Frank Ross Resume

-

Upload

frank-ross -

Category

Documents

-

view

13 -

download

3

Transcript of Frank Ross Resume

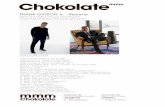

Frank Ross

113 Lucy Court (847) 372-7605Lake Zurich IL, 60047 [email protected]

EducationThe University of Iowa, Iowa City, IA Major: Industrial EngineeringGraduated: May 2015

Engineering Field ExperienceEngineer InternUnited Stationers, Deerfield, IL June 2014 – August 2014International wholesale distributor of business products

Evaluated corrugate packaging pricing from multiple vendors to achieve cost savings for newly acquired business unit

Analyzed the random sample selection method for SOX to determine possibility of predicting which samples would be picked enabling the facility to get the pertinent documentation in place to avoid exceptions

Examined trends in the packing and corrugate supply spend, researched and identified the root cause for spikes and reported to management for remediation

Analyzed inbound supplier violation data for trends attributed to both suppliers and facilities providing the Operations Excellence team with the foundation to further examine and eliminate logistical and operational issues

Process Analysis InternAllsteel, Muscatine, IA June 2013 – August 2013Global manufacturer of office furniture

Improved and updated product Discontinuation Execution Model consolidating important product line information streamlining inventory planning

Created replacement parts and finished goods warranty summaries highlighting potential parts to be stocked for warranty purposes

Developed and refined warranty replacement part plans approximating the cost of warranty parts to be stocked beyond the product line obsolescence date

Generated discontinuation, last order, and obsolescence dates initiating the timeline to end the production of discontinued product lines

Industrial Engineer InternEncore Repair Services, East Dundee, IL June 2011 – July 2011International leader in consumer electronics refurbishing, logistics, and inventory liquidation

Created and implemented a kanban system for parts on assembly line eliminating stock-outs Designed and executed a system for sorting defective and recyclable parts improving inventory control Wrote work instructions that contributed to a doubling of MP3 line productivity Performed time studies for production supervisor improving planning and productivity

Validation Engineer InternMedical Murray, Lake Zurich, IL June 2010 – July 2010FDA registered, ISO 13485 certified manufacturer & distributor of class I, II & III custom medical devices

Assisted with data collection/entry into PQ (Process Qualification) Reports to maintain customer expectations

Processed ECOs (Engineering Change Order) from start to finish including information gathering, drawing revisions, and implementation supporting accurate production documentation

Created Device Master Records (DMRs) consistent with FDA and ISO requirements Performed physical inventory of products and parts in cleanroom improving WIP inventory accuracy Added notes and company heading to product drawings completing required documentation

Frank Ross

(847) 372-7605 [email protected] Page 2

Engineering Leadership ExperienceSecretary, University of Iowa Society of Automotive Engineers (UISAE) June 2013 – PresentVice President, UISAE August 2012 – June 2013 Member, UISAE November 2010 – PresentUniversity of Iowa, Iowa City, IA

Fabricated frame of mini baja car with team per schedule to prepare for national race Recruited and on-boarded new club members continuing club success Supervised team during shop work sessions insuring safety and accuracy of build Accomplished project goals within given time limits and budgets

Engineering Project ExperienceCreation of a more ergonomic aerobar systemProcess Engineering Professor A. Pennathur

Conducted research by interviewing sample population of triathlon cyclists Generated multiple product concepts using brainstorming Selected design based on research and manufacturability Fine-tuned design based on feedback from professor and TA Presented final design to class and in an elevator pitch competition

Handheld Tablet Human Factors Professor P. Pennathur

Designed prototype with project team based on selected age group Collaborated with team members to create PowerPoint prototype Presented prototype to professor and classmates Refined design based on feedback from audience

Popsicle Stick Table Engineering Problem Solving I Professor Wilder

Created prototype table design with team members Constructed prototype design with team on schedule Tested load capacity of prototype table Redesigned table structure based on initial results