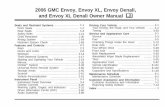

Final Report- Envoy Last

-

Upload

md-motaleb -

Category

Documents

-

view

82 -

download

0

description

Transcript of Final Report- Envoy Last

Envoy Textiles Ltd.

Page 1 of 88

Acknowledgement

At the beginning I remember the Almighty Allah for give me the opportunity to complete

the industrial training. I have completed my industrial training at Envoy Textiles Ltd.

Jamirdia, Bhaluka, Mymensingh. I attended on training from 2nd May 2013 to 30thJune2013.

My special thanks to Prof. Dr. Mustafizur Rahman, Head of the Department of Textile

Engineering, AUST. Heartily thanks to Ms. Nasrin Akter for her continuous guiding. Also

thanks to all the faculty members of Textile Engineering department.

Thanks to all the management body of concern mill for their support and kindness. Cordial

thanks to Mr. Tushar Tripathi,CEO; Mr. Hamimur Rahman (GM ,Human Resource); Mr.

Nanda Dulal Biswas (GM, Production) and I also like to thanks all Sr. Manager, Manager, Sr.

Executives, Executives and other officials of Envoy Textiles Ltd. for providing me support

during attachment period. My gratitude also goes to all the employees of Envoy Textiles

Ltd. for their co-operation, support and valuable advices.

Envoy Textiles Ltd.

Page 2 of 88

Chapter-1 : General Information

Envoy Textiles Ltd., leading denim fabric producer in Bangladesh since 2005, started the

commercial production in early 2008. This industry is professionally managed and

technically sound organization located at Bhaluka, Mymensingh (60 km North of Dhaka

City).The plant is fully integrated with State of the Art technology and machinery from USA,

Japan, Korea, Switzerland, Italy, India& Belgium. Envoy Textiles Ltd. produces indigo denim

fabric with the best and most modern ROPE DYEING Technology. With ever increasing

acceptance of quality fabric and increase in demand the production capacities were

expanded at regular intervals. The target production capacity of Envoy Textiles Ltd. is 20

million meter per year.

Recently, the factory has achieved ISO 9001: 14001 quality certification and its products are OKOTEX certified. Envoy Textiles Ltd. produces a range of products from 6.5oz to 15oz. of denim fabrics and in a variety of shades and cast – basic indigos and sulphur topping or bottoming, in 100% cotton and a variety of blends. ETL targets to be listed in Dhaka Stock Exchange and Chittagong Stock Exchange by issuing IPO by June, 2012. Assigned AA + rating by Credit Rating Agency of Bangladesh.

1.1 Introduction:

Envoy Textiles Ltd.

Page 3 of 88

To become a vertically integrated manufacturer for fabric & garments. Excellence in product quality. Diversify products through continuous product innovation. Customer orientation and cost effectiveness.

Short lead time. Highly skilled manpower at low cost. Diversified Product Portfolio. High Standards of quality and service. Own power generation. State of the art Effluent Treatment Plant to safeguard the environment. Process & Technology improvements.

Envoy Textiles Ltd has received numbers of key Industry standard certifications. These are:

Oeko-Tex Certified – Class1 GOTS Certified (Global Organic Textile Standards) OE100 or OE Blended (Organic Exchange) ISO-9001:2008 Certified ISO-14001:2004 Certified BSR Audit (Business for Social Responsibility) Certified

ETL is in process of achieving GREEN FACTORY certification.

1.2 Vision of The Company:

1.3 Strength:

1.4 COMPLIANCE:

Envoy Textiles Ltd.

Page 4 of 88

Engr.Mr. Kutubuddin Ahmed Chairman

Mr. Abdus Salam Murshedy Managing Director

Mrs. Rashida Ahmed Director

Mrs. Sharmin Salam Director

Mr. Tanvir Ahmed Director

Ms. Shehrin Salam Oishee Director

Mr. Abul Kalam, FCA Director

Factory: Corporate Office:

Envoy Textiles Ltd. Jamirdia, Bhaluka, Mymensingh; Bangladesh. Phone: 0682-555037-40 Fax: 0682555008

Envoy Tower,5th -8th Floor 18/E Lake Circus Kalabagan West Panthopath; Dhaka-1205 Bangladesh. Phone: +88 0 2 9102583-90 Fax:+88 0 2 9103128-29 Web: www.envoytextiles.com

1.5 Board of Directors:

1.6 Company Address:

Envoy Textiles Ltd.

Page 5 of 88

Figure: Location Map of Envoy Textiles Ltd

1.7 Location Map of Envoy Textiles Ltd.(Hand Sketch):

Reedisha

Spinning

Ltd.

Badsha

Textile

Tepantor

Resorte

Dhaka-Mymensingh Highway Square Masterbari

Envoy Textiles Ltd.

Page 6 of 88

24°18'17.24"N 90°23'2.93"E

Figure: Location Map Of Envoy Textiles Ltd (Google Maps)

1.8 Location Map of Envoy Textiles Ltd.(Google Map):

Envoy Textiles Ltd.

Page 8 of 88

1.10 Organizational Structure:

Chairman

C E O

G.M (H R) G.M (Production)

Manager

(P.P)

Manager

(Dyeing)

Manager

(Weaving)

Manager

(Finishing)

Asst.

Manager

Asst.

Manager

Asst.

Manager

Asst.

Manager

Executive

Executive

Executive

Operator Operato

r

Operator Operator

Helper Helper

Helper

Helper

Executive

G M (Mechanical)

Envoy Textiles Ltd.

Page 9 of 88

Section Total Man Power

Ball Warping 60

Dyeing 64

L C B 63

Sizing 27

Weaving 200

Finishing 63

Inspection 54

Lab 16

R&D 17

Planning 4

1.11 Section Wise Manpower ( Production & QA Section):

Envoy Textiles Ltd.

Page 10 of 88

Chapter-2:Sequence of Operation & Raw Material

Sample analysis at R&D department

Production planning

Ball Warping

Rope Dyeing

L C B

Sizing

Weaving

Finishing

Inspection

Dispatch

2.1 Sequence of Operation at Envoy Textiles Ltd :

Envoy Textiles Ltd.

Page 11 of 88

This section has detailed description about the yarn that is usually used by Envoy Textiles

Ltd. for manufacturing high quality denim fabrics. The spinning method of denim yarn is also

described shortly.

Warp yarns for bottom weight jeans typically range in size from Ne 4.0 to Ne 12.5/1. Finer

yarns are used for lighter weight chambray shirting fabrics and lighter weight jeans, vests,

dresses, and skirts. These yarns may range in count from Ne 12.5 to Ne 30.0.

Before the late 1970s, all denim yarns were ring spun. Today, denim fabrics have different

combinations of ring and open-end yarns. The term “ring/ring, open end /open end

(OE/OE), and ring/OE,” it is referring to which yarn is in the warp and which yarn is in the

filling, respectively. For example, ring/OE indicates a ring-spun warp yarn and an open-end

filling yarn. Weaving a combination of ring-spun and open-end yarns can help to reduce

fabric costs while still maintaining some favorable ring-spun fabric characteristics.

Modern ring-spinning frames and open-end machines can be installed with devices that can

manufacture predetermined yarn effects. These effects can vary from slubs (thick places)

with different lengths, different spacing between slubs, or variations in the yarn count.

Using these devices, OE yarns can have a more ring-spun like appearance, and ring-spun

yarns can have an increased rough or “antiqued” quality. Yarn spinners can design patterns

and effects specific to their needs, which can be downloaded into the machine’s electronic

control system.

2.2 Raw Material at Envoy Textiles Ltd.:

2.2.1 Denim Yarn:

2.2.2 Common Yarn Size For Denim:

2.2.2 Yarn Spinning Systems:

2.3 Specialty Yarn:

2.3.1 Structured Denim Yarns

Envoy Textiles Ltd.

Page 12 of 88

Core-spun yarns are produced conventionally on ring-spinning machines by introducing a

spandex filament at the back of the front drafting roll of the machine. The drafted cotton

fibers twist around the spandex core to produce an elastic ring-spun type yarn. There are

also open-end and air-jet spinning machines that have been adapted to produce core-spun

yarns. The core filament yarn (normally spandex) is inserted through the rotor shaft on OE

frame or the spindle of the air-jet frame, and the cotton fiber wraps around the spandex

filament during the process of spinning. The yarn is somewhat similar to the ring core-spun

yarns in terms of yarn and fabric characteristics. Open-end and air-jet core-spun yarns have

fewer knots and splices as compared to ring core-spun yarns.

2.3.2 Elastic Denim Yarns:

Envoy Textiles Ltd.

Page 13 of 88

2.4 Yarn Supplier Name & Origin:

No. Supplier Origin

01 NRG Spinning Ltd. Bangladesh

02 Salek Spinning Ltd. Bangladesh

03 Square Spinning Ltd. Bangladesh

04 Badsha Textile Ltd. Bangladesh

05 Gulsan Spinning Ltd. Bangladesh

06 Jamuna Spinning Ltd. Bangladesh

07 Nahar Spinning Ltd. Bangladesh

08 Purbani Spinning Ltd. Bangladesh

09 Sinha Spinning Ltd. Bangladesh

10 QUETT A Spinning Ltd. India

11 Sel Manufacturing India

12 Suprim Spinning Ltd. India

13 Trident Ltd. India

14 VORDAHAMAN Spinning Ltd. India

15 Din-TEX Pakistan

2.4.1 Cotton Yarn Supplier:

2.4.2 Polyester Yarn Supplier:

No. Supplier Origin

01 Shaoxing Bowarn China

02 Zheijang China

03 Modern Poly Industries Bangladesh

04 AA Synthetic Bangladesh 05 Reliance India

Envoy Textiles Ltd.

Page 14 of 88

Chapter 3 : Ball Warping

Warping is the process of transferring multiple yarns from individual yarn packages onto a

single package assembly. Normally, yarns are collected in a sheet form where the yarns lie

parallel to each other and in the same plane onto a beam, which is a cylindrical barrel with

side flanges. This is known as beam warping.

Settings of warping program according to plan.

Collection of yarn from store as per program.

Powering of machines in presence of electric engineer.

Settings of parameter as per the counting of yarn.

3.1 Warping:

3.2 Ball Warping:

In ball warping 250 to 500 yarn ends are pulled from the creel. The yarns then pass through a comb-like device (sometimes called a hack or reed), which keeps each warp yarn separate and parallel to its neighboring ends. At intervals of every 1000 or 2000 yards (or meters), a lease string is placed across the sheet of warp yarns to aid yarn separation for the re-beaming operation, which will occur later. The yarns then go through a funnel-shaped device called a trumpet or condenser, which collapses and condenses the sheet of yarn into rope form. This device is located at the base of the warper head and traverses back and forth, guiding the newly formed rope of yarn onto a log. The rope must be wound at a constant tension to keep the yarns from tangling.

Figure: Ball-Warping (Rope)

3.3 Working Procedure of Ball Warping :

Envoy Textiles Ltd.

Page 15 of 88

Loading of yarn into machine.

Passing of individual strands of yarn through tension device to

complete read denting.

Accumulating yarn into rope form for passing over the tension

stand and guide roller and into the head stroke trumpet.

Setting of empty ball in the head stroke and setting of safety

guard.

Cleaning of machines before starting

Starting the machine slowly at first and necessary speeds at

later

Checking the tension of the yarn by tension meter

Cutting the ball after completing length as per program

Completing of one set after completing 12 balls.

Suitable for dyeing.

Figure: Top & Side view of Ball Warping Machine

Figure: Ball for Rope Dyeing

Envoy Textiles Ltd.

Page 16 of 88

3.4 Description of Ball Warping Machine :

M/C

No.

Manufacturer Country of

Origin

M/C type Creel

Capacity

Stop Motion

1 GRIFFIN U S A Auto tension m/c

456 Electrical sensor

2 GRIFFIN U S A Gram tension m/c

456 Drop wire

3 GRIFFIN U S A Gram tension m/c

456 Drop wire

4 MORRISON U S A Auto tension m/c

528 Electrical

sensor

3.5 Tension, Ball force & Speed for Gram Tension for Manual Machine:

Count Tension Ball force (Full-

Empty)

Speed

6/1 Ne, 7/1 Ne 65-70 gm 160-320 330 mpm

9/1 Ne,10/1 Ne 60-65gm 140-300 300 mpm

12/1 Ne, 16/1 Ne, 20/1 Ne

50-55gm 120-280 300mpm

3.6 Tension, Ball force & Speed for Gram Tension for Automatic Machine :

Count Tension Ball force

(Full- Empty)

Speed

For OE For Slub

6/1 Ne, 7/1 Ne Jog 87% 160-320 350 mpm 330 mpm

Front 82%

Run 87%

9/1 Ne,10/1 Ne Jog 77% 140-300 350 mpm 330 mpm

Front 72%

Run 77%

12/1 Ne, 16/1 Ne, 20/1 Ne

Jog 67% 120-280 350mpm 330mpm

Front 62%

Run 67%

Envoy Textiles Ltd.

Page 17 of 88

Traveling Package Creels:

These are V-shaped creels with the actively running yarn packages on the outside of the V and the full yarn packages placed on the inside of the V. When the running packages are depleted, the yarn spindles on the creel are rotated so that the empty packages move to the inside of the V-creel for replenishment. The full packages move to the outside of the creel. The new yarn ends have to be pulled forward and threaded properly in the machine before running the next warp. The empty package positions are then replaced with new full packages while the warper is running. This eliminates lost time in creeling up new yarn packages.

Magazine Creels : These are straight-line creels with enough spindles so that each end-running has a reserve

yarn package placed beside of it. The tail end of the running package is tied to the beginning

end of the reserve package. Once the running package is depleted, the yarn transfers over

to the reserve package and the warper continue to run. This is a random method of creeling

yarn packages compared to block creeling normally used on traveling package creels.

Figure: Ball Warping machine Figure: Magazine Creel

3.7 Types of Creels :

Envoy Textiles Ltd.

Page 18 of 88

If ,

Ratio of warp ends in a order : 4 oe : 4 rs : 4 oe (9 Ne:12 Ne: 7 Ne)

Total ends : 4656

Ratio : 2.5

Set Length : 5340 m

Required yarn for this order = ?

Solution :

Sum of the ratio : 4+4+4 =12

No. of ends per Rope = 4656/ 12

=388

Total No. of Rope = 2.5 * 12 = 30

Quantity meters = 5340*2.5 = 13350 meters = 14600 yds

So, Amount of 9 Ne oe yarn= (14600* 1552)/(9*840)

=2997.24 lbs = 1359.54 kg

Amount of 12 Ne rs yarn= (14600*1552)/ (12*840)

=2247 lbs =1019.65 kg

Amount of 7 Ne oe yarn = (14600*1552)/(7*840)

= 3853.60 lbs = 1747.98 kg

So, Total weight of yarn = 1359.54 +1019.65+1747.98

= 4137.17 kg

3.8 Calculation for Ball Warping :

Envoy Textiles Ltd.

Page 19 of 88

Chapter -4: Rope Dyeing

Denim is a rugged cotton twill textile, in which the weft passes under two or more warp

threads. This twill weaving produces the familiar diagonal ribbing of the fabric, which

distinguishes denim from cotton duck. It is characteristic of any indigo denim that only the

warp threads are dyed, whereas the weft threads remain plain white. As a result of the

warp-faced twill weaving, one side of the fabric shows the blue warp threads, the other side

shows the white weft threads. This is why jeans are white from the inside and what makes

their fading characteristics so unique compared to every other fabric.

There have two type of denim dyeing:

1. CONTINUOUS SLASHER DYEING

2. INDIGO ROPE DYEING PROCESS

In Envoy Textiles Ltd Rope Dyeing Technology is used.

The indigo Rope Dyeing Technology for denim production is considered a superior dyeing

technology, where better uniformity of dyeing is achieved than other indigo dyeing

technologies like slasher dyeing. Indigo rope dyeing was started at U S A . Today rope dyeing

accounts for a large percentage of warp yarn dyed for denim production. The system offers

highest production, due to continuous process as there is no stoppage for set change .In this

dyeing method, maximum continuity of shades and minimum danger to centre to selvedge

shade variation can be achieved.

4.1 Denim Dyeing:

4.2 Rope Dyeing:

Envoy Textiles Ltd.

Page 20 of 88

Ball Creel

Draw nip

Mercerization Bath

Wash Bath (1 & 2)

Dye Bath

( 1-8; depends on shade)

Steaming (for sulphur black)

Wash Bath (3- 6)

(Bath 6 contain few amount softener)

Dry Cylinder (1-36)

Coiler

4.3 Process Flow Chart of Rope Dyeing :

Envoy Textiles Ltd.

Page 21 of 88

Generally two types of dye stuff are used to produce the desired shades. As -

Indigo dyes

Sulphur dyes

Indigo blue dye (vat dye) is not soluble in water in normal condition. To make water soluble, reduction is done by using reducing agent. Reducing agent: sodium hydro sulphite (Na 2S 2O4) (trade name - Hydrose) .

In 1893 the chemist Vidol make a reaction of sodium sulphide and sulphur with organic base (paraphenyl- enediamine or paramino phenol) and produce Vidol black. This is known as sulpherdye stuff. To develop the Black color Vidol black is oxidized by potassium di chromate on the cloth surface during dyeing.

Properties:

It is cheap in price. Wet fastness is good but light fastness is not so good. It is insoluble in water. But reacting with Na2S (reducing agent) it produce

Thiol which is water soluble.

Shades that are processed at Envoy Textiles Ltd .:

Regular Indigo

Black

Topping(Indigo then black)

Bottoming (Black then indigo)

4.4 Dyestuff Speciation:

4.4.1 Indigo Dyeing :

4.4.2 Sulphur Dyeing :

Envoy Textiles Ltd.

Page 22 of 88

Name of the Machine: Morrison rope dyeing machine

Country of origin: U.S.A

Total no of ropes: 30

Total no of box: 15

Creel capacity: 30

Maximum Nip Pressure: 5 Ton & 10 Ton

Roller Hardness :

For 5 Ton Roller: 65 deg. shores.

For 10 Ton Roller: 75 deg. shores.

Dye Bath Volume: 3000 liter

Total No. of Drying Cylinder: 36

Dry stack cylinder air pressure: 0-20kg/cm2

Dry stack cylinder moisture content : 0-20%

Water consumption :50000-55000 L/hour

Figure: Rope Dyeing Process Flowchart (Morrison)

4.5 Machine Description :

4.6 Technical Data about Machine:

Envoy Textiles Ltd.

Page 23 of 88

Indigo Preparation :

Mercerization Bath Liquor :

Chemical Name Amount (kg)

Caustic Soda 90 kg

Sequestering Agent 6 kg

Wetting Agent 20 kg

Total volume 3000 liter

Hydrosulphite :

Chemical Name Amount (kg)

Sodium Hydrosulphite 30 kg

Caustic Depends on required PH

Total volume 200 Liter

Caustic Soda Solution:

Concentration Amount Volume

Double 150 kg 600 liter

Single 75 kg 600 liter

4.7 Chemical Preparation Procedure :

Chemical name Amount (kg)

Indigo 350 kg

Caustic 250 kg

Sodium Hydrosulphite 350 kg

Sequestering agent 5 kg

Dispersing agent 14 kg

Wetting agent 17 kg

Total volume 3500 Liter

Envoy Textiles Ltd.

Page 24 of 88

Softener :

Chemical Name Amount (kg)

Softener 70 kg

Carboxylic acid 10 kg

Total volume 1000 liter

Fig: Chemical Preparation Tank

Fig: Mercerization Bath

Fig: Wash Bath

Fig: Dye Bath

Envoy Textiles Ltd.

Page 25 of 88

4.8 Flow Chart for Different Shade:

For Topping For Bottoming For Indigo For Black

Ball creel (Rope)

Mercerization Bath(Temp-30o C )

Wash Box (1& 2; normal wash)

Indigo Dye Box (1 -6; depends on shade depth)

Washing (Dye Box no.-7)

Black Dye Box( Box

No.-8)

Wash Box( 3-6; Box

no. -6 contain softener & carboxylic

acid )

Drying Cylinder (1 -36)

Coiler Rope Can

Ball creel (Rope)

Bottoming(Black,

Brown etc)(Temp-85o C)

Wash Box (1& 2; normal wash)

Indigo Dye Box (1 -8; depends on shade

depth)

Wash Box( 3-6; Box No. -6 contain

softener & carboxylic acid )

Drying Cylinder (1 -36)

Coiler

Rope Can

Ball creel (Rope)

Mercerization

Bath(Temp-30oC )

Wash Box (1& 2; normal wash)

Indigo Dye Box (1 -8; depends on shade

depth)

Wash Box( 3-6; Box no. -6 contain

softener & carboxylic acid )

Drying Cylinder (1 -36)

Coiler

Rope Can

Ball creel (Rope)

Mercerization

Bath(Temp-30oC )

Wash Box (1& 2; normal wash)

Black Dye Box (Box No-8)

Steamer (Temp-110o

C )

Wash Box( 3-6; Box no. -6 contain

softener & carboxylic acid )

Drying Cylinder (1 -36)

Coiler

Rope Can

Envoy Textiles Ltd.

Page 26 of 88

4.9 Chemical Name & Function:

No. Chemical Name Function

1 Caustic Soda Removes fat and wax by the action of soapanification. Mercerize the cotton fiber as a result the amorphous

region is converted to crystalline region , so the lusterand absorbency of cotton is increased .

2 Wetting Agent It emulsify the waxes in the grey cotton and to ensure the satisfactory penetration of dye liquor into the substrate.

3 Sequestering Agent Used to remove the hardness of water ,makes the water soft.

4 Reducing Agents Indigo dyes are not soluble in water . Sodium Hydrosulphite is used to reduce the indigo converted at leucoform .

5 Dispersing Agent Used to resist the aggregation of Indigo dyes .

6 Softener It helps to open the yarn from during long chain beamer section.

7 Carboxylic acid During mercerization and dyeing process the PH of yarn increased , carboxylic acid decrease the PH (6.5-7.5)

8 Fixing agent Helps to the fixation of sulphur black dyes

9 Glucose (dextrose monohydrate)

Used to soluble the sulphurblack dyes in water.

Envoy Textiles Ltd.

Page 27 of 88

1.Reducing Agent :

Brand Name Manufacturer Origin

Reducing Agent DP Clariant Indonesia

Diresul Antioxident Clariant Spain

Hydrosulphit Conz. B A S F Germany

2. Wetting Agent :

Brand Name Manufacturer Origin

Hostapol EH Liquid Clariant Spain

Leophen M C B A S F Germany

Primasol N F B A S F Germany

Permagen NFS Bangapoo chemicals co.ltd Thailand

3. Sequestering Agent:

Brand Name Manufacturer Origin

DEN-PERSE-PT TRITONGGAL Multichem. Indonesia

Anticil Conz. E K Soy Chemicals Turkey

4. Caustic Soda:

Brand Name Origin

Caustic Soda China, India, Saudia Arabia, Local etc.

5. Softener:

Brand Name Manufacturer Origin

Overwax DE Lamberti Asia pacific

Edunine XL-NT Corda-chemicals India

Belfasin GT Pulcra chemicals Turkey

6. Fixing Agent :

Brand Name Manufacturer Origin

Diresul Oxident Clariant Spain

Direfix SD Clariant Spain

4.10 Chemical Brand Name , Supplier & Origin:

Envoy Textiles Ltd.

Page 28 of 88

7. Dispersing Agent :

Brand Name Manufacturer Origin

Setamol WS B A S F Germany

8. Carboxylic Acid

Brand Name Manufacturer Origin

Carboxylic Acid B A S F Germany

9. Dyes:

Brand Name Manufacturer Origin

Diresul Black RDT D Liquid Clariant Spain

Diresul Brilliant Green RDT H Liquid

Clariant Spain

Diresul Brown RDT GS Liquid Clariant Spain

Diresul Red RDT BG Liquid Clariant Spain

Diresul Indigo RDT B Liquid Clariant Spain

Diresul Yellow Clariant Spain

Liquid Indigo B A S F Singapore / China

Apsul Black RF Oxford Technology Taiwan

Powder Black AAA Brand China

Sulphol Liquid Black- B Bhanu Dyes PVT. Ltd. India

Indigo Liyang Skyblue/ Wonderful China

Envoy Textiles Ltd.

Page 29 of 88

Concentration of Hydrosulphite: It is measured by vatometer. It should be from 1.5 gpl to 2.5gpl , or by redox potential of dye bath which should be from -730 mV to -860 mV. Caustic Soda or pH value :

Should be from 11.5-12.5 Dye concentration in Dye bath :

It is measured by spectrophotometer. It should be in g/l Guidelines :

High Indigo Concentration --> Shade is greener and lighter

Low Indigo Concentration --> Shade is dull and Red.

High pH or Caustic Concentration --> Redder and lighter

Low pH or caustic concentration --> greener and darker Dipping Time :

Longer the dipping time, better will be the penetration and lesser will be the ring dyeing effect. It varies from 15-22 seconds. Squeeze Pressure :

High pressure will lead to lower wet pick up and result in lesser color and better penetration. At rope dyeing, squeeze pressure is 5-10 tones, i.e. Wet pick up is as low as 60%. Hardness of squeeze roller is about 70-75 deg. shores. It squeeze rolls are too hard then there are chances of slippage and uneven yarn tension. If squeeze rollers are too soft then shading will occur. Surface of the squeeze rolls should be ground twice a year. Airing Time :

It should be 60-75 seconds. Longer airing time results in high tension on the yarn and

subsequent processes will become difficult.

Drying : Insufficient or unevenly dried yarns will result in poor re-beaming

4.11 Process Control Parameter for Rope Dyeing:

Envoy Textiles Ltd.

Page 30 of 88

Effect of pH : At pH of 10.5 to 11.5, there will be formation of more monophenolate ions, which lead to

higher color yield, as strike rate of the dye to the yarn bundle is very high, and wash down

activities will be very good. At pH higher than this, dye penetration will be less and wash

down characteristics are also poor.

A.Brand Name : Metrohm

Model : 877 Titrino Plus

Origin : Switzerland

Use : Test GPL of Indigo & Hydro& measure Redox Potential for Reducing

agent .

B.Brand Name : Metrohm

Model : 794 Basic Titrino

Origin : Switzerland

Use : Used to check PH

C.Brand Name : HACH LANG

Model : LICO 500

Origin : Germany

Use : Used to check GPL for Black dye bath

4.12 Quality Assurance Equipment’s/ Laboratory Equipment’s :

Fig: Metrohm

Fig: Spectrophotometer

Envoy Textiles Ltd.

Page 31 of 88

1.The number of rollers :

High number of roller = high exchange of dyestuff

= low exchange of bath concentration

Small roller diameter =low dyestuff exchange

= bad material guiding

2. Immersion time :

Long Immersion time = high dyestuff exchange

Short Immersion time = low dyestuff exchange

3.Immursion liquor and intermediate pair of squeeze roller :

With squeezing = high dyestuff exchange

Without squeezing = low dyestuff exchange

4. Dyeing speed :

High speed = high dyestuff exchange

Low speed = low dyestuff exchange

5.Flow profile :

High liquor flow = high dyestuff exchange

Low liquor flow = low dyestuff exchange

4.13 Effect of Mechanical Parameters on Dyeing :

Envoy Textiles Ltd.

Page 32 of 88

Chapter -5: L C B

After the rope dyeing of warp yarn in denim production, the next operation is the Long Chain Beamer (LCB). When the rope has been dyed and dried in the rope dyeing range, it is taken in large cans in coiler section. In rope dyeing range, if the machine has a capacity 24 ropes, then there will be 24 separate coilers which delivers 24 ropes in separate cans. These cans are transferred to the Long Chain Beaming area. The basic purpose of long chain beamer is to open the rope into a sheet form of yarn and wind onto a warper beam which in turn transferred to the sizing machine.

In Long Chain Beamer, the yarn alignment in the dyed rope is change from a rope form to a sheet form. In the Long Chain Beamer the rope pull from the can by moving them upward to a guiding device. The guiding device is mounted above the can, probably in the ceiling. The upward movement of the rope allows the ropes to untangle before nearing the beamer head and allow the rope to shake loose form from the rest of the rope in the can.

The alignment of dyed rope converted to a uniform sheet form .

Prepare the yarn for sizing.

Accepting the can and processing sit from the dyeing department.

Powering the machine in the presence of electric engineer.

Setting of the parameter as per count.

Setting the can under accumulator.

Entering the yarn through accumulator and tension stand to complete read

denting of head stoke.

Cleaning the machine.

Setting an empty beam on the machine.

Starting the machine slowly at first and necessary speeds later.

Putting down the beam after completing program length.

Completing 1set after completing 12 beams.

Suitable for sizing.

5.1 Long Chain Beamer :

5.2 Purpose of Long chain Beamer :

5.3 Working Procedure of L C B:

Envoy Textiles Ltd.

Page 33 of 88

Figure: Passage of LCB

M/C No. Manufacturer Origin Reed Capacity

01-08 GRIFFIN U S A 480

09 & 10 MORRISON U S A 520

Count (Ne) Tension (gm/end) Speed(m/min)

6 80-85 180-200

7 75-80 200

9 & 10 68-73 200-230

12 60-65 200-230

16 50-55 160-180

20 45-50 150-160

Count (Ne) Tension (gm/end) Speed(m/min)

6 33/38 160/180

7 30/35 200

9 & 10 23/28 200/250

12 20/25 200/250

16 17/22 160/200

20 15/20 150/170

5.4 Machine Description :

5.5 Tension and speed for GRIFFIN machine as yarn count :

5.6 Tension and speed for MORRISON machine as yarn count :

Envoy Textiles Ltd.

Page 34 of 88

Fig: Tension Control Denser

Fig: Tension Stand

Figure: L C B Floor

5.7 Different Unit Image of L C B Machine:

Envoy Textiles Ltd.

Page 35 of 88

Chapter-6: Sizing

The main purpose for sizing warp yarns is to encapsulate the yarn with a protective coating.

This protective coating reduces yarn abrasion that takes place during the weaving operation

and reduces yarn hairiness preventing adjacent yarns from entangling with one another at

the weaving machine. Also, this protective coating keeps the indigo dye from rubbing off

during the weaving process. For many years, native starches or slightly modified starches

with corresponding binders were regarded as the most economical way to size indigo warps.

At the back end of the slasher range, the section beams from the beaming process are creeled. The yarns from each beam will be pulled over and combined with the yarns from the other beams to form multiple sheets of yarns, the number of sheets corresponding to the number of size boxes (size applicators) on the machine. As each yarn sheet enters a size box , the yarns are guided downward and submerged in the liquid size. The yarn sheet leaves the size box via a set of squeeze rolls that helps control the wet pick-up, which influences the amount of size added onto the yarn and controls the amount of penetration of the size into the yarn. After this, the yarns are pulled over steam-heated, Teflon coated cans or cylinders where drying takes place. At this point, the yarns are not totally dry, but are monitored to maintain from 6-8% moisture typically. Most warp yarns for weaving denim have 7-14% size add-on (actual dry solids weight added to the original weight of the yarn). This depends on what type of spinning system is used. Too much size causes yarn chaffing and excessive shedding of size particles at the weaving machine, and too little size causes excessive yarn abrasion resulting in dye streaks, clinging, broken and entangled ends resulting

Fig: Inner View Of Size Box

6.1 Sizing:

Envoy Textiles Ltd.

Page 36 of 88

in low weaving efficiencies. In many denim styles, the size is left on the fabric and acts as a stiffening agent for cut-and-sew operations. This accounts for the stiffness of certain jeans, which are purchased by the consumer. All the yarns go through a set of stainless steel split rods, which help to separate them into individual sheets, equivalent to the number of section beams in the creel. This ensures that yarns from one sheet are adhering to yarns from another sheet. After passing through the split rods, the warp yarns are collected into one single sheet and passed through a comb, which helps to separate individual yarns. This expansion type of comb is adjusted to the desired loom beam width. At this point, all the warp yarns are wound onto the loom beam . Normally, several loom beams will be produced from a single set of section beams in the slasher creel .

Fig: Size Box

6.2 Description of Sizing machine:

Manufacturer Origin

Griffin U S A

UKIL Machinery Korea

6.1 Common Recipe for Sizing :

Chemical Name Amount

Modified starch 100 kg

Q S P R 10 kg

Binder 07 kg

Softener (wax) 03 kg

Water 1300 L

6.3 Common Recipe for Sizing :

Envoy Textiles Ltd.

Page 37 of 88

Count 7,9&12 Ne 16 & 20 Ne

Creel tension 33-35 gm/ends 22-28 gm/ends

Squeeze tension 30-33 gm/ends 28-30 gm/ends

Lease 76-80 gm/ends 50 gm/ends

Beam 80-84 gm/ends 55 gm/ends

Pressure roller 70-75 gm/ends 45 gm/ends

For courser count ,Cylinder Temperature : High

For finer count ,Cylinder Temperature : Low

For courser count ,Squeeze roller pressure : High

For finer count , Squeeze roller pressure: Low

Size Pick –up %= 100 %

Sized yarn count :

6.4 Tension in Sizing Process:

6.5 Process Control Parameter :

6.6 Sizing Equation :

Envoy Textiles Ltd.

Page 38 of 88

Figure: Head stock

6.7 Image Of Different Machine Parts:

Fig: Creel Section

Fig: Lease Road

Envoy Textiles Ltd.

Page 39 of 88

Chapter-7: Weaving

The process of interlacing warp yarn with the inserted weft yarn in a definite order to form a

fabric suitable for use as a dress material or industrial purpose is called weaving. The

matching used for this purpose is called loom. Denim clothing never goes out of style. It's

attractive and durable, perfect for most casual occasions. Denim is most common as the

fabric in jeans, but is also used for shirts, jackets, skirts, dresses, hats, handbags and more.

Several different types of denim fabric are available depending on the function and look

people are after.

The weaving process interlaces the warp, which are the length-wise indigo dyed yarn and

the filling, which are the natural-colored cross-wise yarn. The warp thread is in the form of

sheet. The weft thread is inserted between two layers of warp sheets by means of a suitable

carrier, such as shuttle, projectile, rapier, air current, water current, etc.

Denim fabrics are woven by interlacing two sets of yarns perpendicular to one another in

fabric form. Yarns in the machine direction are called warp yarns or warp ends, and these

are interlaced with filling yarns or picks. The sequence or order of interlacing the two sets of

yarns can be varied to produce many different weave designs.

The finished fabric construction is determined by the number of warp and filling yarns per

square inch or centimeter. For example, a typical construction for denim may be 62 x 38.

This is interpreted as 62 warp yarns per inch of width and 38 filling yarns per inch of length

and always in that order. This thread count along with the yarn counts used will influence

fabric properties such as weight, fabric tightness, cover, drape, hand, tensile strength, tear

strength, and other fabric properties.

7.1 Weaving:

7.2 Structure of Denim Fabrics:

Envoy Textiles Ltd.

Page 40 of 88

For a more pronounced twill line in a denim fabric, the direction of twist in the warp yarn

should be opposite to the twill direction in the fabric. For example, if “Z” twisted yarn is

woven into a right-hand twill, the twill line is less pronounced. If “S” twisted yarn is woven

into the same fabric, then the twill line is more pronounced.

Fig: S & Z Twist Direction

Fig: Right & Left Hand Twill Direction

It must be remembered that only Z-twist yarns are formed in open-end yarns, while ring-

spun yarns have either Z or S. For that reason, open-end yarn can be used in left-hand twills

when a more pronounced twill line is desirable. Having the twist direction opposite from the

twill line direction also tends to make the fabric hand a little softer.

Indigo-dyed yarns have been woven in plain weaves known as chambray, oxfords, baskets,

herringbones, bedford cords, and combinations of 3/1 and 1/3 twills. Jacquard designs and

dobby weaves have also been incorporated into denim designs to produce new looks and

textures. As fashion designers create new ideas, the fabric manufacturers have to follow the

demands of marketing teams and market leaders.

7.3 Yarn Twist Direction and Twill Line Direction:

7.4 Non-conventional Denim Fabric Constructions:

Envoy Textiles Ltd.

Page 41 of 88

Warp beam

Drawing-in

Denting

Tying-in (knotting)

Weft insertion

Grey fabric

When a new denim style is put on a weaving machine, it is necessary to draw (thread or

insert) the warp yarns through various elements as in including stop motion devices (drop

wires), weave design control devices (harnesses and heddles), and filling “beat-up” devices

(reed). Each end of yarn must have its own individual element. This procedure can be done

manually or automatically on drawing-in machines. When producing the same style and

when the current loom beam is nearly empty of yarn, an identical full beam of yarn can be

tied to the yarns of the old beam. This is done by a tying-in machine, which automatically

selects an end of yarn from the old beam and ties it to the appropriate end on the new

beam. The knots are then pulled through the weaving machine before fabric is put into

production. It is well documented that many loom stops are caused by improper tying-in of

the warp yarns.

7.5 Flowchart of weaving process:

7.6 Drawing-in & Tying-in of Warp Yarns:

Envoy Textiles Ltd.

Page 42 of 88

Figure: Drawing-in

Figure: Automatic Tying-in Machine

Warp yarns as seen in Figure are fed from the loom beam and pass over a whip roll or

rollers, which control yarn tension variations during weaving motions. The yarns are then

directed through drop wires, heddles, and a comb-like device called a reed. The spaces

between the reed wires across the width of the reed are called dents.

7.7 Yarn Flow in Weaving:

Envoy Textiles Ltd.

Page 43 of 88

Each reed has a certain number of dents per inch with 12 to 18 being the most common for

denim and denim-type fabrics. There are normally four warp yarns drawn per dent in

standard 3/1 twill denim fabrics. The heddles, through which the yarn is threaded, are

located in harness frames with a designed number of warp yarns drawn through each

harness. All warp yarns weaving alike in a design repeat occupy a given harness. The reed

establishes the width of the warp yarn sheet and equal spacing of the yarns before weaving.

It also is the mechanism used for pushing (beating-up) each inserted filling yarn (pick) into

the body of the fabric at the “fell of the cloth.” The fell is the point where yarns become

fabric. At this point, the warp yarn is in fabric form and ready to be collected on a cloth roll.

Some machines have inspection stands that are back lighted for easy inspection of the fabric

as it is woven before cloth roll take-up. The flow of the filling yarn is somewhat simpler. The

filling yarn is fed from large packages located outside of the actual weaving machine. The yarn

comes off the package or packages and is wound onto a storage feeder that allows the yarn to

be under consistent tension for each pick insertion. The yarn is then introduced to the filling

insertion mechanism and inserted across the separated warp yarns, which have formed a tunnel

or path called a weave shed.

Figure : General Scheme diagram of a Weaving Machine

In figure-

1. Warp beam 2. Back rest roller 3. Drop wires 4. Motor driving the warp let-off 5. Heald frame 6. Motor driving the fabric takedown

7. Reed

8. Take down roller

9. Cloth beam

7.8 General Scheme diagram of a Weaving Machine:

Envoy Textiles Ltd.

Page 44 of 88

Each and every machine has some certain movements or motions. A weaving is distinguished from other machines by its specific movements or motions. These motions are divided into two categories as follows:

Primary motion Secondary motion Auxiliary motions.

Primary, essential or fundamental are designed to those motions or movements of weaving in absence of any of them weaving are not practicable. These are fundamental or essential mechanisms. Without these mechanisms, it is practically impossible to produce a fabric. It is for this reason that these mechanisms are called ‘primary’ mechanisms. The primary mechanisms are three in number.

1. Shedding

2. Picking

3. Beating

1. Shedding:

It is the name given to the motion which moves the heald frames up and down in order to separate the warp sheet into two layers and create a triangle in front of the reed (referred to as the shed) through which the weft can be passed.

Figure: shedding

2.Picking:

It is the means by which the weft is projected through the shed. This was traditionally by shuttle, but more recently it is done by projectile, air jet or water jet.

7.9 Loom Motion:

7.10 Primary motion:

Figure : Picking

Envoy Textiles Ltd.

Page 45 of 88

3. Beating:

It is where the reed pushes the weft into the fell of the cloth to form fabric. This requires considerable called beating up. The above mentioned three primary motions of a loom i.e. shedding, picking, beating is performed in a cyclic order and the fabric is produced. Then the fabric is passed over the front rail and wound of the cloth roller.

Figure: Beating

These mechanisms are next in importance to the primary mechanisms. If weaving is to be continuous, these mechanisms are essential. So they are called the secondary mechanisms. They are:

A. Take-up motion B. Let-off motion.

A. Take-up motion:

The take-up motion withdraws the cloth from the weaving area at a constant rate so as to give the required pick-spacing (in picks/inch or picks/cm) and then winds it on to a cloth roller.

B. Let-off motion: The let-off motion delivers the warp to the weaving area at the required rate and at constant tension by unwinding it from the weaver’s beam. The secondary motions are carried out simultaneously.

To get high productivity and good quality of fabric, additional mechanisms, called auxiliary mechanisms, are added to a power loom. The auxiliary mechanisms are useful but not absolutely essential. This is why they are called the „auxiliary mechanisms. These are listed below.

Warp protector mechanism Weft stop motion Temples

7.11 Secondary Motion:

7.12 Auxiliary Mechanisms:

Envoy Textiles Ltd.

Page 46 of 88

Brake Warp stop motion (Predominantly found in automatic looms)

A. Warp protector mechanism:

The warp protector mechanism will stop the loom if the shuttle/weft inserting element gets

trapped between the top and bottom layers of the shed. It thus prevents excessive damage

to the warp threads, reed wires and shuttle.

B. Weft stop motion:

The object of the weft stop motion is to stop the loom when a weft thread breaks or gets

exhausted. This motion helps to avoid cracks in a fabric.

C. Temples:

The function of the temples is to grip the cloth and hold it at the same width as the warp in

the reed, before it is taken up.

D. Brake:

The brake stops the loom immediately whenever required. The weaver uses it to stop the

loom to repair broken ends and picks.

E. Warp stop motion:

The object of the warp stop motion is to stop the loom immediately when a warp thread

breaks during the weaving process.

Primary motions:

Shedding mechanism- Cam shedding

Picking mechanism- Dewas system for rapier and filling insertion by air pressure.

Beat up mechanism- Cam mechanism.

Secondary motions:

Take up mechanism- Electrical

Let of mechanism- Electrical ( individual motor)

Tertiary motion:

Temple –Ring temple

Batching motion - Individual motor drive controlled by machine drive

7.13 Type of Motion at Envoy Textile Ltd :

Envoy Textiles Ltd.

Page 47 of 88

Pre-winder: The pre-winder wind the turn onto their drum and ensure fault free delivery . Opto-electronic sensor monitor the length of yarn on the drum . The per-winder is monitor and synchronized with the machine through microprocessor which enables the pre-winder to quickly adjust to the cloth width.

Balloon-Breaker: The air jet loom for denim weaving is equipped with Balloon-Breaker which reduce the weft tension due to ballooning. This also reduces the energy required for weft insertion for coarse count yarn and ensures faster flight of the weft yarn, less air consumption and higher speed.

7.14 Different Machine Parts Of Air-jet Loom:

Main nozzle: The main nozzle is mounted in a fixed position on the reed holder and move along with it.

Envoy Textiles Ltd.

Page 48 of 88

Auxiliary Main Nozzle: For coarse filling yarn insertion, an auxiliary main nozzle/booster /tandem nozzle is located between the pre winder and the main nozzle . The auxiliary main nozzle pulls the filling yarn form the pre -winder drum delivers it to the main nozzle. It helps to insert coarser weft with less pressure.

Filling Detector : The air jet loom are incorporated with double filling stop motion devices which monitor the arrival of filling at the receiving side and also stop the machine at the of filling breakage .Double weft detector detect the miss-pick in the shed and filling blows off. The first weft detector detects s the filling, where it has reached the right side end. When the filling yarn dose not reaches the right end for any reason, the first detector immediately stop the machine. The second detector detects the broken picks.

Sub Nozzle: Sub Nozzle is used to maintain the constant velocity of inserted weft yarn. Its depends on the width of loom.

Envoy Textiles Ltd.

Page 49 of 88

Profile Reed:

A profile reed for an air jet loom includes a dent having a guide recess and a lower jaw portion

located below the guide recess, and a weft yarn passage formed by a plurality of the dents

juxtaposed in the direction of weft insertion. The guide recess is formed with upper, inner

lower wall surfaces. The inner wall surface is connected with the lower wall surface through a

lower arcuate surface formed with a radius of curvature. The front end of the lower jaw portion

is defined by a lower jaw arcuate surface formed with a radius of curvature. The lower jaw

portion extends frontward for a distance between the inner wall surface and the front end of

the lower jaw portion. The distance is set at or lower than 5.0 millimeters. The sum of the radii

of curvature is smaller than the distance.

. Figure: Profile Reed

Weft Brake System:

After inserting the filling yarn into the tunnel the feeder hook stopped the yarn. At the time

of stoppage of the inserted pick by the feeder hook , a high shock tension is generated by the

filling inertia.

Automatic Leveling Device:

An automatic shade leveling device situated in positive cam motion, atomically closes the shade

after a loom stoppage by leveling all the shaft. This prevents start mark in the fabric.

Selvedge Forming Device:

In Air jet loom Leno selvedge are formed. These selvedge are obtained

by binding with strong additional threads working in gauge weave and by eliminating through

cutting the protruding weft ends. In leno selvedge formation device two complete leno gauge

mechanism works in combination. A leno device produce the selvedge where other device

form the auxiliary selvedge.

Envoy Textiles Ltd.

Page 50 of 88

In Envoy Textiles Ltd. three types of weaving machine is available.

Machine type no.1:

Name of the machine: Air jet loom

Brand name: Tsudakoma

Model no.: ZAX-9100

Manufacturer mane: Tsudakoma Corporation; Japan

Machine R.P.M: 900( maximum)

Reed width: 190 cm

Weft insertion color: 2

Selvedge type: Full cross leno

Total no of machine: 112

Compressor in to main pipe-13 bar, in to machine – 9 bar, actual set in to machine-6

bar.

Machine type no.2:

Name of the machine: Rapier loom

Brand name: Picanol

Model no.: Picanol Optimax-2-P

Manufacturer mane: Picanol, Belgium

Machine R.P.M: 700 ( maximum)

Reed width: 175 cm

Weft insertion color: 6

Selvedge type: Half-cross leno

7.15 Weaving Machine Specification:

Envoy Textiles Ltd.

Page 51 of 88

Total no of machine: 19

Machine type no.3:

Name of the machine: Air jet loom

Brand name: Picanol Omni 800 Plus

Model no.: OMP-800 2-P

Manufacturer mane: Picanol, Belgium

Machine R.P.M: 1000( maximum)

Reed width: 190 cm

Weft insertion color: 2

Selvedge type: Full cross leno

Total no of machine: 1

Compressor in to main pipe-13 bar, in to machine – 9 bar, actual set in to machine-6

bar.

Machine type no.4:

Name of the machine: Air jet loom

Brand name: Picanol Omni Plus Summum

Model no.: 2-P Omni Plus Summum

Manufacturer mane: Picanol, Belgium

Machine R.P.M: 1000( maximum)

Reed width: 190 cm

Weft insertion color: 4

Selvedge type: Full cross leno

Total no of machine: 64(Denim -2)

Compressor in to main pipe-13 bar, in to machine – 9 bar, actual set in to machine-6

bar.

Figure: Tsudakoma Air-Jet Loom

Figure: Picanol Rapier Loom

Envoy Textiles Ltd.

Page 52 of 88

Figure: Picanol Air –Jet(Picanol Omni Plus Summum)

Leno Bobbin Winder: Brand Name: HARUTZ Manufacturer: Izumi International Co. Origin: Japan No of Machine: 01

Catch Cord Winder: Brand Name: BRANDT Manufacturer: F B BRANDT Origin: Germany No of Machine: 01

7.16 Other Machine Specification:

Envoy Textiles Ltd.

Page 53 of 88

Knotting Machine: TODO Brand Name: TODO Manufacturer: TODO Seisakusto Ltd. Origin: Japan No of Machine: 02

Here I tried to introduce some fabric faults occurred in Envoy Textiles Ltd. During my internship period. Starting mark:

Causes:

Main cause is loom stoppage.

Remedy:

This cannot be avoided but can be controlled by starting mark setting or starting

the loom by reversing the loom.

Reed mark:

Causes:

If any fault occur at reed

Faulty denting in the reed

Remedy:

Right selection of the reed and right denting.

7.17 Weaving Faults:

Envoy Textiles Ltd.

Page 54 of 88

Filling stop:

Causes:

If weft is failed to reach FD1

If weft is too long and reach FD2

Remedy:

Correct setting of the weft length

Correct setting of main nozzle

Correct setting of relay nozzle

Proper setting of air pressure

Proper setting of pre-winder

Proper setting of creel position

Snarl:

Causes:

Excess main nozzle pressure

Low filling tension

Remedy:

Main nozzle air pressure control

Correct setting of the PFT finger value

Double pick:

Causes:

Cutting problem of the cutter

Faulty setting of the air pressure

Remedy:

Cutter position is to be set correctly

Air pressure should be reset

Envoy Textiles Ltd.

Page 55 of 88

Miss pick/ broken pick:

Causes:

Excess air pressure of main nozzle

Remedy:

Main nozzle air pressure should be reduced

Warp breakage:

Causes

Bad sizing

Low strength of the yarn

Crossing of the warp yarn

Loose or tight yarn

Remedy:

Re knotting

Proper sizing

CMPX :

It indicate the total breakage for 1,00,000 picks.

If,

Fabric construction is =

Warp Breakage =3

Cloth woven = 63 m

So,

= 2.47

7.18 Weaving Related Calculation :

Envoy Textiles Ltd.

Page 56 of 88

It is similar for weft cmpx calculation.

Width Shrinkage :

If, Reed width = 69 inch

Actual width = 65 inch

=5.79 %

Production calculation :

Production =

If, Fabric construction is =

R P M = 750

Production =

= 14.54 Inch/min

= 0.3693 m/min

=22.15 m/hour

=177.27 m/shift

Envoy Textiles Ltd.

Page 57 of 88

Chapter-8: Finishing

Finishing of grey denim fabric normally carried out after weaving. It takes an important role in fabric properties, appearance, softness and residual fabric shrinkage. The finishing of denim fabric is carried out for several purposes. Finishing of denim fabric can be varied according to the specific requirement of customer. The finishing process may vary from harsh hand (loom state), soft hand (de-sizing) and sulphur over dyeing.

Control of shrinkage between fabric rolls and within rolls is more difficult than with other fabrics.

The heavy weight, twill denim construction is dimensionally unstable after weaving. Denim has high shrinkage after weaving, which requires very high compression (12-15%)

at Sanforizing which can be difficult.

Finishing Process Brand Name Origin

Sanforising Morrison USA

Flat Finishing Kyoto Japan

Skew Bianco Italy

Coating Rollmac Italy

Stenter Harish India

8.1 Challenges in Denim Fabric Finishing:

8.2 Machine Specification:

Envoy Textiles Ltd.

Page 58 of 88

Input J-Box with pulling unit

Brushing and beating unit to remove dust form fabric

Singeing unit with dust suction device

Impregnation tank with squeezer

Weft skew unit and high tension compensator for width adjustment

Can dryer (Number depends on speed of line)

Clip tentering unit

Compressive rubber belt shrinkage unit

Felt calendar

Exit J-Box

Surface winder or plaiter

8.3 Typical Finishing Line of Denim Fabric:

Envoy Textiles Ltd.

Page 59 of 88

8.4 Process Flow Chart Of Different Machine:

Morrison Wet Finish Kyoto Flat Finish Harish Stenter Grey Fabric

J-Box

Brusher Roller

Singing Burner

Chemical Box

Padder Roller

Skew Roller

Drying Cylinder

Rubber Belt

Palmer Unit(Calendaring unit)

Folding

Grey Fabric

J-Box

Brusher Roller

Singing Burner

Caustic Box

Padder Roller

Stenter Chain

Wash Box

Softener Box

Padder Roller

Skew Roller

Drying Cylinder

Water Spray unit

Rubber Belt

Palmer Unit(Calendaring unit)

Folding

Grey Fabric

J-Box

Chemical Box

Padder Roller

Skew Roller

Coating Knife

Infeed Device

Stenter Chain

Gas Burner(Heat Set)

Blower Fan/ Exhaust Fan

Cooling Chamber

Folding

Envoy Textiles Ltd.

Page 60 of 88

Singeing is an Important as it burn the protruding fibers form the fabric surface

Singeing Parameter:

Fabric speed (m/min)

Flame intensity (mbar)

Fabric moisture content (%)

Singeing positions

Burner fabric distance (mm)

Figure: Singeing Unit

8.5 Description Of Various Finishing Process:

8.5.1 Singeing:

8.5.2 Sanforising:

Sanforisation is a treatment applied to fabric to reduce cloth shrinkage after washing. During the sanforising process, the fibers of the cotton fabric are stretched both in length and in width so that cloth that is washed and dried will not shrink much.

Figure: Sanforising Unit

Envoy Textiles Ltd.

Page 61 of 88

Skew Measurement:

8.5.3 Fabric Skewness:

Woven fabrics are constructed with lengthwise and crosswise yarns interlaced at right angles .Skewness in woven fabric is a condition wherethe warp and weft yarns, although straight, are not at right angles to each other. Woven fabric skewness and its measurement Skewness creates difficulties during tailoring, sewing, and the process of three-dimensional forming. Garments made from skewed fabric may behave differently on each part of the body and, as a result, cause the fabric to lose its shape. The problem can occur in the warping, weaving, and finishing processes. The main cause at any step of the finishing process is the variation in running speed across the width of the fabric.

Figure: Skew Roller

Envoy Textiles Ltd.

Page 62 of 88

Calendering is a finishing process used

on cloth where fabric is folded in half

and passed under rollers at high

temperatures and pressures.

Calendering is used on fabrics such

as moire to produce its watered effect

and also on cambric and some types

of sateens.

In preparation for calendering, the fabric

is folded lengthwise with the front side,

or face, inside, and stitched together

along the edges. The fabric can be

folded together at full width; however

this is not done as often as it is more

difficult. The fabric is then run through

rollers that polish the surface and make

the fabric smoother and more

lustrous. High temperatures and

pressure are used as well. Fabrics that

go through the calendering process feel

thin, glossy and papery.

Figure: Calendering(Palmer)unit

It is the process by which natural twist/convolutions are open by the help of concentrated alkali

under tension conditions. It is a treatment which makes the cellulose start to swell at a certain

alkali concentration.

8.5.4 Calendering:

8.5.5 Mercerization:

Envoy Textiles Ltd.

Page 63 of 88

Advantages of Mercerization: improves dye uptake up to 40%

permanent luster is obtained

improves tensile strength

dimensional stability

dead cotton coverage

less pilling effect The advantages of mercerization are considerable. The increase in the dye uptake capacity

results in deep shades and expensive dyes savings can be achieved. Furthermore as a rule, the

color fastness and uniform appearance of goods are also improved.

Figure: Wash Box

Figure: Coating Spray Unit

Figure: In-feed Device

Figure: Dry Cylinder

8.6 Some Image of Different Machine parts:

Envoy Textiles Ltd.

Page 64 of 88

Chapter-9: Inspection

The quality of a final garment depends on the quality of a denim fabric when it is received as a

roll. Even the most outstanding manufacturing methods cannot compensate for defective

materials. Normally, 10% of the rolls received are inspected and evaluated based on a four-

point system. This way, denim fabric related quality problems can be avoided before it is put

into production.

The 4-Point System Assigns 1, 2, 3 And 4 Penalty Points According To The Size And Significance

Of The Defect. It’s A Widely Recognized Inspection Method Frequently Used in The Textile

Industry. It’s A Technique Issued By The American Society For Testing &Materials With

Reference To The Designation ASTMD5 430-93.

Fault length Penalty

1-3 inch. 1

3-6 inch. 2

6-9 inch. 3

9-12 inch. 4

≥ Than 12 inch. 4

If a defect is observed faults are classified and scored with penalty points of 1, 2, 3 and 4,

according to their size and significance. Each defect should be counted as a separate defect

even if the nature is the same and then based on the points allocated to each defect, total

points should be calculated. No more than 4 penalty points can be assigned for any single

defect. No linear yard or meter can contain more than 4 points, regardless of the number of

defects within that yard or meter. If the acceptance criteria are 40 points / 100 yd2, then this

roll is acceptable.

9.1 Four Point System:

Envoy Textiles Ltd.

Page 65 of 88

Yarn Dyeing Sizing Weaving Finishing

Defects Code no

Defects Code no

Defects Code no

Defects Code no

Defects Code no

Corser warp 101 Shade veriation

201 Loose 301 Broken pick

401 Crease mark

501

Corser Weft 102 Satin 202 Tight 302 Double pick

402 Unsigned 502

Finer Warp 103 Stip mark

203 Beam stain

303 Miss pick

403 Width variation

503

Finer Weft 104 S.S.V 204 Size spot

304 Lashing pick

404 M/C stop 504

Oily Warp 105 Dyeing patta

205 Bad selvedge

305 Starting mark

405 Stain 505

Oily Weft 106 Less width

306 Reed mark

406 Torn/Hole 506

Slub 107 Slack End

307 Knot 407 E.H mark 507

Contamination 108 B.F 308 Snarl 408 Weave 508

Thik Thin 109 Smash 409 Sleeve mark

509

Bad selvedge

410

Floating end

411

Double end

412

Wrong drawing

413

Less width

414

Wave 415

MisYarn warp

416

9.2 Department wise defect &code no. For varies defect in fabrics:

Envoy Textiles Ltd.

Page 66 of 88

Quality category

Max Defect points/100 sq. Yards

Grade Max. no of defects in a roll of Yards(60”width)

Max.no of 4 point defects in a roll of Yards

Present Envoy Category

1 15 A+ 100 125 150 200 100 125 150 200 Super Elite

2 20 A 25 31 37 50 2 3 3 4 Elite Plus

3 28 A- 33 42 50 67 4 5 6 8 Elite

4 40 B 47 58 70 93 5 6 7 10 Export

5 >40 C >67 >83 >100 >133 >6 >7 >9 >12 Shady

6 >40 D

Envoy Extra

Figure: Inspection Section

9.3 Quality categories in Denim Fabrics (Revision Date: 12/09/2011):

9.4 Maximum Defect Point/100sq.Yards

Envoy Textiles Ltd.

Page 67 of 88

Chapter-10: Research & Development(R&D)

According to the buyer provides sample, R & D department research about Shade, EPI, PPI,

warp yarn count, weft yarn count, fabric type, width, total ends, yarn type, weave, GSM, reed

count etc.

10.1 Process Flowchart of R&D:

Swatch receive from

marketing

Analysis Swatch

Match with existing

sample No

Yes

Send to

Marketing Tentative

costing

For approval No Yes

Dropped Match with

existing yarn No Yes

Depend on yarn

supply

15 days to develop

Envoy Textiles Ltd.

Page 68 of 88

Regular Fabric :

OE = Regular

OE = Regular Polyester

OE = Regular Stretch

OE = Regular

Poly Stretch ***OE = Open ends ( Rotor spun)

Fig: Regular Fabric

Slub Fabric :

OESL OE= Slub

OESL Polyester= Slub Polyester

OESL Lycra= Slub Stretch

OESL Polyester = Slub Poly

Stretch *** OESL= Open

ends slub (Rotor spun slub)

Fig : Slub Fabric

10.2 Types of Fabric Develop by R&D Department at Envoy Textile Ltd:

Envoy Textiles Ltd.

Page 69 of 88

Cross Slub Fabric:

OESL OESL= Cross Slub

OESLPolyeste

r)= Cross Slub Polyester

OESLLycra)=

Cross Slub Stretch

OESLLycra +

Polyester)= Cross Slub Poly Stretch

Fig: Cross Slub Fabric

Multi-count Fabric:

(OE+OE+OE) OE =Multi-count Fabric

(OE+OE+OE) OESL =Multi-count Slub Fabric

(OE+OE+OE) OE Poly=Multi-count Polyester

(OE+OE+OE) OE Poly Lycra =Multi-count Poly Stretch

Fig : Multi Count Fabric

Envoy Textiles Ltd.

Page 70 of 88

In Envoy Textile Ltd. Four Basic Shade are produce it is very difficult to identify the shade in

human eye for easy identification N, N- Dimethylformamide is used. At first a piece of fabric or

yarn is boiled with N, N- Dimethylformamide then dry. After that we can see:

Topping:

Before N, N- Dimethylformamide Wash After N, N- Dimethylformamide Wash

Bottoming:

Before N, N- Dimethylformamide Wash After N, N- Dimethylformamide Wash

10.3 Shade Identification Process:

Envoy Textiles Ltd.

Page 71 of 88

Indigo:

Before N, N- Dimethylformamide Wash After N, N- Dimethylformamide Wash

Black:

Before N, N- Dimethylformamide Wash After N, N- Dimethylformamide Wash

Envoy Textiles Ltd.

Page 72 of 88

In R&D Department they are flow 6 washing process; these are:

1. Rinse wash

2. Enzyme wash

3. Enzyme Bleach

4. Enzyme Stone

5. Enzyme Stone Bleach

6. Tint wash (Re-dyeing)

For 2 kg fabric,

1. Rinse wash:

Water 100 L

Temperature 45-50O C

De-sizing Chemical 75-100 gm

Time 8-10 minute

***for each shade wash two time

2. Enzyme wash :

Water 80 L

Temperature 45-50O C

Enzyme 100 gm

PH 5-5.5

Time 25-30 minute

10.4 Washing:

10.5 Basic recipe for different washing:

Envoy Textiles Ltd.

Page 73 of 88

3. Enzyme Bleach wash :

*** It is done by after completing enzyme wash

Water 90 L

Temperature 55-60O C

Bleaching chemical 500 CC

Time 6-8 minute

***Wash two times and after complete washing neutralization is essential

Neutralization bath recipe:

4. Enzyme stone and Enzyme heavy stone:

5. Enzyme Stone Bleach:

*** It is done by after completing enzyme stone wash

Water 90 L

Temperature 55-60O C

Bleaching chemical 500 CC

Time 6-8 minute

***Wash two times and after complete washing neutralization is essential

Water 60-70 L

Temperature 50-55o C

Neutralization chemical 250-300 gm

Time 5 min

Water 80 L

Temperature 45-50OC

Enzyme 100 gm

Stone 2-2.5 kg (For heavy stone wash stone 4-6 kg)

Time 35-40 min

Envoy Textiles Ltd.

Page 74 of 88

6. Softening:

Water 50 L

Temperature 40o C

Softener 2 L

Time 5-6 min

Envoy Textiles Ltd.

Page 75 of 88

Chapter-11: LAB & QA

It is very important to maintain the quality of fabric for buyer satisfaction. The buyer of Envoy

Textiles Ltd. are very conscious about fabric quality, so Envoy Textiles Ltd. maintain the

international standard . It flow the rules of ISO, ASTM & AATCC to maintain the quality of fabric.

11.1 Type of Testing In Lab:

For Yarn For Fabric Color Fastness Test

Count Lea strength Single strength CSP test(actual count*lea strength) Twist per Inch Twist Multiplier Spandex(%) Thin& thick place, Neps Hairines Imperfection Slub diamete Slub length

GSM Fabric Width Shrinkage Skewness Constriction Spirality Tensile strength Tear strength Stretch Growth Fabric PH Seam Slippage

Color fastness to wash Color fastness to rubbing

Envoy Textiles Ltd.

Page 76 of 88

N

Lab Scan XE (Hunter Lab) W E

Light Box

GSM Cutter USTER TESTER 5

Electric Balance Titan2 Universal

Strength Tester

Auto Warp Reel 10

Abrasion & Pilling Tester

Lea Strength Tester

Electronic Twist Tester

Crock meter

Electric Balance

Verivide Light

Box Digital Tear Strength Tester

Humidifier Auto Winder

11.2 Layout Of Lab In Envoy Textiles Ltd.:

S

Envoy Textiles Ltd.

Page 77 of 88

No. Test Name Method

01 Spirality /Skew of Fabric AATCC 179; ISO 16322-1,2&3

02 Washing ISO105 C06

03 Rubbing/ Crocking AATCC 8;ISO 105 12

04 Tensile Strength Fabric Tensile-ISO-13934-2 Yarn Tensile-ISO-2062

05 Seam Performance ISO-13936

06 Tear Strength ASTM D-1424 ISO-13937-1

07 Abrasion Resistance ISO-12947

08 Pilling Resistance ISO-12947-2

09 PH value of textile item ISO-3071

10 Thread per unit length ISO-7211-2

11 Fabric weight ( mass per unit area) ISO-3801

12 Fabric Width ISO-3932

13 Twist per unit length ASTM D 1422

14 Length of thread ASTMD a. Up to 3000 m

b. Subsequent 1000 m

11.3 Different Test Method Followers by Envoy Textile Limited:

Envoy Textiles Ltd.

Page 78 of 88

11.4 Machine , Equipment name and their Function:

Machine Name Manufacturer Origin Function

USTER TESTER 5

USTER

Switzerland

Used to determine the CV%, Thin& thick place, neps hairiness, imperfection, slub diameter, slub length etc.

Titan2 Universal strength tester

James H. Heal and Co.

England

Used to determine the Tensile strength, Elongation of yarn and fabric and it is used for determine seam slippage

Auto Warp Reel 10 MAG Solvics pvt. Limited Co.

India Used to make lee for count and lea strength test.

Lea Strength Tester MAG Solvics pvt. Limited Co.

India

Used to determine the strength of lea.

Ele Twist Tester MAG Solvics pvt. Limited Co.

India Used to determine Twist per inch.

Thermograph SK SATO KEIRYOKI CO. LTD

Japan

Used to check lab temperature and relative humidity.

Elmatear(Tear

test)

James H. Heal and Co.

England Used to determine the tear strength of fabric

Verivide Light Box Verivide Ltd. England Used for shade matching

Crock master James H. Heal and Co.

England Used to check the color fastness to rubbing

Nu- Martandal abrasion and pilling tester

James H. Heal and Co.

England Used to check the abrasion and pilling resistance of fabric

Electric Balance OHAUS Corporation USA Used to measure the weight

GSM Cutter James H. Heal and Co.

England Used to check the GSM of fabric

Humidifier STULZ U S A Control temperature and humidity

Skew measurement scale

James H. Heal and Co.

England Used to measure skewness of fabric

Shrinkage and spirality measurement board

James H. Heal and Co.

England Used to measure Shrinkage and spirality of fabric

Envoy Textiles Ltd.

Page 79 of 88

Chapter-12:Utility Section

12.1 Source Of Utility:

Electricity PGCB& Generator

Gas TITAS

Water Pumps

Compressed air Compressor

Steam Boiler Boiler

12.2 Description Of Utility:

12.2.1 EFFLUENT TREATMENT PLANT (ETP):

Purpose of ETP: Water is basic necessity of life used for

many purposes one of which is industrial use.

Industries generally take water from rivers or lakes but they have to pay heavy taxes for that.

So it’s necessary for them to recycle that to reduce cost and also conserve it.

Main function of this ETP is to clean GCP effluent and recycle it for further use.

Figure: ETP Plant

Envoy Textiles Ltd.

Page 80 of 88

Chemical Name Function

Fera Sulphate Used to increase the concentration of sludge and clean the water.

Lime powder Change the color of water

Polymer Separate sludge from water

Hydro caloric acid ( HCl) Used to decrease the PH of water

Phosphoric Acid Remove Bad bad smell of water

Urea Used as a food for Bacteria

Brand Name : Cochran Manufacturer: BIB COCHRAN LTD. Type : Fire Tube Origin : Scotland No, of Boiler : 03 Total Capacity : 21 ton

Fig: Gas Boiler Section

12.2.2 Chemical Used in ETP and their function:

12.2.3 Gas Boiler:

Envoy Textiles Ltd.

Page 81 of 88

Engine Name: Gas Generator

Brand Name: Deutz –MWM Manufacturer: Deutz Power System. Origin: Germany Capacity: 1-3: 1344 KW & 4: 1500KW Total Capacity of 4 Generator: 5.532 MW RPM: 1500 Volt: 400 V Frequency: 50 HZ Figure: Power Plant Section

12.2.4 Compressor:

Brand Name : Atlas Copco Model : ZR 250 Origin : Belgium Maximum Air Pressure: 8.6 Bar RRM: For 1,4&5:2400 For 2&3:1480 Total Machine: 05

Figure: Compressor

12.2.5 Power Plant:

Envoy Textiles Ltd.

Page 82 of 88

Brand Name: Shuangling Manufacturer: Jiangsu Shaungling Air- Condition Equipment Origin: China Chilled water out let Temperature:90C Chilled water in-let Temperature:320C Total Capacity: 829 RT No. of machine: 02

Figure: Chiller

Figure: Cooling Tower

Total No. of Pumps: 03

Use: Supply Water in Hydrant Point

12.2.6 Chiller:

12.2.7 Fire Fighting Pump:

Envoy Textiles Ltd.

Page 83 of 88

Brand Name: INDION Manufacturer: Ion-Exchange Ltd. Origin: India Capacity:100 m3/H Chemical used: Sodium Chloride

Figure: Water Treatment Plant

12.2.8 Water Treatment Plant:

Envoy Textiles Ltd.

Page 84 of 88

Chapter-13:Maintenance

Routes of different utilities like water, stem, gas, electricity, compressed air, etc.

Dyestuff & chemical dosing system.

Drainage system of waste water, color & chemical.

Driving arrangement of different machineries.

Power transmission to different machineries.

Fabric guiding system through the machineries.

Cleanliness of machine parts.

Preventive Maintenance

Preventive maintenance is a predetermined routine actively to ensure on time inspection / checking of facilities to uncover conditions that may lead to production break downs or harmful description. Break down maintenance

In this case, repairs are made after the equipment is out of order and it can’t perform its normal functions. Routine Maintenance

Maintenance of different machines is prepared by expert engineer of maintenance department.

Normally in case of dyeing m/c maintenance after 30 days complete checking of different

important parts are done.

In Ball warding, Dyeing, LCB, Sizing, Finishing, Inspection maintenance one times in a month.

In weaving section loom are maintain Half weekly, Weekly , Half Monthly, Monthly ,Half yearly

& yearly.

13.1 MAINTENANCE ACTIVITIES FOR THEIR OPTIMUM PERFORMANCES AT THEIR

FOLLOWING POINTS:

13.2 Classification of Maintenance:

13.3 Maintenance Schedule:

Envoy Textiles Ltd.

Page 85 of 88

Chapter-14:Marketing

Marketing strategy is a very important factors to sale the products to the buyer. If the marketing strategy is not so developed, it will be very hard to reach the goal. In case of garments marketing the dealings with the buyer is a very important factor. At Envoy Textiles Ltd. mainly senior marketing officers, merchandiser & higher officials deal with the buyer. There are some fixed buyers of the industry. The buyers give their orders continuously all over the year. The marketing officers & the merchandisers communicate with the buying houses to collect the orders. By both side understanding the rate & the order quantity are fixed. A well-defined marketing strategy has the following characteristics: Good quality

Low price or competitive price

Prompt service

Good commitment

Good business communication

No child labor.

No forced labor.

Transport facilities for worker.

Hours of work.

Voluntary over time.

Intervals for rest.

Weekly holidays.

Annual leave.

Festival holidays & leaves with bonus.

Maternity protection.

Worker's welfare committee.

Mineral drinking water.

Sanitary facilities.

First aid box.

Canteen services.

14.1 Marketing Strategy:

14.2 Buyer's Compliance:

Envoy Textiles Ltd.

Page 86 of 88

Day care center.

Health care activities for the worker & employ company doctor.

Fire extinguisher each & every floor & conduct fire drill at least 12 times a year. We are giving a top priority on prevention of fire and eventual evacuation.

Other safety department (no discrimination).

Compensation cases department.

The development of compliance programmer.

Environmental developer.

Smoking free zone.

Germany Turkey Sri Lanka India

14.3 Major Buyer of Envoy Textiles Ltd.:

14.4 Direct Fabric Export To:

Envoy Textiles Ltd.

Page 87 of 88

Chapter-15:Limitations of the Report I have a very limited time. In spite of my willing to study more details it was not

possible to do so.

Some of the points in different chapter are not described as these were not available.

The whole process is not possible to bind in such a small frame as this report, hence

my effort spent on summarizing them.

Envoy Textiles Ltd.

Page 88 of 88

Chapter-16: Conclusion

I have completed my industrial attachment successfully by the grace of Allah. Industrial

attachment sends me to the expected destiny of practical life. The completion of the two

months Industrial attachment at Envoy Textiles Ltd. I have got the impression that factory is one

of the most modern export oriented and first Rope Denim factory in Bangladesh. Though it was