism was employed to represent the identifiedmonomeric structures of lignin: P, p-coumaryl; G, guaiacyl (3-methoxy,4-hydroxyphenyl); and S, syringyl (3,5-dimethoxy, 4-hydroxyphenyl)radicals [21].

Our analytical results revealed significantly different monomericyields among the lignins isolated from the three biomasses (Tables 1and 2). The G-based units were the most abundant monolignolsreleased from each biomass, accounting for 645.6, 285.7 and112.4 μmol g−1 of lignin for MG, AD and RL, respectively (Table 2).The G-type molecules for MG were more than twice the quantity ofAD, thus reflecting a neat diversity in lignin composition betweenthese two biomass forms. However, the content of G units found forRL was about 65% smaller than for AD, thus demonstrating how thecombination of treatments undergone by RL had a noticeable influenceon lignin components. While S-type and P-type units were equallyabundant for MG, syringyl units resulted much greater than P-molecules in AD, and about twice as much in RL (Table 2), suggestingthat the heavily transformed RL lignin resulted with more degraded inS- and G-subunits than for P-based molecules.

The trans-guaiacyl alcohol (compound 37) was the most abundantmonomer in lignins (312.6, 193.5 and 67.5 μmol g−1 of this monolignolin MG, AD and RL, respectively, Table 1), followed by the cis-guaiacylalcohol (compound 34) for MG (95.0 μmol g−1 of lignin) and trans-sinapyl alcohol (compound 46) for both AD (139.0 μmol g−1) and RL(47.3 μmol g−1).

The S/G ratio is considered as an important index to characterize theproperties and reactivity of lignin [4,36]. However, the values foundhere of 0.2 for MG and 0.6 for both AD and RL (Table 2) disagree withthose reported in other studies [29,33,36]. This may be explained by a

Fig. 1. Total ion chromatograms after DFRC procedure for lignin extracted by miscantus(MG) and giant reed (AD) and pretreated giant reed (RL) biomass: p-coumaryl-basedunits; ▲: guaiacyl-based units; ■: syringyl-based units●.

33. 13.17 G\CH2CH2CH2OH 8.4 4.5 ND34. 13.55 cis-G\CH_CH\CH2OH 95.0 28.7 8.235. 13.66 cis-S\cPrOH 2.1 3.8 1.636. 14.10 S\CHOH\CH_CH2 5.6 1.5 ND37. 14.76 trans-G\CH_CH\CH2OH 312.6 193.5 67.538. 14.90 cis-G′\CH_CHCH2OH 7.2 1.3 ND39. 14.98 trans-G\cPr\OH 9.4 3.6 ND40. 15.05 S\CHOH\CO\CH3 0.7 1.2 ND41. 15.49 cis-S\CH_CH\CH2OH 24.5 4.4 4.542. 15.56 trans-S\cPrOH ND 0.8 0.843. 15.61 G\CHOH\CH2\CH2OH 9.5 1.8 ND44. 15.73 G\CHOHCH2CH2Br ND 1.3 ND45. 16.09 trans-G′\CH_CHCH2OH 23.0 2.3 3.546. 16.74 trans-S\CH_CHCH2OH 63.3 139.0 47.347. 17.08 G\CH_CHOH\CHO ND 2.9 ND48. 17.15 G\CHOH\CHOH\CH2OH ND 0.6 ND49. 17.39 G\CHOHCHOH\CH2OH 9.9 1.7 ND50. 17.86 G″\CH_CHCH2OH 14.6 3.3 2.951. 18.34 S\CHOHCHOH\CH2OH 1.9 1.3 ND52. 18.58 S\CHOHCHOH\CH2OH 1.4 1.9 ND

G: guaiacyl-type units; S: syringyl-type units; P: p-hydroxyohenyl-type units; cPr:cyclopropyl radical; G′: 3,4-dihydroxycinnamyl alcohol; G″: 5-hydroxyconiferyl alcohol;ND: not detected.

Table 2Total yields (μmol g−1) of DFRC products of lignins separated from miscanthus (MG),giant reed (AD) and a pre-treated giant reed (RL) biomasses. O (Others) concentrationsare reported as percen"Crossstage of total chromatographic area in GC-MSchromatograms.

Biomass G S P G′ G″ Hy X O S/G

MG 645.6 132.3 133.5 30.3 14.6 3.1 10.2 7.6 0.2AD 285.7 177.2 27.0 3.6 3.3 0.6 20.9 0.5 0.6RL 112.4 65.5 32.6 3.5 2.9 0.0 5.1 4.4 0.6

G: guaiacyl-type units; S: syringyl-type units; P: p-hydroxyohenyl-type units; cPr:cyclopropyl radical; G′: 3,4-dihydroxycinnamyl alcohol; G″: 5-hydroxyconiferyl alcohol;Hy: hydroquinone;X: xylose (as a total amount of both pyranosyl and furanosyl isomers);O: Others (unidentified molecules).

178 D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

different period of harvesting, as shown by Le Ngoc et al. [19], whofound that the S/G ratio for MG species may range from an average of0.56 for plants collected in autumn to an average of 0.64 for winter har-vesting. However, these diversitiesmay also be due to differences eitherin lignin isolation methods or in analytical techniques employed.Villaverde et al. [33] obtained lignin fromMG by either acetic or formicacid extraction and studied it by thioacidolysis. The S/G ratio of the lig-nin isolated by acetic acid was 1.8, while it was 2.0 when extracted by

Fig. 2. Two-dimensional HSQC NMR spectrum of the aliphatic-oxygenated (A—δC/δH 50–90/2.5The other biomass, miscanthus (MG) and a pre-treated giant reed (RL) showed the same peaks.been reported in Table 3.

formic acid. The dependence of S/G ratio on the method of lignin isola-tion fromMGwas also confirmed by Bauer et al. [4], who showed an av-erage S/G ratio of 0.61when ligninwas separatedwith ethanol and 2.18after extraction with dioxane. A lignin obtained from AD by either amilling process or extraction with dioxane, provided an S/G ratio of1.23 and 1.32 for milled and dioxane extracted lignin, respectively[29]. Conversely, extraction of lignin from AD by a soda process and itsanalysis by DFRC gave a larger S/G ratio of 1.6 [36]. It should also be

–6.0) and the aromatic (B—δC/δH 90–106/6.0–8.0) regions for lignin from giant reed (AD).The labels refer to identified lignin sub-units shown in Fig. 3, whose signal assignment has

179D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

considered that the acetylation step by the DFRC sequence fails to deriv-atize carboxyl groups (e.g.: benzoic acids, phenyl acetic acids, phenyl-propanoic acids, etc.), whichmay be already present in the native ligninor formed during an oxidative cleavage of lignins [22]. Despite theselimitations, DFRC is one of the best techniques for characterizing sidechains of lignin monomers, since it combines both mild reaction condi-tions and hardly produces undesirable by-products [21].

Lower amounts of other aromatic molecules were identified byGC-MS among DFRC products of lignins (Tables 1 and 2). These com-pounds were also reported for other plant biomasses [21,26] and as-sumed to be constituents of native lignins [1]. For instance, keto-units(compounds 4, 18, 23, 30–31, 40 in Table 1) may arise from cleavageof β-O-4 linkages in alkyl–aryl ethers present in model dimers contain-ing anα-carbonyl group. The breakdown of this linkagewas reported tooccur under standard DFRC conditions, and yield monomers bearingcarbonyl groups in either Cα or Cβ positions [21]. A cleavage of up to60% of these units in lignin was ascribed to the DFRC method [20]. In-deed, 3,4-dihydroxycinnamyl alcohols (the G′ compounds 38, 45 inTable 1) and 5-hydroxyconiferyl alcohol (the G″ compound 50 inTable 1) may either be constituents of native lignin [18] or derivedfrom minor demethylation reactions [21].

Other molecules were found by GC-MS as products of lignin oxida-tion reactions, such as aldo-units (compounds 7, 19 and 47 in Table 1)or hydroquinone (compound 2 in Table 1). The latter may derive fromthe H2O2 treatment of lignin monomers, via a Dakin-like pathway. Pre-vious studies showed that hydroperoxide anions produced during alka-line H2O2 treatment of lignin model compounds may react with bothbenzyl alcohols and alkyl phenyl ketones, to yield hydroquinones, and,concomitantly, cause the loss of small polar molecules, such as simplealdehydes or carboxylic acids [8,17]. Moreover, brominated products

Fig. 3.Main lignin structures identified in AD, RL and MG substrates by 2D-HSQC spectroscopyformedbyβ–β′,α-O-γ′, andγ-O-α′ linkages; (H) p-hydroxyphenyl unit; (G) guaiacyl unit; (S) sy(J) cinnamyl aldehyde end-groups; (FA) ferulate; (PCA) p-coumarate.

(compound 44 in Table 1) were possibly due to an incomplete hydroly-sis of compounds produced during the Zn reduction step of DFRC20.

Both pyranosyl and furanosyl isomers of xylose were also identifiedby GC-MS among DFRC products of lignins (Table 2). Xylose has beenreported as one of the most abundant components in both miscanthusand giant reed hemicellulose [23], and its presence attributed to anincomplete separation of lignin from plant cell sugars [28].

Since few carbohydrates (10.2, 20.9 and 5.09 μmol g−1 of lignin forMG, AD and RL, respectively) were detected in the biomass (Table 2),themethod adopted here for lignin extraction appears efficient in isolat-ing relatively pure lignins. Finally, unidentified compounds accountedfor 7.6, 0.5 and 4.4% of the total chromatographic area for MG and ADand RL, respectively.

3.1.1. 2D-HSQC-NMR spectroscopyA further molecular identification of monomers and dimers present

in lignins was reached by two-dimensional 1H-13C NMR spectroscopy.The main lignin signals detected in HSQC spectra are reported inFig. 2, while the consequent group and structure assignments areshown in Supporting Table 1 and Fig. 3, respectively. Assignment ofgroup signals to specific structures was done on the basis of previousliterature [27,34,36], and was not qualitatively different among thelignin extracts. Additional cross-peaks were present in the alkyl re-gion (δC/δH 0–50/0–2.5 ppm, Supporting Figure S1), and thoughthey were evidently related to non-oxygenated carbons in ligninside-chains or fatty acids, no assignment to specific structures wasattempted here for these spectral signals.

The oxygenated alkyl region of HSQC spectra in the δC/δH 50–90/2.5–6.0 ppm range highlights the different inter-unit linkages in ligninmolecules (Fig. 2-A, C and E). As expected, the most intense cross-peak

. (A) β-O-4′ linkages; (A′) β-O-4′ linkages with acetylated γ-carbon; (B) resinol structuresringyl unit; (S′) oxidized syringyl unitswith a Ca ketone; (I) cinnamyl alcohol end-groups;

Fig. 4. 31P-NMR spectra for lignins extracted by miscanthus (MG), giant reed (AD) and apre-treated giant reed (RL) biomass.

Table 3Assignment of the main signals in chemical shift ranges of 31P-NMR spectra of ligninsisolated from miscanthus (MG), giant reed (AD) and a pre-treated giant reed (RL) andtheir amount (mmol OH g−1 of lignin) with the relative S/G ratio calculated by thepresented data.

Chemical shift (ppm) Assignment MG AD RL

135.6–133.7 Carboxyl groups 1.00 0.81 1.05140.2–138.4 G-type molecules 0.36 0.17 0.09142.8–141.7 Condensed (4-O-5′, 5-5′) lignin dimers 0.19 0.05 ND143.7–142.2 S-type molecules 0.39 0.37 0.12150.8–146.3 Aliphatic OH 0.58 0.44 0.34

S/G 1.1 2.1 1.4

ND: not detected.

180 D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

is found at 55.45/3.67 ppm and corresponds to the methoxy groupsbound to different lignin sub-units. The Cγ–Hγ correlation in endgroups (Iγ) of cinnamyl alcohol is noted at 61.10/4.03 ppm in bothAD andMG lignins. This signal is missing in the RL spectrum possiblydue to the two treatments this biomass had undergone, and deter-mined a larger degradation of these specific groups. The HSQC sig-nals corresponding to β-O-4′ linkages among aromatic lignin units(Fig. 2-A, C and E), indicated the occurrence of A, and A′ structures(Supporting Table 1). Such cross-signals are assigned to the followingC–H correlations: Cγ–Hγ (59.64/3.57 ppm), Cα–Hα (71.67/4.70 ppm),and Cβ–Hβ (83.85/4.21 and 85.81/4.03 ppm) [34]. In particular, thecross-peak at 83.85/4.21 ppm may be attributed to Cβ–Hβ correlationin both G (A) and in γ-acylated S (A′) units, while the one at85.81/4.03 ppm should derive from Cβ–Hβ correlations in β-O-4′linkages of only S units. Moreover, the cross-signal noted at84.78/4.60 ppm is to be assigned to Cα–Hα correlations occurring in di-meric structures of resinol β–β′ (B) [27]. However, phenylcoumaranβ-5′, spirodienone β-1′, α,β-diaryl ether structures and tricin(Supporting Figure S2) were not found in these lignins, even thoughthese structures were reported to be typical in Graminae and identifiedin lignins of both giant reed [36] and miscanthus [34]. Although thesestructures are believed to resist alkaline treatments [36], they mayalso be degraded when reacting with an alkaline hydrogen peroxidesolution. For instance, theα-O-aryl ethermolecules are very reactive to-wards the hydroperoxide anion produced at pH 11.5 [9–12]. Hence, itcan be inferred that these compoundsmay be further oxidized, possiblyvia a degradation mechanism based on reactivity of hydroxyl anions(Supporting Figure S3) [8].

The aromatic region of HSQC spectra (δC/δH 90–160/6.0–8.0 ppm)revealed a large number of cross-peaks prevalently related to Gand S units (Fig. 2-B, D and F). The main signals corresponded toC2–H2 (G2, 111.22/6.91 ppm), C5–H5 (G5, 115.13/6.76 ppm) andC6–H6 (G6, 119.06/6.73 ppm) nuclei of guaiacyl monomers and toC2,6–H2,6 nuclei of syringyl units (S2,6, 103.83/6.63 ppm). Moreover,the occurrence of p-hydroxyphenyl (H) units was revealed by theC2,6–H2,6 correlation resonating at 127.83/7.20 ppm. Additional com-pounds with an oxidized side-chain were identified, namely cinnamylaldehyde end groups (J) and Cα oxidized compounds (S″ units), reso-nating at 122.33/7.20 [36] and 106.32/7.25 ppm, respectively [27].Again, they may exist in native lignin or produced during the alkalineoxidative extraction of lignins. Furthermore, the cross-peaks at111.59/7.21, 130.02/7.44, 116.11/6.27 and 144.03/7.45 ppm were at-tributed to ferulate (FA) and p-coumarate (PCA) [36].

3.2. 31P NMR spectroscopy

The use of 2-chloro-4,4,5,5-tetramethyl-1,3,2-dioxa-phospholane(CTMP) as a 31P-derivatizating agent to label hydroxyl groups in ligninsenabled their identification by liquid-state NMR spectroscopy [2].In fact, 31P-derivatization of lignin residues significantly enhancedthe intensity of NMR signals and their spreading over a large width of31P-NMR spectra with consequent reduction of signal overlapping.

The 31P-NMR signals resonating between 150.8 and 146.3 ppm(Fig. 4) were attributed to aliphatic hydroxyl groups [2], which mainlyderived from hydroxylated lignin lateral chains (Table 3). The signals be-tween 143.7 and 142.2 ppm were attributed to S-units, while those at142.8 and 141.7 ppm were assigned to condensed phenolic units of the4-O-5′ and 5-5′ type, respectively [6]. The presence of this structure waspreviously inferred by infrared spectrometry [28]. Conversely, the peaksin the 140.2 and 138.4 ppm range were attributed to G-structures [2],while signals resonating at 135.6 and 133.7 ppm, were assigned tocarboxyl groups [3].

An attempt to employ cyclohexanol as internal reactive standardfor quantitative analysis [6] was not successful due to its variable andunreliable reactivity in the differently aggregated water-soluble lignins(data not shown). However, a quantitative analysis (Table 3) was

ensured by selecting an internal standard, triphenyl phosphate (TPP),whose NMR signal was not altered by CTMP. The G-type phenols,accounted for 0.36, 0.17 and 0.09 mmol OH g−1 of lignin, while 0.39,0.47 and 0.12 mmol OH g−1 of lignin were represented by S-typemolecules for MG, AD and RL, respectively. For all three water-solublelignins, the S/G ratios resulting from 31P-NMR spectra (Table 3)were larg-er than those obtained by DFRC-GC-MS (Table 2). This discrepancy is ex-plained with the visibility of carboxylic acids obtained by the 31P-NMRmethod, whose signals accounted for 1.00, 0.81 and 1.05 mmol OH g−1

of lignin for MG, AD and RL, in the order (Table 3). These carboxyl groups

181D. Savy et al. / Fuel Processing Technology 131 (2015) 175–181

may derive from oxidation of side-chains of S-units, thereby suggestinga greater reactivity of these monolignols in alkaline oxidative solutions.The alkyl hydroxyl contentwas larger forMG (0.58mmol OH g−1 of lig-nin), followed by AD and RL (0.44 and 0.34 mmol OH g−1 of lignin, re-spectively). Finally, a consistent amount of free hydroxyls fromcondensed lignin units was found in MG (0.19 mmol OH g−1 of lignin),whereas such structures accounted to 0.05 mmol OH g−1 of lignin forthe AD biomass and have not been detected for RL (Table 3).

4. Conclusions

The findings of this work showed that G-type molecules were themost abundant monomers in water-soluble lignins extracted from bio-mass for energy, followed by S-subunits, although some condensedfragments were still present in lignins. Low carbohydrate content(b21 μmol g−1 of lignin) indicated that alkaline oxidation efficientlyseparated water-soluble lignin from lignocellulose. DFRC techniquefailed to identify carboxyl-containing lignin molecules, which were in-stead revealed by 1H-13C heterocorrelated 2D- and 31P-NMR spectra,after 31P labeling of lignin molecules. The detailed molecular character-ization of water-soluble lignins may become useful in selecting theirexploitation as substrates for new composite materials in industry oras plant biostimulants in agriculture, and contribute to the sustainabilityof biorefineries.

Acknowledgments

Thisworkwas conducted in partial fulfillment of thefirst author's PhDwork and was partially funded by the MIUR project PON01_01966/2“ENERBIOCHEM”. Moreover, the authors are grateful to the Institute ofBiological, Environmental and Rural Sciences (UK) for the sample ofmiscanthus biomass.

References

[1] Y. Archipov, D.S. Argyropoulos, H.I. Bolker, C. Heitner, 31P NMR spectroscopy inwood chemistry. Part I. Lignin model compounds, J. Wood Chem. Technol. 11(1991) 137–157.

[2] D.S. Argyropoulos, Heteronuclear NMR spectroscopy of lignins, in: C. Heitner, D.R.Dimmel, J.A. Schmidt (Eds.), Lignin and Lignans: Advances in Chemistry, Taylorand Francis Group, LLC- Boca Raton, 2010, pp. 245–265.

[3] D.S. Argyropoulos, 31P NMR in wood chemistry, a review of recent progress, Res.Chem. Intermed. 21 (1995) 373–395.

[4] S. Bauer, H. Sorek, V.D. Mitchell, A.B. Ibáñez, D.E. Wemmer, Characterization ofMiscanthus χ giganteus lignin isolated by ethanol organosolv process under refluxcondition, J. Agric. Food Chem. 60 (2012) 8203–8212.

[5] M. Christou, E. Alexopoulou, The terrestrial biomass: formation and properties(crops and residual biomass, in: M. Aresta, A. Dibenedetto, F. Dumeignil (Eds.),Biorefinery: From Biomass to Chemicals and Fuels, Walter De Gruyter Incorporated,Berlin, 2012, pp. 49–80.

[6] C. Crestini, D.S. Argyropoulos, Structural analysis of wheat straw lignin by quantita-tive 31P and 2D NMR spectroscopy. The occurrence of ester bonds and β-O-4substructures, J. Agric. Food Chem. 45 (1997) 1212–1219.

[7] C. Crestini, R. Saladino, P. Tagliatesta, T. Boschi, Biomimetic degradation of ligninand lignin model compounds by synthetic anionic and cationic water solublemanganese and iron porphyrins, Bioorg. Med. Chem. 7 (1999) 1897–1905.

[8] G. Gellestedt, R. Agnemo, The reactions of lignin with alkaline H2O2. Part III. Theoxidation of conjugated carbonyl structures, Acta Chem. Scand. B 34 (1980)275–280.

[9] J. Gierer, The reactions of lignin during pulping, Sven. Pap. 18 (1970) 571–596.[10] J. Gierer, Chemical aspects of kraft pulping, Wood Sci. Technol. 14 (1980) 241–266.

[11] J. Gierer, The chemistry of delignification, Holzforschung 36 (1982) 43–51.[12] J. Gierer, Chemistry of delignification. Part 1. General concept and reactions during

pulping, Wood Sci. Technol. 19 (1985) 289–312.[13] J.M. Gould, Alkaline peroxide delignification of agricultural residues to enhance

enzymatic saccharification, Biotechnol. Bioeng. 26 (1984) 46–52.[14] A. Granata, D.S. Argyropoulos, 2-Chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholane, a

reagent for the accurate determination of the uncondensed and condensed phenolicmoieties in lignins, J. Agric. Food Chem. 43 (1995) 1538–1544.

[15] J.E. Holladay, J.J. Bozell, J.F. White, D. Johnson, Top value-added chemicals from bio-mass volume II—results of screening for potential candidates from biorefinery lignin,Pacific Northwest National Laboratory (PNNL) and the National Renewable EnergyLaboratory (NREL), Richland, WA, USA, 2007. ((October 2007) 84 p. PNNL-16983).

[16] M.N.M. Ibrahim, W.S.W. Ngah, M.S. Norliyana, W.R.W. Daud, M. Rafatullah, O.Sulaiman, R. Hashim, A novel agricultural waste adsorbent for the removal of lead(II) ions from aqueous solutions, J. Hazard. Mater. 182 (2010) 377–385.

[17] J. Kadla, H. Chang, H. Jameel, The reactions of lignin with hydrogen peroxide at hightemperature. Part I. The oxidation of lignin model compounds, Holzforschung 51(1997) 428–434.

[18] C. Lapierre, M.T. Tollier, B. Monties, A new type of constitutive unit in lignins fromthe corn bm3 mutant, C. R. Seances Acad. Sci. III 307 (1998) 723–728.

[19] H.T. Le Ngoc, C. Rémond, R.M. Dheilly, B. Chabbert, Effect of harvesting date on thecomposition and saccharification of Miscanthus χ giganteus, Bioresour. Technol.101 (2010) 8224–8231.

[20] F. Lu, J. Ralph, Derivatization followed by reductive cleavage (DFRC method), a newmethod for lignin analysis: protocol for analysis of DFRC monomers, J. Agric. FoodChem. 45 (1997) 2590–2592.

[21] F. Lu, J. Ralph, The DFRC method for lignin analysis. 2. Monomers from isolatedlignins, J. Agric. Food Chem. 46 (1998) 547–552.

[22] A.V. Lygin, J. Upton, F.G. Dohleman, J. Juvik, O.A. Zabotina, J.M. Widholm, V.V.Lozovaya, Composition of cell wall phenolics and polysaccharides of the potentialbioenergy crop—Miscanthus, GCB Bioenergy 3 (2011) 333–345.

[23] F. Peng, J. Bian, P. Peng, H. Xiao, J. Ren, F. Xu, R. Sun, Separation and characterizationof acetyl and non-acetyl hemicelluloses of Arundo donax by ammonium sulfateprecipitation, J. Agric. Food Chem. 60 (2012) 4039–4047.

[24] J. Peng, F. Lu, J. Ralph, Isochroman lignin trimers from DFRC-degraded Pinus taeda,Phytochemistry 50 (1999) 659–666.

[25] V.I. Popa, M. Dumitru, I. Volfa, N. Anghel, Lignin and polyphenols as allelochemicals,Ind. Crop. Prod. 27 (2008) 144–149.

[26] J. Ralph, R.D. Hatfield, Pyrolysis-GC-MS characterization of forage materials, J. Agric.Food Chem. 39 (1991) 1426–1437.

[27] J. Rencoret, A. Gutíerrez, L. Nieto, J. Jiménez-Barbero, C.B. Faulds, H. Kim, J. Ralph, Á.T.Martìnez, J.C. del Río, Plant Physiol. 155 (2011) 667–682.

[28] D. Savy, A. Piccolo, Physical–chemical characteristics of lignins separated frombiomasses for second-generation ethanol, Biomass Bioenergy 62 (2014) 58–67.

[29] A.M.L. Seca, J.A.S. Cavaleiro, F.M.J. Domingues, A.J.D. Silvestre, D. Evtuguin, C. PascoalNeto, Structural characterization of the lignin from the nodes and internodes ofArundo donax reed, J. Agric. Food Chem. 48 (2000) 817–8247.

[30] R. Sun, J. Tomkinson, S. Wang, W. Zhu, Characterization of lignins fromwheat strawby alkaline peroxide treatment, Polym. Degrad. Stab. 67 (2000) 101–109.

[31] E. Ten, C. Ling, Y. Wang, A. Srivastava, L.A. Dempere, W. Vermerries, Lignin nano-tubes as vehicles for gene delivery into human cells, Biomacromolecules 15(2013) 327–338.

[32] S. Tohmura, D.S. Argyropoulos, Determination of arylglycerol-β-aryl ethers andother linkages in lignins using DFRC/31P NMR, J. Agric. Food Chem. 49 (2001)536–542.

[33] J.J. Villaverde, J. Li, M. Ek, P. Ligero, A. de Vega, Native lignin structure of Miscanthus× giganteus and its changes during acetic and formic acid fractionation, J. Agric.Food Chem. 57 (2009) 6262–6270.

[34] K. Wang, S. Bauer, R.C. Sun, Structural transformation of Miscanthus × giganteuslignin fractionated under mild formosolv, basic organosolv, and cellulolytic enzymeconditions, J. Agric. Food Chem. 60 (2001) 144–152.

[35] C. You, H. Chen, S. Myung, N. Sathitsuksanoh, H. Ma, X.-Z. Zhang, J. Li, Y.H.P. Zhang,Enzymatic transformation of nonfood biomass to starch, Proc. Natl. Acad. Sci. U. S. A.110 (2013) 7182–7187.

[36] T.-T. You, J.-Z. Mao, T.-Q. Yuan, J.-L. Wen, F. Xu, Structural elucidation of the ligninsfrom stems and foliage of Arundo donax Linn, J. Agric. Food Chem. 61 (2013)5361–5370.

[37] J. Zakzeski, P.C.A. Bruijnincx, A.L. Jongerius, B.M. Weckhuysen, The catalytic valoriza-tion of lignin for the production of renewable chemicals, Chem. Rev. 110 (2010)3552–3599.