Formwork System

description

Transcript of Formwork System

1

Choosing the Choosing the RIGHTRIGHT

Formwork System Formwork SystemBCN 3423 - Timber/Formwork Design

Rinker School of Building Construction

University of Florida

2

Why worry about the Why worry about the Choice of Forming Choice of Forming

System?System?

Chek Lap Kok Airport (Hong Kong)

3

Concrete Frame CostsConcrete Frame Costs

Formwork: 50 - 70%

Petronas Tower

Rebar: 15 - 25%

Concrete: 15 - 25%

5

What Choices Do I What Choices Do I Have?Have?

Let’s focus on:Let’s focus on:• Walls

• Slabs

• Columns

8

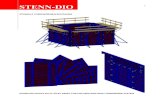

Wall SystemsWall Systems (Prefabricated Panels)(Prefabricated Panels)

Prefab Steel Panel Prefab Alum. Panel

9

Prefabricated PanelsPrefabricated Panels• are durable for many reuses• simplify and reduce the labor required• studs and sheathing are preassembled in units

small enough to be handled• panels are set into position and tied together• wales, ties, and braces are then attached

• made of wood, metal, plywood with metal bracing, or glass fiber and plastic over wood

12

Ganged Panel FormsGanged Panel Forms• ranging up to 30x50 ft• large panels can be assembled flat on the ground

where it is easier to work• stripping is easier (stripped as a unit)• extra bracing is required to withstand the

handling stresses• are frequently used as “climbing” forms in high

wall construction

• small panels can be ganged together to form larger units

18

Slipform ConstructionSlipform Construction• vertical slipforms are moved upward by jacks• can be used for structures such as silos, and for

high rise elevator and stairway cores• working decks and finisher’s scaffolds are

attached to and carried up with the forms• has shorter construction time• appropriate for structures taller than 40 ft• not efficient where there are many projections

to the direction of slide

40

Factors in the ChoiceFactors in the Choice

• What you own

• Availability

• Initial price

• Total cost

41

Factors in the ChoiceFactors in the Choice• Experience of workers

• What will produce the desired results with the least amount of cost?

44

Factors in the ChoiceFactors in the Choice

• History with similar projects• Engineering expertise• Support services• Knowledge of support

personnel• Location

The Supplier:

45

Buy vs. RentBuy vs. Rent• Duration of project• Future usage• Cash flow• Return on

investment

Steel radius wall forms