Subpart E – Exit Routes, Emergency Action Plans, and Fire Prevention Plans

Fire safety and exit routes

-

Upload

orlando-moreno -

Category

Environment

-

view

23 -

download

3

Transcript of Fire safety and exit routes

Fire Prevention

Domain 1: Safety AwarenessSection 4:Fire Safety and Exit Routes

1Read Lesson Link aloud to students:

Foundations of Manufacturing

Presented by Orlando Moreno+1 770.354.3072 [email protected] of California at Berkeley

2Read Lesson Link aloud to students:

Learning ObjectivesIdentify evacuation plans, exit routes, and hazards that hinder evacuation. Describe the proper fire extinguishing agents to use on different classes of fires.Discuss the four classes of fires, their prevention, and associated hazards.3/67

3

Learning Objectives (Contd.)Examine training requirements and applicable standards relating to exits, fire extinguishers, and storage and handling of flammable and combustible materials.Identify the requirements, elements of the applicable standards, and the written plan for emergency response.Describe chemical hazards, exposure, burns, hazard identification, and their importance to emergency response teams.

4/67

Direct students to turn to Page 2-3-1 in their TBL Manufacturing Fundamentals, Unit 2: Safety Awareness, Module 3: Fire Safety and Exit Routes, Student Workbook and continue with the discussion.

4

IntroductionSerious fires occur in 70,000 to 80,000 workplaces annually100 employee deaths, 1,410 employees injured annually$2 billion in property losses annually (2003-2008)OSHA requires employers to meet standards to prevent workplace deaths and injury

5/67

Question: What should employers do to protect workers from fire hazards?Answer: Train workers about fire hazards, and procedures for evacuation, use of firefighting equipment, equipment safety, etc.

5

Locations of Fires22%- Storage properties19%- Business/Mercantile19%- Outside or special properties14%- Public Assembly (church, town hall)26%- Other non-residential

6/67

General Duty ClauseEmployer must provide workplace free from recognized hazardsEmployers must comply with OSHA, state and local standards for safety and healthful workplace

7/67

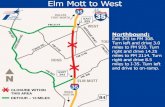

Evacuation Plans and Exit RoutesEmployers responsibility to put evacuation plan in placeEmployees responsibility to understand and execute the planKnow where all emergency routes are locatedPath must be open all the timeTwo exit routes required8/67

EvacuationShut down equipmentEvacuateHeadcountKeep fire exits clearAnnual drills

9/67

9

Evacuation PreparednessKeep evacuation organized.Know your evacuation plans.Train for and practice evacuation procedures.Conduct ERT training within 30 days for newhires and then annually.

10/67

10

Mock Tabletop Evacuation DrillResponding to alarmEvacuation roles and understanding themShut down critical equipmentExit the areaAssemble promptlyHead count

11/67

Tabletop Exercise (TTX): A tabletop exercise involves key personnel discussing simulated scenarios in an informal setting. TTXs can be used to assess plans, policies, and procedures

Question: What are some important things to do during an emergency evacuation/evacuation drill?Answer: Keep fire exits clear. Shut down and secure critical equipment. Evacuate to designated assembly areas and wait for the head count. Evaluate practice drills.Discuss each answer further to ensure student understanding.

Question: Should a company have a different notification procedure for chemical spills?Answers will vary.

Question: Does your company have distinctive alarms for specific emergencies? Example: One alarm tone indicates a local fire, a different tone indicates a chemical spill and another indicates the need for total evacuation.Answers will vary.

Question: What evacuation procedure does your company have in place?Answers will vary.

11

QUESTIONAn emergency alarm just went off. You should:

Initiate emergency shut down procedures and evacuate12/67

Emergency Drills and IncidentsRecord the overall status of any drills that take placeDocument any incidents that occur 13/67

Exit Route (Egress)A continuous and unobstructed path of exit travel that is permanent and has enough exits for quick escapeConsists of three parts:Exit accessExitExit discharge

14/67

14

Exit DischargeMust lead directly outside or to a street, walkway, refuge area, public way, or open space with access to the outside that is large enough to accommodate all building occupants likely to use the exit routeExit stairs that continue beyond the level on which the exit discharge is located must be interrupted on that level by doors, partitions, or other effective means that clearly indicate the direction of travel to the exit discharge

15/67

15

QUESTIONWhy do we need to keep exit paths clear and doors closed?

16/67

A for fire safety and containment

16

Exit Door and Route RequirementsDoors remain unlocked Must be able to open from the inside at all times without keys, tools, or special knowledgeA device such as a panic bar that locks only from the outside is permittedMust be free of any device or alarm that could restrict emergency use if the device or alarm fails

17/67

17

Exit Route RequirementsSupport the maximum permitted occupant load for each floor servedCapacity must not decrease in the direction of exit route travel to the exit dischargeCeiling at least 7 feet 6 inches high with no projection reaching a point less than 6 feet 8 inches from floorAccess at least 28 inches wide at all points18/67

18

Exit Marking RequirementsEach exit clearly visible and marked with an Exit signEach exit route door must be free of decorations or signs that obscure the visibility of the door

19/67

19

Exit Markings Requirements (Contd.)

20/67

Exit Markings Requirements (Contd.)

21/67

Refuge AreaA space along an exit route protected from fireMay be a floor with at least two spaces separated by smoke resistance partitions

22/67

22

Safe Escape FactorsConsiderationsPanic and confusionPoor visibilityLack of information or misinformation

23/67

23

Emergency Action PlanEmergency escape/evacuation proceduresPre-evacuation procedures for critical operationsPost-evacuation employee accountability proceduresRescue/medical dutiesFire/emergency reportingproceduresContacts for further planinformation

24/67

24

Medical and Rescue Duties First Responders should administer first aidOthers should dial 911 to report emergency and assist in directing first responders to scene25/67

Fire Prevention PlanList of major fire hazards and handling, storage, and control proceduresNames of persons responsible for maintaining equipment and systems to prevent or control ignitions or firesName of persons responsible for controlling fuel source hazardsList of required training for all employees who have responsibilities in the planEvacuation procedures, including escape procedures and escape route assignmentsAlarm systemsFire hazards and prevention

26/67

26

Fire Prevention Plan (Contd.)Fire response proceduresFire protection equipmentCritical plant operations shutdown procedureProcedure to account for all personnelAssignment of rescue and medical dutiesMeans for reporting emergenciesIdentification of responsible persons to contact for further information27/67

27

AlarmsYell for helpMain alarm systemFire suppression system will automatically signal an alarm to the fire department

28/67

Question: What does your main alarm system consist of? Does it have a back-up alarm? Does it work if the electrical power is out?Answers will vary.

Question: What is your companys preferred means of reporting an emergency?Answers will vary.

28

General Plan RequirementsAvailable for employee reviewEmergency trainingFire emergency alertsEvacuation signals and alarm systemEvacuation routes and proceduresEmployee accountabilityEmergency response information29/67

29

Flammable and Combustible LiquidsCommon materials people often use carelesslyIgnite with explosive force

Burn readily and give off twice the heat of an ordinary material fire

30/67

Question: Why should we be concerned about flammable and combustible liquids?Answer: These materials ignite with explosive force and burn readily while giving off twice the heat of ordinary fires.30

Common Flammable and Combustible LiquidsFlammable liquidsIsopropyl alcoholPropaneAcetone, MEK, paint thinnerGasoline, keroseneAerosol cansCombustible liquids Oil Greases and lubricants Oil-based paints

31/67

Question: What other flammable or combustible materials do you use at work?Answers will vary. Allow time for discussion.31

FlashpointLowest temperature at which a liquid gives off enough vapors to be ignited Low Flashpoint = High FlammabilityFlammable liquids have a flashpoint less than 100FCombustible liquids have a flashpoint greater than or equal to 100F

32/67

Questions: Consider the following scenario:A driver has a portable gas tank (either plastic or metal) in the bed of his or her truck. While the driver was traveling to the gas station, the tank was free to move around in the truck bed. Because of this, the tank built up a static charge. When the driver stopped to put gas in the portable tank, s/he left the tank sitting in the truck bed instead of placing the container on the ground. Invite students to discuss the possible consequences of the drivers actions.Answer: Since the driver did not remove the portable tank from the truck and place it on the ground, it was not grounded. Therefore, it is possible that when the gas nozzle touched the container the static discharged from the container and into the nozzle, which then ignited the gasoline fumes.32

Sources of IgnitionLit cigarettesWelding and cuttingStatic electricitySparksHot equipmentElectrical equipment

33/67

Invite students to discuss their companys smoking policy and designated smoking areas.

Question: Why do gasoline stations have No Smoking signs near the fuel pumps?Answer: Because gasoline and its vapors are highly flammable. For that same reason, No Smoking signs are also placed near other flammable liquids and gases.

33

Sparks and Heat SourcesMachinery and combustion enginesNo flammables near hot work!Ovens and heaters/blowersElectric panels

34/67

Risk Assessment/ SDSSmoking restrictionsProper storageProper dispensingFire and explosion dataSpill/leak response

35/67

35

NFPA LabelNot as detailed as SDSFlashpoint ratings in red square

4 = Below 73F3 = Below 100F2 = Below 200F1 = Above 200F0 = Will not burn

36/67

36

NFPA Labeling

37/67

Storage Room RequirementsWarning signsVentilated roomExplosion-proof electrical equipmentCovers over light fixtures

38/67

38

Chemical Storage

39/67

39

Indoor/Outdoor Storage TipsBonded and ground containers with flammablesKeep storage areas free of other combustible materials Avoid stacking containers Do not store with incompatible materials Locate in a cool area, out of direct sunlightMaintain safe distance from electrical panels or furnaces40/67

40

NFPA Labeling

41/67

Safe Handling of Flammable LiquidsStatic electricity is main concernSpark-proof toolsFire-resistant containers Labeled containersUse only what is neededPractice good housekeepingWelding/torch cutting restrictions

42/67

42

Housekeeping PracticesKeep combustible dusts under control.Dispose of contaminated rags.Keep area free of combustible materials.Keep exits clear.Keep emergency response equipment access clear.43/67

Question: What is your facilitys most serious housekeeping concern?Answers will vary, but may include: Combustible dusts such as sawdust, metal grindings, lint, or grain dust Accumulation of cardboard boxes or wooden crates Oily or solvent-soaked rags not disposed of properly43

Fire Hazards and PreventionHazards and prevention:CigarettesGenerally prohibitedWelding and cutting stationsMaintain a clear 30 ft. radiusElectricityCheck for faulty wiringHot equipmentKeep free from rags or large dust build upsCombustible liquids or gasesStore in cool, well-ventilated area

1244/67

Talk about fire watch for welding44

Fire ResponseProceduresActivate alarm.Set up equipment.Get a fire extinguisher.Evaluate the situation.

45/67

45

Fire ResponseGeneral equipment requirementsFire extinguishers strategically locatedManual foam or water systemsSprinkler systemsInspect firefighting equipment regularlyTrained and authorized employees use equipment

46/67

46

Extinguishing AgentsWaterCO2Dry ChemicalHalon - used around electricalAFFF - aqueous film fighting foamAPC - aqueous potassium carbonate47/67

Fire BasicsClass A ordinary combustibles (wood, cloth, paper)Class B flammable liquids, gases, greasesClass C energized electrical equipmentClass D combustible metalsClass K combustible cooking media (New)

A

B

CDOrdinaryCombustiblesCombustibleMetalsFlammableLiquidsElectricalEquipment48/67

Question: How do you extinguish a class B fire?Answer: Remove oxygen so vapors do not reach ignition source using foam, CO2, dry chemical or halon fire extinguishers.

Question: What are the characteristics of a class C fire?Answer: White or black smoke coming from energized electrical equipment.

Question: What cautions should you take in extinguishing a class K fire?Answers: Do not use water; evacuate unnecessary personnel.

Note: The class of extinguisher should be clearly marked on the extinguisher shell. The picture-symbol labeling system currently in use is designed to make the operation of fire extinguishers more effective and safe to use through the use of less confusing pictorial labels. The system also emphasizes when not to use an extinguisher on certain types of fires.

48

Proper Fire Extinguishing Agents to Use on Different Classes of FiresClass ACool the material below its flashpointUse an ABC rated fire extinguisherPossible agents include pressurized water or foam49/67

Proper Fire Extinguishing Agents to Use on Different Classes of Fires (Contd.)Class BWater will make the fire worse!Eliminate the presence of oxygenAgents include foam, carbon dioxide, BC rated extinguishers, and halon50/67

Proper Fire Extinguishing Agents to Use on Different Classes of Fires (Contd.)Class CWater will not work!Use non-conductive agentsAgents include carbon dioxide, BC rated extinguishers, and halon51/67

Proper Fire Extinguishing Agents to Use on Different Classes of Fires (Contd.)Class DSpread agents over the fire in a 1 thick blanketAgents include a sodium chloride base or special graphite base52/67

Proper Fire Extinguishing Agents to Use on Different Classes of Fires (Contd.)Class KUse dry chemicalsAgents include halon, carbon dioxide, or foam53/67

Fire Suppression EquipmentFixed fire extinguishing systems Portable fire extinguishers

54/67

54

Maintaining Portable Fire ExtinguishersKeep fully charged and in operable condition.Keep in designated places at all times except during use.Conduct annual maintenance checks.Record the annual maintenance date and retain this record for one year.55/67

55

Portable Fire ExtinguisherTraining and EducationEmployees must be provided with an educational program on:General principles of fire extinguisher useHazards of incipient (beginning) stage fire- fightingEmployees designated to use extinguishers must receive instruction and hands-on practice in the operation of equipment

56/67

56

Operating an ExtinguisherPull the pin.Aim at the base of the fire.Squeeze the trigger.Sweep side to side.NOTE: Keep your back to an exit so you can escape if necessary57/67

Display a fire extinguisher and allow students to hold it if they wish. Point out the location of the pin and simulate how to pull the trigger and sweep the area.

Invite students to share their experiences with using a fire extinguisher. Ask about the specific situation and how they and the people around them reacted to the situation.

57

Firefighting HazardsFlameHeatSmokeToxic vaporsSuffocationExplosions

58/67

58

First Aid ProceduresGet fresh air.Flush the eyes.Wash skin with soap and water.If ingested, consult a doctor, and or activate EMS.

59/67

59

Burn First AidMinor (first degree) skin burns are best treated with cool waterSecond degree includes blisteringThird degree very deep and involve all layers of the skin

60/67

Welding and Fire SafetyObtain hot work permit.Weld in designated area.Inspect surrounding area for hazards (keep a 30 feet clear area around a cutting operation).Post fire watch when needed and for the time required.

61/67

61

Fire Safety Regulations/CodesOSHA 1910 Subpart E: Exit routes, emergency action/fire prevention plans1926.152: Flammable and combustible liquids1926.153: Liquefied petroleum gasNFPA NFPA 30: Flammable and combustible liquidsNFPA 51B: Fire prevention during welding, cutting and other hot work NFPA 55: Storage, use, and handling of compressed gases and cryogenic fluids in portable and stationary containers, cylinders, and tanks62/67

62

Chemical HazardsMay cause harm through inhalation or contact with the skinKeep in a well-ventilated areaCan occur without heatSymptomsRednessIrritationBurningPain or numbnessBlisters or dead skinCoughing or vomiting

63/67

Chemical SpillsEvacuate the area.Notify a supervisor or the emergency response team.Remove ignition sources(if safe to do so).

64/67

64

Diked SpillsBefore draining a diked area of rainwater. Check to make sure there is not a visible sheen of oil on the surface.

65/67

65

Natural GasIn any form, a minute amount of odorant such as t-butyl mercaptan, with a rotting-cabbage-like smell, is added to the otherwise colorless and almost odorless gas, so that leaks can be detected before a fire or explosion occurs. Sometimes a related compound, thiophane is used, with a rotten-egg smell. Adding odorant to natural gas began in the United States after the 1937 New London School explosion. The buildup of gas in the school went unnoticed, killing three hundred students and faculty when it ignited. Odorants are considered non-toxic in the extremely low concentrations occurring in natural gas delivered to the end user.

66/67

66

Training ReminderTraining on relevant emergency procedures and first aid

For new hires within 30 days

Refresher Training once per year67/67

SummaryUnderstand how to prevent emergencies.Understand emergency response.Only use fire-fighting equipment if trained.Know your role in an evacuation.Apply this information at work and at home.Ask your supervisor.68/67

68

69/48QUESTIONS ?Orlando Moreno+1 [email protected]

69