flen v1 sstr std links - Seydelmann€¦ · International II Die Fleischerei 6/2015 Non-stop...

Transcript of flen v1 sstr std links - Seydelmann€¦ · International II Die Fleischerei 6/2015 Non-stop...

International

II Die Fleischerei 6/2015

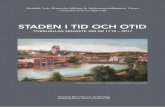

Non-stop cutting333 Regional specialties, excellently crafted, are

among the strengths of the Edwin Grasmehr GmbH in Weilburg, Germany. Around 80 employees working in a spacious, 3,500 m2 area produce and sell a complete range of meat products that includes the bratwurst sold in the soccer stadium of Frankfurt’s team, “Eintracht Frankfurt”. For the most part, the company still uses recipes from an age when such products were still made at home – recipes that have been passed down from generation to generation. Since 2001, the brothers Werner and Klaus Grasmehr have run the company that their parents founded in 1963. The grilled meat loaf “Edwin” is a con-venience product named in honor of Werner and Klaus Grasmehr’s father. Although the Grasmehr company used no Seydelmann machines in its early years, recent purchases have gradually turned it into a pure “Seydelmann business”. Among other machines, Edwin Grasmehr GmbH now uses Seydelmann’s innovative Konti-Kutter KK 140 AC-6 for production.

Great time savings, no quality lossIt was the company’s development that led to the deci-sion to purchase a Konti-Kutter, as Werner Grasmehr recalls: “Over the years, we specialized more and more in sausage production. At some point, we took a leap

The Edwin Grasmehr

company produces ten

tons of sausage every day.

The Konti-Kutter KK 140

AC-6 from Seydelmann

is essential for this. In

this Fleischerei field test,

master butcher Werner

Grasmehr, Managing

Director of production,

discusses his experiences

with this high-performance

machine.

Sey

del

man

n

Faster sausage production: Managing Director Werner Grasmehr (r.) and production head Hans Maurer are completely convinced by the Konti-Kutter KK 140 AC-6.

from producing six tons of sausage a day to ten. Our production methods up to then, that is, using a meat grinder and bowl cutter, only resulted in overtime.” Grasmehr was faced with the challenge of saving production time without sacrificing quality. Shifting part of the sausage production process from bowl cut-ters to a conventional emulsifier would not have solved the problem. “At the time, our production head, Hans Maurer, and I tried out a number of machines from vari-ous manufacturers, which were all designed to save time in the sausage production process in some way or anoth-er. But when it came to quality, only Seydelmann’s Konti-Kutter convinced us,” reminisces Werner Grasmehr. The Konti-Kutter KK 140 AC-6 stands below the MR 1800, an 1,800-l mixer also from Seydelmann, which fills the pre-mixed product directly into the Konti-Kutter hopper. A rotating pump wheel draws the prod-uct through a cutting system of vertically arranged plates: fixed hole plates and rotating cutting plates. The Konti-Kutter works continuously, without batch-related interruptions, which makes it enormously efficient in terms of time. “We can produce a ton of sausage mixture in fifteen minutes,” reports Master butcher Grasmehr. “This means one less shift for sausage pro-duction.”The Konti-Kutter is also extremely flexible. The operator regulates the desired fineness of the emulsion by changing the number and size of the plates – three, five or a maxi-mum of seven places can be arranged above each other. In addition, the rotation speed set by the operator also af-fects the emulsion quality – both its fineness as well as its protein development. Important: although the distances between the hole plates and cutting plates are reduced to a minimum, the plates do not touch anywhere. This lack of contact ensures the long life of these plates and

Master butcher Werner Grasmehr rates the

Seydelmann Konti-Kutter KK 140 AC-6 as follows:

Working speed: ++Arrangement of operating controls: ++Familiarization period: +Functionality: ++Value for the money: ++Size/space requirements: ++Noise level: +Material and workmanship: ++After Sales Service: ++

++ = excellent, + = good, o = average, – = poor

Conclusion

International

Die Fleischerei 6/2015 III

hinders any contamination of the sausage mixture with metal particles.

Ergonomic handling, robust designGrasmehr also assigns top ratings to how the machine is operated. “It has everything needed for daily tasks. Butchers often need a lot of strength for their work, but with this machine, I don’t need to worry. Everything is where it needs to be so that we can work easily.” The Konti-Kutter KK 140 AC-6 is equipped with the “Command 500” electronic controller. All relevant pa-rameters such as speed, cutting plate speed, running time, temperature and time of day can be read from the controller. It reminds us when maintenance and service is necessary, and displays error messages in the event of a problem. We program the desired rotation speeds via the controller and select them with the robust joystick. Dur-ing production, we can rapidly change to the ideal speed for any product or grain thanks to six pre-programmable speeds.The machine’s ease of use is also apparent when it comes to hygiene. All surfaces are rounded, polished and

Sey

del

man

n

The Konti-Kutter works continuously, without batch-related interruptions, for enormous efficiency in terms of time.

Sey

del

man

n

The vertically arranged hole plates and cutting plates do not touch, which prevents any con-tamination of the sausage mixture with metal particles.

Sey

del

man

n

Among other things, master butcher Grasmehr praises the robust, high-quality processing of the Konti-Kutter.

sloped so that water can easily run off. Plate changes – and thus, their cleaning – are very easy due to their vertical arrangement. “We remove the blade set, lather the machine, hose it down, and it’s completely clean again. It takes almost no effort at all,” says a satisfied Grasmehr. He also praises the robust, high-quality ex-terior of the Konti-Kutter, which is manufactured en-tirely of stainless steel. “This visible quality is something that Seydelmann stands for.” And operators are exposed to safty risks neither when re-moving the blade set nor during production. “The blade set cannot be reached through the hopper. Injuries are impossible – except, of course, if someone wants to do something malicious.”

Sey

del

man

n

At Grasmehr, the Konti-Kutter KK 140 AC-6 stands below the 1,800-l MR 1800 mixer, which fills the pre-mixed product directly into the Konti-Kutter hopper.

International

IV Die Fleischerei 6/2015

Standard equipment/FeaturesBlade set: 3, 5 or 7 parts

AC-6 drive: Frequency controlled, continuous

Speed: Six continuous, pre-programmable

Level measurement (optional)

No current spikes during power-on or changeover

Thermal overload control

Separate electric control box

Command 500 controllerDigital display for speed, cutting plate speed, run-

ning time, temperature, time of day and pressure

in the case of direct piping

Automatic shut-off function: Temperature

(optional)

Display of maintenance/customer service intervals

Error messages

Stainless steel housing: Water- and rust-proof

Can be cleaned with high pressure

Specifications: Konti-Kutter KK 140 AC-6

Sey

del

man

n

Regional specialties with a hand-crafted character, such as meaty sausages, are among the strengths of the Edwin Grasmehr GmbH.

Reliable serviceHardly anything is more significant in food production than reliabil-ity. Any unintentional production standstill has immediate conse-quences for a company and its customers. In this regard, Werner Grasmehr sees another of the man-ufacturer’s strengths. “The support we get from our point of contact at Seydelmann is really outstanding. It was perfect right from the start – from our first purchase on. When we were learning to use the Konti-Kut-

ter, a Seydelmann technician provided us with intensive support. There is one man who is responsible for regular maintenance, and he is thus extremely knowledgeable. If something happens between maintenance intervals – whether with the Konti-Kutter or another machine – we have contacts at Seydelmann who reliably take care of our concerns.” Werner Grasmehr has never questioned his decision to use the Konti-Kutter KK 140 AC-6 for sau-sage production.

The innovative cutter system lets him make sausage mixtures much faster, with results that are in no way inferior to products previously made with a meat grind-er and bowl cutter. In addition to production time, the robust, reliable machine also saves him labor and energy. Dirk Bongardt

![Inline filter RE 51401/08.08 [inch] filtri in linea/40 FLEN, 40... · Inline filter 1/10 Types 40 FLEN 0160 to 1000; ... BV, DNV, DRIRE, UDT, etc.) is available on request. ... 2)](https://static.fdocuments.net/doc/165x107/5b16623a7f8b9a4f6d8ba71e/inline-filter-re-514010808-inch-filtri-in-linea40-flen-40-inline-filter.jpg)